Press release

Groundnut Oil Manufacturing Plant Project Report 2026: Machinery Cost, CapEx/OpEx, ROI and Raw Materials

The global edible oils industry is experiencing a transformative shift driven by rising consumer preference for natural cooking oils, increasing awareness regarding heart-healthy alternatives, and expanding demand from food processing and hospitality sectors. At the core of these developments lies a critical edible oil category-groundnut oil. As consumers increasingly prioritize oils with favorable fatty acid profiles and proven cardiovascular benefits, establishing a groundnut oil manufacturing plant presents a strategically compelling business opportunity for entrepreneurs and industrial investors seeking to capitalize on this steadily growing market driven by health consciousness and dietary transitions.IMARC Group's report, "Groundnut Oil Manufacturing Plant Project Report 2026: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue," offers a comprehensive guide for establishing a processing plant. The groundnut oil manufacturing plant setup cost report offers insights into the processing process, financials, capital investment, expenses, ROI, and more for informed business decisions.

Request for a Sample Report: https://www.imarcgroup.com/groundnut-oil-manufacturing-plant-project-report/requestsample

Market Overview and Growth Potential

The global groundnut oil market demonstrates steady growth trajectory, valued at USD 11.36 Billion in 2025. According to IMARC Group's comprehensive market analysis, the market is projected to reach USD 17.03 Billion by 2034, exhibiting a consistent CAGR of 4.6% from 2026-2034. This sustained expansion is driven by increasing consumer preference for natural edible oils, rising awareness regarding heart-healthy cooking alternatives, and expanding demand from food processing and HoReCa sectors.

Groundnut oil, also known as peanut oil, is an edible vegetable oil extracted from premium groundnut seeds through mechanical pressing or solvent extraction methods. The product features a mild taste enabling versatile cooking applications, high smoke point suitable for deep frying, and balanced fatty acid composition containing monounsaturated and polyunsaturated fats. Groundnut oil contains vitamin E, antioxidants, and bioactive compounds promoting cardiovascular health and protecting against oxidative damage. The product achieves widespread use in cooking, frying, and food preparation due to its thermal stability and neutral flavor profile, while refined variants provide food manufacturers with products maintaining quality and extended shelf life.

The industry is driven by rising population, increasing disposable incomes, and shifting dietary preferences toward natural and minimally processed edible oils. Consumers prioritize oils with higher monounsaturated fat content and proven heart-health benefits, strengthening groundnut oil's market position. In emerging economies, urbanization and organized retail growth improve product accessibility and brand penetration. The food processing industry expands its groundnut oil usage due to stability under high temperatures and neutral sensory characteristics. Asia-Pacific remains the dominant production and consumption region, led by India and China, owing to abundant groundnut cultivation and strong domestic demand.

Plant Capacity and Production Scale

The proposed groundnut oil manufacturing facility is designed with an annual production capacity ranging between 30,000-60,000 MT per year, enabling economies of scale while maintaining operational flexibility. This capacity range allows manufacturers to serve diverse market segments-from household cooking oil consumers and food processing companies to HoReCa sector establishments and traditional medicine applications-ensuring steady demand and consistent revenue streams across multiple distribution channels.

Buy Now: https://www.imarcgroup.com/checkout?id=15812&method=2175

Financial Viability and Profitability Analysis

The groundnut oil manufacturing business demonstrates healthy profitability potential under normal operating conditions. The financial projections reveal margins supported by stable demand and established market positioning:

• Gross Profit Margins: 15-25%

• Net Profit Margins: 5-10%

These margins are supported by consistent year-round consumption patterns, established position as a staple cooking oil in major markets, and the essential nature of edible oils in food preparation. The project demonstrates viable return on investment (ROI) potential, making it an attractive proposition for both new entrants and established food industry players looking to secure edible oil supply chains and diversify product portfolios.

Operating Cost Structure

Understanding the operating expenditure (OpEx) is crucial for effective financial planning and cost management. The cost structure for a groundnut oil manufacturing plant is characterized by very high raw material intensity:

• Raw Materials: 80-85% of total OpEx

• Utilities: 10-15% of OpEx

• Other Expenses: Including labor, packaging, transportation, maintenance, depreciation, and taxes

Groundnuts (peanuts) constitute the dominant raw material input, representing the highest proportion among all manufacturing plants in this series. Additional materials include solvents for extraction processes, caustic soda and bleaching earth for refining operations, and packaging materials. The cost structure's extreme raw material dependency emphasizes the critical importance of strategic groundnut procurement, farmer relationship management, and efficient processing operations for maintaining competitive economics and profitability.

Capital Investment Requirements

Setting up a groundnut oil manufacturing plant requires substantial capital investment across several critical categories:

Land and Site Development: Selection of an optimal location with strategic proximity to groundnut cultivation regions, target consumer markets, and robust infrastructure including reliable transportation networks, utilities, and waste management systems. The site must accommodate storage for agricultural raw materials and comply with food safety regulations.

Machinery and Equipment: The largest portion of capital expenditure (CapEx) covers specialized processing equipment essential for efficient production. Key machinery includes:

• Seed cleaners for impurity removal

• Decorticators for shell separation

• Oil expellers for mechanical extraction

• Solvent extractors for maximum oil recovery

• Neutralizers for refining processes

• Deodorizers for flavor optimization

• Filters for oil clarification

• Filling machines for packaging operations

Civil Works: Building construction, factory layout optimization, and infrastructure development designed to accommodate bulk agricultural material handling, ensure food safety standards, and minimize operational complexities.

Other Capital Costs: Pre-operative expenses, machinery installation costs, food safety certifications, initial working capital requirements, and contingency provisions for unforeseen circumstances during plant establishment.

Major Applications and Market Segments

Groundnut oil finds extensive applications across diverse consumption and commercial sectors:

Household Cooking: Daily cooking applications benefit from groundnut oil's pleasant flavor, high smoke point, and nutritional profile, making it suitable for various cooking methods including frying, sautéing, and general food preparation.

Food Processing: Manufacturers utilize groundnut oil in snacks, ready-to-eat foods, bakery items, and sauces, valuing its thermal stability and neutral taste characteristics that preserve product flavor profiles.

HoReCa Sector: Restaurants and commercial kitchens prefer groundnut oil for deep frying and bulk cooking operations due to its high smoke point and cost-effectiveness in high-volume applications.

Ayurvedic and Traditional Uses: Cold-pressed groundnut oil serves applications in traditional medicine and wellness products, capitalizing on natural processing methods and bioactive compound retention.

End-use sectors encompass household consumption, food and beverage manufacturing, food processing operations, and HoReCa establishments, all contributing to sustained market demand.

Ask Analyst for Customization: https://www.imarcgroup.com/request?type=report&id=15812&flag=C

Why Invest in Groundnut Oil Manufacturing?

Several compelling factors make groundnut oil manufacturing an attractive investment opportunity:

Essential Edible Oil Segment: Groundnut oil serves as a staple cooking oil experiencing year-round consumption across multiple global markets, ensuring consistent demand independent of seasonal fluctuations.

Favorable Entry Dynamics: Groundnut oil manufacturing requires moderate technological sophistication compared to complex chemical processing, enabling market entry through brand development and product differentiation strategies.

Health-Driven Consumption Trends: Increasing consumer preference for oils with favorable monounsaturated fat profiles and cardiovascular benefits positions groundnut oil advantageously against saturated fat alternatives and supports premium product positioning.

Agricultural Linkages and Policy Support: Government programs promoting oilseed cultivation, edible oil production, and agro-processing development enhance raw material availability while supporting industrial expansion through favorable policy frameworks.

Localization and Supply Security: Domestic production reduces import dependency for edible oils while enabling local manufacturers to establish supply chain efficiency and cost advantages through proximity to agricultural production regions.

Manufacturing Process Excellence

The groundnut oil manufacturing process involves several controlled stages ensuring product quality and safety:

• Cleaning: Raw groundnuts undergo cleaning to remove dirt, stones, and foreign matter

• Shelling: Decorticators separate kernels from shells

• Crushing: Kernels are crushed to facilitate oil extraction

• Oil Extraction: Mechanical pressing or solvent extraction recovers oil from crushed material

• Filtration: Crude oil undergoes filtration to remove solid particles

• Refining: Neutralization, bleaching, and deodorization produce refined oil meeting quality standards

Industry Leadership

The global groundnut oil industry includes established manufacturers with diverse production capabilities. Key industry players include:

• Georgia-Pacific Chemicals LLC

• De Hekserij

• PAG KIMYA SAN. TIC. LTD. STI.

• GrantChem, Inc.

• Eurovanille

• LLC PK 'XimProm'

• Fujian Qina Trading Co. Ltd.

• Matole Ltd

• Gemini Edibles & Fats India Ltd

These companies serve end-use sectors including food and beverage, food processing, and HoReCa, demonstrating the broad market reach of groundnut oil manufacturing.

Recent Industry Developments

March 2025: Agrocrops announced entry into the FMCG space with the launch of MyMani, a brand centered on peanut-based snacks and edible oils. The new portfolio includes cold-pressed peanut and sesame oils, flavored peanut snacks, and premium nuts. This expansion into branded peanut-based FMCG products strengthens consumer awareness and accessibility of groundnut oil, accelerating demand and supporting sustained market growth.

June 2025: Marico Limited unveiled the Saffola Cold Pressed Oils range, marking its entry into the cold-pressed oils category. The new lineup features groundnut-based single-seed oils and dual-seed blends such as groundnut with sesame and safflower, designed to offer balanced nutrition and authentic taste. This launch expands Saffola's oils portfolio and strengthens focus on heart-healthy cooking for Indian households.

April 2025: Freedom Healthy Cooking Oils released an updated package design for its groundnut oil product. The company simultaneously established a digital platform showcasing classic Indian recipes for pickles and chutneys, seeking to honor India's diverse food traditions while offering home cooks authentic recipes pairing well with everyday cooking.

Browse Related Reports:

• Zinc Borohydride Production Plant Cost: https://industrytoday.co.uk/chemicals/zinc-borohydride-production-cost-report-2025-capexopex-analysis-with-profitability-forecasts

• Muesli Manufacturing Plant Cost: https://industrytoday.co.uk/manufacturing/muesli-manufacturing-plant-cost-2025-feasibility-and-profitability-roadmap-for-investors

• Metal Fabrication Manufacturing Plant Cost: https://industrytoday.co.uk/manufacturing/metal-fabrication-manufacturing-plant-project-report-2025-setup-details-capital-investments-and-business-plan

About Us:

IMARC Group is a global management consulting firm that helps the world's most ambitious changemakers to create a lasting impact. The company excels in understanding its client's business priorities and delivering tailored solutions that drive meaningful outcomes. We provide a comprehensive suite of market entry and expansion services. Our offerings include thorough market assessment, feasibility studies, company incorporation assistance, factory setup support, regulatory approvals and licensing navigation, branding, marketing and sales strategies, competitive landscape, and benchmarking analyses, pricing and cost research, and procurement research.

Contact Us:

IMARC Group

134 N 4th St. Brooklyn, NY 11249, USA

Email: sales@imarcgroup.com

Tel No: (D) +91 120 433 0800

United States: (+1-201-971-6302)

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Groundnut Oil Manufacturing Plant Project Report 2026: Machinery Cost, CapEx/OpEx, ROI and Raw Materials here

News-ID: 4368762 • Views: …

More Releases from IMARC Group

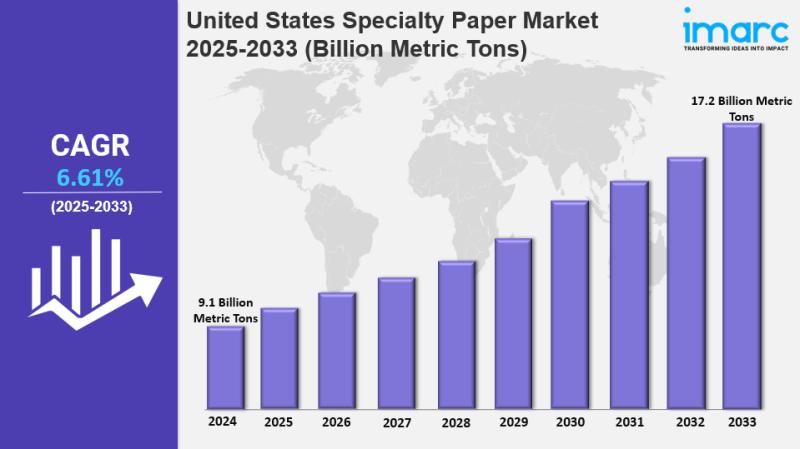

United States Specialty Paper Market Size, Growth, Latest Trends and Forecast To …

IMARC Group has recently released a new research study titled "United States Specialty Paper Market Report by Type (Label and Release Papers, Printing Papers, Flexible Packaging Papers, Rolling Papers, Décor Papers, Banknotes and Security Papers, and Others), Raw Material (Pulp, Fillers and Binders, Additives, Coatings, and Others), Application (Packaging and Labeling, Printing and Writing, Industrial Use, Building and Construction, Food Service, and Others), and Region 2025-2033", offers a detailed analysis…

Chicken Processing Plant Project Report 2026: Business Plan, Raw Materials, and …

The global food industry is experiencing a transformative shift driven by rising consumer demand for affordable protein sources, increasing health consciousness, and rapid expansion of organized food service sectors. At the core of these developments lies a critical protein commodity-chicken meat. As consumers worldwide increasingly prefer poultry as their primary protein source due to its nutritional benefits, lower cost compared to red meat, and culinary versatility, establishing a chicken processing…

Soft Skills Training Market: Workforce Readiness, Leadership Development and Lea …

Market Overview

The global soft skills training market size was valued at USD 33.39 Billion in 2024 and is projected to reach USD 92.59 Billion by 2033. The market is expected to grow at a CAGR of 11.40% during the forecast period from 2025 to 2033. Growth is driven by increasing demand for workforce development, leadership, communication skills, and adaptability, supported by rising adoption of e-learning and virtual training. North America…

AI in Healthcare Market 2025-2033: Focus on Robotic Surgery, Virtual Nursing & B …

The global artificial intelligence in healthcare market reached USD 7.8 Billion in 2024. Forecasts suggest it will escalate to USD 68.7 Billion by 2033, demonstrating a CAGR of 26.04% during 2025-2033. Growth is driven by rising demand for personalized medicine, remote patient monitoring, and advancements in machine learning techniques for efficient medical image analysis and patient outcome prediction.

Study Assumption Years

Base Year: 2024

Historical Years: 2019-2024

Forecast Period: 2025-2033

Artificial Intelligence in Healthcare…

More Releases for Groundnut

Groundnut Oil Manufacturing Plant Project Report: Business Plan, Cost Analysis a …

Syndicated Analytics' latest report titled "Groundnut Oil Manufacturing Plant Project Report 2024: Industry Analysis (Market Performance, Segments, Price Analysis, Outlook), Detailed Process Flow (Product Overview, Unit Operations, Raw Materials, Quality Assurance), Requirements and Cost (Machinery, Raw Materials, Packaging, Transportation, Utility, Human Resource), Project Economics (Capital Investments, Operating Costs, Profit Projections, Financial Analysis, Revenue), and Investment Opportunities" covers all the aspects including industry performance, key success, and risk factors, manufacturing requirements, project costs,…

Comprehensive Approach to Setting Up a Groundnut Oil Manufacturing Plant | Syndi …

Syndicated Analytics latest report titled "Groundnut Oil Manufacturing Plant Project Report: Industry Trends, Manufacturing Process, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue 2023-2028" covers all the aspects including industry performance, key success, and risk factors, manufacturing requirements, project costs, and economics, expected returns on investment, profit margins, etc. required for setting up a groundnut oil manufacturing plant. The study, which is based both on desk research and…

Global Groundnut Oil Market, Global Groundnut Oil Industry, Covid-19 Impact Glob …

For most of us, the groundnut has been an accurate companion throughout the snack-time hunger, sheer boredom and casual strolls in the park. Fried, roasted, boiled or salted, they delight the taste buds in the substantial manner. They are an appropriate source of protein and fibre and are certainly a healthier substitute for oily snacks. The goodness of such legumes can be consumed in a wholly dissimilar form as well…

Groundnut Market to Set Phenomenal Growth| Bunge, Cargill, Donlinks, Longda, Cor …

HTF MI broadcasted a new title “United States Groundnut Market Report 2018 ” with 110 pages and in-depth assessment including key market trends, upcoming technologies, industry drivers, challenges, regulatory policies, with key company profiles and strategies of players such as ADM, Bunge, Cargill, Louis Dreyfus, Wilmar International, Corbion, Shandong Luhua, Cofco, Donlinks, Yihai Kerry, Longda, Qingdao Changsheng, Shangdong Jinsheng, Shandong Bohi Industry, Xiamen Zhongsheng, Hunan Jinlong, Sanhe hopefull, Dalian Huanong,…

Whole Groundnut Oil Market Size, Share, Development by 2025 - QY Research, Inc.

This report studies the Groundnut Oil market size (value and volume) by players, regions, product types and end industries, history data 2013-2017 and forecast data 2018-2025; This report also studies the global market competition landscape, market drivers and trends, opportunities and challenges, risks and entry barriers, sales channels, distributors and Porter's Five Forces Analysis.

Groundnut oil, also known as groundnut oil or arachis oil, is a mild-tasting vegetable oil derived from groundnuts.…

Global Groundnut Seeds Market 2016 Industry Trends, Sales, Supply, Demand, Analy …

Global Groundnut Seeds Industry 2015 Market Size Share Growth Forecast Research and Development

The Global Groundnut Seeds Industry report gives a comprehensive account of the Global Groundnut Seeds market. Details such as the size, key players, segmentation, SWOT analysis, most influential trends, and business environment of the market are mentioned in this report. Furthermore, this report features tables and figures that render a clear perspective of the Groundnut Seeds market. The…