Press release

Precast Concrete Manufacturing Plant Cost 2026: Capital Investment, Raw Material Needs & Revenue Projections

The Precast Concrete Manufacturing Plant Project Report 2026 provides an authoritative market and feasibility analysis for establishing a precast concrete production facility. Precast concrete refers to concrete parts produced in a controlled factory environment and then transported to construction sites for final assembly, enabling enhanced quality control and dimensional precision. It includes structural elements such as beams, columns, slabs, walls, pipes, culverts, staircases and panels.This mode of production has become an important trend in the construction sector due to its ability to reduce on-site labor dependency, improve safety and predictability, and minimize material waste. Its controlled manufacturing conditions ensure consistent strength and durability - key prerequisites for high-performance construction projects. The use of precast concrete is increasing across residential, commercial, industrial, transportation, and urban infrastructure applications.

Driven by rapid urbanization, growing infrastructure investments and rising demand for efficient, cost-effective building solutions, precast concrete manufacturing presents promising growth potential for investors and developers.

Market Overview and Growth Potential

The global precast concrete market was valued at USD 139.99 Billion in 2025, reflecting its significant economic footprint in the construction materials sector. IMARC Group's analysis projects that the market will expand to USD 202.03 Billion by 2034, supported by a robust CAGR of 4.2% from 2026 to 2034.

This growth is underpinned by several macroeconomic and industry-specific drivers:

• Infrastructure Investments: Both public and private spending on infrastructure - such as roads, railways, bridges and urban development - continues to surge, supporting long-term demand for precast components.

• Urbanization and Housing Demand: Faster residential and commercial construction cycles demand materials that can accelerate build timelines without compromising quality.

• Modular and Time-Efficient Construction: The trend toward off-site modular construction and standardized components increases the appeal of precast solutions.

• Durability and Quality Control: Factory-controlled production leads to improved material performance and structural reliability.

These factors collectively enhance the outlook for precast concrete manufacturing within the broader construction ecosystem.

IMARC Group's report, "Precast Concrete Manufacturing Plant Project Report 2026: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue," offers a comprehensive guide for establishing a plant. The precast concrete manufacturing plant cost report offers insights into the process, financials, capital investment, expenses, ROI, and more for informed business decisions.

Plant Capacity and Production Scale

The proposed precast concrete manufacturing facility is designed for an annual production capacity of 50,000-100,000 cubic meters of precast concrete products. This capacity range enables economies of scale while preserving operational flexibility, allowing producers to adjust output based on demand conditions and project pipelines.

Serving a diverse set of construction needs, this production scale can support the following market segments:

• Residential structural panels and elements

• Commercial and industrial building components

• Infrastructure precast elements such as drainage, road and bridge structures

• Urban development and modular construction systems

Request for a Sample Report: https://www.imarcgroup.com/precast-concrete-manufacturing-plant-project-report/requestsample

Financial Viability and Profitability Analysis

The financial profile of a precast concrete manufacturing plant demonstrates strong profitability potential under typical operational conditions:

• Gross Profit Margins: Typically between 30-40%

• Net Profit Margins: Around 12-18%

These margins reflect the value-added nature of precast manufacturing and stable demand for precast products. They also indicate that once operational, such plants can support favorable returns on capital invested.

While detailed figures such as break-even period and ROI are not explicitly provided in the report's summary, the inclusion of comprehensive financial models indicates that investors will be equipped to evaluate financial viability across different investment scenarios and time horizons once they examine the full feasibility data.

Operating Cost Structure

Operating costs in a precast concrete manufacturing plant are heavily influenced by raw materials and utility consumption. According to IMARC Group's data:

• Raw Materials: Approx. 60-70% of total operating expenses

• Utilities: Approx. 10-15% of operating expenses

Raw materials primarily include cement and aggregates - critical inputs that dictate production quality and cost competitiveness. Utilities cover electricity, water, curing resources and other essential services required for uninterrupted production.

Other operating cost elements such as transportation, packaging, salaries and overheads are recognized but not quantified in the publicly available summary. Effective cost management strategies will therefore involve securing reliable supplies of cement and other raw materials - potentially through long-term contracts - as well as optimizing plant utility consumption through energy-efficient practices.

Capital Investment Requirements

The capital investment for establishing a precast concrete plant encompasses multiple categories - most of which are outlined in the feasibility report:

Land and Site Development

• Acquisition of land and development for production, storage and logistics functions.

• Preparation of site infrastructure including access roads and utilities.

Machinery and Equipment

• Essential machinery includes:

• Concrete batching and mixing equipment

• Molds and formwork systems

• Vibration and compaction equipment

• Curing chambers

• Cranes and material handling systems

• Finishing and inspection tools

Civil Works

• Construction of manufacturing sheds, storage areas, quality control labs, administrative offices, wastewater management and safety installations.

Other capital costs cover environmental compliance systems, safety infrastructure and utility hookups.

Specific cost values for these components are available only in the detailed report sample but are not published in the summary.

Ask Analyst for Customization: https://www.imarcgroup.com/request?type=report&id=7567&flag=C

Major Applications and Market Segments

Precast concrete products serve a wide variety of construction applications and end-use industries:

Primary Applications:

• Structural components

• Building wall panels

• Drainage systems

• Road and bridge elements

• Modular construction systems

End-Use Industries:

• Residential housing

• Commercial real estate developments

• Industrial facilities

• Transportation infrastructure

• Urban smart city construction

These segments benefit from precast concrete's modular nature, structural integrity, and speed of installation relative to traditional cast-in-place systems.

Why Invest in Precast Concrete Manufacturing?

Investing in a precast concrete manufacturing plant aligns with multiple strategic trends:

Strategic Advantages:

• Offers faster construction cycles with superior quality control.

• Reduces dependence on on-site labor and material waste.

• Enhances consistency, strength, and durability across components.

Market Trend Alignment:

• Rising infrastructure investment worldwide continues to push demand for precast elements.

• Urban development and modular construction require scalable production models.

• Demand for time-efficient and cost-effective solutions supports price stability and product uptake.

Policy and Sustainability Benefits:

• Controlled factory settings reduce waste and environmental impact.

• Efficient resource utilization supports green construction initiatives.

Entry Barriers:

• Upfront capital requirements for machinery and site development.

• Need for operational expertise and quality control systems.

Nonetheless, once established, the precast plant can significantly benefit from long-term demand across diverse building sectors and infrastructure growth.

Industry Leadership

Leading global players identified in the report include:

• Balfour Beatty plc

• Boral Limited

• CEMEX S.A.B. de C.V.

• Elementbau Osthessen GmbH & Co. ELO KG

• Forterra Inc.

These companies serve end-use markets spanning construction, industrial facilities, infrastructure and urban development.

Buy Now: https://www.imarcgroup.com/checkout?id=7567&method=2175

Conclusion

The precast concrete manufacturing plant presents a compelling investment opportunity in 2026, backed by a strong global market outlook, growing infrastructure investments, and evolving construction techniques. Key benefits include scalable production capacities, strong gross and net profit margins, and applicability across multiple end-use sectors - from residential and commercial buildings to major infrastructure. Strategic advantages such as quality consistency, sustainability, and efficiency reinforce the plant's long-term competitiveness.

Investors can benefit from comprehensive feasibility analyses and financial models contained within detailed feasibility reports to make informed decisions that align with industry trends and long-term demand trajectories.

Browse Related Reports:

Metal Cable Tray Manufacturing Plant Cost: https://www.openpr.com/news/4358012/metal-cable-tray-manufacturing-plant-dpr-unit-setup-2026

Mango Pulp Manufacturing Plant Cost: https://www.openpr.com/news/4358031/mango-pulp-manufacturing-plant-dpr-2026-raw-materials-cost

Mattress Manufacturing Plant Cost: https://www.openpr.com/news/4358053/mattress-manufacturing-plant-report-dpr-2026-unit-setup

Sealants Manufacturing Plant Cost: https://www.openpr.com/news/4359644/sealants-manufacturing-plant-dpr-unit-setup-2026-demand

About Us:

IMARC Group is a global management consulting firm that helps the world's most ambitious changemakers to create a lasting impact. The company provide a comprehensive suite of market entry and expansion services. IMARC offerings include thorough market assessment, feasibility studies, company incorporation assistance, factory setup support, regulatory approvals and licensing navigation, branding, marketing and sales strategies, competitive landscape and benchmarking analyses, pricing and cost research, and procurement research.

Services:

• Plant Setup

• Factoring Auditing

• Regulatory Approvals, and Licensing

• Company Incorporation

• Incubation Services

• Recruitment Services

• Marketing and Sales

Contact Us:

IMARC Group

134 N 4th St. Brooklyn, NY 11249, USA

Email: sales@imarcgroup.com

Tel No:(D) +91 120 433 0800

United States: +1-201971-6302

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Precast Concrete Manufacturing Plant Cost 2026: Capital Investment, Raw Material Needs & Revenue Projections here

News-ID: 4373432 • Views: …

More Releases from IMARC Group

Tomato Ketchup Manufacturing Plant DPR 2026, Machinery Cost, and Profit Analysis

The global condiments and processed foods industry stands firmly anchored by universally beloved products that transcend cultural boundaries, cuisines, and demographic segments. Among these essential food products, tomato ketchup represents one of the most recognizable, consistently consumed, and commercially successful condiments worldwide-serving as an indispensable table accompaniment, cooking ingredient, and flavor enhancer across household consumption, quick-service restaurants, institutional catering, and food processing applications globally. According to the India Brand Equity…

Decoding the USD 229.3 Billion Europe Furniture Market: Trends, Data & Projectio …

Market Overview

The Europe furniture market size was valued at USD 229.3 Billion in 2025 and is projected to reach USD 306.3 Billion by 2034, growing at a CAGR of 3.27% during the forecast period of 2026-2034. The market is expanding due to rising demand for sustainable and eco-friendly furniture, increased e-commerce retailing, the demand for modular and multifunctional furniture, growing interest in luxury furniture, and Scandinavian and minimalist designs.

Download a…

Canned Tuna Manufacturing Plant (DPR) 2026: Feasibility Study and Profit Analysi …

The global canned tuna manufacturing industry is witnessing robust growth driven by the rapidly expanding packaged food sector and increasing demand for convenient, protein-rich products. At the heart of this expansion lies a critical seafood processing segment: canned tuna. As consumer markets transition toward ready-to-eat meals and shelf-stable nutrition solutions, establishing a canned tuna manufacturing plant presents a strategically compelling business opportunity for entrepreneurs and food processing investors seeking to…

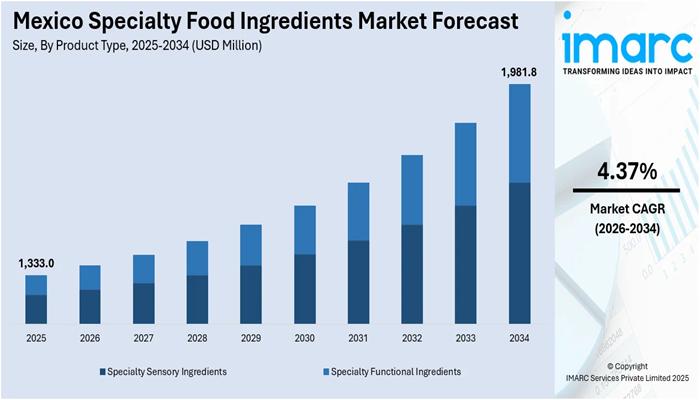

Mexico Specialty Food Ingredients Market Size to Surpass USD 1,981.8 Million by …

Market Overview

The Mexico specialty food ingredients market size reached USD 1,333.0 Million in 2025 and is anticipated to reach USD 1,981.8 Million by 2034, growing at a CAGR of 4.37% during the forecast period 2026-2034. This growth is driven by rising health awareness, demand for clean-label and fortified products, urban lifestyle changes, processed and functional foods expansion, and interest in natural flavors, plant proteins, and low-calorie ingredients.

Study Assumption Years

Base Year:…

More Releases for Plant

How to Establish a Modular Switch manufacturing plant Plant

Setting up a modular switch manufacturing facility necessitates a detailed market analysis alongside granular insights into various operational aspects, including unit processes, raw material procurement, utility provisions, infrastructure setup, machinery and technology specifications, workforce planning, logistics, and financial considerations.

IMARC Group's report titled "Modular Switch Manufacturing Plant Project Report 2025: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue" offers a comprehensive guide for establishing a modular…

How To Setup a Plant Growth Hormones Manufacturing Plant

Setting up a plant growth hormones manufacturing facility necessitates a detailed market analysis alongside granular insights into various operational aspects, including unit processes, raw material procurement, utility provisions, infrastructure setup, machinery and technology specifications, workforce planning, logistics, and financial considerations.

IMARC Group's report titled "Plant Growth Hormones Manufacturing Plant Project Report 2025: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue" offers a comprehensive guide for establishing…

Plant-Powered Eating: Trends in the Plant-Based Food Market

The plant-based food market has experienced exponential growth in recent years, driven by increasing consumer awareness of health, environmental sustainability, and ethical considerations. This burgeoning sector encompasses a wide range of products, from plant-based meat alternatives to dairy-free beverages and vegan snacks. In this overview, we'll explore key points, trends, and recent industry news shaping the plant-based food market.

Download a Free sample copy of Report:https://www.marketdigits.com/request/sample/3771

Key Companies Profiled

Amy's Kitchen

Danone S.A.

Atlantic…

Chocolate Syrup Manufacturing Plant Cost 2023-2028: Manufacturing Process, Plant …

Syndicated Analytics latest report titled "Chocolate Syrup Manufacturing Plant Project Report: Industry Trends, Project Report, Manufacturing Process, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue 2023-2028" covers all the aspects including industry performance, key success and risk factors, manufacturing requirements, project costs, and economics, expected returns on investment, profit margins, etc. required for setting up a chocolate syrup manufacturing plant. The study, which is based both on desk…

Garlic Powder Manufacturing Plant 2023-2028: Manufacturing Process, Plant Cost, …

Syndicated Analytics latest report titled "Garlic Powder Plant Project Report: Industry Trends, Manufacturing Process, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue 2023-2028" covers all the aspects including industry performance, key success, and risk factors, manufacturing requirements, project costs, and economics expected returns on investment, profit margins, etc. required for setting up a garlic powder manufacturing plant. The study, which is based both on desk research and multiple…

Frozen Food Manufacturing Plant 2023-2028: Project Report, Business Plan, Plant …

Syndicated Analytics latest report titled "Frozen Food Manufacturing Plant Project Report: Industry Trends, Manufacturing Process, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue 2023-2028" covers all the aspects including industry performance, key success, and risk factors, manufacturing requirements, project costs, and economics, expected returns on investment, profit margins, etc. required for setting up a frozen food manufacturing plant. The study, which is based both on desk research and…