Press release

Soap Manufacturing Plant Setup Report 2026: Machinery Cost, & Investment Insights

The global soap manufacturing industry is experiencing transformative growth driven by increasing hygiene awareness, rising urbanization, expanding population, growth in healthcare facilities, and growing demand for personal care products. At the heart of this expansion lies a critical consumer product-soap. As industries and households demand more reliable, safe, and high-performance cleansing solutions, establishing a soap manufacturing plant presents a strategically compelling business opportunity for entrepreneurs and industrial investors seeking to capitalize on this growing market.IMARC Group's report, "Soap Manufacturing Plant Project Report 2026: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue," offers a comprehensive guide for establishing a manufacturing plant. The soap manufacturing plant report offers insights into the manufacturing process, financials, capital investment, expenses, ROI, and more for informed business decisions.

Request for Sample Report: https://www.imarcgroup.com/soap-manufacturing-plant-project-report/requestsample

Market Overview and Growth Potential

The India soap market demonstrates remarkable growth trajectory, valued at USD 4.13 Billion in 2025. According to IMARC Group's comprehensive market analysis, the market is projected to reach USD 5.48 Billion by 2034, exhibiting a robust CAGR of 3.2% from 2026-2034. This sustained expansion is driven by rising hygiene awareness, increasing urbanization levels, expanding population, growth in healthcare infrastructure, and emphasis on infection prevention.

Soap is a detergent obtained through saponification between fatty acids and an alkali like sodium or potassium hydroxide. Soap appears in various types including bar soap, liquid soap, and powder soap. Soap has surfactant characteristics that allow it to emulsify oils, clean surfaces and skin, and decrease the number of microbes on a surface or skin. Soap can be manufactured from natural oils, synthesized fatty acids, and other additives like fragrances and colorings.

The soap market is experiencing sustained expansion driven by increasing hygiene awareness, population growth, and rising urbanization levels. Growth in the hospitality sector, including hotels and food services, further supports soap consumption. According to the National Travel and Tourism Office, expenditures by international visitors in the United States were USD 213.1 billion in 2023, and the U.S. received over 66 million international visitors. Additionally, product innovation such as herbal, organic, and medicated soaps has expanded consumer appeal. Government and public health initiatives promoting sanitation and cleanliness also contribute to sustained market demand.

Plant Capacity and Production Scale

The proposed soap manufacturing facility is designed with an annual production capacity ranging between 30,000-60,000 MT per year, enabling economies of scale while maintaining operational flexibility. This capacity range allows manufacturers to cater to diverse market segments-from personal care and cosmetics to pharmaceuticals, hospitality, retail, and industrial cleaning-ensuring steady demand and consistent revenue streams across multiple industry verticals.

Financial Viability and Profitability Analysis

The soap manufacturing business demonstrates healthy profitability potential under normal operating conditions. The financial projections reveal:

• Gross Profit Margins: 25-35%

• Net Profit Margins: 10-15%

These margins are supported by stable demand across personal care sectors, value-added manufacturing capabilities, and the essential nature of soap products in hygiene applications. The project demonstrates strong return on investment (ROI) potential, making it an attractive proposition for both new entrants and established industrial players looking to diversify their product portfolio in the consumer goods sector.

Operating Cost Structure

Understanding the operating expenditure (OpEx) is crucial for effective financial planning and cost management. The cost structure for a soap manufacturing plant is primarily driven by:

• Raw Materials: 70-80% of total OpEx

• Utilities: 5-10% of OpEx

• Other Expenses: Including labor, packaging, transportation, maintenance, depreciation, and taxes

Raw materials constitute the largest portion of operating costs, with palm oil being the primary input material. Additional materials include caustic soda, perfumes, colors, and sodium silicate that enhance product characteristics. Establishing long-term contracts with reliable suppliers helps mitigate price volatility and ensures consistent material supply, which is critical given that raw material price fluctuations represent the most significant cost factor in soap manufacturing.

Capital Investment Requirements

Setting up a soap manufacturing plant requires substantial capital investment across several critical categories:

Land and Site Development: Selection of an optimal location with strategic proximity to key raw materials such as palm oil/tallow, caustic soda, perfumes, colors, and sodium silicate. Proximity to target markets will help minimize distribution costs. The site must have robust infrastructure, including reliable transportation, utilities, and waste management systems. Compliance with local zoning laws and environmental regulations must also be ensured.

Machinery and Equipment: The largest portion of capital expenditure (CapEx) covers specialized manufacturing equipment essential for production. Key machinery includes:

• Saponification reactors/kettles for chemical conversion processes

• Mixers and blenders for combining ingredients uniformly

• Soap cutters for precise sizing and portioning

• Milling and plodding machines for refining soap texture and consistency

• Slab or bar presses for shaping final products

• Stamping and embossing units for branding and design application

• Curing racks for proper drying and hardening

• Wrapping or packaging lines for finished product handling

• Advanced monitoring systems for quality control

• Effluent treatment systems for environmental compliance

Civil Works: Building construction, factory layout optimization, and infrastructure development designed to enhance workflow efficiency, ensure workplace safety, and minimize material handling complexities throughout the production process. The layout should be optimized with separate areas for raw material storage, production, quality control, and finished goods storage.

Other Capital Costs: Pre-operative expenses, machinery installation costs, regulatory compliance certifications, initial working capital requirements, and contingency provisions for unforeseen circumstances during plant establishment.

Buy Now: https://www.imarcgroup.com/checkout?id=9680&method=2175

Major Applications and Market Segments

Soap manufacturing products find extensive applications across diverse industrial sectors, demonstrating their versatility and critical importance:

Soap Manufacturing: Production of bar soaps, liquid soaps, and specialty cleansing products for various consumer and commercial applications.

Personal Care: Hand washes, body washes, and skincare formulations designed for daily hygiene and wellness routines.

Household Cleaning: Laundry soaps, dishwashing liquids, and surface cleaners essential for maintaining domestic hygiene standards.

Industrial & Institutional Cleaning: Heavy-duty soaps and hygiene solutions specifically formulated for commercial use in healthcare facilities, hospitality establishments, food service operations, and industrial premises.

End-use industries include personal care, cosmetics, pharmaceuticals, hospitality, retail, and industrial cleaning, all of which contribute to sustained market demand. Applications span bar soaps, medicated cleansers, luxury bath products, hotel amenities, and specialty industrial cleaners.

Why Invest in Soap Manufacturing?

Several compelling factors make soap manufacturing an attractive investment opportunity:

Essential Consumer & Hygiene Product: Soap is consumed by people in households, healthcare facilities, hotels, restaurants, and institutional premises, making it a non-discretionary product for repeated purchase. It caters to the necessities of people in all such settings, ensuring consistent sales and demand stability.

Moderate but Defensible Entry Barriers: While less capital-intensive than advanced chemicals, soap manufacturing requires formulation expertise, quality control, regulatory compliance, fragrance and additive know-how, and brand trust. Consistency, safety standards, and long customer qualification cycles favor established, quality-focused producers over low-grade entrants.

Megatrend Alignment: Increasing health awareness, urbanization, growing population, premiumization of personal care products, and increasing importance of personal hygiene following the pandemic have fuelled the demand for soaps, liquid cleansing agents, and specialty products. Personal care markets are steadily growing in both emerging and established economies.

Policy & Public Health Support: Government policies and initiatives for sanitation, cleanliness, and healthcare-including public hygiene campaigns, sanitation in schools, healthcare in hospitals, and MSME manufacturing facilitation-support demand for soaps and cleansing products in indirect but meaningful ways.

Localization & Supply Chain Resilience: Brands, institutions, and distributors increasingly prefer local and reliable manufacturers to ensure consistent supply, adapt formulations to regional preferences, manage raw material volatility (oils, fats, fragrances), and reduce logistics risk-creating opportunities for regional soap manufacturers with efficient operations and sourcing capabilities.

Product Innovation Opportunities: The market supports continuous innovation through herbal, organic, and medicated soap variants that expand consumer appeal and enable premium pricing strategies. Diverse product formats and affordable pricing strengthen penetration across both developed and developing economies.

Speak to an Analyst for Customized Report: https://www.imarcgroup.com/request?type=report&id=9680&flag=C

Manufacturing Process Excellence

The soap manufacturing process involves several precision-controlled stages:

• Saponification: Chemical reaction between fatty acids and alkali to produce soap base material

• Mixing and Blending: Combining ingredients including oils, caustic soda, fragrances, colors, and additives to achieve desired formulation

• Milling and Plodding: Refining soap texture, consistency, and uniformity through mechanical processing

• Pressing and Shaping: Forming soap into bars or desired shapes using slab or bar presses

• Stamping and Embossing: Applying brand logos, designs, and identification marks to finished products

• Curing: Allowing soap bars to dry and harden properly on specialized racks

• Quality Control: Rigorous testing for chemical composition, physical properties, safety standards, and performance characteristics

• Packaging: Wrapping finished products using moisture-resistant materials for safe transport and storage

Industry Leadership

The global soap manufacturing industry is led by established manufacturers with extensive production capabilities and diverse application portfolios. Key industry players include:

• Unilever PLC

• Procter & Gamble Co.

• Reckitt Benckiser Group

• Colgate-Palmolive Company

• Godrej Consumer Products Ltd.

These companies serve diverse end-use sectors including personal care, cosmetics, pharmaceuticals, hospitality, retail, and industrial cleaning, demonstrating the broad market applicability of soap products.

Recent Industry Developments

February 2025: Dawn launched the new Dawn PowerSuds, its best liquid dish soap, perfect for lots of dishes, signaling continued product innovation and market development in the cleansing products sector.

Browse Related Reports:

• Copper Pipe Manufacturing Plant Cost: https://industrytoday.co.uk/manufacturing/copper-pipe-manufacturing-plant-cost-2025-industry-trends-machinery-and-profit-insights

• Waste Plastic Recycling Plant Cost: https://industrytoday.co.uk/recycling_and_waste/waste-plastic-recycling-plant-report-2025-market-trends-project-cost-industry-outlook

• Smart Water Meter Manufacturing Plant Cost: https://industrytoday.co.uk/manufacturing/smart-water-meter-manufacturing-plant-cost-report-2025-capital-investment-and-profit-projections

• Tablet Manufacturing Plant Cost: https://industrytoday.co.uk/manufacturing/tablet-manufacturing-plant-report-2025-project-cost-setup-details-and-business-plan

• Biopolymer Production Plant Cost: https://industrytoday.co.uk/chemicals/biopolymer-production-plant-setup-report-2025-market-overview-cost-analysis-profitability

Conclusion

The soap manufacturing sector presents a strategically positioned investment opportunity at the intersection of consumer hygiene, public health awareness, and essential product demand. With favorable profit margins ranging from 25-35% gross profit and 10-15% net profit, strong policy support through sanitation and healthcare initiatives, and accelerating global demand driven by urbanization and hygiene consciousness, establishing a soap manufacturing plant offers significant potential for long-term business success and sustainable returns. The combination of moderate entry barriers, proven manufacturing technology, diverse application markets, and growing population needs creates an attractive value proposition for serious industrial investors committed to quality manufacturing and operational excellence.

About Us:

IMARC Group is a global management consulting firm that helps the world's most ambitious changemakers to create a lasting impact. The company excels in understanding its client's business priorities and delivering tailored solutions that drive meaningful outcomes. We provide a comprehensive suite of market entry and expansion services. Our offerings include thorough market assessment, feasibility studies, company incorporation assistance, factory setup support, regulatory approvals and licensing navigation, branding, marketing and sales strategies, competitive landscape, and benchmarking analyses, pricing and cost research, and procurement research.

Contact Us:

IMARC Group

134 N 4th St. Brooklyn, NY 11249, USA

Email: sales@imarcgroup.com

Tel No: (D) +91 120 433 0800

United States: (+1-201-971-6302)

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Soap Manufacturing Plant Setup Report 2026: Machinery Cost, & Investment Insights here

News-ID: 4366545 • Views: …

More Releases from IMARC Group

India Digital Health Market is Expected to Reach USD 84,076.5 Million by 2034 | …

Introduction

According to IMARC Group's report titled "India Digital Health Market Size, Share, Trends and Forecast by Type, Component, and Region, 2026-2034" the report offers a comprehensive analysis of the industry, including India digital health market share, growth, trends, and regional insights.

How Big is the India Digital Health Market?

The India digital health market size reached USD 19,145.3 Million in 2025. Looking forward, IMARC Group expects the market to reach USD 84,076.5…

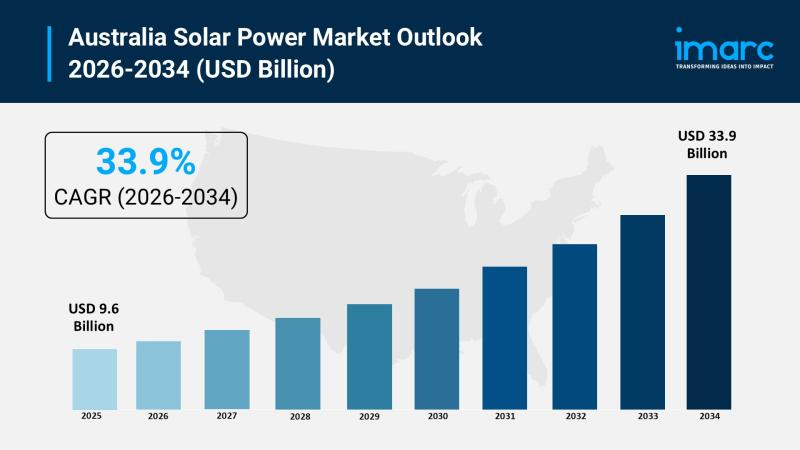

Australia Solar Power Market 2026 | Projected to Reach USD 33.9 Billion by 2034

Market Overview

The Australia solar power market reached USD 9.6 Billion in 2025 and is forecast to grow to USD 33.9 Billion by 2034. The market exhibits a robust growth rate of 15.00% during the forecast period 2026-2034. This expansion is driven by supportive government policies, technological advancements, and increasing adoption across residential, commercial, and utility sectors, positioning solar energy as a cornerstone of Australia's clean energy future.

Grab a sample PDF…

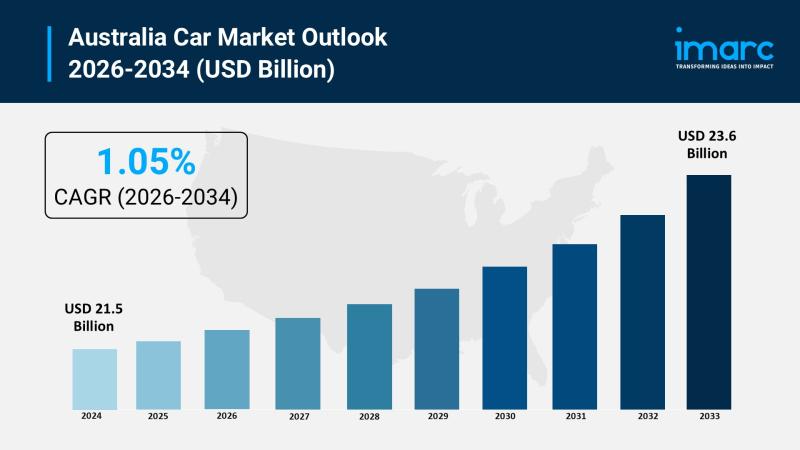

Australia Car Market 2026 | Surge to Grow to USD 23.6 Billion by 2034

Market Overview

The Australia car market reached a size of USD 21.5 Billion in 2025 and is forecasted to grow to USD 23.6 Billion by 2034. The market is expected to expand at a CAGR of 1.05% throughout the forecast period from 2026 to 2034. Growth is driven primarily by increasing demand for electric vehicles, SUVs, and connected car technologies, spurred by environmental awareness, lifestyle changes, and technological innovation toward sustainable…

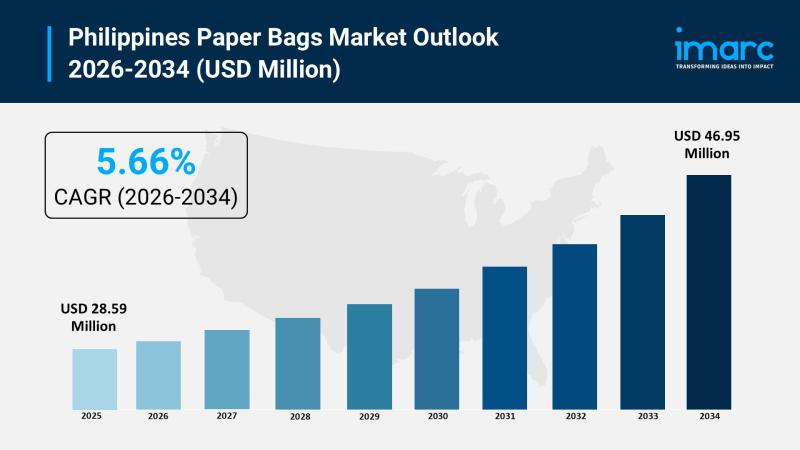

Philippines Paper Bags Market 2026 | Expected to Reach USD 46.95 Million by 2034

Market Overview

The Philippines paper bags market size was valued at USD 28.59 Million in 2025 and is expected to reach USD 46.95 Million by 2034, with a growth rate of 5.66% CAGR from 2026 to 2034. This growth is driven by increasing environmental concerns, government bans on single-use plastics, and rising adoption by retailers and foodservice providers. The expanding food and beverage sector, coupled with heightened awareness of plastic pollution,…

More Releases for Soap

Patriot Soap: A Natural, Masculine Soap for the Modern Man

Patriot Soap is a handcrafted bar soap created specially for men, especially those aged 50 and up, who are looking for a healthier, more natural way to care for their skin. This product promises a return to traditional soap making methods, using high-quality, natural ingredients and avoiding the harmful additives often found in commercial body washes and soaps.

This isn't your average department store bar. Patriot Soap positions itself as a…

Handmade Soap Market

The "Handmade Soap Market" is expected to reach USD xx.x billion by 2031, indicating a compound annual growth rate (CAGR) of xx.x percent from 2024 to 2031. The market was valued at USD xx.x billion In 2023.

Growing Demand and Growth Potential in the Global Handmade Soap Market, 2024-2031

Verified Market Research's most recent report, "Handmade Soap Market: Global Industry Trends, Share, Size, Growth, Opportunity and Forecast 2023-2030," provides an in-depth examination…

Utility Soap Bar Market to see Booming Business Sentiments | Guelph Soap, Shea M …

Latest Study on Industrial Growth of Utility Soap Bar Market 2023-2028. A detailed study accumulated to offer Latest insights about acute features of the Utility Soap Bar market. The report contains different market predictions related to revenue size, production, CAGR, Consumption, gross margin, price, and other substantial factors. While emphasizing the key driving and restraining forces for this market, the report also offers a complete study of the future trends…

Liquid Hand Soap Market

The Liquid Hand Soap Market report has recently been added to Stratview Research’s offering. This report shows lucrative growth opportunities in the industry during the next five-year period and ensures more information regarding the market trends. The following summary will give an overview of the challenges, dynamics, and key market players.

Liquid Hand Soap Market Forecast:

Liquid Hand Soap Market is likely to witness an impressive Healthy CAGR of 10.0% during the…

Organic Liquid Soap Market Company Profiles, Financial Perspective 2026 | Oregon …

"LOS ANGELES, United States: The report is an all-inclusive research study of the global Organic Liquid Soap market taking into account the growth factors, recent trends, developments, opportunities, and competitive landscape. The market analysts and researchers have done extensive analysis of the global Organic Liquid Soap market with the help of research methodologies such as PESTLE and Porter’s Five Forces analysis. They have provided accurate and reliable market data and…

Herbal Soap Market is Expected to Grow at a Healthy CAGR with Top Players: LC Lo …

Herbal soaps are organic products made from natural herbs and ingredients that are beneficial and healthier for skin. These soaps are totally chemical free so there is negligible chance of any harmful or side effect from them as these contain natural oils like Almond oil, castor oil, some essential oils like saffron, sandalwood, strawberry, and rose water which are very beneficial for skin whitening, brightening, and smoothening. Consumers are shifting…