Press release

Rice Processing Plant Project Report 2026: Cost Structure, Production Process & ROI

The global rice processing industry continues to expand due to rising global rice consumption, increasing preference for polished and packaged rice, growth in urban populations, and the expansion of organized retail and export-oriented supply chains. At the heart of this growth lies a fundamental staple food-rice. As markets demand more consistent quality, hygienic processing, and branded packaging, establishing a rice processing plant presents a strategically compelling business opportunity for entrepreneurs and agricultural investors seeking to capitalize on this essential and growing market.IMARC Group's report, "Rice Processing Plant Project Report 2026: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue," offers a comprehensive guide for establishing a manufacturing plant. The rice processing plant cost offers insights into the manufacturing process, financials, capital investment, expenses, ROI, and more for informed business decisions.

Request for a Sample Report: https://www.imarcgroup.com/rice-processing-plant-project-report/requestsample

Market Overview and Growth Potential

The global rice market demonstrates steady growth trajectory, valued at USD 316.58 Billion in 2025. According to IMARC Group's comprehensive market analysis, the market is projected to reach USD 384.74 Billion by 2034, exhibiting a CAGR of 2.2% from 2026-2034. This sustained expansion is driven by rising global rice consumption, increasing preference for polished and packaged rice, growth in urban populations, and the expansion of organized retail and export-oriented supply chains.

Rice is a cereal grain obtained from the paddy plant and serves as a primary dietary staple for a large portion of the global population. The processing of rice requires multiple steps, which include cleaning and dehusking, polishing, grading, and packaging to create white, brown, and parboiled rice products that people can eat. The nutritional value of rice changes according to its milling process because different milling methods lead to the retention of specific nutrients, which include carbohydrates and fiber, vitamins, and minerals. The market offers different types of processed rice, which include long-grain, medium-grain, short-grain, aromatic, and fortified rice products.

Global rice processing operations experience persistent growth due to increasing international rice consumption, worldwide population expansion, and rising demand for packaged food. The shift from purchasing loose rice to branded, hygienically processed rice products occurs because urban areas expand and consumer behavior patterns change. Government funding for agricultural infrastructure development and storage facility construction, and food security initiative support, strengthens the organized rice processing industry. For instance, about 92,393 projects valued at INR 56,334 crore received sanctions under India's Agriculture Infrastructure Fund (AIF), mobilizing nearly INR 91,856 crore in investment. These projects expanded warehouses, cold storage, grading, and primary processing facilities, directly strengthening post-harvest systems and supporting higher efficiency, quality, and market growth for rice.

Plant Capacity and Production Scale

The proposed rice processing facility is designed with an annual production capacity ranging between 50,000-100,000 MT paddy per year, enabling economies of scale while maintaining operational flexibility. This capacity range allows processors to cater to diverse market segments-from household and retail consumption to foodservice operations, food processing industry applications, and export markets-ensuring steady demand and consistent revenue streams across multiple distribution channels.

Financial Viability and Profitability Analysis

The rice processing business demonstrates healthy profitability potential under normal operating conditions. The financial projections reveal:

Gross Profit Margins: 15-25%

Net Profit Margins: 5-10%

These margins are supported by stable demand across household consumption, institutional catering, and export sectors, value-added processing capabilities through milling and grading operations, and the essential nature of rice as a staple food product. The project demonstrates strong return on investment (ROI) potential, making it an attractive proposition for both new entrants and established agricultural processors looking to diversify their product portfolio in the food processing sector.

Operating Cost Structure

Understanding the operating expenditure (OpEx) is crucial for effective financial planning and cost management. The cost structure for a rice processing plant is primarily driven by:

Raw Materials: 80-85% of total OpEx

Utilities: 10-15% of OpEx

Other Expenses: Including labor, packaging, transportation, maintenance, depreciation, and taxes

Raw materials constitute the largest portion of operating costs, with paddy rice being the primary input material. Establishing long-term procurement contracts with reliable paddy suppliers and farming communities helps mitigate price volatility and ensures consistent raw material supply, which is critical given that paddy price fluctuations represent the most significant cost factor in rice processing operations.

Buy Now: https://www.imarcgroup.com/checkout?id=10668&method=2175

Capital Investment Requirements

Setting up a rice processing plant requires substantial capital investment across several critical categories:

Land and Site Development: Selection of an optimal location with strategic proximity to paddy rice growing regions. Proximity to target markets will help minimize distribution costs. The site must have robust infrastructure, including reliable transportation, utilities, and waste management systems. Compliance with local zoning laws and environmental regulations must also be ensured.

Machinery and Equipment: The largest portion of capital expenditure (CapEx) covers specialized processing equipment essential for production. Key machinery includes:

• Cleaners for removing impurities, stones, and foreign materials from raw paddy

• Dehuskers for separating husk from brown rice through mechanical friction

• Separators for efficiently dividing husk, brown rice, and unhusked paddy

• Whiteners for removing bran layers to produce white polished rice

• Polishers for enhancing grain appearance and achieving desired finish quality

• Graders for sorting rice by size, length, and uniformity specifications

• Sorters including color sorters for removing discolored, damaged, or defective grains

• Packaging machines for weighing, filling, and sealing finished rice products

• Dust control systems for maintaining clean processing environment and worker safety

Civil Works: Building construction, factory layout optimization, and infrastructure development designed to enhance workflow efficiency, ensure workplace safety, and minimize material handling complexities throughout the production process. The layout should be optimized with separate areas for raw material storage, production, quality control, and finished goods storage.

Other Capital Costs: Pre-operative expenses, machinery installation costs, regulatory compliance certifications, initial working capital requirements, and contingency provisions for unforeseen circumstances during plant establishment.

Major Applications and Market Segments

Processed rice products find extensive applications across diverse market segments, demonstrating their versatility and critical importance:

Household and Retail Consumption: Processed rice products provide a reliable source of edible grains for consumption within households and retail outlets, serving as the primary staple food for millions of consumers globally.

Foodservice and HoReCa Sector: Consistent grain quality, along with bulk packaging, facilitates efficient cooking in hotels, restaurants, catering operations, and institutional kitchens where volume requirements and quality standards are paramount.

Food Processing Industry: Rice is used as a raw material to prepare food processing products such as rice flour, snacks, ready meals, breakfast cereals, and various value-added food products requiring specific grain characteristics.

Export Markets: Graded and polished rice complies with international quality standards for export purposes, serving global markets with premium quality products that meet stringent buyer specifications and regulatory requirements.

End-use industries include household retail food segment, institutional catering segment, HoReCa segment, food processing industry, and rice export markets, all of which contribute to sustained demand.

Why Invest in Rice Processing?

Several compelling factors make rice processing an attractive investment opportunity:

Essential Staple Demand: Rice remains a primary food staple across large populations, which creates a continuous market requirement throughout time. This non-discretionary consumption pattern ensures stable demand regardless of economic cycles.

Reduction in Post-Harvest Losses: Modern processing techniques increase grain recovery rates while they decrease losses that occur during the processes of handling and storage, directly improving overall supply chain efficiency and profitability.

Value Addition Opportunities: The process of milling, grading, and polishing, together with branded packaging, creates significant product value extensions that improve profit margins beyond raw paddy pricing.

Export Growth Potential: Processed rice with dependable quality enables access to high-value international markets where premium pricing and consistent demand support strong export revenues.

Scalable Operations: Rice processing plants can be expanded incrementally with moderate capital investment and operational flexibility, allowing businesses to grow capacity in response to market demand without complete facility redesign.

Government Support: Agricultural infrastructure funds and food security initiatives provide financial support and policy backing for rice processing investments, as evidenced by substantial government allocations that strengthen post-harvest infrastructure and processing capabilities.

Consumer Preference Shift: The transition from loose rice to branded, hygienically processed rice products driven by urbanization and changing consumer behavior creates opportunities for quality-focused processors with strong branding and distribution capabilities.

Manufacturing Process Excellence

The rice processing operation involves several precision-controlled stages:

• Cleaning and Pre-cleaning of Paddy: Removal of stones, dust, straw, and foreign materials from raw paddy using cleaning equipment

• Dehusking: Separation of husk from brown rice through mechanical friction in rubber roller dehuskers

• Separation of Husk and Brown Rice: Pneumatic separation of lighter husk from heavier brown rice grains using aspirators

• Whitening and Polishing: Removal of bran layers through abrasive whiteners and polishers to produce white rice with desired appearance

• Grading and Sorting: Classification of rice by length, size, and quality using graders and advanced color sorting technology

• Inspection: Quality control checks for moisture content, grain uniformity, broken percentage, and contamination levels

• Packaging: Weighing, filling, and sealing of finished rice into consumer packages or bulk bags for distribution

Ask Analyst for Customization: https://www.imarcgroup.com/request?type=report&id=10668&flag=C

Industry Leadership

The global rice processing industry is supported by established processors with extensive production capabilities and diverse market portfolios. Key industry players include:

• Anheuser-Busch Companies LLC (AB InBev)

• Bunge Limited

• California Family Foods

• Cargill Incorporated

• Farmers' Rice Cooperative

These companies serve diverse end-use sectors including household consumption, foodservice operations, government supply programs, and export markets, demonstrating the broad market applicability of processed rice products.

Recent Industry Developments

November 2025: Pairwise entered a licensing agreement with the International Rice Research Institute (IRRI) to provide non-exclusive access to the Fulcrum gene editing platform, including the SHARC system. The collaboration aims to accelerate the development of high-yielding, climate-resilient, nutrient-enhanced rice varieties, supporting faster breeding pipelines and improved productivity for global rice systems.

July 2025: BASF (Malaysia) Sdn. Bhd., alongside the Malaysian Agricultural Research and Development Institute (MARDI), unveiled two Clearfield rice varieties, MR CL3 and MR CL4. The partnership reinforces sustainable rice production through non-GM Clearfield seeds, TREK herbicide, and stewardship, tackled weedy rice, targets yields beyond seven tons per hectare, and aligned with Five Times in Two Years and SMART SBB.

Browse Related Reports:

• Nut Spread Manufacturing Plant Cost: https://industrytoday.co.uk/manufacturing/nut-spread-manufacturing-plant-cost-2025-detailed-project-report-unit-setup-and-investment-opportunities

• Kitchen Appliances Manufacturing Plant Cost: https://industrytoday.co.uk/manufacturing/kitchen-appliances-manufacturing-plant-setup-cost-2025-layout-machinery-raw-materials-and-financial-outlook

• Aloe Vera Gel Manufacturing Plant Cost: https://industrytoday.co.uk/manufacturing/aloe-vera-gel-manufacturing-plant-cost-2025-feasibility-and-profitability-roadmap-for-investors

About Us:

IMARC Group is a global management consulting firm that helps the world's most ambitious changemakers to create a lasting impact. The company excels in understanding its client's business priorities and delivering tailored solutions that drive meaningful outcomes. We provide a comprehensive suite of market entry and expansion services. Our offerings include thorough market assessment, feasibility studies, company incorporation assistance, factory setup support, regulatory approvals and licensing navigation, branding, marketing and sales strategies, competitive landscape, and benchmarking analyses, pricing and cost research, and procurement research.

Contact Us:

IMARC Group

134 N 4th St. Brooklyn, NY 11249, USA

Email: sales@imarcgroup.com

Tel No: (D) +91 120 433 0800

United States: (+1-201-971-6302)

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Rice Processing Plant Project Report 2026: Cost Structure, Production Process & ROI here

News-ID: 4371021 • Views: …

More Releases from IMARC Group

Global Respiratory Protective Equipment Market Report 2025-2033: Product, Filter …

The global respiratory protective equipment market size reached USD 8.7 Billion in 2024 and is expected to grow to USD 12.1 Billion by 2033, exhibiting a CAGR of 3.48% during the forecast period 2025-2033. This growth is driven by increasing awareness about health risks and safety, technological innovations enhancing product effectiveness and comfort, and the rising transmission of severe infectious diseases. The demand for respiratory protective equipment is rising globally…

Global Green Coffee Market Report 2025-2033: Size, Arabica vs Robusta, Demand, G …

The global green coffee market was valued at USD 38.3 Billion in 2024 and is projected to reach USD 52.7 Billion by 2033, growing at a CAGR of 3.62% during the forecast period 2025-2033. The market growth is driven by rising coffee consumption, rapid expansion of the e-commerce sector, and the expanding specialty coffee industry that emphasizes premium, sustainable, and unique coffee products.

Study Assumption Years

Base Year: 2024

Historical Years: 2019-2024

Forecast…

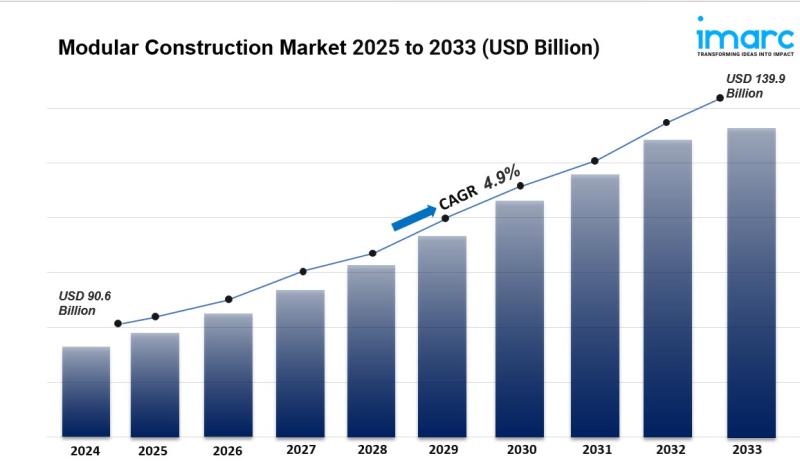

Modular Construction Market Size, Share And Forecast Report 2033

Modular Construction Market Overview:

The global Modular Construction Market was valued at USD 90.6 Billion in 2024 and is forecast to reach USD 139.9 Billion by 2033, growing at a CAGR of 4.9% during 2025-2033. This growth is driven by increasing demand for cost-effective and time-saving construction methods, rising urbanization and affordable housing needs, advancements in prefabrication technology and digital tools, and expanding applications across residential, commercial, healthcare, and education sectors.

The…

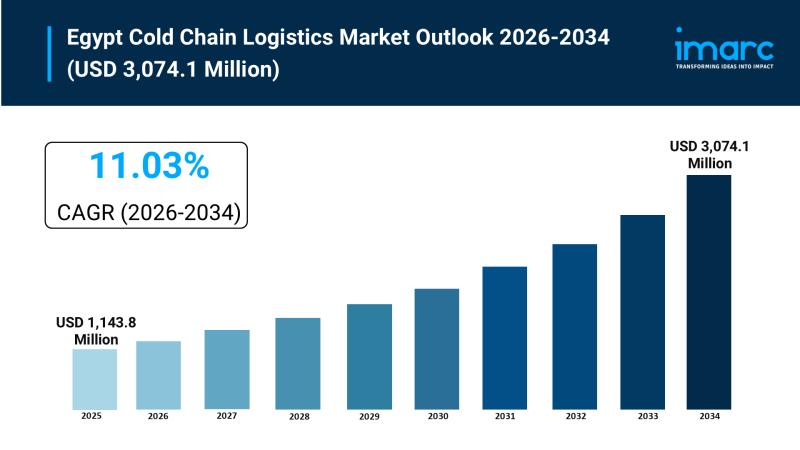

Egypt Cold Chain Logistics Market Size to Hit USD 3,074.1 Million in 2034 | Grow …

Egypt Cold Chain Logistics Market Overview

Market Size in 2025: USD 1,143.8 Million

Market Size in 2034: USD 3,074.1 Million

Market Growth Rate 2026-2034: 11.03%

According to IMARC Group's latest research publication, "Egypt Cold Chain Logistics Market: Industry Trends, Share, Size, Growth, Opportunity and Forecast 2026-2034", The Egypt cold chain logistics market size reached USD 1,143.8 Million in 2025. Looking forward, IMARC Group expects the market to reach USD 3,074.1 Million by 2034, exhibiting…

More Releases for Rice

Global Rice Market Report byType (Red Rice, Arborio Rice, Black Rice, Grain Frag …

Global Rice Market Analysis

The global rice market is projected to grow significantly, reaching USD 369.94 billion by 2032, up from USD 298.26 billion in 2023, with a promising compound annual growth rate (CAGR) of 2.42% from 2024 to 2032.

Global Rice Market Table of Content and Sample Download: https://www.renub.com/global-rice-market-p.php

Rice Market Definition

Rice, a staple food for over half of the world's population, plays a crucial role in global agriculture and food security.…

Rice Syrup Market Is Booming Worldwide | Brown Rice, White Rice, Certified Organ …

Rice Syrup Market: The extensive research on Rice Syrup Market, by Qurate Research is a clear representation on all the essential factors that are expected to drive the market considerably. Thorough study on Rice Syrup Market helps the buyers of the report, customers, the stakeholders, business owners, and stockholders to understand the market in detail. The updated research report comprises key information on the market, such as market rate, estimated…

Basmati Rice Market to See Major Growth by 2026 | Kohinoor Rice, Aeroplane Rice, …

Stay up-to-date and exploit latest trends of Basmati Rice Market with latest edition released by AMA.

A Latest intelligence report published by AMA Research with title "Basmati Rice Market Outlook to 2026.A detailed study accumulated to offer Latest insights about acute features of the Global Basmati Rice market. This report provides a detailed overview of key factors in the Basmati Rice Market and factors such as driver, restraint, past and current…

Rice Market to Witness Remarkable Growth | Asia Golden Rice, Capital Rice, Thana …

Latest released study “Global Rice Market Report 2020” with 121 pages and in-depth assessment including market trends, upcoming technologies, industry drivers, challenges, regulatory policies, with key company profiles and strategies of players such as Asia Golden Rice, Capital Rice Group, Thanasan Group, Ake Rice Mill Co., Ltd, Alobha, Kohinoor, Lal Qilla, Daawat, ADM Rice, American Rice, Gulf Rice Milling, Inc, REI Agro Ltd, KRBL Ltd, Kohinoor Foods Ltd & Lakshmi…

How Covid-19 Is Transforming the Calrose Rice Market? Major Key Players: Califor …

A recent report published by QMI on calrose rice market is a detailed assessment of the most important market dynamics. After carrying out thorough research of calrose rice market historical as well as current growth parameters, business expectations for growth are obtained with utmost precision. The study identifies specific and important factors affecting the market for calrose rice during the forecast period. It can enable companies investing in calrose rice…

Basmati Rice Market Is Thriving Worldwide | Kohinoor Rice, Aeroplane Rice, Tilda …

The Basmati Rice Market has witnessed continuous growth in the last few years and is projected to grow even further during the forecast period of 2020-2026. The exploration provides a 360� view and insights, highlighting major outcomes of the industry. These insights help the business decision-makers to formulate better business plans and make informed decisions to improved profitability. In addition, the study helps venture or private players in understanding the…