Press release

Poultry Feed Manufacturing Plant Cost 2026: Capital Investment, Machinery Setup, and Market Outlook

The global poultry feed industry stands at the forefront of agricultural transformation, driven by unprecedented demand for affordable animal protein and the expansion of organized livestock production systems. As poultry farming continues to emerge as the most cost-effective source of meat and eggs worldwide, the poultry feed manufacturing sector presents compelling investment opportunities for entrepreneurs and businesses seeking to enter this dynamic market. This comprehensive guide explores the technical, financial, and strategic dimensions of establishing a poultry feed manufacturing plant, drawing upon the latest industry data and market intelligence.Market Overview and Growth Potential

The poultry feed market is experiencing robust expansion, primarily fueled by:

• Rapid growth of the poultry farming sector

• Rising consumption of poultry meat and eggs

• Increasing demand for nutritionally balanced animal feed

• Expansion of organized livestock production systems

The global poultry feed market was valued at USD 225.19 Billion in 2025, and according to comprehensive market analysis, the sector is projected to reach USD 302.66 Billion by 2034, exhibiting a steady CAGR of 3.3% from 2026 to 2034. This impressive growth trajectory reflects fundamental shifts in global dietary patterns and agricultural practices. The promotion of large-scale poultry farming operations has created sustained demand for high-quality, standardized feed products that guarantee uniformity in performance and output. Contract farming methods have further reinforced the need for reliable feed solutions specifically tailored to production goals. Additionally, technological advancements in feed formulation have significantly enhanced birds' growth rates, health outcomes, and feed conversion efficiency, making specialized poultry feed increasingly indispensable to modern farming operations.

IMARC Group's report, "Poultry Feed Manufacturing Plant Project Report 2026: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue," offers a comprehensive guide for establishing a plant. The poultry feed manufacturing plant setup report offers insights into the process, financials, capital investment, expenses, ROI, and more for informed business decisions.

Plant Capacity and Production Scale

The proposed poultry feed manufacturing facility is designed with strategic flexibility and scalability in mind. The annual production capacity ranges between 100,000 to 200,000 MT, enabling significant economies of scale while maintaining operational adaptability to market conditions.

The production scale supports diverse feed formulations including:

• Broiler feed for meat production

• Layer feed for egg-laying hens

• Breeder feed for reproductive performance

• Starter, grower, and finisher feeds for different growth phases

This versatility ensures the plant can respond dynamically to market demands and establish multiple revenue streams across the poultry farming ecosystem, serving market segments from small rural units to large integrated operations.

Request for a Sample Report: https://www.imarcgroup.com/poultry-feed-manufacturing-plant-project-report/requestsample

Financial Viability and Profitability Analysis

The poultry feed manufacturing business demonstrates compelling financial fundamentals under normal operating conditions:

• Gross Profit Margins: 15-25%

• Net Profit Margins: 5-10%

These margins provide attractive returns while maintaining competitive pricing in the market. The financial projections developed for this project are based on realistic assumptions related to capital investment, operating costs, production capacity utilization, pricing trends, and demand outlook. These comprehensive financial models provide stakeholders with clear visibility into the project's financial viability, return on investment (ROI), profitability trajectory, and long-term sustainability.

The stable demand characteristics of poultry feed, combined with the essential nature of the product in the protein supply chain, create favorable conditions for consistent cash flows and predictable financial performance.

Operating Cost Structure

Understanding the operating cost structure is crucial for effective business planning and profitability management:

• Raw Materials: 85-90% of OpEx

• Utilities: 5-8% of OpEx

• Additional Costs: Transportation, packaging, salaries and wages, depreciation, taxes, and other expenses

Key Raw Materials Include:

• Cereals (maize, wheat)

• Protein sources (soybean meal, fish meal)

• Vitamins and minerals

• Additives (enzymes, amino acids)

The raw material mix varies based on poultry type and growth stage to ensure balanced nutrition. The heavy concentration of costs in raw materials, particularly maize, emphasizes the strategic importance of establishing long-term contracts with reliable suppliers to mitigate price volatility and ensure consistent supply of quality materials.

Capital Investment Requirements

Establishing a poultry feed manufacturing plant requires careful consideration of capital expenditure across multiple categories:

Capital Expenditure (CapEx) Components:

• Land and Site Development Costs

• Civil Works Costs

• Machinery Costs (largest portion of CapEx)

• Other Capital Costs

Site Selection Considerations:

• Easy access to key raw materials (maize and soymeal)

• Proximity to target markets to minimize distribution costs

• Robust infrastructure including reliable transportation, utilities, and waste management systems

• Compliance with local zoning laws and environmental regulations

• Space for future expansion

Essential Machinery Requirements:

• Hammer mills for crushing raw materials

• Batch or continuous mixers for uniform blending

• Pellet mills for forming feed pellets

• Coolers to reduce moisture content

• Crumblers for texture modification

• Conveyors for material handling

• Packing machines for final product packaging

All machinery must comply with industry standards for safety, efficiency, and reliability. High-quality, corrosion-resistant equipment tailored for poultry feed manufacturing ensures optimal operational performance and longevity.

Manufacturing Process Overview

The poultry feed manufacturing process involves several critical unit operations:

• Raw material receiving

• Cleaning and grinding

• Weighing and batching

• Mixing and homogenization

• Conditioning

• Pelleting or crumbling

• Cooling

• Quality inspection

• Packaging

This multi-step operation requires careful material handling and quality checks at each stage to ensure consistent product quality and nutritional value.

Ask Analyst for Customization: https://www.imarcgroup.com/request?type=report&id=8451&flag=C

Major Applications and Market Segments

Poultry feed manufacturing serves multiple critical applications:

Primary Applications:

• Commercial Poultry Farming: Supporting healthy growth, meat yield, and egg production

• Integrated Poultry Operations: Ensuring consistent feed quality across large-scale farms

• Contract Poultry Growers: Supplied as packaged feed formulations

• Rural and Semi-Organized Poultry Units: Used for small and medium-scale poultry rearing

End-Use Industries:

• Poultry farming sector

• Commercial broiler and layer farms

• Integrated poultry companies

• Livestock feed distributors

Buy Now: https://www.imarcgroup.com/checkout?id=8451&method=2175

Why Invest in Poultry Feed Manufacturing?

Multiple strategic factors converge to make poultry feed manufacturing an attractive investment proposition:

✓ Growth in Poultry Meat and Egg Consumption: Rising protein intake continues to support expansion of poultry farming

✓ Need for Balanced Nutrition: Commercial poultry production depends on scientifically formulated feed for performance and health

✓ Stable Year-Round Demand: Poultry feed demand remains consistent throughout the year

✓ Product Segmentation Opportunities: Different feed variants can be produced for specific bird age groups and farming models

✓ Scalable Production Setup: Feed plants allow capacity expansion with moderate additional investment

The business model offers predictable revenue streams and facilitates efficient capacity utilization throughout annual production cycles, distinguishing it from seasonal agricultural products.

Industry Leadership

The global poultry feed industry features several established leaders with extensive production capacities and diverse application portfolios:

Leading Manufacturers:

• New Hope Liuhe Co. Ltd

• Charoen Pokphand Foods Public Co. Ltd

• Land O'Lakes Inc

• Guangdong HAID Group Co. Ltd

• Cargill, Incorporated

These multinational corporations serve end-use sectors including the poultry farming sector, commercial broiler and layer farms, integrated poultry companies, and livestock feed distributors across multiple continents. These industry leaders have established comprehensive value chains demonstrating the strategic value of feed manufacturing as a foundational component of integrated poultry operations.

Conclusion

The poultry feed manufacturing sector presents a compelling investment opportunity characterized by strong market fundamentals, healthy profit margins, and sustainable growth prospects. For entrepreneurs and businesses seeking to participate in the global protein supply chain, poultry feed manufacturing offers a proven pathway to creating value while contributing to food security and agricultural development. The sector's growth trajectory, coupled with the fundamental importance of the product to poultry farming operations worldwide, ensures continued relevance and opportunity for well-executed manufacturing ventures.

Browse Related Reports:

Fatty Acid Production Plant Cost: https://industrytoday.co.uk/chemicals/cost-of-starting-a-fatty-acid-production-plant-2025

Laptop Manufacturing Plant Cost: https://industrytoday.co.uk/manufacturing/strategic-insights-into-laptop-manufacturing-2025-plant-cost-setup

Tomato Sauce Manufacturing Plant Cost: https://industrytoday.co.uk/manufacturing/cost-analysis-for-tomato-sauce-manufacturing-plant-2025-setup-requirements

Paver Block Manufacturing Plant Cost: https://industrytoday.co.uk/Construction/paver-block-manufacturing-plant-cost-report-2025

Rice Husk Based Charcoal Powder Manufacturing Plant Cost: https://industrytoday.co.uk/energy_and_environment/rice-husk-based-charcoal-powder-manufacturing-plant-cost-report-2025

About Us :

IMARC Group is a global management consulting firm that helps the world's most ambitious changemakers to create a lasting impact. The company provide a comprehensive suite of market entry and expansion services. IMARC offerings include thorough market assessment, feasibility studies, company incorporation assistance, factory setup support, regulatory approvals and licensing navigation, branding, marketing and sales strategies, competitive landscape and benchmarking analyses, pricing and cost research, and procurement research.

Services:

• Plant Setup

• Factoring Auditing

• Regulatory Approvals, and Licensing

• Company Incorporation

• Incubation Services

• Recruitment Services

• Marketing and Sales

Contact Us:

IMARC Group

134 N 4th St. Brooklyn, NY 11249, USA

Email: sales@imarcgroup.com

Tel No:(D) +91 120 433 0800

United States: +1-201971-6302

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Poultry Feed Manufacturing Plant Cost 2026: Capital Investment, Machinery Setup, and Market Outlook here

News-ID: 4366321 • Views: …

More Releases from IMARC Group

Float Glass Manufacturing Plant Report 2026: Unit Setup, Cost and Requirements

Float glass stands as one of the most essential materials in modern construction, automotive, and renewable energy industries. Manufactured through a sophisticated process of floating molten glass on a bath of molten tin, this flat glass product delivers exceptional optical clarity, uniform thickness, and remarkably smooth surfaces that eliminate the need for grinding and polishing. The material's outstanding light transmission, high mechanical strength, and excellent thermal stability make it indispensable…

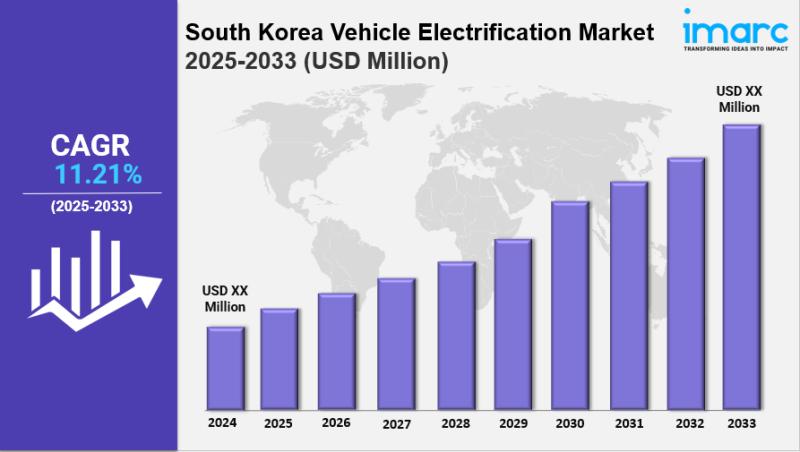

South Korea Vehicle Electrification Market Size, Growth, Key Players, Latest Tre …

IMARC Group has recently released a new research study titled "South Korea Vehicle Electrification Market Report by Product Type (Starter Motor, Alternator, Electric Car Motors, Electric Water Pump, Electric Oil Pump, Electric Vacuum Pump, Electric Fuel Pump, Electric Power Steering, Actuators, Start/Stop System), Vehicle Type (Internal Combustion Engine (ICE) and Micro-Hybrid Vehicle, Plug-in Hybrid Electric Vehicle (PHEV) and Battery Electric Vehicle (BEV), Hybrid Electric Vehicle (HEV)), Sales Channel (Original Equipment…

Hand Wash Detergents Manufacturing Plant 2026: Machinery Requirement, Setup Cost …

The hand wash detergents industry represents a cornerstone of the global personal hygiene sector, driven by sustained hygiene awareness, expanding institutional hand hygiene programs, and increasing consumer preference for premium formulations. Hand wash detergents are surfactant-based cleansing solutions designed to eliminate dirt, oils, and temporary bacteria from hands during rinsing. Commercial products are typically liquid or foaming systems composed of primary surfactants for cleaning and foam generation, co-surfactants for mildness…

Peas Processing Plant DPR & Unit Setup - 2026: Demand Analysis and Project Cost

The global peas processing industry represents a significant opportunity for investors seeking to capitalize on the growing demand for nutritious, convenient food products. Peas, small spherical seeds derived from the legume Pisum sativum, are cultivated extensively for both human consumption and animal feed. Rich in protein, dietary fiber, vitamins (notably vitamin C, vitamin K, and several B vitamins), and essential minerals such as iron, magnesium, and potassium, peas have become…

More Releases for Cost

Steel Production Cost - Process Economics, Raw Materials, and Cost Drivers

Steel is the backbone of modern industry, and its production cost is one of the most closely tracked indicators across construction, infrastructure, automotive, and manufacturing sectors. Unlike niche chemicals or APIs, steel economics are driven by scale, energy intensity, and raw material volatility.

Here's the thing: steel production cost isn't just about iron ore prices. It's a layered equation involving coking coal, electricity, labor, emissions compliance, logistics, and technology choice. A…

Egg Powder Manufacturing Plant Setup Cost | Cost Involved, Machinery Cost and In …

IMARC Group's report titled "Egg Powder Manufacturing Plant Project Report 2024: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue" provides a comprehensive guide for establishing an egg powder manufacturing plant. The report covers various aspects, ranging from a broad market overview to intricate details like unit operations, raw material and utility requirements, infrastructure necessities, machinery requirements, manpower needs, packaging and transportation requirements, and more.

In addition to…

Glucose Manufacturing Plant Cost Report 2024: Requirements and Cost Involved

IMARC Group's report titled "Glucose Manufacturing Plant Project Report 2024: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue" provides a comprehensive guide for establishing a glucose manufacturing plant. The report covers various aspects, ranging from a broad market overview to intricate details like unit operations, raw material and utility requirements, infrastructure necessities, machinery requirements, manpower needs, packaging and transportation requirements, and more.

In addition to the operational…

Fatty Alcohol Production Cost Analysis: Plant Cost, Price Trends, Raw Materials …

Syndicated Analytics' latest report titled "Fatty Alcohol Production Cost Analysis 2023-2028: Capital Investment, Manufacturing Process, Operating Cost, Raw Materials, Industry Trends and Revenue Statistics" includes all the essential aspects that are required to understand and venture into the fatty alcohol industry. This report is based on the latest economic data, and it presents comprehensive and detailed insights regarding the primary process flow, raw material requirements, reactions involved, utility costs, operating costs, capital…

Corn Production Cost Analysis Report: Manufacturing Process, Raw Materials Requi …

The latest report titled "Corn Production Cost Report" by Procurement Resource, a global procurement research and consulting firm, provides an in-depth cost analysis of the production process of the Corn. Read More: https://www.procurementresource.com/production-cost-report-store/corn

Report Features - Details

Product Name - Corn Production

Segments Covered

Manufacturing Process: Process Flow, Material Flow, Material Balance

Raw Material and Product/s Specifications: Raw Material Consumption, Product and Co-Product Generation, Capital Investment

Land and Site Cost: Offsites/Civil Works, Equipment Cost, Auxiliary Equipment…

Crude Oil Production Cost Analysis Report: Manufacturing Process, Raw Materials …

The latest report titled "Crude Oil Production Cost Report" by Procurement Resource, a global procurement research and consulting firm, provides an in-depth cost analysis of the production process of the Crude Oil. Read More: https://www.procurementresource.com/production-cost-report-store/crude-oil

Report Features - Details

Product Name - Crude Oil

Segments Covered

Manufacturing Process: Process Flow, Material Flow, Material Balance

Raw Material and Product/s Specifications: Raw Material Consumption, Product and Co-Product Generation, Capital Investment

Land and Site Cost: Offsites/Civil Works, Equipment Cost,…