Press release

Biogas Manufacturing Plant Setup Cost, DPR 2026: Business Plan Report, and Machinery Requirement

The global energy landscape is undergoing a fundamental transformation as nations worldwide seek sustainable alternatives to conventional fossil fuels. At the forefront of this renewable energy revolution stands biogas-a clean, versatile energy source generated from organic waste materials. As governments intensify their commitment to carbon reduction targets and circular economy principles, establishing a biogas manufacturing plant presents a strategically compelling investment opportunity for entrepreneurs and industrial stakeholders seeking to participate in the sustainable energy transition while addressing critical waste management challenges.IMARC Group's report, "Biogas Manufacturing Plant Project Report 2026: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue," offers a comprehensive guide for establishing a manufacturing plant. The biogas manufacturing plant report offers insights into the manufacturing process, financials, capital investment, expenses, ROI, and more for informed business decisions.

Request for Sample Report: https://www.imarcgroup.com/biogas-manufacturing-plant-project-report/requestsample

Market Overview and Growth Potential

The global biogas market demonstrates robust and sustained growth, valued at USD 77.21 Billion in 2025. According to IMARC Group's comprehensive market analysis, the market is projected to reach USD 108.20 Billion by 2034, exhibiting a steady CAGR of 3.8% from 2026 to 2034. This consistent expansion is primarily driven by increasing demand for renewable energy solutions, sustainable waste management imperatives, and supportive government initiatives promoting clean energy adoption across developed and emerging economies.

Biogas is a green energy source generated through anaerobic digestion of organic waste materials, including agricultural residues, food waste, animal manure, and sewage sludge. Its primary components are methane (CH4) and carbon dioxide (CO2), enabling its use as fuel for electricity generation, heating applications, and cooking purposes. Biogas facilities employ anaerobic digesters to produce clean energy from biodegradable materials, while the remaining digestate serves as nutrient-rich organic fertilizer. As a renewable energy source, biogas significantly reduces fossil fuel consumption, mitigates greenhouse gas emissions, and promotes environmentally sustainable waste management practices that support circular economy objectives.

The biogas sector benefits from growing volumes of industrial and agricultural waste, expanding applications in electricity generation and cooking fuel substitution, and increasing government support for clean energy infrastructure. The Asia-Pacific market, led by India and China, is predicted to experience the fastest growth rate due to extensive agricultural practices, pressing waste management challenges, and substantial government incentives for renewable energy sector development. Europe and North America continue expanding their biogas plant networks as integral components of decarbonization strategies and circular economy policy frameworks.

Plant Capacity and Production Scale

The proposed biogas manufacturing facility is designed with an annual production capacity ranging between 3-6 MW equivalent, enabling economies of scale while maintaining operational flexibility to accommodate varying feedstock availability and market conditions. This capacity range allows manufacturers to serve diverse applications including distributed power generation, compressed biogas (CBG) production for transportation fuel, and organic fertilizer manufacturing, ensuring multiple revenue streams and enhanced financial stability.

Financial Viability and Profitability Analysis

The biogas manufacturing business demonstrates exceptionally attractive profitability potential under normal operating conditions. The financial projections reveal:

• Gross Profit Margins: 50-60%

• Net Profit Margins: 20-30%

These impressive margins are supported by multiple revenue streams including electricity sales, compressed biogas distribution, carbon credit monetization, and organic fertilizer sales. The relatively low raw material costs combined with premium pricing for renewable energy products and organic agricultural inputs create favorable economics. Government subsidies, feed-in tariffs, and renewable energy certificates further enhance project profitability, making biogas manufacturing one of the most financially attractive renewable energy investments available to investors.

Operating Cost Structure

Understanding the operating expenditure (OpEx) is essential for effective financial planning and long-term sustainability. The cost structure for a biogas manufacturing plant differs significantly from conventional manufacturing due to the nature of feedstock and process requirements:

• Raw Materials: 20-30% of total OpEx

• Utilities: 10-15% of OpEx

• Other Expenses: Including labor, maintenance, quality control, packaging, transportation, depreciation, and taxes

Raw materials, primarily organic waste and animal manure, constitute a relatively modest portion of operating costs compared to other manufacturing industries. This favorable cost structure results from the ability to source feedstock from agricultural operations, food processing facilities, and municipal waste streams, often at minimal cost or even with tipping fees that generate additional revenue. Establishing reliable feedstock supply agreements with local agricultural cooperatives, food processors, and municipal authorities ensures consistent material availability while optimizing transportation costs.

Utility expenses include electricity for process control systems, water for digester operations, and fuel for auxiliary heating during cold weather periods. The ability to generate on-site power from biogas significantly reduces net utility costs, creating additional economic advantages.

Capital Investment Requirements

Establishing a biogas manufacturing plant requires substantial but strategically justified capital investment across several critical categories:

Land and Site Development: Selection of optimal location with convenient access to organic waste sources, agricultural communities, and power transmission infrastructure. The site must provide adequate space for anaerobic digesters, gas storage facilities, power generation equipment, digestate handling systems, and future expansion capabilities. Comprehensive environmental impact assessments and compliance with local zoning regulations form essential components of site development planning.

Machinery and Equipment: Capital expenditure for specialized biogas production equipment represents the largest component of total investment. Essential machinery includes:

• Anaerobic digesters with precise temperature and mixing control systems

• Gas holders and storage tanks for biogas accumulation

• Gas scrubbing and purification systems to remove impurities and carbon dioxide

• Compressors for compressed biogas (CBG) production

• Power generators or combined heat and power (CHP) systems for electricity generation

• Digestate handling machinery including separators and storage facilities

• Advanced monitoring and control systems for process optimization

• Safety equipment including gas detection systems and emergency shutdown mechanisms

Civil Works: Construction of digester tanks, foundation systems, control buildings, digestate storage facilities, and access roads designed to support heavy equipment and material handling operations. Proper civil engineering ensures structural integrity, operational safety, and long-term durability under demanding operating conditions.

Other Capital Costs: Pre-operative expenses including feasibility studies, environmental clearances, regulatory approvals, engineering design fees, installation costs, commissioning activities, initial working capital, and contingency provisions for unforeseen circumstances during plant establishment.

Buy Now: https://www.imarcgroup.com/checkout?id=18491&method=2175

Major Applications and Market Segments

Biogas production enables multiple value-added applications across diverse market segments:

Power Generation: Biogas fuels combined heat and power (CHP) systems that generate electrical energy while capturing thermal energy for industrial or community heating applications, maximizing overall energy efficiency and revenue potential.

Cooking Fuel: Compressed biogas (CBG) serves as clean, renewable cooking fuel for residential, commercial, and industrial kitchens, directly substituting conventional LPG and reducing dependence on imported fossil fuels.

Agriculture: Digestate residue from biogas production provides nutrient-rich organic fertilizer that enhances soil fertility, improves crop yields, reduces chemical fertilizer requirements, and supports sustainable agricultural practices.

Industrial Applications: Biogas substitutes for natural gas in industrial boilers, furnaces, dryers, and thermal process equipment, reducing operational costs and carbon emissions for manufacturing facilities.

Transportation Fuel: Purified and compressed biogas serves as renewable vehicle fuel compatible with compressed natural gas (CNG) vehicles, supporting clean transportation initiatives in urban areas.

End-use industries include renewable energy sector, agriculture, waste management, transportation, and manufacturing, all contributing to sustained multi-sector demand growth.

Why Invest in Biogas Manufacturing?

Several compelling factors establish biogas manufacturing as an exceptionally attractive investment opportunity:

Sustainable Energy Production: Biogas represents environmentally friendly, renewable energy with minimal emissions compared to conventional fossil fuels, supporting energy security objectives while advancing environmental sustainability goals and carbon neutrality commitments.

Moderate Entry Barriers: Access to organic feedstock, proven anaerobic digestion technology, and substantial government incentives for renewable energy projects reduce operational risks for new market entrants, making biogas production more accessible than many other renewable energy technologies despite technical requirements.

Global Clean Energy Alignment: Worldwide adoption of biogas accelerates due to universal demand for renewable energy, sustainable waste management solutions, and aggressive decarbonization initiatives across government and corporate sectors.

Policy and Infrastructure Support: Government subsidy schemes, feed-in tariffs, renewable energy certificates, carbon credits, and supportive regulatory frameworks directly enhance biogas project economics and reduce investment risks.

Circular Economy Opportunities: Converting organic waste into renewable energy and organic fertilizer exemplifies efficient resource utilization, reduces environmental pollution, mitigates landfill requirements, and creates closed-loop production systems aligned with circular economy principles.

Multiple Revenue Streams: Biogas plants generate income from electricity sales, compressed biogas distribution, organic fertilizer sales, tipping fees for waste acceptance, and carbon credit trading, creating diversified revenue portfolios that enhance financial stability.

Speak to an Analyst for Customized Report: https://www.imarcgroup.com/request?type=report&id=18491&flag=C

Manufacturing Process Excellence

The biogas manufacturing process employs proven anaerobic digestion technology through carefully controlled stages including feedstock preparation and pre-treatment, controlled anaerobic digestion in sealed reactors, biogas collection and storage, gas scrubbing and purification to remove impurities, compression for CBG production or direct utilization in power generation equipment, digestate separation and processing for fertilizer applications, and comprehensive quality monitoring throughout all production stages.

Industry Leadership

The global biogas industry features established technology providers and project developers with extensive operational experience. Leading companies include:

• Engie SA

• IES Biogas

• BEKON GmbH

• EnviTec Biogas AG

• AEV Energy GmbH

• DMT International

• Weltec Biopower GmbH

• Hitachi Zosen Inova AG

These organizations serve renewable energy, agriculture, and waste management sectors across global markets, demonstrating proven technology reliability and operational success.

Recent Industry Developments

June 2025: Hindustan Petroleum Corporation Ltd (HPCL) announced plans to invest ₹20,000 crore (USD 231 million) over the next 2-3 years to establish 24 compressed biogas (CBG) plants across India, reinforcing the country's green energy initiative. Each facility will produce 10-15 tons of CBG daily from organic waste, supporting India's mandate to blend CBG into transportation fuel with a target of 5% by 2028-2029.

October 2025: Union Minister Amit Shah inaugurated India's first cooperative-run Compressed Bio-Gas (CNG) and Spray Dryer Potash Granule Project at Shankarrao Kolhe Cooperative Sugar Factory in Kopargaon, Maharashtra, promoting circular economy principles while producing renewable fuel and potash fertilizer to support rural economic development.

Browse Related Reports:

• PVC Conduit Pipes Manufacturing Plant Cost: https://industrytoday.co.uk/manufacturing/pvc-conduit-pipes-manufacturing-plant-setup-2025-business-plan-and-investment-opportunities

• Dishwashing Detergent Manufacturing Plant Cost: https://industrytoday.co.uk/chemicals/dishwashing-detergent-manufacturing-plant-cost-2025-industry-trends-machinery-and-profit-insights

• Water Bottling Plant Cost: https://industrytoday.co.uk/manufacturing/water-bottling-plant-setup-report-2025-market-trends-project-cost-industry-outlook

• Calcium Silicate Production Plant Cost: https://industrytoday.co.uk/chemicals/calcium-silicate-production-plant-setup-cost-2025-capital-investment-and-business-plan

Conclusion

The biogas manufacturing sector presents an exceptionally attractive investment opportunity at the convergence of renewable energy demand, sustainable waste management imperatives, and circular economy implementation. With outstanding profit margins of 50-60% gross profit and 20-30% net profit, comprehensive government policy support including subsidies and feed-in tariffs, and accelerating global commitment to carbon reduction targets, establishing a biogas manufacturing plant offers substantial potential for superior financial returns combined with meaningful environmental and social impact. The combination of proven technology, multiple revenue streams, diverse feedstock availability, and strong regulatory tailwinds creates a compelling value proposition for investors seeking sustainable, profitable participation in the global energy transition.

About Us:

IMARC Group is a global management consulting firm that helps the world's most ambitious changemakers to create a lasting impact. The company excels in understanding its client's business priorities and delivering tailored solutions that drive meaningful outcomes. We provide a comprehensive suite of market entry and expansion services. Our offerings include thorough market assessment, feasibility studies, company incorporation assistance, factory setup support, regulatory approvals and licensing navigation, branding, marketing and sales strategies, competitive landscape, and benchmarking analyses, pricing and cost research, and procurement research.

Contact Us:

IMARC Group

134 N 4th St. Brooklyn, NY 11249, USA

Email: sales@imarcgroup.com

Tel No: (D) +91 120 433 0800

United States: (+1-201-971-6302)

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Biogas Manufacturing Plant Setup Cost, DPR 2026: Business Plan Report, and Machinery Requirement here

News-ID: 4366444 • Views: …

More Releases from IMARC Group

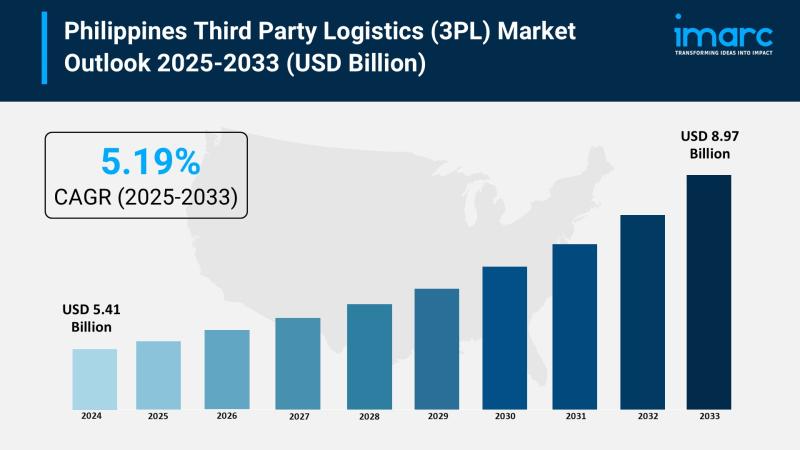

Philippines Third Party Logistics (3PL) Market | Worth USD 8.97 Billion From 202 …

Market Overview

The Philippines third party logistics (3PL) market size reached USD 5.41 Billion in 2024 and is anticipated to grow to USD 8.97 Billion by 2033, exhibiting a growth rate (CAGR) of 5.19% during 2025-2033 This growth is attributed to the surge in e-commerce activities, increased cross-border trade, and the demand for efficient supply chain management. The market benefits from the adoption of technology-driven solutions including automation and real-time tracking,…

Automotive Wiper Motor Manufacturing Plant Setup: Requirements & Process Flow

Automotive wiper motors are essential components in vehicles, powering windshield wipers to ensure clear visibility during rain, snow, or dust conditions. They are widely used in passenger cars, commercial vehicles, buses, and trucks. The increasing automotive production, focus on vehicle safety, and demand for reliable wiper systems are driving the growth of this sector.

Setting up an automotive wiper motor manufacturing plant involves sourcing high-quality electric motors, gears, brushes, housings, armatures,…

Base Oil Production Plant Setup: Machinery and Raw Materials Requirements

Base oil is a fundamental component in the formulation of lubricants, greases, and various industrial fluids. It serves as the primary carrier fluid providing viscosity, thermal stability, and lubrication performance. Base oils are widely used in automotive, industrial, and marine applications, making them a critical raw material in the petroleum and chemical sectors.

Setting up a base oil production plant involves sourcing crude oil feedstock, refining catalysts, and specialized chemicals. Investment…

Capital Requirements for Automotive Filter Manufacturing Plant Setup

Automotive filters are essential components in vehicles that ensure the proper functioning of engines, fuel systems, air intake, and hydraulic systems by removing contaminants, dust, and impurities. Common types include air filters, oil filters, fuel filters, and cabin filters. With increasing vehicle production and emphasis on engine efficiency and emission control, automotive filters are critical for performance, safety, and longevity of vehicles.

Setting up an automotive filter manufacturing plant involves sourcing…

More Releases for Biogas

Biogas Plants Market Next Big Thing | IES Biogas, EnviTec Biogas, Air Liquide, S …

Latest Study on Industrial Growth of Biogas Plants Market 2023-2028. A detailed study accumulated to offer Latest insights about acute features of the Biogas Plants market. The report contains different market predictions related to revenue size, production, CAGR, Consumption, gross margin, price, and other substantial factors. While emphasizing the key driving and restraining forces for this market, the report also offers a complete study of the future trends and developments…

Biogas Power Plant Market Next Big Thing | Scandinavian Biogas, PlanET Biogas Gl …

Latest Study on Industrial Growth of Biogas Power Plant Market 2023-2028. A detailed study accumulated to offer Latest insights about acute features of the Biogas Power Plant market. The report contains different market predictions related to revenue size, production, CAGR, Consumption, gross margin, price, and other substantial factors. While emphasizing the key driving and restraining forces for this market, the report also offers a complete study of the future trends…

Biogas Technology Market to See Huge Growth | EnviTec Biogas, PlanET Biogas, Zor …

Advance Market Analytics added research publication document on Worldwide Biogas Technology Market breaking major business segments and highlighting wider level geographies to get deep dive analysis on market data. The study is a perfect balance bridging both qualitative and quantitative information of Worldwide Biogas Technology market. The study provides valuable market size data for historical (Volume** & Value) from 2017 to 2021 which is estimated and forecasted till 2027*. Some…

Europe Biogas Market Excellent Revenue Growth 2024 by IES Biogas, Xergi, ENGIE, …

Europe biogas market is set to witness strong growth on account of growing focus toward decarbonizing the energy sector supported by a multitude of legislative schemes and policies. The EU Directive 2009/28/EC establishes common legislative framework concerning the use of energy from renewable sources with an objective to minimize greenhouse gas emissions. Increased production and use of biogas to support the circular economy and renewable energy mix will stimulate the…

Viessmann, CH4 Biogas listed in Study of Europe Biogas Market - 2024 by IES Biog …

The popularity of biogas as a renewable energy source has exponentially soared in the last few years, massively impacting Europe biogas market. Unlike fossil fuels like oil and coal, biogas does not add to the greenhouse effect, a factor that has encouraged the European Union to undertake favorable measures for promoting the utilization of this eco-friendly fuel, providing a further stimulus to Europe biogas market. Many European countries have been…

Biogas Plant Market : AmerescoInc., PlanET Biogas Global, Scandinavian Biogas, …

Industry Overview of Biogas Plant Market :

Excellence consistency maintains by Garner Insights in Research Report in which studies the global Biogas Plant market status and forecast, categorizes and Equipment.

The Global Biogas Plant Market Report provides a detailed analysis of the current dynamics of the market with an extensive focus on the secondary research. It also studies current situation of the market estimate, share, demand, development patterns, and forecast in the coming…