Press release

CCIG's Global Leading Automated Flexible Sheet Metal Line Production Driving High-Efficiency Manufacturing

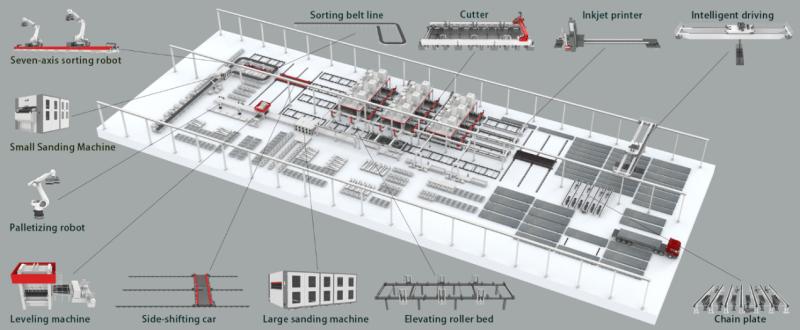

The contemporary manufacturing landscape is undergoing a decisive shift characterized by the transition from mass production to high-mix, low-volume flexibility. In an era where product life cycles are shrinking and consumer demands for customization are rising, industrial agility has become the primary metric of competitiveness. To navigate these complexities, enterprises are moving away from labor-intensive, siloed processes toward integrated intelligent systems. At the forefront of this industrial "agility revolution," CCIG-a leading force in intelligent manufacturing-is facilitating this transition through its Global Leading Automated Flexible Sheet Metal Line Production(https://www.ccig-ind.com/advanced-manufacturing), effectively transforming traditional sheet metal fabrication into a streamlined, autonomous smart production ecosystem.The Foundation of High-Efficiency: Precision and Integration

The technical core of CCIG's manufacturing prowess lies in its deployment of world-class equipment, most notably the Salvagnini S4+P4 system. This integrated line represents a benchmark in "punching, shearing, and bending" technology, designed to eliminate the inefficiencies typically found in disconnected fabrication stages. By processing material thicknesses ranging from 0.8mm to 2.5mm and accommodating a substantial working area of 2500mm x 1250mm, the system offers the versatility required for diverse industrial applications.

One of the defining features of this setup is the seamless transition between processes. Unlike traditional methods where workpieces are moved manually between separate punching and bending stations-leading to potential damage and cumulative tolerances-the S4+P4 system maintains a continuous workflow. This continuity is further enhanced by its full compatibility with advanced robotic welding systems. The result is a production chain where flat sheets enter and complex, semi-finished components emerge with minimal human intervention. For global manufacturers, this means a significant reduction in lead times and a drastic improvement in repeatable precision, ensuring that the first part produced is as accurate as the ten-thousandth.

Engineering Complexity through Laser and Bending Fusion

As engineering requirements evolve, the demand for non-standard parts and complex irregular shapes has intensified. CCIG addresses these high-difficulty engineering challenges through the Salvagnini SL4+P4 system, which integrates laser cutting directly into the punching and bending process chain. This "laser-punch-bend" fusion provides a level of technical redundancy that allows for the creation of intricate geometries that were previously impossible or cost-prohibitive to manufacture.

The SL4 capability is particularly vital for industries such as new energy vehicles (NEVs), aerospace, and high-end electromechanical equipment, where weight reduction and structural optimization often result in irregular profiles. By utilizing a fully integrated process chain, CCIG ensures that these non-standard parts are processed with the same speed and efficiency as standard components. This capability not only solves the pain point of complex geometry fabrication but also allows designers greater freedom to innovate without being constrained by the limitations of traditional sheet metal tooling.

Systemic Advantages: The Fully Integrated Process Chain

Beyond the individual capabilities of high-end machinery, the true value of CCIG's advanced manufacturing lies in its systemic approach to production. By implementing a fully integrated process chain, the enterprise effectively minimizes material handling and inter-process inventory. In a traditional factory, material transit and waiting times can account for a significant portion of the total production cycle; CCIG's flexible lines virtually eliminate these "hidden" costs.

This integration significantly boosts material utilization rates through optimized nesting and precise shearing, which is essential for maintaining sustainability and cost-efficiency in high-strength plate processing. Furthermore, the reduction in manual handling directly translates to a higher yield rate, as the risk of surface scratches or structural deformation is mitigated. This "one-stop" production(https://www.ccig-ind.com/mfgWorld) philosophy-from raw material to precision-formed part-enables CCIG to provide end-to-end delivery that meets the stringent quality requirements of the international market.

Agricultural Machinery Manufacturing Case:

A major agricultural equipment manufacturer in Eastern Europe partnered with CCIG to modernize their tractor chassis and harvester component production. By deploying the S4+P4 integrated line, they achieved 45% reduction in production cycle time (from 6 days to 3.3 days per batch), 99.2% first-pass yield rate, and 30% material cost savings through optimized nesting of high-strength steel plates. The automated workflow eliminated welding distortion issues common in manual operations, ensuring structural integrity for heavy-duty field applications.

Industrial Electrical Enclosure Case: A German industrial control cabinet manufacturer facing labor shortages adopted CCIG's SL4+P4 laser-punch-bend solution for complex server rack chassis. Results: 60% labor cost reduction, delivery time shortened from 4 weeks to 10 days, and zero tolerance deviation on critical mounting holes. The system's ability to handle 200+ non-standard SKUs without tooling changes was transformative for their high-mix production model.

These outcomes demonstrate how CCIG's integrated approach translates technical capability into tangible business value: faster time-to-market, predictable quality, and sustainable cost structure.

Strategic Heritage and Global Vision

CCIG, formerly known as CRRC Urban Transportation Co., Ltd., carries a distinguished pedigree as a mixed-ownership, state-owned capital holding enterprise. Established as a joint venture between CRRC and local state-owned capital in the Yangtze River Delta, the company serves as a pilot field for state enterprise reform and innovation. With headquarters in Fenhu, Suzhou-a demonstration zone for regional integration-CCIG manages total assets of nearly 50 billion yuan and a dedicated workforce of approximately 10,000 employees.

The company's commitment to high-efficiency manufacturing is backed by a robust global R&D and manufacturing network(https://www.ccig-ind.com/about-us/global-network). With electromechanical and electrical research institutes in Germany and Japan, CCIG remains at the cutting edge of global technological trends. This expertise is deployed across a sprawling manufacturing footprint that includes the Yangtze River Delta, Pearl River Delta, and Central China, as well as strategic international bases in Hungary, Malaysia, and Singapore. This global structure ensures that CCIG does not merely supply equipment; it provides holistic transformation services for regional traditional industries, helping them upgrade to smart manufacturing standards.

Conclusion: Shaping the Future of Intelligent Fabrication

As the global manufacturing sector continues to move toward a more digitized and flexible future, the role of integrated production solutions becomes increasingly pivotal. CCIG's strategic focus on automated flexible sheet metal lines, supported by high-precision CNC machining and intelligent automation platforms, positions it as a key architect of this new industrial era.

By combining the stability and scale of a state-owned enterprise with the agility of a global innovation leader, CCIG offers a reliable pathway for manufacturers seeking to enhance their production efficiency and technical capability. The integration of the Salvagnini S4 and SL4 systems is a testament to this commitment-providing the precision, flexibility, and speed required to excel in the 21st-century marketplace. CCIG invites global partners to explore the possibilities of this new manufacturing frontier, where intelligence and efficiency drive sustainable growth.

For more information on advanced manufacturing solutions, visit: https://www.ccig-ind.com/.

CHINA CITY INDUSTRIAL GROUP CO.,LTD

No. 66, Wujiang Avenue, Lili Town, Wujiang District, Suzhou City, Jiangsu Province, China

william.zuo1984@gmail.com

+86 15921115720

Founded in March 2016, CCIG (formerly known as "CRRC Urban Transportation Co., Ltd") is a mixed ownership, state-owned capital holding enterprise established as a joint venture between CRRC and local state-owned capital and strategic investors in the Yangtze River Delta region.

The company is headquartered in Fenhu, Wujiang, Suzhou, a demonstration zone of Yangtze River Delta integration, with total assets of nearly 50 billion yuan, net assets of more than 28 billion yuan, and nearly 10,000 employees.

The company carries the mission of the pilot field of state enterprises mixed reform and the pathfinder of state-owned capital innovation, and is committed to the investment in intelligent manufacturing industry and the transformation and upgrading service of regional traditional industries. it has important manufacturing and service bases in Yangtze River Delta, Pearl River Delta, Bohai Rim, Central China and Hungary, Malaysia and Singapore, with electromechanical and electrical research and development institutes in Germany and Japan.

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release CCIG's Global Leading Automated Flexible Sheet Metal Line Production Driving High-Efficiency Manufacturing here

News-ID: 4363524 • Views: …

More Releases from CHINA CITY INDUSTRIAL GROUP CO.,LTD

What Makes a High Quality International Standard CNC Equipment Supply Factory Re …

The landscape of global industrial procurement has undergone a profound transformation in recent years. As large-scale infrastructure projects and advanced manufacturing initiatives expand across borders, the criteria for selecting technology partners have shifted from simple cost-efficiency to a rigorous evaluation of long-term reliability. For multi-national corporations and government agencies managing complex projects, identifying a High Quality International Standard CNC Equipment Supply Factory(https://www.ccig-ind.com/advanced-manufacturing) is no longer just a procurement goal-it is…

Evolution of Grinding: Why This Automated CNC Cylindrical Grinding Manufacturer …

The trajectory of industrial manufacturing has always been defined by the pursuit of the micron. In the high-tech sectors of aerospace, medical instrumentation, and electric vehicle (EV) production, the difference between peak performance and catastrophic failure often resides in the surface finish of a single rotating component. Historically, grinding was seen as a labor-intensive final touch, but the modern era demands something far more rigorous. As a prominent Automated CNC…

More Releases for CCIG

Help Desk Outsourcing Market Update: Key Business Segments Spiral Up Again

Advance Market Analytics published a new research publication on "Help Desk Outsourcing Market Insights, to 2030" with 232 pages and enriched with self-explained Tables and charts in presentable format. In the Study you will find new evolving Trends, Drivers, Restraints, Opportunities generated by targeting market associated stakeholders. The growth of the Help Desk Outsourcing market was mainly driven by the increasing R&D spending across the world.

Get inside Scoop of the…

Help Desk Outsourcing Market Increasing Demand by key players Adaptive AG, AlfaV …

Advance Market Analytics published a new research publication on "Help Desk Outsourcing Market Insights, to 2030" with 232 pages and enriched with self-explained Tables and charts in presentable format. In the Study you will find new evolving Trends, Drivers, Restraints, Opportunities generated by targeting market associated stakeholders. The growth of the Help Desk Outsourcing market was mainly driven by the increasing R&D spending across the world.

Get Free Exclusive PDF Sample…

Help Desk Outsourcing Market to See Booming Growth | Qcom Outsourcing, Wipro, Ac …

Advance Market Analytics published a new research publication on "Global Help Desk Outsourcing Market Insights, to 2030" with 232 pages and enriched with self-explained Tables and charts in presentable format. In the Study, you will find new evolving Trends, Drivers, Restraints, Opportunities generated by targeting market-associated stakeholders. The growth of the Help Desk Outsourcing market was mainly driven by the increasing R&D spending across the world.

Get Free Exclusive PDF Sample…

Oil Gas Risk Management Market | ABS Group, CCIG, CGE Risk, DNV GL AS

The global oil gas risk management market report is a comprehensive report that provides a detailed analysis of the current status and future trends of the oil gas risk management market worldwide. This report provides valuable information to industry stakeholders by offering an in-depth perspective on market dynamics, competitive landscape, growth opportunities, and key challenges faced by industry participants.

From the perspective of market dynamics, this report explores the factors driving…

Help Desk Outsourcing Market Next Big Thing | Major Giants- IBM, ActivSupport, W …

A Latest intelligence report published by AMA Research with title "Global Help Desk Outsourcing Market Outlook to 2028. A detailed study accumulated to offer Latest insights about acute features of the Help Desk Outsourcing market. This report provides a detailed overview of key factors in the Global Help Desk Outsourcing Market and factors such as driver, restraint, past and current trends, regulatory scenarios and technology development.

Definition:

Helpdesk outsourcing, a process…

Help Desk Outsourcing Market is Going To Boom | HCL Technologies, IBM, Infosys L …

Advance Market Analytics published a new research publication on "Global Help Desk Outsourcing Market Insights, to 2027" with 232 pages and enriched with self-explained Tables and charts in presentable format. In the Study you will find new evolving Trends, Drivers, Restraints, Opportunities generated by targeting market associated stakeholders. The growth of the Help Desk Outsourcing market was mainly driven by the increasing R&D spending across the world.

Major players profiled in…