Press release

Why Proper Alignment Saves Time in High-Precision CNC Work

In CNC machining, time is money-but not all time losses are obvious. While many shops focus on cutting cycle times or automating tool changes, they often overlook a more subtle time killer: poor alignment.Whether you're dialing in a vise, setting up a part in a lathe, or swapping out tools in a live turret, misalignment introduces problems that ripple across every aspect of the job. These aren't just dimensional issues-they're time delays hidden inside setup adjustments, repeat inspections, tool rework, and failed quality checks.

In high-precision CNC work, proper alignment doesn't just improve accuracy-it saves hours of labor, reduces rework, and increases throughput. The shops that understand this treat alignment as a core process, not an afterthought.

Misalignment Creates Hidden Delays

The most dangerous thing about misalignment is that it rarely announces itself with a flashing red light. Instead, it shows up as:

Re-indicating a part more than once

Making excessive touch-off passes

Constantly adjusting tool offsets mid-run

Catching an error at final inspection and scrapping the part

Having to re-cut a feature due to inconsistent tool location

Each of these actions may only take a few minutes, but over a full shift or multiple jobs, they add up to significant lost productivity.

Misaligned Fixtures

One of the most common sources of inefficiency is misaligned workholding. If your vise or rotary table isn't properly squared to the machine, nothing else will be accurate-no matter how precise your toolpath is.

Simple fixes like verifying parallelism and squareness during setup can eliminate repeated indicating and unnecessary tool compensation. High-precision measuring tools like a dial caliper https://www.haastooling.com/c/calipers make it easy to confirm part placement, feature dimensions, and reference points quickly.

Even more critical, improper alignment in fixturing affects consistency across multiple parts. If you're machining a run of high-tolerance components, even a 0.002" misalignment can ruin repeatability-and your confidence in the setup.

Toolholder and Spindle Alignment

Tool misalignment is another major issue, especially in turning centers and live-tool turrets. If your VDI holder https://www.haastooling.com/c/vdi-toolholding isn't properly aligned or is worn, it introduces angular error or axial offset that affects:

Surface finish

Bore concentricity

Tool wear

Part geometry

These types of issues don't always appear immediately. They might not trigger an alarm or an obvious defect, but they slowly degrade the quality of every part that passes through the machine-and they force your team to spend more time on inspections and minor adjustments.

VDI holders are a great option for repeatability and rigidity-but only when properly seated, aligned, and maintained. Shops that shortcut this part of the setup often end up paying for it in lost time and quality control failures.

Verifying Alignment Early Improves Accuracy and Throughput

The earlier you catch alignment issues, the more time you save. That's why smart shops integrate alignment checks into their pre-machining process, not just during in-process verification or post-run inspection.

1. Alignment During Setup

When setting up your machine, take the time to verify the squareness of your fixture, the parallelism of your jaws, and the runout of your spindle and tools.

For mills, that might mean using an indicator to sweep the vise or table. For lathes, it could mean checking that your collet chuck is properly seated. A 5C collets https://www.haastooling.com/c/-5c-collets system, for example, is an excellent choice for high-precision turning of small parts-but even collets require proper cleaning and seating to avoid runout.

Simple mistakes-like leaving chips under a collet or over-tightening-can lead to part deviation and wasted time diagnosing the problem later.

2. Alignment in Repeat Jobs

In shops running repeat jobs or short production batches, alignment errors often get overlooked because "it worked last time." But that assumption is risky. Workholding can shift, tools can wear, and fixtures can be moved.

Instead, build a checklist for repeat jobs that includes:

Verifying the centerline location

Measuring the part's distance from the fixed jaw

Checking the runout of live tools or spindles

These small alignment checks take minutes but save hours over the course of a production run-especially when tolerances are tight and inspection standards are high.

3. Real-Time Feedback Saves More Than Time

When parts are running slightly off, the temptation is to adjust the program, offset, or feedrate. But in most cases, these are just patch fixes for an underlying alignment issue.

By aligning everything correctly from the beginning and using reliable measuring tools like a dial test indicator, calipers, or edge finders, you eliminate the need for guesswork. You spend less time chasing problems and more time letting the machine do what it was built to do-cut accurately.

The Cumulative Advantage of Alignment

In high-precision shops, alignment isn't just a technical detail-it's a time management strategy. When everything is aligned properly:

Setup becomes faster and more reliable

Your first article inspection passes more often

Tool life is extended

Quality control issues are minimized

Throughput increases without needing faster feedrates

Shops that consistently check alignment spend less time reacting to errors and more time producing high-quality parts. The goal is to move from reactive troubleshooting to proactive process control-and alignment is at the heart of that shift.

Final Thoughts: Don't Chase Speed-Chase Alignment

The fastest way to lose time in a CNC shop is to rush setup and skip alignment checks. What feels like a shortcut often leads to tool rework, part scrapping, or hours of tweaking offsets.

Instead, build alignment into your machining process. Use precise measuring tools like a dial caliper, align your parts consistently with systems like 5C collets, and make sure your VDI holder is seated perfectly every time.

P.O Bagarji Town Bagarji Village Ghumra Thesil New Sukkur District Sukkur Province Sindh Pakistan 65200.

Wiki Blogs News always keeps careful online users to provide purposeful information and to keep belief to provide solution based information.

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Why Proper Alignment Saves Time in High-Precision CNC Work here

News-ID: 4370936 • Views: …

More Releases from wikiblogsnews

Nursing School Applicants Turn to Free Online TEAS Prep Tools as Admissions Comp …

February 2026 - Anyone applying to nursing school now will tell you the same thing: the field is harsh. There just aren't enough seats, not because the coursework scares people away. More than 65,000 eligible candidates were turned down for nursing programs between 2024 and 2025; these individuals fulfilled all requirements and ticked all the boxes, but they were still told "no" since the school was already full.

And yet the…

Why ITIL Version 5 is Essential for Digital First Organisations

Are you considering an ITIL® 5 Foundation Course https://www.itil.org.uk/training/itil-foundation-level-courses/itil-version-5-foundation-certification-course because your organisation is moving towards a digital-first model? That is not surprising. Businesses today depend fully on digital platforms, data, and automation. Yet many still struggle with service gaps and poor coordination. You may also be wondering, What is ITIL Version 5 https://www.itil.org.uk/blog/itil-version-5-a-complete-guide and why does it matter now. It is more than a framework. It connects digital products, people,…

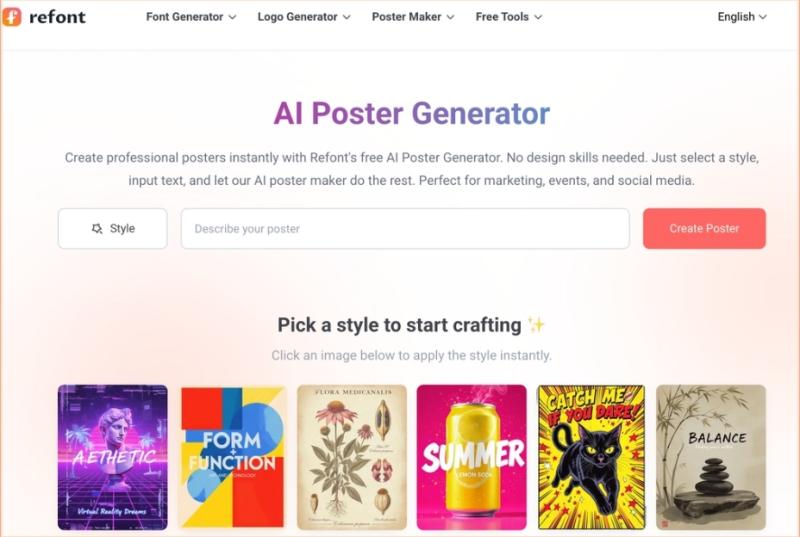

Tired of the Design Bottleneck? How I Finally Found a Practical AI Poster Genera …

If you're anything like me, you've probably spent more hours than you'd like to admit fighting with design software. We've all been there: you have a killer idea for a promotion, a social post, or a brand announcement, but by the time you've messed around with layers, alignment, and hunting for stock photos, the inspiration is gone and so is half your afternoon.

I've tried the early wave of generative AI…

Best Exotic Car Rental in Miami: Experience Luxury Without Overspending

Miami has a way of turning every drive into a cinematic experience. Picture yourself cruising down Ocean Drive at sunset with the gentle ocean breeze mixing in with the roar of your high-performance engine, smiling people looking over your car. For those who seek this experience, the best exotic car rental in Miami is your ticket to unlocking this fantasy.

But there's a catch: Miami's luxury car scene is flooded, and…

More Releases for Alignment

Global Wafer Bond Alignment System Market Expands as Semiconductor Miniaturizati …

Wafer Bond Alignment System Market Size

The global market for Wafer Bond Alignment System was valued at US$ 249 million in the year 2023 and is projected to reach a revised size of US$ 423 million by 2030, growing at a CAGR of 7.9% during the forecast period.

By Type

• Manual

• Semi Automatic

• Fully Automatic

By Application

• 4-inch Wafer

• 6-inch Wafer

• 8-inch Wafer

• 12-inch Wafer

Key Companies

Mycronic, ASMPT, BESI, EV Group, Advanced Spectral Technology, Applied Microengineering Ltd, Marubeni Information System, Ayumi…

Mastering Business Alignment Trademark Launches MBAAT Trademark to Help Leaders …

Image: https://www.globalnewslines.com/uploads/2026/01/1768824191.jpg

Mastering Business Alignment Trademark has launched the Mastering Business Alignment Assessment Tool (MBAAT Trademark ), an AI-powered solution that helps leaders measure organizational alignment and detect early signs of alignment drift.

Mastering Business Alignment Trademark , a proven organizational alignment solution that helps leaders connect strategy, people, and execution to drive measurable business results, today announced the launch of the Mastering Business Alignment Assessment Tool (MBAAT Trademark ) [https://www.stopalignmentdrift.com/mbaat-tool], now…

Mask Alignment Systems Market Size and Forecast

𝐔𝐒𝐀, 𝐍𝐞𝐰 𝐉𝐞𝐫𝐬𝐞𝐲- The global Mask Alignment Systems Market is expected to record a CAGR of XX.X% from 2024 to 2031 In 2024, the market size is projected to reach a valuation of USD XX.X Billion. By 2031 the valuation is anticipated to reach USD XX.X Billion.

Mask Alignment Systems Market Size and Scope

The mask alignment systems market is experiencing steady growth, driven by the rising demand in semiconductor manufacturing and…

Vehicle Maintenance Four Wheel Alignment System Market Precise Alignment Solutio …

Global Vehicle Maintenance Four Wheel Alignment System Market Overview:

The Vehicle Maintenance Four Wheel Alignment System market is a broad category that includes a wide range of products and services related to various industries. This market comprises companies that operate in areas such as consumer goods, technology, healthcare, and finance, among others.

In recent years, the Vehicle Maintenance Four Wheel Alignment System market has experienced significant growth, driven by factors such as…

Mask Alignment Lithography Market Technological breakthroughs 2025

A photomask is a solid plate with transparencies or holes that let light to pass from one side to the other in a predefined pattern. The photomask perform the function of blocking the light in specific areas. Lithographic photomasks are usually translucent fused silica planks covered with a defined pattern with a metal-absorbing film.

Usually, photomasks are used at wavelengths of 193 nm, 248 nm and 365 nm. Photomasks are…

Global Wheel Alignment Tester Market 2017

Global Wheel Alignment Tester Market Report 2017 presents a professional and deep analysis on the present state of Wheel Alignment Tester Market 2017.

In the first part, Wheel Alignment Tester Market study deals with the comprehensive overview of the Wheel Alignment Tester market, which consists of definitions, a wide range of applications, classifications and a complete Wheel Alignment Tester industry chain structure. The global Wheel Alignment Tester market analysis further consists…