Press release

Aniline Hydrochloride Production Cost Analysis Report: Raw Materials, Process Economics & Pricing Trends

Aniline hydrochloride is an important chemical intermediate produced by the reaction of aniline with hydrochloric acid. It is widely used in pharmaceuticals, dyes and pigments, rubber processing chemicals, agrochemicals, and specialty chemical synthesis. Due to its role as a precursor in multiple value-added chemical products, aniline hydrochloride holds significant importance in the fine chemicals and specialty chemicals industry.With increasing demand from pharmaceutical manufacturing, textile dyes, and rubber additives, the global consumption of aniline hydrochloride continues to grow steadily. Manufacturers are increasingly focusing on cost optimization, process efficiency, and regulatory compliance to maintain profitability in a competitive chemical market.

An aniline hydrochloride production cost analysis evaluates all major cost components involved in manufacturing, including raw material sourcing, utilities, labor, capital investment, operating expenses, and profitability metrics. Such analysis is essential for investors, chemical manufacturers, and project planners to assess economic feasibility and optimize production strategies.

Request for a Sample Report: https://www.imarcgroup.com/aniline-hydrochloride-manufacturing-plant-project-report/requestsample

IMARC Group's "Aniline Hydrochloride Production Cost Analysis Report 2026" provides a detailed breakdown of production economics, offering insight into cost drivers, price trends, process efficiencies, and financial viability. The report covers both macro-level market dynamics and micro-level operational costs, enabling stakeholders to make informed investment and sourcing decisions.

Aniline Hydrochloride Industry Overview:

Aniline hydrochloride is produced through a controlled neutralization reaction between aniline and hydrochloric acid, followed by crystallization, filtration, drying, and packaging. The compound is valued for its high purity and reactivity, making it suitable for downstream chemical synthesis. Growth in pharmaceutical APIs, rubber chemicals, and dye intermediates is directly influencing demand.

Speak to Analyst for Customized Cost Analysis:

https://www.imarcgroup.com/request?type=report&id=13483&flag=C

Aniline Hydrochloride Production Process Overview:

Key Process Steps:

• Aniline procurement and storage

• Hydrochloric acid handling and dosing

• Neutralization reaction

• Crystallization of aniline hydrochloride

• Solid-liquid separation (filtration or centrifugation)

• Drying and sizing

• Quality testing and packaging

Key Cost Components in Aniline Hydrochloride Production:

Raw Material Costs:

• Aniline

• Hydrochloric acid

• Process water

• Auxiliary chemicals and additives

Raw materials account for the largest share of production costs, with aniline price volatility significantly impacting overall economics.

Utility Costs:

• Electricity

• Steam

• Cooling water

• Compressed air

Energy consumption during reaction control, drying, and material handling contributes notably to operating expenses.

Labor Costs:

• Chemical engineers

• Plant operators

• Quality control personnel

• Maintenance and safety staff

Labor costs depend on plant automation levels and regional wage structures.

Machinery and Equipment Costs:

• Reaction vessels

• Crystallizers

• Filters or centrifuges

• Dryers

• Storage tanks

• Packaging equipment

Capital investment varies based on plant capacity, material of construction, and automation level.

Infrastructure and Overheads:

• Plant construction and civil works

• Utilities infrastructure

• Environmental control systems

• Safety systems

• Administrative and insurance costs

Capital Expenditure (CapEx) Analysis:

• Land and site development

• Plant and machinery installation

• Utility systems setup

• Laboratory and quality control facilities

• Environmental compliance infrastructure

CapEx is influenced by production scale, process technology, and regulatory requirements.

Operational Expenditure (OpEx) Analysis:

• Raw material consumption

• Utilities and energy costs

• Labor and maintenance

• Packaging and logistics

• Waste treatment and disposal

Efficient raw material utilization and energy optimization play a key role in reducing operating costs.

Profitability and Financial Analysis:

• Total Production Cost per Metric Ton

• Gross Margin Analysis

• Net Profit Margin

• Break-even Analysis

• Return on Investment (ROI)

• Sensitivity Analysis (raw material price fluctuations)

Buy Now:

https://www.imarcgroup.com/checkout?id=13483&method=2175

Economic Trends Impacting Aniline Hydrochloride Production Costs:

• Volatility in aniline and benzene prices

• Fluctuations in hydrochloric acid availability

• Rising energy and utility costs

• Increasing environmental compliance expenses

• Automation and process optimization investments

• Labor cost variations

• Transportation and logistics costs

• Inflation and interest rate pressures

Challenges and Risk Factors in Cost Management:

• Dependence on upstream petrochemical feedstocks

• Hazardous chemical handling and safety compliance

• Waste acid and effluent management

• Regulatory and environmental approvals

• Market competition and pricing pressure

• Supply chain disruptions

Conclusion:

The aniline hydrochloride production cost analysis highlights the importance of raw material price management, energy efficiency, and process optimization in maintaining profitability. While the industry faces challenges related to feedstock volatility and regulatory compliance, strategic sourcing, efficient plant design, and automation can significantly improve cost competitiveness. With steady demand from pharmaceuticals, dyes, and specialty chemicals, aniline hydrochloride production remains a viable and profitable opportunity for chemical manufacturers and investors.

About Us:

IMARC Group is a global management consulting firm that helps the world's most ambitious changemakers to create a lasting impact. The company excel in understanding its client's business priorities and delivering tailored solutions that drive meaningful outcomes. We provide a comprehensive suite of market entry and expansion services. Our offerings include thorough market assessment, feasibility studies, company incorporation assistance, factory setup support, regulatory approvals and licensing navigation, branding, marketing and sales strategies, competitive landscape, and benchmarking analyses, pricing and cost research, and procurement research.

Contact Us:

IMARC Group

134 N 4th St. Brooklyn, NY 11249, USA

Email: sales@imarcgroup.com

Tel No:(D) +91 120 433 0800

United States: (+1-201971-6302)

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Aniline Hydrochloride Production Cost Analysis Report: Raw Materials, Process Economics & Pricing Trends here

News-ID: 4359422 • Views: …

More Releases from IMARC Group

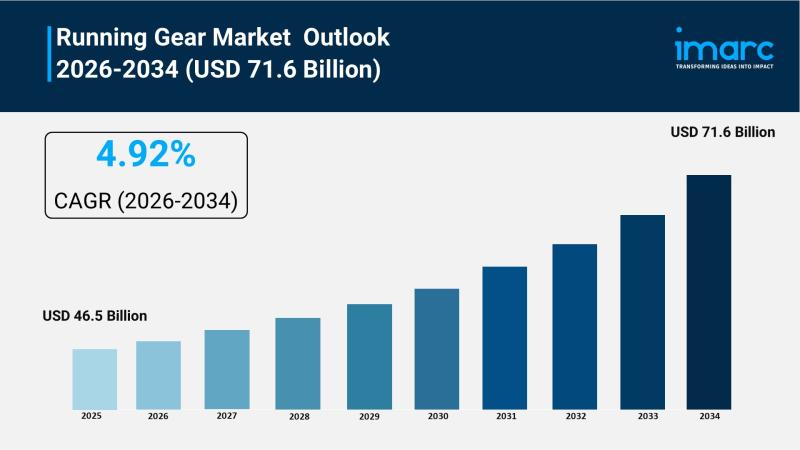

Running Gear Market Size Worth USD 71.6 Billion, Globally, by 2034 at a CAGR of …

Market Overview:

According to IMARC Group's latest research publication, "Running Gear Market: Global Industry Trends, Share, Size, Growth, Opportunity and Forecast 2026-2034", The global running gear market size was valued at USD 46.5 Billion in 2025. Looking forward, IMARC Group estimates the market to reach USD 71.6 Billion by 2034, exhibiting a CAGR of 4.92% from 2026-2034.

This detailed analysis primarily encompasses industry size, business trends, market share, key growth factors, and…

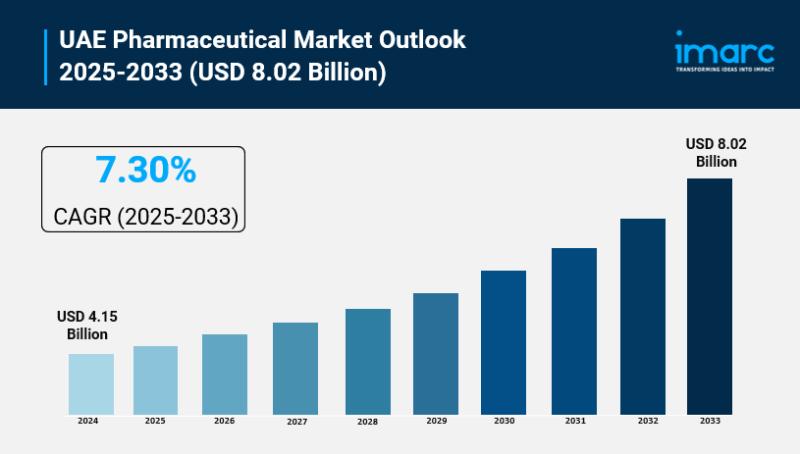

UAE Pharmaceutical Market Size is Expected to Reach USD 8.02 Billion By 2033 | C …

UAE Pharmaceutical Market Overview

Market Size in 2024: USD 4.15 Billion

Market Size in 2033: USD 8.02 Billion

Market Growth Rate 2025-2033: 7.30%

According to IMARC Group's latest research publication, "UAE Pharmaceutical Market Trends, Share, Size, Growth, Opportunity and Forecast 2025-2033", The UAE pharmaceutical market size was valued at USD 4.15 Billion in 2024. Looking forward, IMARC Group estimates the market to reach USD 8.02 Billion by 2033, exhibiting a CAGR of 7.30% from…

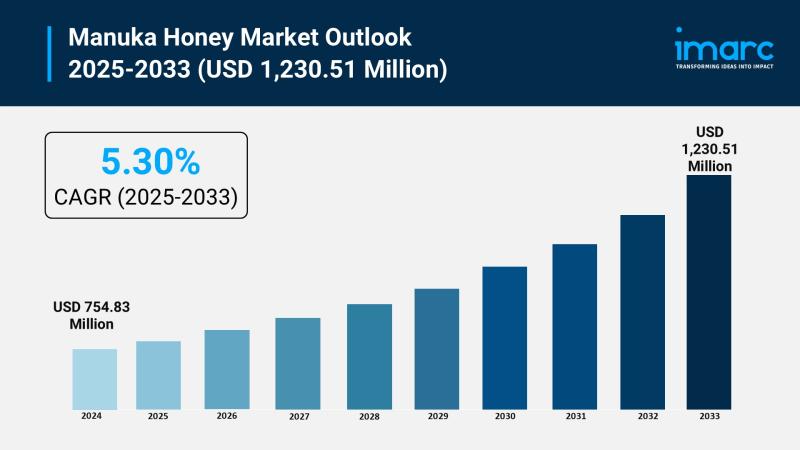

Manuka Honey Market Predicted to Exceed USD 1,230.51 Million by 2033, Rising at …

Market Overview:

According to IMARC Group's latest research publication, "Manuka Honey Market: Global Industry Trends, Share, Size, Growth, Opportunity and Forecast 2025-2033", The global manuka honey market size reached USD 754.83 Million in 2024. Looking forward, IMARC Group expects the market to reach USD 1,230.51 Million by 2033, exhibiting a growth rate (CAGR) of 5.30% during 2025-2033.

This detailed analysis primarily encompasses industry size, business trends, market share, key growth factors, and…

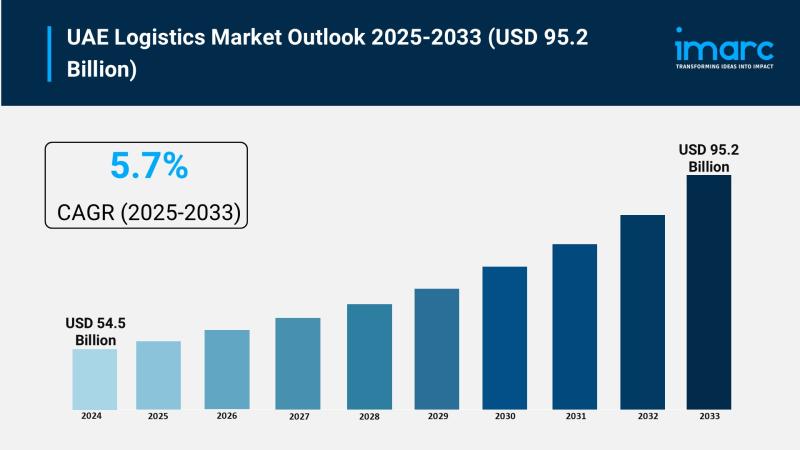

UAE Logistics Market Size to Hit USD 95.2 Billion by 2033 | With a 5.7% CAGR

UAE Logistics Market Overview

Market Size in 2024: USD 54.5 Billion

Market Size in 2033: USD 95.2 Billion

Market Growth Rate 2025-2033: 5.7%

According to IMARC Group's latest research publication, "UAE Logistics Market Trends, Share, Size, Growth, Opportunity and Forecast 2025-2033", the UAE Logistics market size was valued at USD 54.5 Billion in 2024. Looking forward, IMARC Group estimates the market to reach USD 95.2 Billion by 2033, exhibiting a CAGR of 5.7% from…

More Releases for Cost

Steel Production Cost - Process Economics, Raw Materials, and Cost Drivers

Steel is the backbone of modern industry, and its production cost is one of the most closely tracked indicators across construction, infrastructure, automotive, and manufacturing sectors. Unlike niche chemicals or APIs, steel economics are driven by scale, energy intensity, and raw material volatility.

Here's the thing: steel production cost isn't just about iron ore prices. It's a layered equation involving coking coal, electricity, labor, emissions compliance, logistics, and technology choice. A…

Egg Powder Manufacturing Plant Setup Cost | Cost Involved, Machinery Cost and In …

IMARC Group's report titled "Egg Powder Manufacturing Plant Project Report 2024: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue" provides a comprehensive guide for establishing an egg powder manufacturing plant. The report covers various aspects, ranging from a broad market overview to intricate details like unit operations, raw material and utility requirements, infrastructure necessities, machinery requirements, manpower needs, packaging and transportation requirements, and more.

In addition to…

Glucose Manufacturing Plant Cost Report 2024: Requirements and Cost Involved

IMARC Group's report titled "Glucose Manufacturing Plant Project Report 2024: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue" provides a comprehensive guide for establishing a glucose manufacturing plant. The report covers various aspects, ranging from a broad market overview to intricate details like unit operations, raw material and utility requirements, infrastructure necessities, machinery requirements, manpower needs, packaging and transportation requirements, and more.

In addition to the operational…

Fatty Alcohol Production Cost Analysis: Plant Cost, Price Trends, Raw Materials …

Syndicated Analytics' latest report titled "Fatty Alcohol Production Cost Analysis 2023-2028: Capital Investment, Manufacturing Process, Operating Cost, Raw Materials, Industry Trends and Revenue Statistics" includes all the essential aspects that are required to understand and venture into the fatty alcohol industry. This report is based on the latest economic data, and it presents comprehensive and detailed insights regarding the primary process flow, raw material requirements, reactions involved, utility costs, operating costs, capital…

Corn Production Cost Analysis Report: Manufacturing Process, Raw Materials Requi …

The latest report titled "Corn Production Cost Report" by Procurement Resource, a global procurement research and consulting firm, provides an in-depth cost analysis of the production process of the Corn. Read More: https://www.procurementresource.com/production-cost-report-store/corn

Report Features - Details

Product Name - Corn Production

Segments Covered

Manufacturing Process: Process Flow, Material Flow, Material Balance

Raw Material and Product/s Specifications: Raw Material Consumption, Product and Co-Product Generation, Capital Investment

Land and Site Cost: Offsites/Civil Works, Equipment Cost, Auxiliary Equipment…

Crude Oil Production Cost Analysis Report: Manufacturing Process, Raw Materials …

The latest report titled "Crude Oil Production Cost Report" by Procurement Resource, a global procurement research and consulting firm, provides an in-depth cost analysis of the production process of the Crude Oil. Read More: https://www.procurementresource.com/production-cost-report-store/crude-oil

Report Features - Details

Product Name - Crude Oil

Segments Covered

Manufacturing Process: Process Flow, Material Flow, Material Balance

Raw Material and Product/s Specifications: Raw Material Consumption, Product and Co-Product Generation, Capital Investment

Land and Site Cost: Offsites/Civil Works, Equipment Cost,…