Press release

Redefining Precision: How Wandian Living Elevates Down Duvet Manufacturing with the Diagonal Filling Port Design

In premium bedding manufacturing, innovation doesn't always come from complex machinery or futuristic fabrics. Sometimes, it's hidden in structural details-small refinements that quietly resolve long-standing challenges and significantly enhance the product experience.After introducing the Double-Layer Integrated Weaving Technology (seamless, needle-free, zero down leakage), Wandian Living continued to optimize the product design. We asked ourselves: Which structural detail could further improve duvet performance, durability, and production efficiency?

The answer lies in an often-overlooked feature-the filling port.

The Problem with Traditional Vertical Filling Ports

In traditional Down Duvet [https://www.wandianliving.com/down-duvet/] designs, the filling port is usually positioned vertically along the edge. However, during fabric cutting, trimming, and alignment, the vertical filling port tends to be:

Partially covered or cut off during trimming

Difficult to locate for filling operations

Positioned at tension-prone edges, increasing the risk of micro gaps

More likely to cause long-term down leakage and sealing issues

At Wandian Living, we discovered that the filling port is not just a functional opening-it plays a crucial role in sealing performance, production efficiency, and long-term product quality.

The Innovation: Wandian Living's Diagonal Filling Port

We redesigned the filling port from a traditional vertical orientation to a diagonal structure.This simple angular transformation delivers significant advantages in stability, sealing performance, filling efficiency, and visual integration.

The diagonal design avoids the tension-concentrated edge zone, making the closure stronger and more secure. It also remains fully exposed after trimming, increasing filling accuracy and efficiency.

Key Benefits of the Diagonal Filling Port

1. Stronger Sealing - Reduced Down LeakageThe diagonal closure avoids stress points and tension-prone areas, minimizing potential micro gaps and significantly enhancing long-term sealing performance-even after repeated use and washing.

2. Faster and More Accurate FillingThe filling port remains consistently visible and unobstructed after cutting, eliminating the need for manual searching or repositioning. This improves production speed and precision.

3. Seamless Compatibility with Double-Layer Integrated WeavingThe diagonal port works perfectly with our seamless one-piece weaving technology, maintaining visual integrity and preserving the zero-stitch, no-needle-hole structure.

4. Better Visual Integration with Patterns and Edge DesignsThe diagonal placement naturally aligns with borders, geometric patterns, and fabric textures-without disrupting the visual harmony.

A Small Innovation, Enhanced at Every Stage

This improvement goes beyond just filling-it enhances the entire lifecycle of duvet production and use:

Design right Cutting right Filling right Sealing right Washing right Long-Term Use

It improves not only production efficiency, but also structural stability, durability, and consumer satisfaction. It turns a simple adjustment into a meaningful innovation.

What This Means for Brands and Business Partners

For brands focused on high-end bedding, differentiation, or technical innovation, Wandian Living's diagonal filling port offers:

A visible structural innovation for product storytelling

Stronger sealing performance-ideal for premium goose down products

Enhanced durability without increasing material cost

A unique technical advantage that supports OEM/ODM customization

A feature that elevates both product quality and brand positioning

At Wandian Living, we believe innovation doesn't always have to be complex-but it must be meaningful.This time, we didn't just change the design-we changed the logic behind the design.We improved the product by changing the angle.

Image: https://ecdn6.globalso.com/upload/p/4157/image_other/2025-11/screenshot_2025-11-18_155230_323.png

Media Contact

Company Name: KUNSHAN WANDIAN TRADING CO., LTD.

Email:Send Email [https://www.abnewswire.com/email_contact_us.php?pr=redefining-precision-how-wandian-living-elevates-down-duvet-manufacturing-with-the-diagonal-filling-port-design]

Country: China

Website: https://www.wandianliving.com/

Legal Disclaimer: Information contained on this page is provided by an independent third-party content provider. ABNewswire makes no warranties or responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you are affiliated with this article or have any complaints or copyright issues related to this article and would like it to be removed, please contact retract@swscontact.com

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Redefining Precision: How Wandian Living Elevates Down Duvet Manufacturing with the Diagonal Filling Port Design here

News-ID: 4363385 • Views: …

More Releases from ABNewswire

Self Employed Tax Software UK: Why Freelancers and Sole Traders Are Switching to …

With Many individuals are seeking software that simplifies tax filing while ensuring full compliance with HMRC requirements. Manual spreadsheets and paper-based calculations are being replaced by real-time, automated systems that give users visibility over their tax position throughout the year. Among the platforms gaining traction is Pie, a UK-based digital tax app built specifically to support self-employed individuals with modern income needs.

LONDON, United Kingdom - February 19, 2026 - Demand…

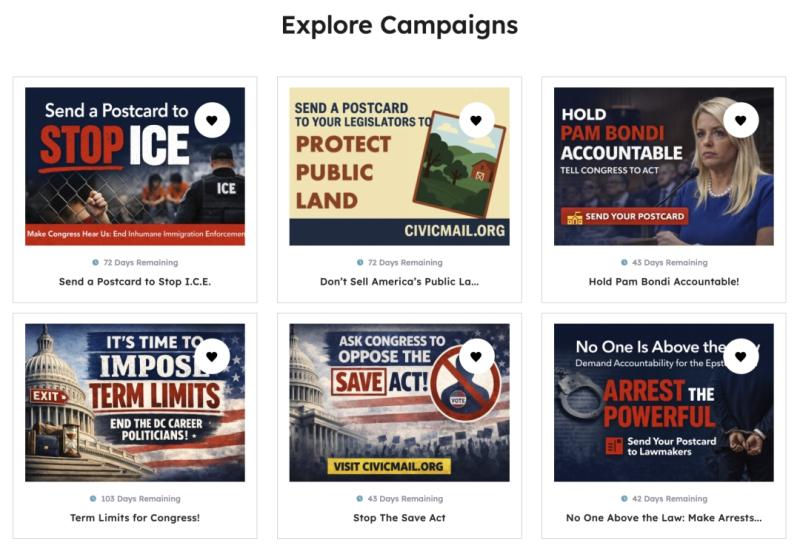

CivicMail.org Reinvents Postcard Campaigns for Grassroots Advocacy

CivicMail.org aims to bring civic engagement back to basics through the power of pen, paper, and postage.

Image: https://www.abnewswire.com/upload/2026/02/2addd1e9e0381d7e2262e1edbb064123.jpg

CivicMail.org [https://civicmail.org/] has announced its launch to help Americans send real, physical postcards to their elected officials with just a few clicks, delivering personalized messages directly to the desks of decision-makers at the local, state, and federal levels.

Research shows [https://www.concordia.ca/news/stories/2021/09/24/personalized-messages-are-more-likely-to-get-a-response-from-politicians-new-research-finds.html] that physical mail carries more weight with elected officials than petitions, emails, or…

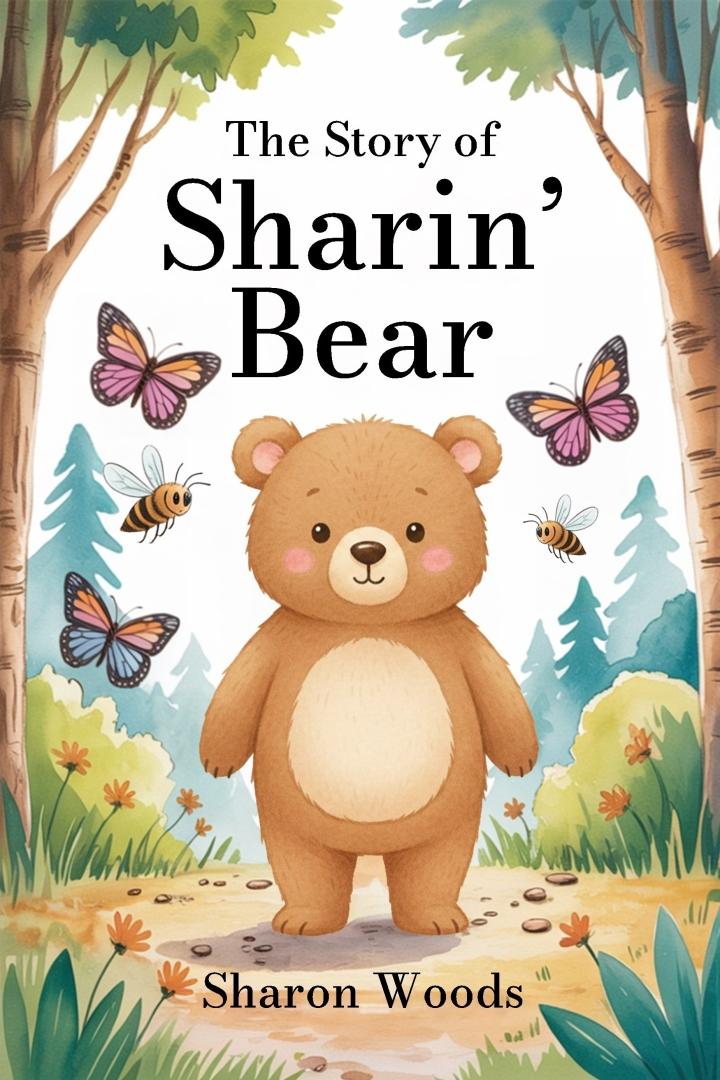

New Children's Story: The Story of Sharin' Bear

A Heartfelt Message Of Courage, Kindness, And The True Meaning Of Giving

A pleasant new story for children, The Story of Sharin' Bear by Sharon Woods , introduces families to a lovable little cub whose journey of bravery and compassion changes him into a representation of sharing for children globally.

Entrenched in adventure, innocence, and emotional growth, this uplifting tale offers an unforgettable reminder that even the smallest acts of kindness can…

Fast-Growing Newman's Brew Combines Organic Coffee Excellence with Abandoned Ani …

Newman's Brew is experiencing rapid expansion by delivering on dual commitments that resonate with today's conscious consumers: exceptional fresh-roasted organic coffee and meaningful support for abandoned animals. The company's growing inventory and ethical business practices demonstrate that quality and social responsibility can drive sustainable business success in the competitive specialty coffee market.

Newman's Brew is riding a wave of growth that reflects fundamental shifts in how consumers approach coffee purchasing decisions.…

More Releases for Wandian

Expand The Connection with Wandian: Follow The Journey on LinkedIn

Expand Your Connection with Wandian: Follow Our Journey on LinkedIn!

We are excited to announce the official launch of the Kunshan Wandian Trading Co., Ltd. LinkedIn page! As we continue to grow and innovate in the global home textiles industry, our LinkedIn channel will be the premier destination for exclusive company updates, industry insights, and a look inside our world of scientific sleep solutions.

Image: https://ecdn6.globalso.com/upload/p/4157/image_other/2025-09/wechat_2025-09-02_093425_919.png

Founded in 2019 and headquartered in Kunshan-the…

Wandian Secures Patent for Its Decade-in-the-Making Breakthrough: The Double-Wea …

A Revolution in Craftsmanship

Traditional Down Duvet [https://www.wandianliving.com/down-duvet/]s rely on hand quilting, a process that demands intensive labor and often struggles with consistency. Our patentedDouble-Weave Technology replaces stitching with precision weaving on advanced computerized looms. Three-dimensional patterns and down chambers are woven directly into the fabric, requiring only efficient down-filling and sealing.

The result?

*

80% savings in labor and energy

*

Perfectly integrated structures without stitching marks

*

Seamless minimalism that elevates both aesthetics and durability

This breakthrough…

Wandian Living Achieves OEKO-TEX Registered Certification: A New Milestone in Qu …

Wandian Living [https://www.wandianliving.com/contact-us/]is proud to announce that we have officially achieved OEKO-TEX Registered certification, marking an important milestone in our commitment to delivering safer, higher-quality, and more environmentally responsible textile products to our global customers.

What the OEKO-TEX Registered Certification Means

The OEKO-TEX Registered certification is one of the world's most recognized and trusted textile [https://www.wandianliving.com/products/] safety standards. Products carrying this certification are independently tested for harmful substances and must comply with…

China Autonomous Last-Mile Delivery Market 2032: Impact of AI, Robotics & E-comm …

China Autonomous Last-Mile Delivery Market reached US$4.37 billion in 2024 and is expected to reach US$15.98 billion by 2032, growing with a CAGR of 17.60% during the forecast period 2025-2032.

China Autonomous Last-Mile Delivery Market demonstrated strong resilience and steady growth in its initial phase, rising from US$ 3.06 billion in 2022 to US$ 3.72 billion in 2023.

ground delivery vehicles segment expanded from US$ 1.14 billion in 2022 to US$…