Press release

Biometric Sensors Manufacturing Plant DPR & Unit Setup Report 2026

Biometric sensors are electronic devices that capture and analyze unique biological characteristics-such as fingerprints, facial features, iris patterns, voice, or heartbeat rhythms-for identity verification and authentication. These sensors convert physical or behavioral traits into digital data, enabling secure access control, surveillance, attendance systems, mobile devices, and financial applications. Their accuracy, speed, and reliability make them essential for modern security and digital identity solutions.Setting up a biometric sensors manufacturing plant requires advanced semiconductor or electronics assembly facilities, cleanroom environments, precision equipment, and skilled technical personnel. The process includes sensor fabrication or module assembly, firmware integration, calibration, testing, and packaging. Strong quality control systems, intellectual property protection, and compliance with international safety and data standards are critical for successful operations.

IMARC Group's report, titled "Biometric Sensors Manufacturing Plant Setup Cost 2026: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue," provides a complete roadmap for setting up a biometric sensors manufacturing plant. It covers a comprehensive market overview to micro-level information, such as unit operations involved, raw material requirements, utility requirements, infrastructure requirements, machinery and technology requirements, manpower requirements, packaging requirements, transportation requirements, etc.

Biometric Sensors Industry Outlook 2026:

The biometric sensors industry outlook for 2025 is strong, driven by rising demand for secure digital authentication across banking, government, healthcare, smartphones, and smart infrastructure. Growth in digital payments, e-governance, IoT devices, and smart cities, along with increasing concerns over data security and fraud, is expected to fuel sustained market expansion worldwide.

Request for Sample Report: https://www.imarcgroup.com/biometric-sensors-manufacturing-plant-project-report/requestsample

Key Insights for Biometric Sensors Manufacturing Plant Setup:

Detailed Process Flow:

• Product Overview

• Unit Operations Involved

• Mass Balance and Raw Material Requirements

• Quality Assurance Criteria

• Technical Tests

Project Details, Requirements and Costs Involved:

• Land, Location and Site Development

• Plant Layout

• Machinery Requirements and Costs

• Raw Material Requirements and Costs

• Packaging Requirements and Costs

• Transportation Requirements and Costs

• Utility Requirements and Costs

• Human Resource Requirements and Costs

Buy Now: https://www.imarcgroup.com/checkout?id=17659&method=2175

Capital Expenditure (CapEx) and Operational Expenditure (OpEx) Analysis:

Project Economics:

• Capital Investments

• Operating Costs

• Expenditure Projections

• Revenue Projections

• Taxation and Depreciation

• Profit Projections

• Financial Analysis

Profitability Analysis:

• Total Income

• Total Expenditure

• Gross Profit

• Gross Margin

• Net Profit

• Net Margin

Key Cost Components of Setting Up a Biometric Sensors Plant:

• Land or facility leasing and cleanroom setup

• Semiconductor or electronics assembly machinery

• Sensor components, chips, and raw materials

• R&D, software, and firmware development

• Testing, calibration, and quality assurance equipment

• Skilled engineers, technicians, and training costs

• Certification, IP protection, and regulatory compliance

Speak to an Analyst for Customized Report: https://www.imarcgroup.com/request?type=report&id=17659&flag=C

Economic Trends Influencing Biometric Sensors Plant Setup Costs 2026:

• Growing demand for domestic electronics and semiconductor manufacturing

• High costs of advanced fabrication and testing equipment

• Fluctuating prices of chips and electronic components

• Government incentives for electronics and security technology manufacturing

• Increasing automation and AI integration in production

• Rising investment in digital identity and cybersecurity systems

Challenges and Considerations for Investors in Biometric Sensors Plant Projects:

• High capital intensity and technology complexity

• Rapid innovation cycles and risk of obsolescence

• Dependence on specialized global suppliers for chips

• Strict data security, privacy, and certification requirements

• Strong competition from established international players

• Need for continuous R&D and product differentiation

Browse Related Reports:

• Fiber Optic Cable Manufacturing Plant Cost: https://industrytoday.co.uk/manufacturing/fiber-optic-cable-manufacturing-plant-dpr-unit-setup-2026-machinery-cost-capexopex-roi-and-raw-materials

• Cement Blocks Manufacturing Plant Cost: https://industrytoday.co.uk/manufacturing/cement-blocks-manufacturing-plant-dpr-2026-investment-cost-market-growth-and-machinery

• LED Ceiling Light Manufacturing Plant Cost: https://industrytoday.co.uk/manufacturing/led-ceiling-light-manufacturing-plant-dpr-2026-cost-structure-production-process-roi

• Quartz Countertop Manufacturing Plant Cost: https://industrytoday.co.uk/manufacturing/quartz-countertop-manufacturing-plant-dpr-unit-setup-report-2026

• Drip Irrigation Pipes Manufacturing Plant Cost: https://industrytoday.co.uk/manufacturing/drip-irrigation-pipes-manufacturing-plant-dpr-unit-setup-2026-demand-analysis-and-project-cost

About Us:

IMARC Group is a global management consulting firm that helps the world's most ambitious changemakers to create a lasting impact. The company excels in understanding its client's business priorities and delivering tailored solutions that drive meaningful outcomes. We provide a comprehensive suite of market entry and expansion services. Our offerings include thorough market assessment, feasibility studies, company incorporation assistance, factory setup support, regulatory approvals and licensing navigation, branding, marketing and sales strategies, competitive landscape, and benchmarking analyses, pricing and cost research, and procurement research.

Contact Us:

IMARC Group

134 N 4th St. Brooklyn, NY 11249, USA

Email: sales@imarcgroup.com

Tel No: (D) +91 120 433 0800

United States: (+1-201-971-6302)

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Biometric Sensors Manufacturing Plant DPR & Unit Setup Report 2026 here

News-ID: 4364865 • Views: …

More Releases from IMARC Group

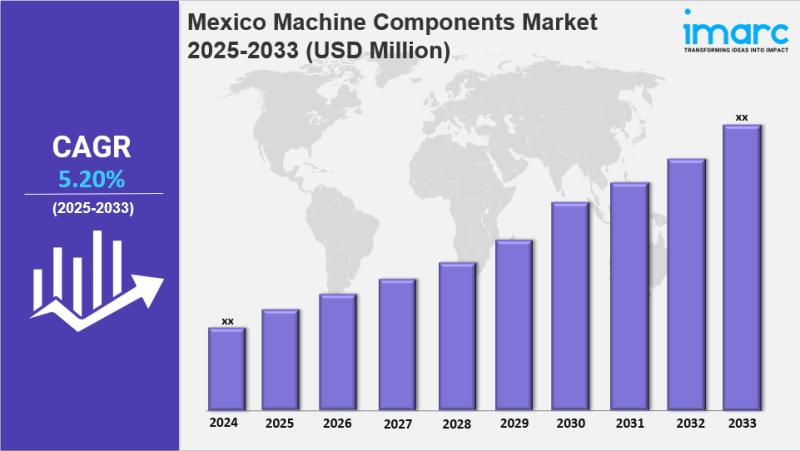

Mexico Machine Components Market 2025: Size, Trends, Growth, Latest Insights and …

IMARC Group has recently released a new research study titled "Mexico Machine Components Market Size, Share, Trends and Forecast by Component Type, Material, End Use Industry, and Region, 2025-2033", offers a detailed analysis of the market drivers, segmentation, growth opportunities, trends and competitive landscape to understand the current and future market scenarios.

Market Overview

The Mexico Machine Components Market is projected to grow at a CAGR of 5.20% during the forecast period…

Tungsten Carbide Price Index 2025 Highlights Price Trend and Forecast

North America Tungsten Carbide Prices Movement 2025:

Tungsten Carbide Prices in USA:

USA tungsten carbide prices in Q3 2025 averaged USD 50.8/kg, supported by steady demand from tooling and aerospace sectors. The tungsten carbide price trend remained stable amid balanced supply. The tungsten carbide price index showed minimal variation, while the tungsten carbide price chart reflected controlled movement. The tungsten carbide price forecast suggests steady pricing with limited short-term volatility.

Get the Real-Time…

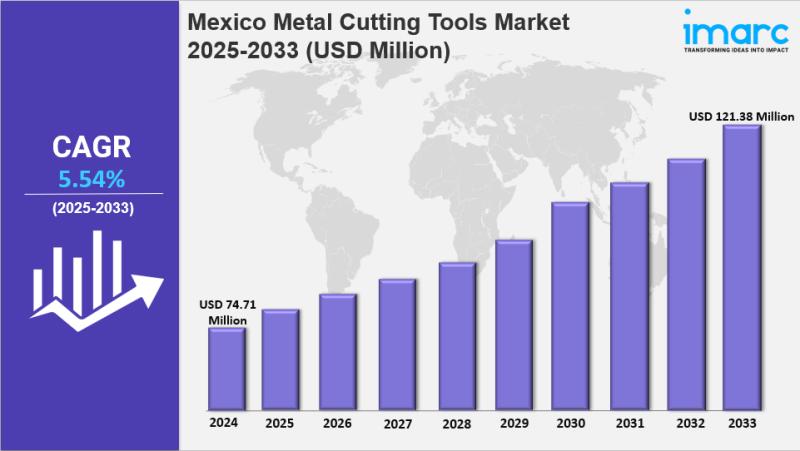

Mexico Metal Cutting Tools Market Outlook: Key Growth Drivers, Trends and Opport …

IMARC Group has recently released a new research study titled "Mexico Metal Cutting Tools Market Size, Share, Trends and Forecast by Tool Type, Product Type, Application, and Region, 2025-2033", offers a detailed analysis of the market drivers, segmentation, growth opportunities, trends and competitive landscape to understand the current and future market scenarios.

Market Overview

The Mexico metal cutting tools market reached a size of USD 74.71 Million in 2024 and is projected…

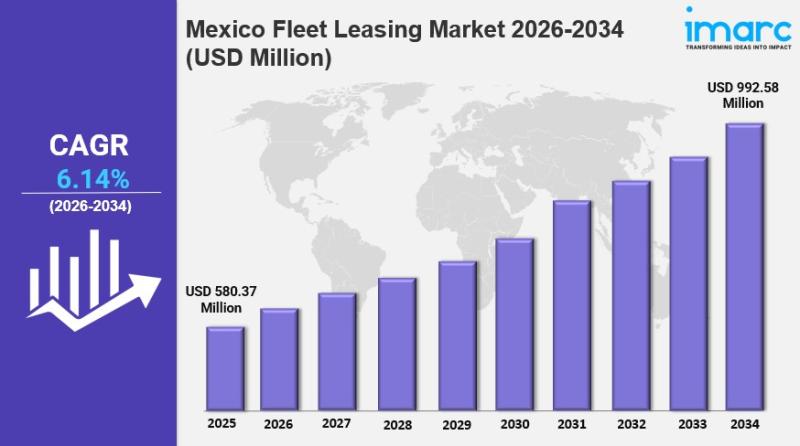

Mexico Fleet Leasing Market 2026 : Industry Size to Reach USD 992.58 Million by …

IMARC Group has recently released a new research study titled "Mexico Fleet Leasing Market Size, Share, Trends and Forecast by Lease Type, Vehicle Type, Lease Duration, End Use Industry, and Region, 2026-2034", offers a detailed analysis of the market drivers, segmentation, growth opportunities, trends and competitive landscape to understand the current and future market scenarios.

Market Overview

The Mexico fleet leasing market size was valued at USD 580.37 Million in 2025 and…

More Releases for Cost

Steel Production Cost - Process Economics, Raw Materials, and Cost Drivers

Steel is the backbone of modern industry, and its production cost is one of the most closely tracked indicators across construction, infrastructure, automotive, and manufacturing sectors. Unlike niche chemicals or APIs, steel economics are driven by scale, energy intensity, and raw material volatility.

Here's the thing: steel production cost isn't just about iron ore prices. It's a layered equation involving coking coal, electricity, labor, emissions compliance, logistics, and technology choice. A…

Egg Powder Manufacturing Plant Setup Cost | Cost Involved, Machinery Cost and In …

IMARC Group's report titled "Egg Powder Manufacturing Plant Project Report 2024: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue" provides a comprehensive guide for establishing an egg powder manufacturing plant. The report covers various aspects, ranging from a broad market overview to intricate details like unit operations, raw material and utility requirements, infrastructure necessities, machinery requirements, manpower needs, packaging and transportation requirements, and more.

In addition to…

Glucose Manufacturing Plant Cost Report 2024: Requirements and Cost Involved

IMARC Group's report titled "Glucose Manufacturing Plant Project Report 2024: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue" provides a comprehensive guide for establishing a glucose manufacturing plant. The report covers various aspects, ranging from a broad market overview to intricate details like unit operations, raw material and utility requirements, infrastructure necessities, machinery requirements, manpower needs, packaging and transportation requirements, and more.

In addition to the operational…

Fatty Alcohol Production Cost Analysis: Plant Cost, Price Trends, Raw Materials …

Syndicated Analytics' latest report titled "Fatty Alcohol Production Cost Analysis 2023-2028: Capital Investment, Manufacturing Process, Operating Cost, Raw Materials, Industry Trends and Revenue Statistics" includes all the essential aspects that are required to understand and venture into the fatty alcohol industry. This report is based on the latest economic data, and it presents comprehensive and detailed insights regarding the primary process flow, raw material requirements, reactions involved, utility costs, operating costs, capital…

Corn Production Cost Analysis Report: Manufacturing Process, Raw Materials Requi …

The latest report titled "Corn Production Cost Report" by Procurement Resource, a global procurement research and consulting firm, provides an in-depth cost analysis of the production process of the Corn. Read More: https://www.procurementresource.com/production-cost-report-store/corn

Report Features - Details

Product Name - Corn Production

Segments Covered

Manufacturing Process: Process Flow, Material Flow, Material Balance

Raw Material and Product/s Specifications: Raw Material Consumption, Product and Co-Product Generation, Capital Investment

Land and Site Cost: Offsites/Civil Works, Equipment Cost, Auxiliary Equipment…

Crude Oil Production Cost Analysis Report: Manufacturing Process, Raw Materials …

The latest report titled "Crude Oil Production Cost Report" by Procurement Resource, a global procurement research and consulting firm, provides an in-depth cost analysis of the production process of the Crude Oil. Read More: https://www.procurementresource.com/production-cost-report-store/crude-oil

Report Features - Details

Product Name - Crude Oil

Segments Covered

Manufacturing Process: Process Flow, Material Flow, Material Balance

Raw Material and Product/s Specifications: Raw Material Consumption, Product and Co-Product Generation, Capital Investment

Land and Site Cost: Offsites/Civil Works, Equipment Cost,…