Press release

Gypsum Board Manufacturing Plant Setup 2026: Process Details, Market Outlook, and Profitability Analysis

The global construction materials industry is experiencing transformative growth driven by rising demand for fire-resistant building materials, accelerating construction activities across residential and commercial sectors, and increasing adoption of eco-friendly construction solutions. At the core of these developments lies an essential building material-gypsum board. As modern construction increasingly favors lightweight, fast-installation interior finishing systems over traditional masonry, establishing a gypsum board manufacturing plant presents a strategically compelling business opportunity for entrepreneurs and industrial investors seeking to capitalize on urbanization, housing development, and infrastructure expansion driving sustained market growth.IMARC Group's report, "Gypsum Board Manufacturing Plant Project Report 2026: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue," offers a comprehensive guide for establishing a manufacturing plant. The gypsum board manufacturing plant cost report offers insights into the manufacturing process, financials, capital investment, expenses, ROI, and more for informed business decisions.

Request for a Sample Report: https://www.imarcgroup.com/gypsum-board-manufacturing-plant-project-report/requestsample

Market Overview and Growth Potential

The global gypsum board market demonstrates solid growth trajectory, valued at USD 31.72 Billion in 2025. According to IMARC Group's comprehensive market analysis, the market is projected to reach USD 47.91 Billion by 2034, exhibiting a steady CAGR of 4.7% from 2026-2034. This sustained expansion is driven by rising demand for fire-resistant building materials, increasing construction activities, and adoption of eco-friendly materials in the construction industry.

Gypsum board, commonly known as drywall or plasterboard, is a panel manufactured from gypsum plaster sandwiched between two layers of heavy paper. The product serves primarily for interior wall and ceiling construction in residential, commercial, and industrial buildings. Gypsum board offers multiple advantages including fire resistance, soundproofing capabilities, and ease of installation. Its lightweight, durable, and versatile characteristics make it an essential material in modern construction, particularly in dry environments where moisture resistance is not a primary concern.

Market growth is fueled by surge in global construction activities, increasing demand for residential and commercial buildings, and growing adoption of fire-resistant materials. The residential construction industry, which grew at 6.8% during FY2024-25, is positioned to reach USD 350 billion by 2030 according to industrial reports. Regions experiencing rapid urbanization and infrastructure development demonstrate particularly high gypsum board demand. The Asia-Pacific region, especially China and India, leads market expansion due to increased construction projects, government infrastructure initiatives, and growing demand for eco-friendly building materials.

Plant Capacity and Production Scale

The proposed gypsum board manufacturing facility is designed with an annual production capacity ranging between 20-40 million square meters per year, enabling economies of scale while maintaining operational flexibility. This capacity range allows manufacturers to serve diverse market segments-from residential housing projects and commercial building developments to industrial facilities and infrastructure projects-ensuring steady demand and consistent revenue streams across multiple construction categories.

Financial Viability and Profitability Analysis

The gypsum board manufacturing business demonstrates healthy profitability potential under normal operating conditions. The financial projections reveal attractive margins supported by stable construction demand and essential material positioning:

• Gross Profit Margins: 30-40%

• Net Profit Margins: 12-18%

These margins are notably favorable compared to many construction material sectors, supported by consistent construction activity, essential role in modern building systems, value-added fire resistance properties, and the increasing preference for lightweight interior finishing solutions over traditional masonry. The project demonstrates strong return on investment (ROI) potential, making it an attractive proposition for both new entrants and established construction materials manufacturers looking to expand product portfolios and capture growing interior finishing market demand.

Operating Cost Structure

Understanding the operating expenditure (OpEx) is crucial for effective financial planning and cost management. The cost structure for a gypsum board manufacturing plant balances raw material and energy requirements:

• Raw Materials: 50-60% of total OpEx

• Utilities: 20-25% of OpEx

• Other Expenses: Including labor, packaging, transportation, maintenance, depreciation, and taxes

Gypsum rock or stucco constitutes the primary raw material, accompanied by paper facing materials, additives, and foaming agents. The significant utilities component reflects energy-intensive calcination and drying processes essential for gypsum board production. Establishing reliable sourcing relationships with gypsum mines and paper suppliers ensures consistent material supply. The balanced cost structure between materials and energy emphasizes the importance of both procurement efficiency and operational optimization for maintaining competitive production economics.

Buy Now: https://www.imarcgroup.com/checkout?id=7659&method=2175

Capital Investment Requirements

Setting up a gypsum board manufacturing plant requires substantial capital investment across several critical categories:

Land and Site Development: Selection of an optimal location with strategic proximity to gypsum rock sources or stucco suppliers, target construction markets, and robust infrastructure including reliable transportation networks, utilities, and waste management systems. The site must accommodate large-scale production operations and comply with environmental regulations.

Machinery and Equipment: The largest portion of capital expenditure (CapEx) covers specialized processing equipment essential for efficient production. Key machinery includes:

• Rock crushers for gypsum preparation

• Calcining kilns for stucco production

• Board formers for panel shaping

• Mixers for slurry preparation

• Conveyors for material handling

• Drying ovens for moisture removal

• Cutters for panel sizing

• Edge sealers for finishing

• Packaging systems for finished product handling

Civil Works: Building construction, factory layout optimization, and infrastructure development designed to accommodate continuous production lines, ensure workplace safety, and minimize material handling complexities throughout the manufacturing process.

Other Capital Costs: Pre-operative expenses, machinery installation costs, environmental compliance systems, initial working capital requirements, and contingency provisions for unforeseen circumstances during plant establishment.

Major Applications and Market Segments

Gypsum board finds extensive applications across diverse construction sectors, demonstrating its versatility and critical importance:

Wall Partitions: Gypsum board serves as the primary material for interior wall construction and room partitions in both residential and commercial buildings, offering fast installation and smooth finishing surfaces.

Ceilings: Suspended ceiling systems and direct ceiling applications utilize gypsum board for aesthetics, acoustics, and concealment of building services while providing fire resistance.

Fire-Resistant Applications: Specially formulated fire-rated gypsum boards provide critical passive fire protection in stairwells, elevator shafts, and fire-rated wall assemblies, meeting stringent building safety codes.

Soundproofing: Acoustic gypsum boards enhance sound insulation between rooms and spaces, particularly important in multi-family housing, hotels, hospitals, and commercial offices.

Flooring: Specialized gypsum-based floor leveling and underlayment products provide smooth surfaces for finished flooring installations in renovation and new construction projects.

End-use industries encompass construction, real estate development, commercial building, and residential housing sectors, all contributing to sustained market demand across the construction value chain.

Why Invest in Gypsum Board Manufacturing?

Several compelling factors make gypsum board manufacturing an attractive investment opportunity:

Essential Building Material for Modern Construction: Gypsum boards constitute a core component of interior construction, widely used for walls, ceilings, partitions, and fire-rated assemblies-making them indispensable to residential, commercial, and industrial building projects across all construction categories.

Moderate but Defensible Entry Barriers: While not as capital-intensive as cement or steel production, gypsum board manufacturing requires specialized continuous production lines, consistent raw material quality control, precise process management, and compliance with fire, strength, and moisture standards-favoring established and quality-focused manufacturers over new entrants.

Alignment with Urbanization and Housing Megatrends: Rapid urbanization, affordable housing initiatives, commercial real estate expansion, and infrastructure development drive sustained demand for fast, lightweight, and cost-efficient construction systems. Gypsum boards increasingly replace traditional masonry in interior applications, accelerating market penetration.

Policy and Infrastructure Tailwinds: Government spending on housing, smart cities, commercial infrastructure, healthcare facilities, educational institutions, and public buildings-combined with green building codes and fire-safety regulations-directly supports long-term demand for gypsum board solutions in compliant construction projects.

Shift Toward Localized and Reliable Supply: Builders and contractors prefer regional gypsum board manufacturers to reduce logistics costs, ensure consistent supply availability, maintain pricing stability, and meet tight construction timelines-creating strong opportunities for localized, scalable production operations serving regional construction markets.

Ask Analyst for Customization: https://www.imarcgroup.com/request?type=report&id=7659&flag=C

Manufacturing Process Excellence

The gypsum board manufacturing process involves several controlled stages ensuring product quality and performance:

• Gypsum Powder Production: Raw gypsum rock undergoes crushing and grinding to produce fine powder

• Calcination: Gypsum powder is heated in kilns to produce stucco (calcium sulfate hemihydrate)

• Board Forming: Stucco mixed with water, additives, and foaming agents is continuously formed between paper liners on forming machines

• Drying: Formed boards pass through drying ovens removing excess moisture and completing the hydration reaction

• Cutting and Finishing: Dried boards are cut to standard lengths, edges are sealed, and products undergo quality inspection

• Packaging and Storage: Finished boards are bundled, wrapped, and stored for distribution to construction sites

Industry Leadership

The global gypsum board industry is led by established multinational manufacturers with extensive production capabilities and market presence. Key industry players include:

• Saint-Gobain

• USG Corporation

• Knauf Insulation

• National Gypsum Company

• LafargeHolcim

These companies serve diverse end-use sectors including construction, real estate, commercial buildings, and residential housing, demonstrating the broad market applicability of gypsum board manufacturing.

Recent Industry Developments

October 2024: Saint-Gobain unveiled CarbonLow, a new line of low-carbon gypsum wallboard to be sold in Canada starting in 2025. With up to 60% less embodied carbon cradle-to-gate than traditional alternatives, CarbonLow allows contractors and homeowners to utilize quality CertainTeed solutions while reducing environmental footprint.

October 2024: Knauf Egypt Ltd inaugurated its third gypsum board factory in Egypt, marking an 80-million-euro investment to expand production capabilities and deliver high-quality products for local and regional markets.

Browse Related Reports:

• Stretch Film Manufacturing Plant Cost: https://industrytoday.co.uk/manufacturing/stretch-film-manufacturing-plant-setup-cost-2025-industry-trends-machinery-and-raw-materials

• Cream Cheese Manufacturing Plant Cost: https://industrytoday.co.uk/manufacturing/cream-cheese-manufacturing-plant-setup-2025-business-plan-raw-materials-and-industry-trends

• Binding Wire Manufacturing Plant Cost: https://industrytoday.co.uk/manufacturing/binding-wire-manufacturing-plant-project-report-2025-layout-machinery-raw-materials-and-financial-outlook

About Us:

IMARC Group is a global management consulting firm that helps the world's most ambitious changemakers to create a lasting impact. The company excels in understanding its client's business priorities and delivering tailored solutions that drive meaningful outcomes. We provide a comprehensive suite of market entry and expansion services. Our offerings include thorough market assessment, feasibility studies, company incorporation assistance, factory setup support, regulatory approvals and licensing navigation, branding, marketing and sales strategies, competitive landscape, and benchmarking analyses, pricing and cost research, and procurement research.

Contact Us:

IMARC Group

134 N 4th St. Brooklyn, NY 11249, USA

Email: sales@imarcgroup.com

Tel No: (D) +91 120 433 0800

United States: (+1-201-971-6302)

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Gypsum Board Manufacturing Plant Setup 2026: Process Details, Market Outlook, and Profitability Analysis here

News-ID: 4369084 • Views: …

More Releases from IMARC Group

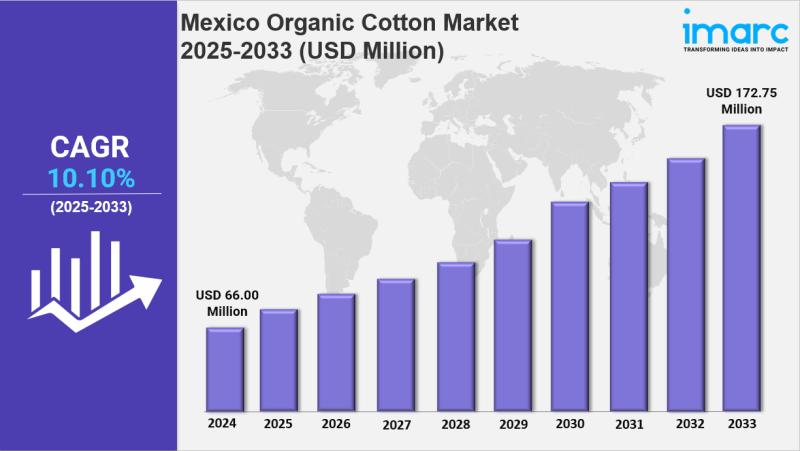

Mexico Organic Cotton Market Size, Growth, Latest Trends and Forecast 2025-2033

IMARC Group has recently released a new research study titled "Mexico Organic Cotton Market Size, Share, Trends and Forecast by Type, Quality Type, Application, and Region, 2025-2033" which offers a detailed analysis of the market drivers, segmentation, growth opportunities, trends, and competitive landscape to understand the current and future market scenarios.

Market Overview

The Mexico organic cotton market size was USD 66.00 Million in 2024 and is projected to reach USD 172.75…

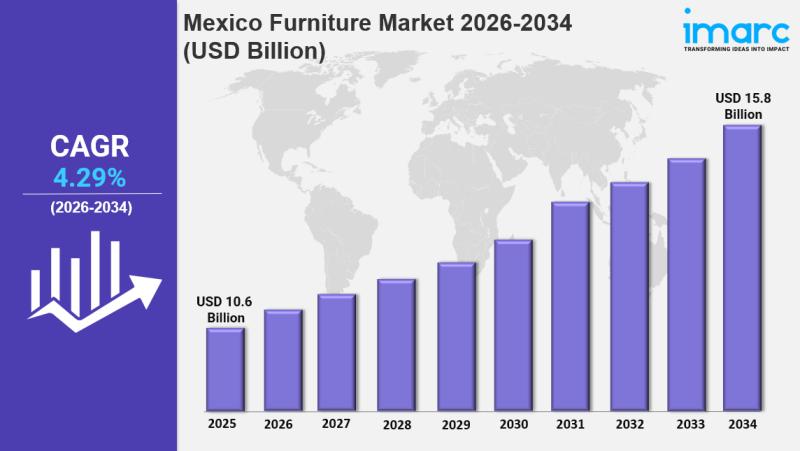

Mexico Furniture Market Size, Share, Trends, Growth and Forecast 2026-2034

IMARC Group has recently released a new research study titled "Mexico Furniture Market Report by Material (Metal, Wood, Plastic, Glass, and Others), Distribution Channel (Supermarkets and Hypermarkets, Specialty Stores, Online Stores, and Others), End Use (Residential, Commercial), and Region 2026-2034" which offers a detailed analysis of the market drivers, segmentation, growth opportunities, trends, and competitive landscape to understand the current and future market scenarios.

Market Overview

The Mexico furniture market size reached…

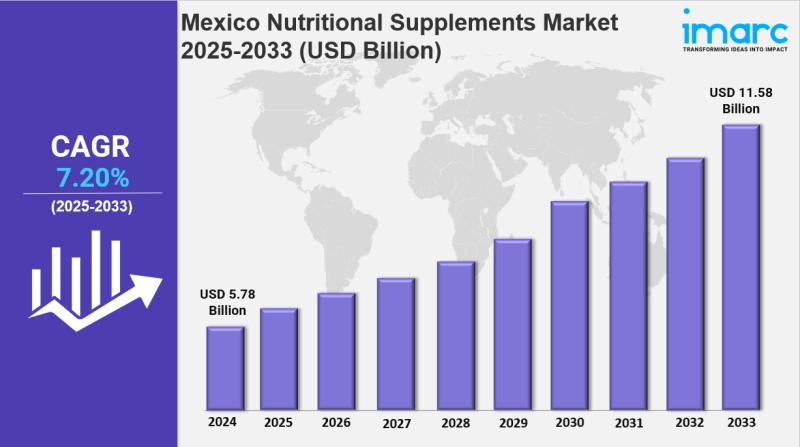

Mexico Nutritional Supplements Market : Trends, Drivers, and Growth Opportunitie …

IMARC Group has recently released a new research study titled "Mexico Nutritional Supplements Market Size, Share, Trends and Forecast by Product Type, Form, Distribution Channel, Consumer Group, and Region, 2025-2033" which offers a detailed analysis of the market drivers, segmentation, growth opportunities, trends, and competitive landscape to understand the current and future market scenarios.

Market Overview

The Mexico nutritional supplements market size was valued at USD 5.78 Billion in 2024 and is…

Groundnut Oil Manufacturing Plant Project Report 2026: Machinery Cost, CapEx/OpE …

The global edible oils industry is experiencing a transformative shift driven by rising consumer preference for natural cooking oils, increasing awareness regarding heart-healthy alternatives, and expanding demand from food processing and hospitality sectors. At the core of these developments lies a critical edible oil category-groundnut oil. As consumers increasingly prioritize oils with favorable fatty acid profiles and proven cardiovascular benefits, establishing a groundnut oil manufacturing plant presents a strategically compelling…

More Releases for Gypsum

Gypsum Board Market 2021 | Global Key Player; American Gypsum, Certainteed, Geor …

Gypsum board Market – Market Overview;

The future of the construction industry holds good opportunities in residential, non-residential, and infrastructure applications. Increasing housing activities and growing infrastructure projects due to increasing urbanization and growing population are the major drivers for the growth of this market. Availability of innovative construction solutions that are durable and require low maintenance is expected to impact the market favorably. The increase in the new construction start-ups…

Gypsum Board Market 2021 | Global Key Player; American Gypsum, Certainteed, Geor …

Gypsum board Market – Market Overview

The future of the construction industry holds good opportunities in residential, non-residential, and infrastructure applications. Increasing housing activities and growing infrastructure projects due to increasing urbanization and growing population are the major drivers for the growth of this market. Availability of innovative construction solutions that are durable and require low maintenance is expected to impact the market favorably. The increase in the new construction start-ups…

Gypsum Board Market 2021 Global Key Player; American Gypsum, Certainteed, Georgi …

Global Gypsum Board Market Information by type (Regular Gypsum Board and Type X Gypsum Board), by applications (residential, institutional, commercial and others) and by product (gypsum wallboard and gypsum ceiling board) - Forecast to 2021

The report for Global Gypsum Board Market of Market Research Future comprises of extensive primary research along with the detailed analysis of qualitative as well as quantitative aspects by various industry experts, key opinion leaders…

Gypsum Board Market Share 2021; American Gypsum, Certainteed, Georgia-Pacific, N …

Global Gypsum Board Market Information by type (Regular Gypsum Board and Type X Gypsum Board), by applications (residential, institutional, commercial and others) and by product (gypsum wallboard and gypsum ceiling board) - Forecast to 2021

The report for Global Gypsum Board Market of Market Research Future comprises of extensive primary research along with the detailed analysis of qualitative as well as quantitative aspects by various industry experts, key opinion leaders…

Gypsum Board Market 2021 Global Key Player: American Gypsum, Certainteed, Georgi …

Global Gypsum Board Market Information by type (Regular Gypsum Board and Type X Gypsum Board), by applications (residential, institutional, commercial and others) and by product (gypsum wallboard and gypsum ceiling board) - Forecast to 2021

The report for Global Gypsum Board Market of Market Research Future comprises of extensive primary research along with the detailed analysis of qualitative as well as quantitative aspects by various industry experts, key opinion leaders…

Gypsum Board Market | 2018-2021; American Gypsum, Certainteed, Georgia-Pacific, …

Global Gypsum Board Market Information by type (Regular Gypsum Board and Type X Gypsum Board), by applications (residential, institutional, commercial and others) and by product (gypsum wallboard and gypsum ceiling board) - Forecast to 2021

The report for Global Gypsum Board Market of Market Research Future comprises of extensive primary research along with the detailed analysis of qualitative as well as quantitative aspects by various industry experts, key opinion leaders…