Press release

Aerospace High Performance Alloys Market to Reach US$ 492.3 Mn by 2033 Driven by Rising Aircraft Demand and 7.1% CAGR

Market Overview: Rising Demand for Advanced Aerospace MaterialsThe aerospace industry is undergoing a transformative phase, driven by rapid technological advancements, increasing air passenger traffic, and the growing demand for fuel-efficient aircraft. As aircraft manufacturers strive to achieve higher performance, lower emissions, and improved safety, the need for advanced materials capable of withstanding extreme operating conditions has become essential. Aerospace high performance alloys have emerged as critical materials in modern aircraft manufacturing due to their superior strength-to-weight ratio, corrosion resistance, and thermal stability. These alloys play a vital role in enhancing aircraft durability, operational efficiency, and overall performance in challenging flight environments.

According to the latest study by Persistence Market Research, the global aerospace high performance alloys market is expected to be valued at US$ 304.6 million in 2026 and is projected to reach US$ 492.3 million by 2033, growing at a CAGR of 7.1% between 2026 and 2033. This steady growth outlook reflects the rising production of commercial and military aircraft, increasing investments in next-generation aviation technologies, and the growing replacement of conventional materials with advanced alloy solutions. As the aviation sector expands globally, high performance alloys will remain indispensable in shaping the future of aerospace engineering.

Get Your FREE Sample Report Instantly - Click Now: https://www.persistencemarketresearch.com/samples/34731

Key Growth Drivers: Innovation and Demand for Lightweight Aircraft

One of the primary drivers fueling the aerospace high performance alloys market is the aviation industry's continuous push for lightweight yet durable materials. Reducing aircraft weight is crucial for improving fuel efficiency, lowering operational costs, and minimizing carbon emissions. High performance alloys, particularly aluminum, titanium, and nickel-based variants, provide the ideal balance between strength and weight, making them highly preferred over traditional materials. The growing emphasis on sustainable aviation solutions has further accelerated material innovation, encouraging manufacturers to adopt alloys that contribute to improved fuel economy without compromising safety or performance.

Another major growth factor is the increasing demand for commercial aircraft due to rising global air travel. Emerging economies are witnessing a surge in air passenger traffic, leading to expanded airline fleets and new aircraft orders. Additionally, defense modernization programs across several nations are driving demand for high-performance military aircraft that require alloys capable of withstanding high stress, pressure, and extreme temperatures. Technological advancements in alloy manufacturing, including precision casting and additive manufacturing, are also supporting market growth by enabling complex component designs with enhanced performance characteristics.

Alloy Type Insights: Material Innovation Shaping Aerospace Engineering

By alloy type, the aerospace high performance alloys market includes aluminum alloys, titanium alloys, stainless steel alloys, nickel alloys, and others such as copper and brass. Aluminum alloys continue to dominate aircraft structural applications due to their lightweight nature, cost-effectiveness, and high corrosion resistance. These alloys are widely used in fuselage structures, wings, and internal frameworks where reducing weight is essential for improving flight efficiency. Continuous improvements in aluminum alloy compositions have enhanced fatigue resistance and mechanical stability, further increasing their adoption in modern aircraft manufacturing.

Titanium and nickel alloys are witnessing strong demand growth due to their exceptional heat resistance and mechanical strength. Titanium alloys are extensively used in jet engines, airframes, and landing gear structures where high load-bearing capacity and corrosion resistance are critical. Meanwhile, nickel-based alloys play a crucial role in turbine engines and exhaust systems due to their ability to withstand extreme temperatures and pressure conditions. Stainless steel alloys also maintain relevance in aerospace fasteners and structural supports. The continuous evolution of alloy compositions is expanding their application scope across both commercial and military aircraft platforms.

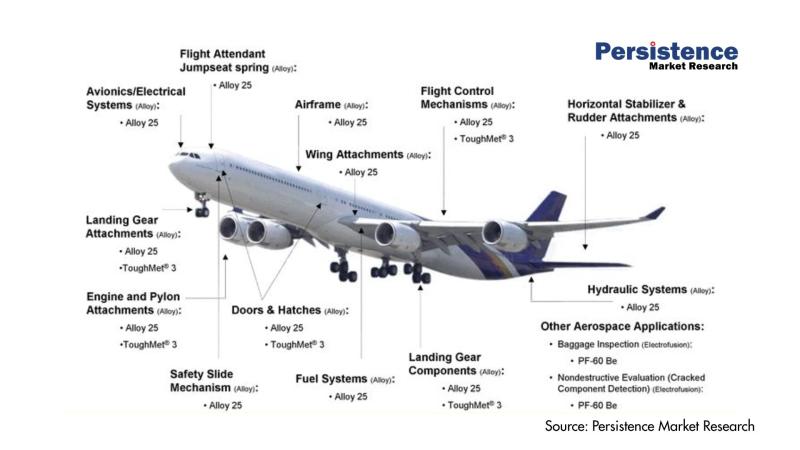

Application Insights: Expanding Use Across Aircraft Components

By application, aerospace high performance alloys are utilized in jet engines, turbine blades, aircraft structures, exhaust systems, aerospace fasteners, and other critical components. Jet engines represent a major application segment, as these propulsion systems require alloys capable of enduring extreme thermal and mechanical stress. Nickel and titanium alloys dominate engine manufacturing due to their ability to maintain stability under high rotational forces and elevated temperatures. Turbine blades, in particular, rely heavily on superalloys that offer superior creep resistance and thermal fatigue endurance.

Aircraft structures constitute another major application area, where aluminum and titanium alloys provide the necessary strength-to-weight advantage. The increasing use of composite materials in aircraft manufacturing has not diminished the relevance of metal alloys; instead, hybrid designs integrating composites and high-performance alloys have become more common. Exhaust systems and aerospace fasteners also depend on stainless steel and nickel alloys for corrosion resistance and durability. As aircraft designs evolve to support next-generation propulsion and aerodynamic efficiency, the role of high performance alloys across these applications will continue to expand.

Get a Customized Market View in One Click: https://www.persistencemarketresearch.com/request-customization/34731

Regional Outlook: Global Expansion of Aerospace Manufacturing Hubs

By region, the aerospace high performance alloys market spans North America, Europe, East Asia, South Asia & Oceania, Latin America, and the Middle East & Africa. North America remains the leading market due to the strong presence of major aircraft manufacturers, defense contractors, and advanced material producers. The United States continues to invest heavily in commercial aviation expansion and military aircraft modernization, driving sustained demand for high performance alloys in both structural and propulsion applications.

Europe follows closely, supported by well-established aerospace manufacturing ecosystems in countries such as France, Germany, and the United Kingdom. The region's focus on sustainable aviation technologies and next-generation aircraft design is further strengthening demand for lightweight and fuel-efficient alloy materials. East Asia, led by China and Japan, is emerging as a high-growth region with expanding domestic aircraft production and government-backed aviation initiatives. Meanwhile, South Asia & Oceania, Latin America, and the Middle East & Africa are witnessing steady growth due to rising air travel demand, fleet expansions, and increased defense procurement programs.

Competitive Analysis: Key Players Driving Market Innovation

The aerospace high performance alloys market is characterized by the presence of established global manufacturers investing in research, material innovation, and strategic collaborations with aerospace OEMs. These companies focus on developing advanced alloy compositions that meet evolving industry requirements for higher strength, lower weight, and improved resistance to harsh operating environments. Continuous investments in manufacturing capabilities, precision casting, and metallurgical advancements allow leading players to strengthen their market positions and meet rising global demand.

Under the Company Insights section, key players operating in the market include,

✦ Precision Castparts Corp.

✦ CRS Holdings, LLC (Carpenter)

✦ HAYNES INTERNATIONAL

✦ ATI Materials

✦ Thyssenkrupp Aerospace

✦ Continental Steel & Tube Company

✦ Kennametal Inc.

✦ VSMPO-AVISMA

✦ Aviva Metals

✦ Tata Steel

✦ Kobe Steel Limited

✦ NeoNickel

✦ Alcoa

These companies are actively expanding production capacities, forming long-term supply agreements with aircraft manufacturers, and developing next-generation alloy products to gain competitive advantages in the growing aerospace materials industry.

Market Segmentation Overview: Diverse Opportunities Across Categories

Market segmentation highlights the diversity of opportunities within the aerospace high performance alloys industry. By alloy type, the market is segmented into Aluminium Alloys, Titanium Alloys, Stainless Steel Alloys, Nickel Alloys, and Others (Copper/Brass). Each category serves specific aircraft manufacturing requirements, offering unique combinations of strength, thermal stability, and corrosion resistance. By application, segmentation includes Jet Engines, Turbine Blades, Aircraft Structures, Exhaust Systems, Aerospace Fasteners, and Others, demonstrating the widespread integration of these alloys across multiple aircraft systems.

By region, the market covers North America, Europe, East Asia, South Asia & Oceania, Latin America, and Middle East & Africa. This structured segmentation reflects the global nature of aerospace manufacturing and highlights region-specific demand patterns. With aircraft production rates increasing worldwide and supply chains becoming more interconnected, segmentation-based strategies enable alloy manufacturers to target high-growth application areas and strengthen their presence in key geographic markets.

For In-Depth Competitive Analysis, Buy Now: https://www.persistencemarketresearch.com/checkout/34731

Future Outlook: Technological Advancements and Sustainable Aviation Goals

The future of the aerospace high performance alloys market is closely tied to technological innovation and the aviation industry's sustainability objectives. Aircraft manufacturers are increasingly exploring next-generation propulsion systems, including hybrid-electric and hydrogen-powered aircraft, which require materials capable of operating under new thermal and mechanical conditions. This shift will create fresh opportunities for alloy developers to design materials that support future aviation architectures while meeting environmental performance targets.

Additionally, additive manufacturing and digital material engineering are revolutionizing alloy production processes, enabling complex component designs with reduced waste and enhanced performance precision. As sustainability becomes a core focus, recycled metal alloys and energy-efficient production methods will gain prominence in material sourcing strategies. With the market projected to grow steadily at a CAGR of 7.1% through 2033, aerospace high performance alloys will remain central to the advancement of modern aviation, offering critical solutions for efficiency, reliability, and long-term industry growth.

Contact Us:

Persistence Market Research

Second Floor, 150 Fleet Street,

London, EC4A 2DQ, United Kingdom

USA Phone: +1 646-878-6329

UK Phone: +44 203-837-5656

Email: sales@persistencemarketresearch.com

Web: https://www.persistencemarketresearch.com

About Persistence Market Research:

At Persistence Market Research, we specialize in creating research studies that serve as strategic tools for driving business growth. Established as a proprietary firm in 2012, we have evolved into a registered company in England and Wales in 2023 under the name Persistence Research & Consultancy Services Ltd. With a solid foundation, we have completed over 3600 custom and syndicate market research projects, and delivered more than 2700 projects for other leading market research companies' clients.

Our approach combines traditional market research methods with modern tools to offer comprehensive research solutions. With a decade of experience, we pride ourselves on deriving actionable insights from data to help businesses stay ahead of the competition. Our client base spans multinational corporations, leading consulting firms, investment funds, and government departments. A significant portion of our sales comes from repeat clients, a testament to the value and trust we've built over the years.

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Aerospace High Performance Alloys Market to Reach US$ 492.3 Mn by 2033 Driven by Rising Aircraft Demand and 7.1% CAGR here

News-ID: 4364404 • Views: …

More Releases from Persistence Market Research

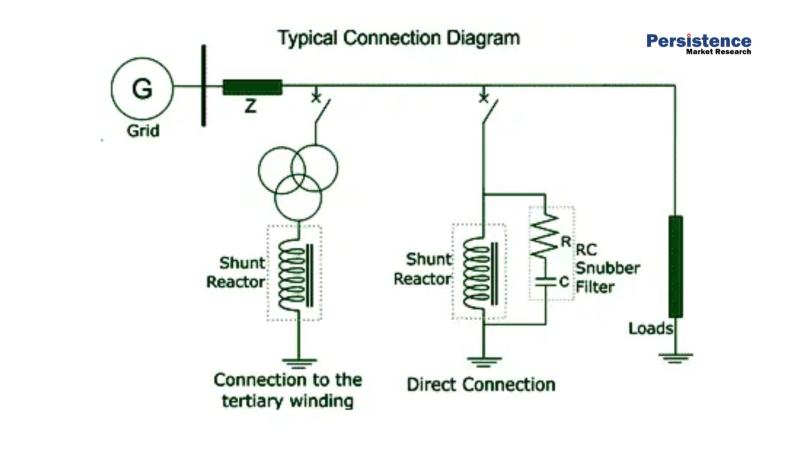

Shunt Reactor Market to Reach US$ 4.8 Billion by 2033 Driven by Power Grid Expan …

Market Overview: Rising Need for Grid Stability Solutions

The global power sector is undergoing a massive transformation, driven by rapid electrification, expanding transmission networks, and rising integration of renewable energy sources. In this evolving landscape, shunt reactors play a vital role in maintaining voltage stability and reducing transmission losses in high-voltage power systems. These reactors are essential for absorbing reactive power generated by long transmission lines, preventing overvoltage conditions, and improving…

Lubricant Packaging Market to Reach US$ 8.7 Billion by 2033 Driven by Automotive …

The lubricant packaging market plays a critical supporting role in the global lubricants industry by enabling safe storage, transportation, dispensing, and branding of automotive and industrial lubricants. Lubricant packaging solutions are designed to protect products from contamination, leakage, and degradation while also ensuring ease of handling across supply chains. Packaging formats range from small consumer packs for automotive aftermarket use to large industrial containers used in manufacturing plants, power generation…

Liquid Egg Whites Market US$ 425.1 Mn by 2033 Driven by Bakery Growth and High P …

Liquid egg whites are widely recognized for their functional versatility, nutritional profile, and ease of handling compared to shell eggs. As a fat-free, cholesterol-free, and high-protein ingredient, liquid egg whites are increasingly used in bakery products, prepared foods, beverages, nutritional supplements, and foodservice operations. The growing emphasis on clean-label formulations, protein enrichment, and food safety compliance is further strengthening the role of liquid egg whites in modern food processing.

The market…

Wood Tar Market on the Rise to US$ 126.6 Mn by 2033 Driven by Sustainable Bio-Ba …

Introduction: Renewed Interest in a Traditional Bio-Based Material

The wood tar market is gaining renewed global attention as industries search for sustainable, bio-based, and naturally derived materials to replace petroleum-based chemicals. Wood tar, obtained through thermal decomposition of wood in low-oxygen conditions, has historically been used for waterproofing, preservation, and coating applications. Today, its relevance is increasing again due to rising environmental awareness, stricter emission regulations, and growing interest in renewable…

More Releases for Aerospace

Aerospace Wiring Harness Market will reach $4.1 billion by 2032: Amphenol Aerosp …

The Latest published market study on Global Aerospace Wiring Harness Market provides an overview of the current market dynamics in the Aerospace Wiring Harness space, as well as what our survey respondents- all outsourcing decision-makers- predict the market will look like in 2032. The study breaks the market by revenue and volume (wherever applicable) and price history to estimate the size and trend analysis and identify gaps and opportunities. Some…

Aerospace Composites Market Future Growth Insight And Competitive Outlook 2025 | …

The Global Aerospace Composites Market is expected to reach USD 57.04 billion by 2025, from USD 26.90 billion in 2017, growing at a CAGR of 9.4% during the forecast period of 2018 to 2025. The upcoming market report contains data for historic years 2015 & 2016, the base year of calculation is 2017 and the forecast period is 2018 to 2025.Global Aerospace Composites Market, By Fibre Type (Carbon, Glass, Ceramic),…

Aerospace Evacuation Market 2025 By Top Key Players UTC Aerospace Systems, Zodia …

Asia Pacific will witness a significant growth rate in the aerospace evacuation market place over the forecast timeframe. This is attributed to the increasing air travel coupled with investments in aviation industry across the region. International Air Transport Association (IATA) estimates that the region will have around 3.5 billion passengers by 2036.

Europe aircraft evacuation market holds substantial share with the expansion of airlines. In August 2018, Wizz Air announced expansion…

Aircraft Evacuation Market 2025 | UTC Aerospace Systems, GKN Aerospace, Zodiac A …

Asia Pacific aircraft evacuation market share will witness a significant growth owing to increasing demand for air travel. Further, as per IATA, the region is witnessing an annual increase of around 5.5% passenger traffic. Continuous investments by industry players for setting up of manufacturing facilities are further supporting the regional growth till 2025.

Europe aircraft evacuation market holds substantial share with the expansion of airlines. In August 2018, Wizz Air announced…

Aerospace Lavatory System Market Outlook to 2027 - Percival Aviation, Zodiac Aer …

The Aerospace Lavatory System Market research report analyzes factors affecting market from both demand and supply side and further evaluates market dynamics affecting the market during the forecast period i.e., drivers, restraints, opportunities, and future trend. The report also provides exhaustive Poter's five forces analysis.

Factors responsible to drive the growth of aerospace lavatory system is increase in the number of passengers has raised the demand for more commercial aircraft equipped…

Aerospace Control Surface Market - Spirit AeroSystems, Aernnova Aerospace, GKN A …

North America aerospace control surface market size is expected to lead owing to presence of key manufacturers in the region. Europe led by Germany, France, UK and Russia is estimated to witness significant growth in aerospace control surface market during the forecast timeframe. Advancement in technology with implementation of light weight composites allowing improved efficiency of aircraft will support the overall industry demand.

Aerospace control surface market can be segmented based…