Press release

Gypsum Plasterboard Manufacturing Plant DPR - 2026: Complete Project Cost & Setup Guide

Gypsum plasterboard, also known as drywall or gypsum board, is a widely used construction material made from a core of gypsum sandwiched between paper liners. It is valued for its smooth finish, fire resistance, sound insulation, and ease of installation. Gypsum plasterboard is commonly used for walls, ceilings, and partitions in residential, commercial, and industrial buildings, offering a cost-effective and efficient alternative to traditional plastering methods.Setting up a gypsum plasterboard manufacturing plant involves sourcing high-quality gypsum, installing calcination, board forming, drying, and cutting machinery, and ensuring consistent quality control. Key considerations include plant layout, energy efficiency, raw material logistics, skilled manpower, and compliance with environmental regulations. Strategic location and demand analysis help optimize production costs and profitability.

IMARC Group's report, titled "Gypsum Plasterboard Manufacturing Plant Project Report 2026: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue," provides a complete roadmap for setting up a gypsum plasterboard manufacturing plant. It covers a comprehensive market overview to micro-level information such as unit operations involved, raw material requirements, utility requirements, infrastructure requirements, machinery and technology requirements, manpower requirements, packaging requirements, transportation requirements, etc.

Request for a Sample Report: https://www.imarcgroup.com/gypsum-plasterboard-manufacturing-plant-project-report/requestsample

Gypsum Plasterboard Manufacturing Industry Outlook 2026

The gypsum plasterboard industry remains strong in 2026 as a fundamental part of the global construction materials market, driven by rising demand for sustainable, energy-efficient building solutions and expanding residential, commercial, and infrastructure projects worldwide. The global market was valued at USD 25,395.34 Million in 2025 and is forecast to reach USD 50,765.39 Million by 2034, growing at a CAGR of 8.0% from 2026 to 2034, underscoring robust long-term growth prospects. Gypsum plasterboard is essential for modern construction due to its fire resistance, ease of installation, and applicability in walls, ceilings, and partitions. The industry benefits from urbanization, green building initiatives, and increased construction investments, positioning gypsum plasterboard manufacturing as a compelling opportunity for investors and manufacturers.

Key Insights for Gypsum Plasterboard Manufacturing Plant Setup

Detailed Process Flow

• Product Overview

• Unit Operations Involved

• Mass Balance and Raw Material Requirements

• Quality Assurance Criteria

• Technical Tests

Project Details, Requirements and Costs Involved:

• Land, Location and Site Development

• Plant Layout

• Machinery Requirements and Costs

• Raw Material Requirements and Costs

• Packaging Requirements and Costs

• Transportation Requirements and Costs

• Utility Requirements and Costs

• Human Resource Requirements and Costs

Buy Now: https://www.imarcgroup.com/checkout?id=14390&method=2175

Capital Expenditure (CapEx) and Operational Expenditure (OpEx) Analysis:

Project Economics:

• Capital Investments

• Operating Costs

• Expenditure Projections

• Revenue Projections

• Taxation and Depreciation

• Profit Projections

• Financial Analysis

Profitability Analysis:

• Total Income

• Total Expenditure

• Gross Profit

• Gross Margin

• Net Profit

• Net Margin

Key Cost Components of Setting Up a Gypsum Plasterboard Manufacturing Plant

• Land and site development - cost of land acquisition or lease, site leveling, internal roads, drainage, and boundary work.

• Civil construction and buildings - production shed, raw material storage, finished goods warehouse, utilities block, and administrative offices.

• Plant machinery and equipment - gypsum calcination system, slurry preparation unit, board forming line, drying kiln, cutting and finishing machines, and packaging systems.

• Utilities and infrastructure - power supply systems, transformers, boilers, water supply, compressed air systems, and effluent treatment facilities.

• Raw materials inventory - gypsum, paper liners, additives, binders, and packaging materials.

• Labor and manpower - skilled and unskilled labor, supervisors, engineers, and administrative staff.

• Maintenance and consumables - routine repairs, replacement parts, lubricants, and chemicals.

• Quality control and compliance - laboratory setup, testing equipment, certifications, and environmental compliance expenses.

Ask Analyst for Customization: https://www.imarcgroup.com/request?type=report&id=14390&flag=C

Economic Trends Influencing Gypsum Plasterboard Manufacturing Plant Setup Costs 2026

• Growth in construction and infrastructure spending is increasing demand for gypsum plasterboard, encouraging new plant setups but also pushing up land, equipment, and construction costs.

• Raw material price fluctuations, particularly for gypsum and paper liners, are impacting both initial investment planning and long-term cost stability.

• Rising energy prices are significantly influencing setup costs, as gypsum calcination and board drying are energy-intensive processes.

• Labor cost inflation and skill shortages are raising expenses related to workforce hiring, training, and plant commissioning.

• Stricter environmental regulations are driving higher capital investment in pollution control, waste management, and energy-efficient technologies.

• Higher interest rates and tighter financing conditions are increasing the overall cost of capital for plant construction and machinery procurement.

• Increased adoption of automation and advanced manufacturing technologies is raising upfront plant setup costs while improving productivity and reducing long-term operating expenses.

Challenges and Considerations for Investors

• High capital intensity - Significant upfront investment is required for land, civil works, machinery, and utilities, impacting payback timelines.

• Raw material availability and pricing - Dependence on consistent gypsum and paper liner supply can expose projects to price volatility and logistics risks.

• Energy cost exposure - Calcination and drying are energy-intensive; fluctuating power and fuel prices can compress margins.

• Regulatory and environmental compliance - Emission controls, waste handling, and sustainability norms increase CapEx and ongoing compliance costs.

• Market competition and pricing pressure - Presence of established players may limit pricing power, especially in mature markets.

• Technology and automation risks - Advanced lines improve efficiency but require skilled operators and reliable maintenance support.

• Financing and interest rate risk - Higher borrowing costs can affect project viability and return on investment (ROI).

Browse Related Reports:

• Particleboard Manufacturing Plant: https://industrytoday.co.uk/manufacturing/particleboard-manufacturing-plant-setup-2026-complete-dpr-with-process-flow-machinery-profitability

• Biscuit and Cookie Manufacturing Plant Cost: https://industrytoday.co.uk/manufacturing/biscuit-and-cookie-manufacturing-plant-dpr-2026-machinery-raw-materials-and-industry-outlook

• Polycarbonate (PC) Manufacturing Plant Cost: https://industrytoday.co.uk/manufacturing/polycarbonate-pc-manufacturing-plant-setup-dpr-2026-machinery-cost-and-business-plan

• Water Filter Manufacturing Plant: https://industrytoday.co.uk/manufacturing/water-filter-manufacturing-plant-setup-cost-report-2026-market-trends-machinery-roi

• Egg White Powder Manufacturing Plant: https://industrytoday.co.uk/manufacturing/egg-white-powder-manufacturing-plant-setup-cost-2026-complete-investment-guide-e1a7r

About Us: IMARC Group is a global management consulting firm that helps the world's most ambitious changemakers to create a lasting impact. The company excels in understanding its client's business priorities and delivering tailored solutions that drive meaningful outcomes. We provide a comprehensive suite of market entry and expansion services. Our offerings include thorough market assessment, feasibility studies, company incorporation assistance, factory setup support, regulatory approvals and licensing navigation, branding, marketing and sales strategies, competitive landscape, and benchmarking analyses, pricing and cost research, and procurement research.

Contact Us:

IMARC Group

134 N 4th St. Brooklyn, NY 11249, USA

Email: sales@imarcgroup.com

Tel No:(D) +91 120 433 0800

United States: +1-201-971-6302

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Gypsum Plasterboard Manufacturing Plant DPR - 2026: Complete Project Cost & Setup Guide here

News-ID: 4364965 • Views: …

More Releases from IMARC Group

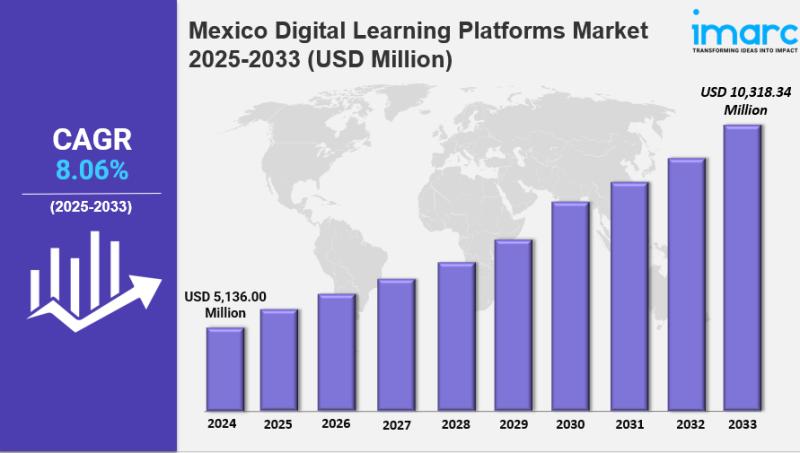

Mexico Digital Learning Platforms Market Size, Growth, Key Players, Opportunity …

IMARC Group has recently released a new research study titled "Mexico Digital Learning Platforms Market Size, Share, Trends and Forecast by Type of Platform, End User, and Region, 2025-2033", offers a detailed analysis of the market drivers, segmentation, growth opportunities, trends and competitive landscape to understand the current and future market scenarios.

Mexico Digital Learning Platforms Market Overview

The Mexico digital learning platforms market size reached USD 5,136.00 Million in 2024. Looking…

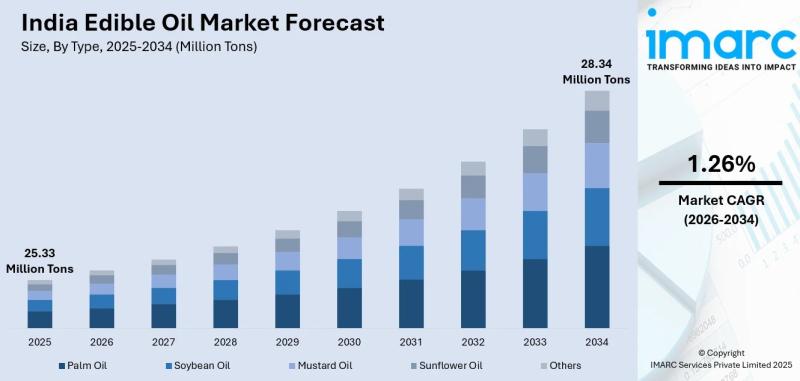

India Edible Oil Market Size, Share, Trends, Growth, Consumption and Demand, For …

Report ID: SR112026A2403 | Format: PDF + Excel | Verified by: IMARC Group

Quick Market Snapshot

Feature

• Market Size (2025): 25.33 Million Tons

• Forecast Value (2034): 28.34 Million Tons

• Growth Rate (CAGR): 1.26% (2026-2034)

• Leading Type: Palm Oil (38% Share)

• Key Trend: Shift toward Fortified & Premium Oils

What is the India Edible Oil Market Size, Share, Trends, and Growth Forecast (2026-2034)?

According to the latest analysis by IMARC Group, the India edible oil market size reached 25.33 Million…

Tire Market is Expected to Grow USD 272.6 Billion by 2034 | At CAGR 4.33%

IMARC Group has recently released a new research study titled "Tire Market Size, Share, Trends and Forecast by Design, End-Use, Vehicle Type, Distribution Channel, Season, and Region, 2026-2034", offers a detailed analysis of the market drivers, segmentation, growth opportunities, trends and competitive landscape to understand the current and future market scenarios.

The global tire market size reached USD 181.1 Billion in 2025 and is projected to grow to USD 272.6 Billion…

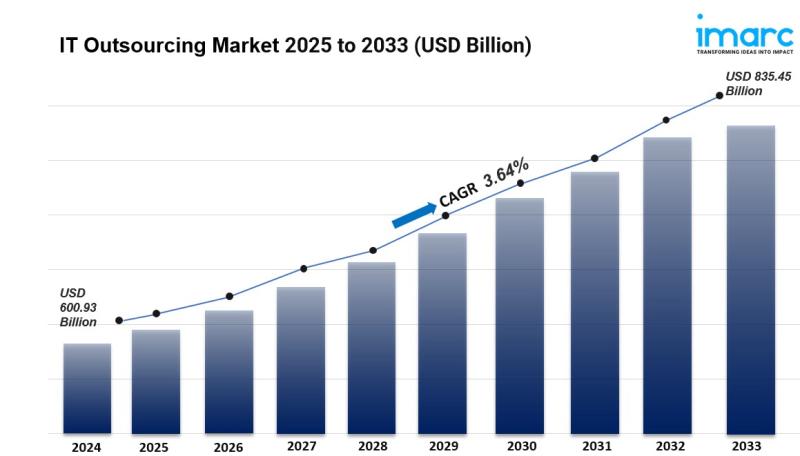

IT Outsourcing Market Size to Surpass USD 835.45 Billion by 2033 | At CAGR 3.64%

IT Outsourcing Market Overview:

The global IT Outsourcing Market was valued at USD 600.93 Billion in 2024 and is projected to reach USD 835.45 Billion by 2033. It is expected to grow at a CAGR of 3.64% during the forecast period 2025-2033. Market growth is driven by cost-effective solutions, rapid technology advancements such as AI, cloud computing, and big data analytics, and the increasing need for scalable and flexible IT infrastructure.

The…

More Releases for Plant

How to Establish a Modular Switch manufacturing plant Plant

Setting up a modular switch manufacturing facility necessitates a detailed market analysis alongside granular insights into various operational aspects, including unit processes, raw material procurement, utility provisions, infrastructure setup, machinery and technology specifications, workforce planning, logistics, and financial considerations.

IMARC Group's report titled "Modular Switch Manufacturing Plant Project Report 2025: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue" offers a comprehensive guide for establishing a modular…

How To Setup a Plant Growth Hormones Manufacturing Plant

Setting up a plant growth hormones manufacturing facility necessitates a detailed market analysis alongside granular insights into various operational aspects, including unit processes, raw material procurement, utility provisions, infrastructure setup, machinery and technology specifications, workforce planning, logistics, and financial considerations.

IMARC Group's report titled "Plant Growth Hormones Manufacturing Plant Project Report 2025: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue" offers a comprehensive guide for establishing…

Plant-Powered Eating: Trends in the Plant-Based Food Market

The plant-based food market has experienced exponential growth in recent years, driven by increasing consumer awareness of health, environmental sustainability, and ethical considerations. This burgeoning sector encompasses a wide range of products, from plant-based meat alternatives to dairy-free beverages and vegan snacks. In this overview, we'll explore key points, trends, and recent industry news shaping the plant-based food market.

Download a Free sample copy of Report:https://www.marketdigits.com/request/sample/3771

Key Companies Profiled

Amy's Kitchen

Danone S.A.

Atlantic…

Chocolate Syrup Manufacturing Plant Cost 2023-2028: Manufacturing Process, Plant …

Syndicated Analytics latest report titled "Chocolate Syrup Manufacturing Plant Project Report: Industry Trends, Project Report, Manufacturing Process, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue 2023-2028" covers all the aspects including industry performance, key success and risk factors, manufacturing requirements, project costs, and economics, expected returns on investment, profit margins, etc. required for setting up a chocolate syrup manufacturing plant. The study, which is based both on desk…

Garlic Powder Manufacturing Plant 2023-2028: Manufacturing Process, Plant Cost, …

Syndicated Analytics latest report titled "Garlic Powder Plant Project Report: Industry Trends, Manufacturing Process, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue 2023-2028" covers all the aspects including industry performance, key success, and risk factors, manufacturing requirements, project costs, and economics expected returns on investment, profit margins, etc. required for setting up a garlic powder manufacturing plant. The study, which is based both on desk research and multiple…

Frozen Food Manufacturing Plant 2023-2028: Project Report, Business Plan, Plant …

Syndicated Analytics latest report titled "Frozen Food Manufacturing Plant Project Report: Industry Trends, Manufacturing Process, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue 2023-2028" covers all the aspects including industry performance, key success, and risk factors, manufacturing requirements, project costs, and economics, expected returns on investment, profit margins, etc. required for setting up a frozen food manufacturing plant. The study, which is based both on desk research and…