Press release

Metal Binder Jetting 3D Printers Market Size, Growth Trends, and Forecast 2026-2036

Metal Binder Jetting 3D Printers Market OverviewThe global metal binder jetting 3D printers market is gaining strong momentum as manufacturers increasingly adopt additive manufacturing for large-scale metal part production. In 2025, the market was valued at USD 318.4 million and is projected to expand significantly, reaching approximately USD 1,567.6 million by 2036. From 2026 to 2036, the market is expected to grow at a compound annual growth rate of 15.8%, highlighting the rising confidence of industries in binder jetting as a reliable production technology.

This growth is largely driven by the need for cost-effective, high-volume metal manufacturing solutions that overcome the limitations of traditional machining and laser-based metal 3D printing. Binder jetting has emerged as a compelling alternative due to its ability to deliver faster production speeds, larger build volumes, and lower per-part costs. As aerospace, automotive, and medical industries continue to scale operations and modernize supply chains, binder jetting technology is becoming a core pillar of industrial additive manufacturing.

Download Sample Report Here : https://www.meticulousresearch.com/download-sample-report/cp_id=6377

Understanding Metal Binder Jetting Technology

Metal binder jetting 3D printers operate by selectively depositing a liquid binding agent onto layers of metal powder to form a "green" part at room temperature. The printed part is later sintered to achieve full density and mechanical strength. Unlike laser powder bed fusion systems, binder jetting separates printing and densification, enabling higher throughput and reduced thermal distortion during printing.

This process allows manufacturers to nest multiple components within a single build without the need for support structures, significantly improving productivity. Modern binder jetting systems range from compact benchtop machines for research applications to large-format industrial platforms capable of producing hundreds of metal components in one build cycle. The technology is particularly valued for its compatibility with a wide range of materials and its ability to achieve surface finishes and tolerances comparable to metal injection molding and casting.

Market Size and Growth Outlook

The metal binder jetting 3D printers market is expected to grow from USD 363.0 million in 2026 to nearly USD 1.57 billion by 2036. This expansion reflects the broader transformation of the global manufacturing sector toward digital, flexible, and decentralized production models. Manufacturers are increasingly leveraging binder jetting to eliminate tooling costs, shorten production timelines, and reduce dependence on complex supply chains.

North America currently leads the market, supported by advanced manufacturing infrastructure and strong adoption across aerospace and defense industries. Asia Pacific, however, is emerging as a high-growth region due to aggressive industrialization, rapid automotive expansion, and increasing government support for advanced manufacturing technologies.

Browse in Depth : https://www.meticulousresearch.com/product/metal-binder-jetting-3d-printers-market-6377

Why Is Metal Binder Jetting Gaining Preference Over Traditional Metal Manufacturing?

Metal binder jetting is gaining preference because it combines the scalability of traditional manufacturing with the flexibility of additive production. Unlike machining or casting, binder jetting eliminates expensive tooling and significantly reduces lead times. Manufacturers can move directly from digital designs to production while maintaining competitive unit costs. The ability to produce complex geometries, lightweight structures, and consolidated components makes binder jetting particularly attractive for industries seeking performance optimization and supply chain resilience.

Key Trends Shaping the Market

One of the most notable trends in the metal binder jetting 3D printers market is its rapid adoption in aerospace and defense for serial production. Leading aerospace programs have demonstrated that binder jetting can reduce component weight by up to 50% while maintaining structural integrity. This translates into improved fuel efficiency and reduced operating costs. Defense organizations are also integrating binder jetting into supply chains to enable on-demand manufacturing of critical components, improving logistics efficiency and operational readiness.

Another important trend is the expansion of binder jetting into automotive high-volume manufacturing. As the automotive industry accelerates its shift toward electric vehicles, manufacturers are seeking efficient ways to produce lightweight metal components such as motor housings, brackets, and battery system parts. Binder jetting enables automotive suppliers to produce dozens of components simultaneously without the long lead times associated with conventional tooling, making it ideal for both validation and medium-volume production.

Market Drivers and Opportunities

The primary driver of the metal binder jetting 3D printers market is its cost advantage over traditional metal manufacturing methods. The elimination of tooling costs and the ability to nest parts in three dimensions significantly improve production economics, especially for low-to-medium volume runs. This flexibility allows manufacturers to respond quickly to changing demand without maintaining large inventories.

A major opportunity lies in the growing medical and dental sectors, where demand for patient-specific devices is increasing rapidly. Binder jetting supports the production of customized implants, surgical instruments, and dental prosthetics with excellent surface finish and dimensional accuracy. As personalized medicine continues to expand, binder jetting systems are expected to play a critical role in next-generation medical manufacturing.

Type, Material, and Application Insights

Fully automatic metal binder jetting systems dominate the market due to their suitability for high-throughput industrial environments. These systems offer minimal operator intervention, consistent quality, and seamless integration with automated powder handling and quality monitoring solutions. Semi-automatic systems, meanwhile, continue to gain adoption among research institutions and small manufacturers due to their lower capital requirements and operational flexibility.

Stainless steel remains the most widely used material in binder jetting applications, thanks to its corrosion resistance, mechanical strength, and mature sintering processes. Aerospace and defense applications hold the largest market share, driven by the need for lightweight, high-performance components. Automotive and medical applications are also expanding rapidly, supported by electrification trends and the growing demand for customized healthcare solutions.

Buy the Complete Report with an Impressive Discount: https://www.meticulousresearch.com/view-pricing/1694

Regional Market Dynamics

North America maintains its leadership position due to strong investment in aerospace, defense, and advanced manufacturing. The presence of leading binder jetting equipment manufacturers and supportive regulatory frameworks further strengthens the region's market dominance. Asia Pacific is witnessing rapid growth as countries such as China, Japan, and South Korea invest heavily in additive manufacturing to support automotive and electronics production. Europe continues to adopt binder jetting as part of its Industry 4.0 initiatives, focusing on sustainable and localized manufacturing models.

Competitive Landscape

The global metal binder jetting 3D printers market is led by established players such as Desktop Metal, HP Inc., GE Additive, and Markforged, which offer comprehensive industrial platforms for serial production. Specialized and emerging companies are also gaining traction by introducing compact systems, advanced binder chemistries, and software-driven process optimization solutions. As innovation accelerates, competition is expected to intensify, further driving technological advancement and market expansion.

Related Reports:

Barcode Printers Market: https://www.meticulousresearch.com/product/barcode-printers-market-6043

3D Printers Market : https://www.meticulousresearch.com/product/3d-printers-market-5228

Polymer Additive Manufacturing Market : https://www.meticulousresearch.com/product/polymer-additive-manufacturing-market-6128

About Us:

We are a trusted research partner for leading businesses worldwide, empowering Fortune 500 organizations and emerging enterprises with actionable market intelligence tailored to drive revenue transformation and strategic growth. Our insights reveal forward-looking revenue opportunities, providing our clients with a competitive edge through a diverse suite of research solutions-syndicated reports, custom research, and direct analyst engagement.

Each year, we conduct over 300 syndicated studies and manage 60+ consulting engagements across eight key industry sectors and 20+ geographic markets. With a focus on solving the complex challenges facing global business leaders, our research enables informed decision-making that propels sustainable growth and operational excellence. We are dedicated to delivering high-impact solutions that transform business performance and fuel innovation in the competitive global marketplace.

Contact Us:

Meticulous Market Research Pvt. Ltd.

1267 Willis St, Ste 200 Redding,

California, 96001, U.S.

Email- sales@meticulousresearch.com

USA: +1-646-781-8004

Europe: +44-203-868-8738

APAC: +91 744-7780008

Visit Our Website: https://www.meticulousresearch.com/

For Latest Update Follow Us:

LinkedIn- https://www.linkedin.com/company/meticulous-research

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Metal Binder Jetting 3D Printers Market Size, Growth Trends, and Forecast 2026-2036 here

News-ID: 4372954 • Views: …

More Releases from Meticulous Research®

AI in Defense & Aerospace Market Size, Growth Trends, and Forecast 2026-2036

AI in Defense & Aerospace Market Overview

The global AI in defense and aerospace market is entering a phase of rapid expansion as artificial intelligence becomes central to modern military strategy and aerospace operations. The market is projected to grow from USD 4.2 billion in 2026 to USD 42.8 billion by 2036, registering an impressive CAGR of 26.4% over the forecast period. This growth reflects a fundamental shift in how defense…

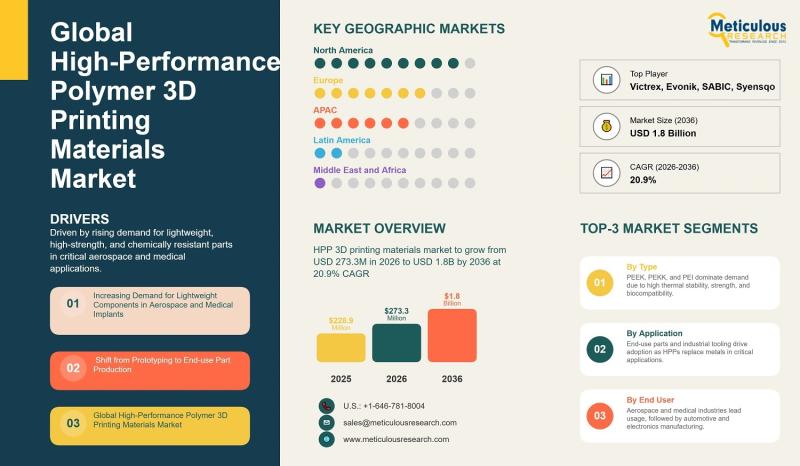

High-Performance Polymer 3D Printing Materials Market Report: Trends, Opportunit …

High-Performance Polymer 3D Printing Materials Market Overview

The global high-performance polymer (HPP) 3D printing materials market is undergoing a rapid transformation as additive manufacturing moves from experimental prototyping to full-scale industrial production. In 2025, the market was valued at approximately USD 228.9 million and is projected to grow significantly, reaching nearly USD 1.8 billion by 2036. From 2026 to 2036, the market is expected to expand at a strong compound annual…

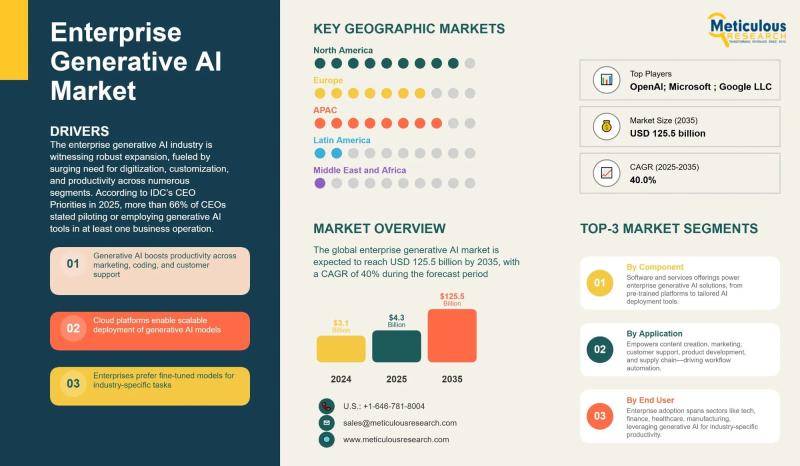

Enterprise Generative AI Market to Reach USD 125.5 Billion by 2035

The global enterprise generative AI market was valued at USD 3.1 billion in 2024 and is projected to grow from USD 4.3 billion in 2025 to USD 125.5 billion by 2035, registering an exceptional CAGR of 40.0% during the forecast period of 2025-2035. The market's rapid expansion is driven by accelerating enterprise digitization, growing demand for customized business solutions, and strong productivity improvements enabled by generative AI technologies.

Enterprise generative AI…

Enterprise Data Visualization System Market to Reach USD 40.16 Billion by 2035

The global enterprise data visualization system market was valued at USD 9.75 billion in 2024 and is projected to grow from USD 11.13 billion in 2025 to USD 40.16 billion by 2035, registering a strong CAGR of 13.6% during the forecast period. Market expansion is fueled by rapid digital transformation, widespread cloud adoption, and the integration of AI-powered analytics across enterprise environments.

Enterprise data visualization platforms have become essential decision-support tools…

More Releases for Metal

Metal Roofing Companies Revolutionizing the Industry: Classic Metal Roofs Leads …

Classic Metal Roofs has established itself as a leading provider of durable and energy-efficient roofing systems in Southern New England. With over 20 years of experience, the company is known for high-quality installations, customer satisfaction, and sustainable metal roofing solutions.

As homeowners increasingly seek durable and energy-efficient solutions, metal roofing companies continue to provide top-tier roofing systems. Among the industry leaders, Classic Metal Roofs [http://business.bigspringherald.com/bigspringherald/markets/article/abnewswire-2025-2-15-classic-metal-roofs-expert-aluminum-shingle-metal-roof-installation-and-services/] stands out for its commitment to…

Rare Metal Raw Materials - Boron(B) Metal

Boron Powder [https://www.urbanmines.com/boron-powder-product/]

Short Description:

Boron [,%20a%20chemical%20element%20with%20the%20symbol%20B%20and%20atomic%20number%205,%20is%20a%20black/brown%20hard%20solid%20amorphous%20powder.%20It%20], a chemical element with the symbol B and atomic number 5, is a black/brown hard solid amorphous powder. It is highly reactiveand soluble in concentrated nitric and sulfuric acids but insoluble in water, alcohol and ether. It has a high neutro absorption capacity. UrbanMines specializes in producing high purity Boron Powder with the smallest possible average grain sizes. Our standard powderparticle sizes average in the…

Metal Polishing Services Market Trends and Leading Players 2023-2030 | Metal Pol …

With a CAGR of 6.1%, the Metal Polishing Services Market is expected to grow from USD 1.5 billion in 2023 to USD 2.3 billion by 2030, offering a gleaming finish to metal surfaces for aesthetic and functional purposes.

Market Overview:

The Metal Polishing Services market is poised for rapid growth, driven by several pivotal drivers. There is a continuous demand for metal finishing and polishing services that improve the appearance and…

Metal-to-metal Seal Market 2021 | Detailed Report

Metal-to-metal Seal Market Forecasts report provided to identify significant trends, drivers, influence factors in global and regions, agreements, new product launches and acquisitions, Analysis, market drivers, opportunities and challenges, risks in the market, cost and forecasts to 2027.

Get Free Sample PDF (including full TOC, Tables and Figures) of Metal-to-metal Seal Market @ https://www.reportsnreports.com/contacts/requestsample.aspx?name=5089735

The report provides a comprehensive analysis of company profiles listed below:

- Parker

- CPI

- HTMS

- American Seal &…

Metal Polishing Services Market Research Report 2020 Analysis: Enhanced Growth a …

Metal Polishing Services Market

Global Metal Polishing Services Market is providing the summarized study of several factors encouraging the growth of the market such as manufacturers, market size, type, regions and numerous applications. By using the report consumer can recognize the several dynamics that impact and govern the market. For any product, there are several companies playing their role in the market, some new, some established and some are planning to…

Worldwide Recycled Metal Market By Metal 2024 | Nucor, Steel Dynamics, Schnitzer …

The 2018-2024 report on global Recycled Metal market explores the essential factors of Recycled Metal industry covering current scenario, market demand information, coverage of active companies and segmentation forecasts.

North America recycled metal market was estimated close to USD 8.5 billion in 2017. This is mainly attributed to strong presence of transportation, electrical & electronics and defense industry which majorly constitute to the overall product demand. Moreover, strict laws formulated…