Press release

Metal Cutting Tools Market Comprehensive Industry Overview, Emerging Trends, and Long-Term Growth Outlook

Metal Cutting Tools Market size was valued at USD 88.98 Billion in 2025 and the total Metal Cutting Tools revenue is expected to grow at a CAGR of 4.9% from 2025 to 2032, reaching nearly USD 124.38 Billion by 2032.Metal Cutting Tools Market Overview:

The Metal Cutting Tools Market plays a vital role in modern manufacturing by enabling precision shaping, drilling, milling, and turning of metals across industries such as automotive, aerospace, construction, electronics, and heavy machinery. These tools are essential for achieving tight tolerances, surface accuracy, and repeatable production outcomes. The market includes a wide range of products such as drills, end mills, inserts, reamers, taps, and saw blades, manufactured using materials like high-speed steel, carbide, ceramics, and cubic boron nitride. With industrial production becoming more automated and quality-driven, demand for advanced cutting tools that offer durability, speed, and precision is rising steadily. Manufacturers are increasingly focusing on innovation to improve tool life, heat resistance, and cutting efficiency. Additionally, global industrial expansion, infrastructure development, and growth in metal-intensive sectors are reinforcing the importance of metal cutting tools in both mass production and customized manufacturing environments.

Request a sample copy of the report to see what's inside: https://www.maximizemarketresearch.com/request-sample/35510/

Metal Cutting Tools Market Key Market Trends for 2026:

In 2026, the Metal Cutting Tools Market is expected to witness strong momentum driven by technological upgrades and smart manufacturing practices. One of the most prominent trends is the increasing adoption of CNC machining and Industry 4.0 solutions, which require high-precision cutting tools compatible with automated systems. Tool manufacturers are investing in advanced coatings such as titanium aluminum nitride and diamond-like carbon to enhance tool performance and lifespan. Lightweight materials and complex component designs in aerospace and electric vehicles are also influencing tool geometry innovation. Another key trend is the growing preference for sustainable manufacturing, encouraging the use of recyclable tool materials and eco-friendly production processes. Digital tool monitoring and predictive maintenance solutions are gaining traction, allowing manufacturers to optimize cutting performance and reduce downtime. Customization and application-specific tools are becoming more common to meet specialized industrial needs.

Metal Cutting Tools Market Dynamics: What's Driving Growth:

The growth dynamics of the Metal Cutting Tools Market are shaped by rapid industrialization and increasing global manufacturing output. Rising demand for precision-engineered components in automotive, aerospace, medical devices, and electronics is significantly boosting the need for advanced cutting tools. The expansion of electric vehicle production is further accelerating demand, as EV components require high-accuracy machining of lightweight metals and alloys. Growth in infrastructure and construction projects worldwide is increasing consumption of metal components, driving higher tool usage. Technological advancements in machine tools, including high-speed and multi-axis machining, are also pushing demand for tools capable of operating under extreme conditions. Additionally, manufacturers are under constant pressure to reduce production costs and cycle times, making efficient, long-lasting metal cutting tools a critical investment. These combined factors are creating sustained market growth across both developed and emerging economies.

Metal Cutting Tools Market Key Market Drivers:

Several key drivers are fueling expansion in the Metal Cutting Tools Market, with industrial automation being a primary factor. As manufacturers shift toward automated and robotic machining systems, the demand for reliable, high-performance cutting tools continues to rise. The automotive sector remains a major driver, driven by increasing vehicle production and the transition toward electric and hybrid models. Aerospace manufacturing is another significant contributor, as it requires ultra-precise tools for machining high-strength alloys and composite metals. Rising demand for consumer electronics, which rely on compact and precision-machined metal parts, further supports market growth. Additionally, government initiatives supporting manufacturing and infrastructure development are stimulating tool demand. The continuous need to improve productivity, reduce material waste, and enhance machining accuracy is encouraging industries to invest in technologically advanced metal cutting solutions.

Metal Cutting Tools Market Opportunities:

The Metal Cutting Tools Market offers substantial growth opportunities, particularly in emerging economies where manufacturing capabilities are rapidly expanding. Countries investing heavily in industrial infrastructure and local production are creating new demand for metal cutting solutions. The rise of additive manufacturing combined with traditional machining presents opportunities for hybrid cutting tools designed for post-processing 3D-printed metal parts. Increasing adoption of electric vehicles and renewable energy equipment also opens new application areas for specialized tools. There is strong potential in developing application-specific and customized cutting tools tailored to unique materials and complex geometries. Digital integration, including smart tools with embedded sensors for performance tracking, offers another promising avenue for innovation. Additionally, aftermarket services such as tool reconditioning and recycling present revenue opportunities while supporting sustainable manufacturing practices.

Need Reliable Market Data? Save 30% This New Year: https://www.maximizemarketresearch.com/market-report/global-metal-cutting-tools-market/35510/

Metal Cutting Tools Market Major Market Challenges:

Despite strong growth prospects, the Metal Cutting Tools Market faces several notable challenges. Fluctuating raw material prices, particularly for carbide and specialty alloys, can impact production costs and profit margins. High initial costs of advanced cutting tools may discourage small and medium-sized manufacturers from adoption. Tool wear and breakage under high-speed machining conditions remain technical challenges, especially when machining hard or composite materials. Intense competition among global and regional players often leads to pricing pressure, affecting profitability. Additionally, rapid technological change requires continuous investment in research and development, which can strain resources. Skill shortages in advanced machining and tool handling further limit efficient tool utilization. Environmental regulations related to manufacturing processes and waste disposal also add compliance costs, creating operational challenges for market participants.

Metal Cutting Tools Market Segmentation:

by Tool Type

Milling Tools

Drilling Tools

Turning Tools

Grinding Tools

Others

by Material Type

High-Speed Steel (HSS)

Carbide

Ceramics

Cermet

Diamond

Cubic Boron Nitride

by Application

Automotive

Aerospace & Defense

Construction & Mining

Electronics & Electrical

Energy & Power

Medical

General Manufacturing

by Material

Industrial Machinery

Automotive

Aerospace & Defense

Oil & Gas

Power Generation

Metal Fabrication

Metal Cutting Tools Market, Key Players

1. Sandvik AB

2. Kennametal Inc.

3. Mitsubishi Materials Corporation

4. ISCAR Ltd. (IMC Group)

5. OSG Corporation

6. Sumitomo Electric Industries, Ltd.

7. Seco Tools AB

8. Dormer Pramet

9. Kyocera Corporation

10. Guhring Inc.

11. Walter AG

12. Makita Corporation

13. Tungaloy Corporation

14. YG-1 Co., Ltd.

15. Ceratizit Group

16. Ingersoll Cutting Tools

17. Nachi-Fujikoshi Corp.

18. ANCA Pty Ltd.

19. Hanjiang Tool Co., Ltd.

20. Fraisa SA

21. Korloy Inc.

22. Mapal Group

23. Sandhog Precision Tools

24. Tivoly S.A.

25. Sumitomo Hardmetal

26. EMUGE-FRANKEN

27. Amada Tooling Solutions

28. Union Tool Co.

29. Carmex Precision Tools

30. Hitachi Tool Engineering, Ltd.

Metal Cutting Tools Market FAQs:

1. What are metal cutting tools?

Metal cutting tools are specialized tools used to remove material from metal workpieces through machining processes such as turning, milling, drilling, and grinding to achieve precise shapes and dimensions.

2. Which industries primarily use metal cutting tools?

Major end-use industries include automotive, aerospace, construction, electronics, heavy machinery, medical devices, and industrial manufacturing.

3. What materials are commonly used to manufacture metal cutting tools?

Common materials include high-speed steel (HSS), carbide, ceramics, cubic boron nitride (CBN), and polycrystalline diamond (PCD).

4. What factors are driving demand for metal cutting tools?

Key drivers include industrial automation, growth in automotive and aerospace manufacturing, expansion of infrastructure projects, and increasing demand for precision-engineered components.

5. How does CNC machining impact the metal cutting tools market?

CNC machining increases demand for high-precision, durable cutting tools that can operate at high speeds with consistent accuracy in automated environments.

6. What are coated metal cutting tools, and why are they important?

Coated tools have surface layers that improve hardness, heat resistance, and tool life, enabling better performance and reduced downtime during machining.

7. What challenges does the metal cutting tools market face?

Challenges include high raw material costs, tool wear, intense competition, skill shortages, and the need for continuous technological upgrades.

8. Are metal cutting tools used in electric vehicle manufacturing?

Yes, electric vehicle production requires high-precision cutting tools for machining lightweight metals, battery components, and complex assemblies.

9. What role does sustainability play in this market?

Manufacturers are focusing on recyclable materials, tool reconditioning, and eco-friendly coatings to support sustainable manufacturing practices.

10. What is the future outlook for the metal cutting tools market?

The market is expected to grow steadily, driven by advanced manufacturing technologies, smart factories, and rising demand from emerging economies.

Related Reports:

Hydraulic Cylinder Market https://www.maximizemarketresearch.com/market-report/global-hydraulic-cylinder-market/3211/

Coffee Machine Market https://www.maximizemarketresearch.com/market-report/coffee-machine-market/216041/

Industrial Automation Market https://www.maximizemarketresearch.com/market-report/industrial-automation-market/39668/

Global Building Optimization and Commissioning Services Market https://www.maximizemarketresearch.com/market-report/global-building-optimization-and-commissioning-services-market/83770/

India Power Tool Market https://www.maximizemarketresearch.com/market-report/india-power-tool-market/31817/

Contact Maximize Market Research:

3rd Floor, Navale IT Park, Phase 2

Pune Banglore Highway, Narhe,

Pune, Maharashtra 411041, India

sales@maximizemarketresearch.com

+91 96071 95908, +91 9607365656

Maximize Market Research is a multifaceted market research and consulting company with professionals from several industries. Some of the industries we cover include medical devices, pharmaceutical manufacturers, science and engineering, electronic components, industrial equipment, technology and communication, cars and automobiles, chemical products and substances, general merchandise, beverages, personal care, and automated systems. To mention a few, we provide market-verified industry estimations, technical trend analysis, crucial market research, strategic advice, competition analysis, production and demand analysis, and client impact studies.

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Metal Cutting Tools Market Comprehensive Industry Overview, Emerging Trends, and Long-Term Growth Outlook here

News-ID: 4354690 • Views: …

More Releases from MAXIMIZE MARKET RESEARCH PVT. LTD.

Ready-to-Drink Beverages Market Size to Reach USD 1,227.81 Billion by 2032

Ready-to-Drink Beverages Market is poised for substantial growth over the forecast period, driven by changing consumer lifestyles, rising disposable income, expanding urbanization, and increasing demand for convenient beverage solutions. According to recent industry analysis, the global Ready-to-Drink Beverages Market was valued at USD 766.69 Billion in 2024 and is projected to grow at a compound annual growth rate (CAGR) of 6.22% from 2025 to 2032, reaching nearly USD 1,227.81 Billion…

Second hand Product Market Set to Surpass USD 1451.34 Billion by 2032, Expanding …

Second hand Product Market was valued at USD 594.45 Billion in 2025 and is projected to grow at a robust CAGR of 13.6% from 2025 to 2032, reaching nearly USD 1451.34 Billion by 2032. The rapid expansion of resale ecosystems, increasing consumer preference for cost-effective purchasing, and rising sustainability awareness are significantly driving the growth of the Second hand Product Market globally.

Market Overview

The Second hand Product Market is undergoing a…

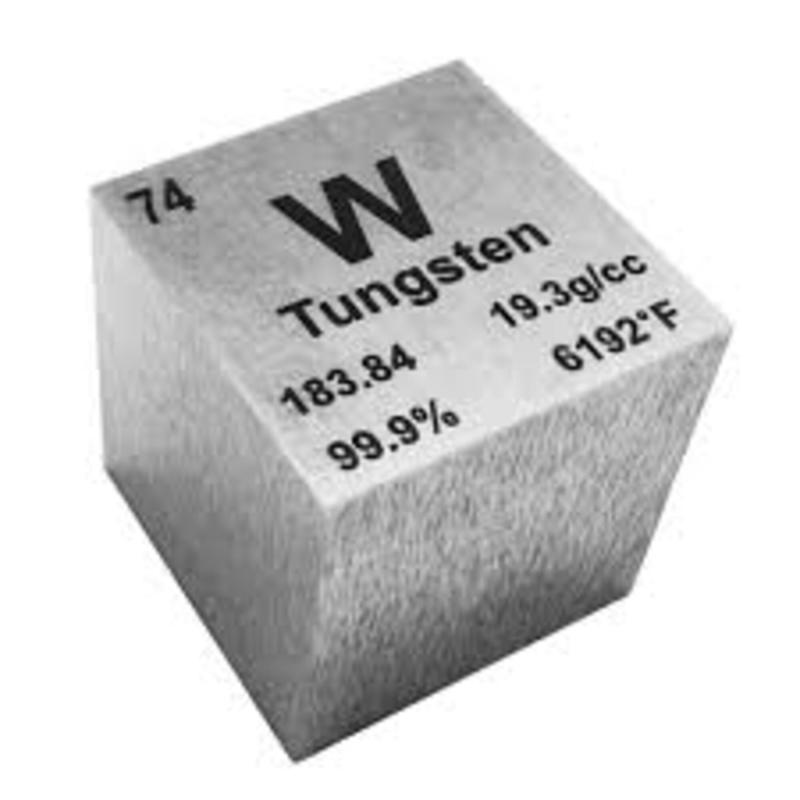

Tungsten Market to Reach USD 10.99 Billion by 2032, Driven by Expanding Aerospac …

The Global Tungsten Market is poised for significant expansion over the coming years, with the market size valued at USD 6.41 Billion in 2025 and projected to grow at a CAGR of 8% from 2025 to 2032, reaching nearly USD 10.99 Billion by 2032. Rising industrial demand, technological advancements in material science, and increasing applications in high-performance sectors are collectively driving this steady growth trajectory.

Tungsten, recognized for its exceptional hardness,…

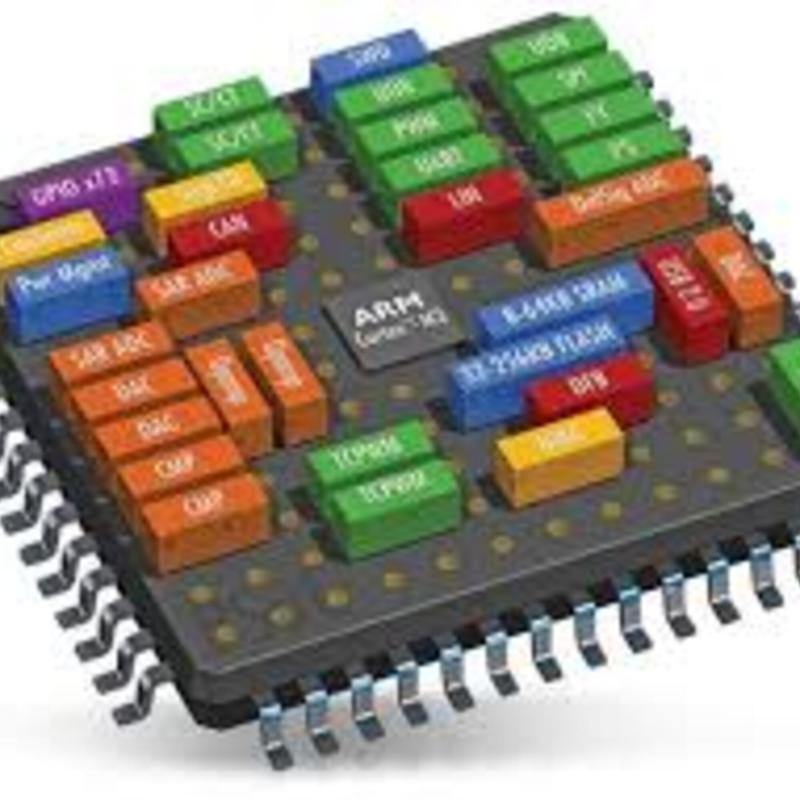

System-on-Chip (SoC) Market to Reach USD 391.61 Billion by 2032, Driven by 5G, A …

The global System-on-Chip (SoC) Market is poised for significant growth over the forecast period, reflecting the rapid evolution of semiconductor technologies and increasing demand for high-performance, energy-efficient electronic devices. Valued at USD 228.06 Billion in 2025, the market is projected to grow at a CAGR of 8.03% from 2025 to 2032, reaching nearly USD 391.61 Billion by 2032.

♦ Request a Free Sample Copy or View Report Summary:https://www.maximizemarketresearch.com/request-sample/33954/

System-on-Chip (SoC) Market Overview

A…

More Releases for Tool

Data Annotation Tool Market Data Annotation Tool Market

The study on the Global Data Annotation Tool Market published by Fact.MR is a comprehensive analysis of the key factors that are likely to determine the growth of Data Annotation Tool Market in the upcoming years. Further, the study dives deep to investigate the micro and macro-economic parameters that are expected to influence the global scenario of the Data Annotation Tool Market during the forecast period (2022-2031).

The report examines the…

Research Report and Overview on Titanium Carbide Tool Market, 2020-2026 with Mit …

"Global Titanium Carbide Tool Industry Research Report” Provides Detailed Insight Covering all Important Parameters Including Development Trends, Challenges, Opportunities, Key Insights and Competitive Analysis of Titanium Carbide Tool Market.

COVID-19 can affect the global economy in 3 main ways: by directly affecting production and demand, by creating supply chain and market disturbance, and by its financial impact on firms and financial markets.

To know How COVID-19 Pandemic will impact this market/industry-DOWNLOAD sample…

Aluminum Carbide Tool Market Trend, Segmentation and Forecast to 2025| Mitsubish …

High speed steel tools and carbide tools are widely used machine tools. From which carbide tools are most popular for machining applications. Carbide tools have exceptional characteristics like wear resistance, material strength, chemical inertness and other superior properties.

The Aluminum Carbide Tool market was valued at xx Million US$ in 2018 and is projected to reach xx Million US$ by 2025, at a CAGR of xx% during the forecast period. In…

Titanium Carbide Tool Market Size Study and Regional Forecasts 2019-2025| Mitsub …

High speed steel tools and carbide tools are widely used machine tools. From which carbide tools are most popular for machining applications. Carbide tools have exceptional characteristics like wear resistance, material strength, chemical inertness and other superior properties.

The Titanium Carbide Tool market was valued at xx Million US$ in 2018 and is projected to reach xx Million US$ by 2025, at a CAGR of xx% during the forecast period. In…

What's driving the Solid Carbide Tool Market growth? Key Players are: Mitsubishi …

The worldwide market for Solid Carbide Tool is expected to grow at a CAGR of roughly over the next five years, will reach million US$ in 2024, from million US$ in 2019, according to a new Big Market Research study.

Get Discount Sample @ https://www.bigmarketresearch.com/request-for-discount/3009309?utm_source=SBL

This report focuses on the Solid Carbide Tool in global market, especially in North America, Europe and Asia-Pacific, South America, Middle East and Africa. This report categorizes…

Global Knurling Tool Market 2018-2025 Aloris Tool, Dorian Tool, Sassatelli

Recently added detailed market study "Global Knurling Tool Market" examines the performance of the Knurling Tool market 2018. It encloses an in-depth Research of the Knurling Tool market state and the competitive landscape globally. This report analyzes the potential of Knurling Tool market in the present and the future prospects from various angles in detail.

The Global Knurling Tool Market 2018 report includes Knurling Tool market Revenue, market Share, Knurling Tool…