Press release

Beyond the Mold: Integrated Casting Excellence and CNC Precision at Taiyuan Simis

The global industrial manufacturing sector is currently undergoing a radical transformation, driven by the dual demands of high-precision engineering and sustainable production. As heavy industries seek components that offer both structural integrity and reduced weight, the role of expert foundries has become more pivotal than ever. At the center of this industrial evolution is Taiyuan SIMIS Investment Casting Co., Ltd., an organization that has earned its reputation as a China Top Die Casting Service provider. By seamlessly integrating decades of metallurgical tradition with cutting-edge CNC technology, Simis is setting new global benchmarks for high-scale casting and specialized component development.1. Industry Outlook 2026: The New Frontiers of Casting(https://www.simis-manufacturer.com/products/)

As we look toward the second half of the 2020s, the casting and foundry industry is being reshaped by several key macro-trends. For a market leader like Taiyuan Simis, these shifts represent an opportunity to demonstrate superior technical resource management and strategic foresight:

The "Megacasting" Revolution: The automotive industry, particularly in the Electric Vehicle (EV) space, is shifting toward large-scale integrated castings. This approach reduces the need for hundreds of individual parts, thereby streamlining the allocation of manufacturing resources and improving the overall structural performance of vehicles.

Decarbonization of Foundries: Sustainability has moved from a secondary concern to a primary business driver. Modern foundries are now measured by their energy efficiency. Simis's strategic location in Shanxi-a hub of energy and raw materials-allows for a more localized and energy-efficient supply chain, enhancing the long-term sustainability value of their production.

Precision via Digital Twins: The industry is moving toward "Zero-Defect" manufacturing. By utilizing advanced thermal simulation and digital modeling before the first drop of molten metal is poured, leaders like Simis are maximizing project efficiency and reducing material waste.

2. Core Strengths: The Foundation of Foundary Leadership

Established in 2004, but carrying a heritage that spans over 40 years, Taiyuan Simis has built a production ecosystem that is as robust as the materials it processes. Their standing as a China Top Die Casting Service is built upon several foundational pillars:

A. Unmatched Resource Integration

Situated in Taiyuan City, Shanxi Province, Simis operates in the heart of China's iron and coal country. This provides a unique competitive edge: the strategic accessibility to raw materials. In an era of global supply chain volatility, Simis offers its international partners a rare level of stability and resource consistency, ensuring that large-scale production schedules are met without disruption.

B. Versatility in Manufacturing Processes

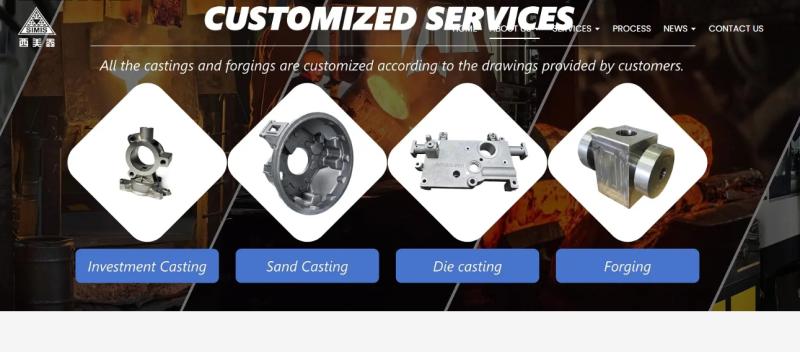

Unlike specialized workshops that offer only one type of casting, Simis has mastered a comprehensive suite of technologies:

Sophisticated Investment Casting: Delivering near-net-shape components with intricate details and superior surface finishes.

Detailed Die Casting: Providing high-speed, high-precision non-ferrous solutions for the modern automotive and electronics sectors.

Sand and Shell Mold Casting: Catering to the heavy-duty needs of the energy and construction industries.

C. Advanced CNC Integration

A cast part is often only as good as its final tolerances. With two advanced CNC machining workshops, Simis ensures that "standard parts" are transformed into "high-precision components." This vertical integration reduces the logistical friction for clients, providing a one-stop-shop solution from raw casting to finished assembly.

[Image: A CNC technician inspecting a precision-machined turbine housing for a renewable energy project]

3. Product Application Scenarios: Powering Global Progress

The diverse capabilities of Taiyuan Simis mean their products are essential components in the world's most demanding environments.

I. Automotive & Aerospace: The Quest for Performance

In the automotive sector, Simis's die-casting expertise is used to create lightweight transmission housings and structural components that are vital for fuel efficiency and EV range. In aerospace, where the allocation of specialized metallurgical resources is critical, their investment casting process delivers components that meet the industry's most stringent safety and performance specifications.

II. Energy & Chemical: Resilience Under Pressure

The energy sector-ranging from traditional oil and gas to wind and solar-relies on Simis for heavy-duty valves, pump casings, and heat exchanger parts. These components are engineered to withstand extreme pressures and corrosive environments, protecting the long-term operational integrity of global energy infrastructures.

III. Construction & Infrastructure

From high-rise buildings to massive bridge projects, Simis provides the structural hardware and hydraulic components that drive urban development. Their shell mold casting process is particularly favored for producing durable, large-scale parts that ensure the safety and longevity of public works.

4. Driving Value: Strategic Client Partnerships

Over four decades, Simis has moved beyond being a mere "vendor" to becoming a Strategic Engineering Partner. They focus on enhancing the commercial utility of every design.

Case Study: European Industrial Equipment Manufacturer A major European client was struggling with the high sc-rap rates of a complex pump housing produced by their previous supplier. Simis's engineering team utilized advanced simulation software to optimize the gating and riser design. By strategically adjusting the technical resource deployment, Simis was able to deliver a 20% improvement in casting yield, significantly enhancing the overall project value for the client.

Case Study: North American Energy Grid Project For a large-scale power distribution project, the client required custom-engineered connectors that could survive decades of outdoor exposure. Simis provided a specialized investment casting solution using high-corrosion-resistance alloys. Their ability to handle the "complex custom project" while maintaining a "high-scale production" allowed the client to meet their infrastructure milestones with full confidence in the material durability.

5. Innovation and Excellence: The Simis Commitment

What truly sets Taiyuan Simis apart is their ongoing strategic investment in both technology and human capital. Their state-of-the-art facilities are not just about machinery; they are about precision. Equipped with the latest spectrometers for chemical analysis and 3D coordinate measuring machines (CMM), Simis ensures that every part leaving the factory is a testament to their dedication to excellence.

Their team of professionals is adept at taking a "detailed design" and translating it into a "large-scale production" reality. This human expertise is the bridge between a client's vision and the tangible, high-quality results that drive international industries forward.

6. Conclusion: Shaping the Global Industrial Future

As a China Top Die Casting Service, Taiyuan Simis Investment Casting Co., Ltd. represents the perfect synergy of resource-rich heritage and future-ready innovation. In a world where the strategic efficiency of the supply chain is the ultimate differentiator, Simis provides the reliability, technical depth, and manufacturing scale required to meet the challenges of 2026 and beyond.

From automotive innovations to the infrastructure that powers our cities, the components crafted by Simis are the building blocks of modern civilization. Their commitment to quality and customized solutions ensures that their partners aren't just buying parts-they are investing in industrial longevity and strategic success.

For global B2B partners looking to secure their supply chain with world-class casting expertise, the search leads to Taiyuan Simis.

To explore our extensive portfolio of casting solutions or to discuss your next high-scale custom project, please visit our official website.

Official Website: https://www.simis-manufacturer.com/

No 251, Changzhi Road, Taiyuan City, Shanxi Province, China

+86-17735177558

info@simis-manufacturer.com

https://www.simis-manufacturer.com/products/

Taiyuan Simis Investment Casting Co., Ltd.

Established in 2004, Taiyuan SIMIS Investment Casting Co., Ltd. has become a formidable presence in the foundry sector, expertly integrating product development with high-scale production. Situated in Taiyuan City, Shanxi Province-a region distinguished by its abundant iron ore and coal resources-our company has developed a robust production capability in diverse casting processes including sophisticated investment casting, versatile sand casting, detailed die casting, and efficient shell mold casting. These capabilities enable us to serve a broad spectrum of industries such as automotive, aerospace, chemical, construction, and energy.

Taiyuan SIMIS operates six specialized casting facilities and two advanced CNC machining workshops, positioning us to manage a variety of orders, from standard parts to complex custom projects. With a track record spanning over 40 years, we have established ourselves as industry leaders, known for our commitment to quality and customized casting solutions.

Our dedication to excellence is underscored by our ongoing investments in advanced technologies and skilled personnel. Our state-of-the-art facilities are equipped with the latest machinery that enables precise manufacturing to meet strict client specifications. Our team of professionals is adept at handling detailed designs and large-scale productions, ensuring top-quality results across all projects.

Expansion and Innovation

In 2023, Taiyuan SIMIS embarked on a mission to explore adjacent market segments closely aligned with the foundry industry. This included the introduction of refractories, Ceramic Foam Filters, Samplings, Thermocouple, and other related products.

In an even more significant milestone, 2024 marked the introduction of automotive parts products by Taiyuan SIMIS. The addition of Three-way Catalytic Converters and their carriers, along with Portable EV Charging Equipment and Adapters for new energy vehicles, marked a significant leap forward for the company. These novel product lines not only enrich the company's portfolio but also significantly bolster its competitiveness within the market.

Our strategic location in one of China's key coal and steel production centers gives us a significant operational advantage. Access to local raw materials and cost-effective energy allows us to produce high-quality ferrous metal casting components, including cast iron and steel, at competitive rates. This advantage not only enhances our production capacity but also allows us to offer cost savings to our clients.

Taiyuan SIMIS Investment Casting Co., Ltd. also shines in several specialized areas beyond our primary casting capabilities. Our in-house tooling operations are meticulously designed for precise control over the production process, ensuring that every component we create adheres strictly to client specifications while minimizing production lead times. This attention to detail extends to our rapid prototyping services, where we employ the latest technologies to accelerate the design and development phases. This not only speeds up the overall manufacturing timeline but also facilitates iterative testing and refinement, enabling optimal product outcomes.

Our dedication to providing customized solutions is a cornerstone of our business strategy. We excel in modifying our processes and materials to perfectly align with the unique requirements of our clients. Whether it involves adjusting material properties for superior performance or crafting complex geometries for specific applications, our team is fully equipped to develop and deliver highly specialized products. This flexibility and adaptability underscore our commitment to meeting the diverse needs of our customers with precision and efficiency.

At Taiyuan SIMIS Investment Casting Co., Ltd., we utilize state-of-the-art CNC machining centers to ensure high accuracy and superior finishes in our machining operations. This enables us to produce components with precise dimensions and complex geometries, essential for industries like aerospace and medical devices.

We enhance the durability and appearance of our castings with various surface treatments such as electroplating, anodizing, painting, and powder coating. These processes improve wear resistance and corrosion protection, allowing us to deliver ready-to-use components tailored to specific applications.

Our heat treatment processes, including annealing, quenching, and tempering, are crucial for modifying the mechanical properties of our products. These treatments enhance strength, ductility, and resistance to wear, ensuring components can withstand demanding operational conditions.

Taiyuan SIMIS is ISO 9001 certified, reflecting our commitment to maintaining the highest quality standards. Our rigorous quality control measures cover every production stage, from raw material receipt to final product inspection. We employ advanced testing methods to ensure that each component consistently exceeds customer expectations, reinforcing our reputation as a reliable industry leader.

By integrating precise manufacturing techniques and strict quality controls, Taiyuan SIMIS delivers not just products, but comprehensive solutions that enhance our clients' operational efficiency and product reliability.

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Beyond the Mold: Integrated Casting Excellence and CNC Precision at Taiyuan Simis here

News-ID: 4354664 • Views: …

More Releases for CNC

Industrial CNC Machinery

Industrial CNC (Computer Numerical Control) machinery plays a crucial role in modern manufacturing, offering precision, efficiency, and flexibility. These machines are programmed to automate the fabrication process, allowing for intricate designs and consistent quality across large production runs. By minimizing human error, CNC machinery enhances accuracy, which is vital in industries such as aerospace, automotive, and electronics. The ability to swiftly change designs and adapt to market demands without extensive…

CNC Controller Market Report 2024 - CNC Controller Market Trends, Opportunities …

"The Business Research Company recently released a comprehensive report on the Global CNC Controller Market Size and Trends Analysis with Forecast 2024-2033. This latest market research report offers a wealth of valuable insights and data, including global market size, regional shares, and competitor market share. Additionally, it covers current trends, future opportunities, and essential data for success in the industry.

Ready to Dive into Something Exciting? Get Your Free Exclusive Sample…

CNC Controller Global Market to Generate $3.84 Billion By 2028, Registering at a …

"The new report published by The Business Research Company, titled CNC Controller Global Market Report 2024 - Market Size, Trends, And Global Forecast 2024-2033, delivers an in-depth analysis of the leading size and forecasts, investment opportunities, winning strategies, market drivers and trends, competitive landscape, and evolving market trends.

As per the report, the cnc controller market size has grown strongly in recent years. It will grow from $2.82 billion…

Silver CNC Now Offers CNC Rotary Tables for CNC Machining Centers

Silver CNC is now offering a new line of CNC rotary tables that are perfect for use with CNC machining centers. The rotary tables are available in three different sizes, and each one is made from high-quality cast iron to ensure durability and precision. With a built-in indexing system, the rotary tables make it easy to position your workpiece exactly where you need it. Plus, they're backed by a full…

Trending 2020: CNC Machine (CNC Machine Tools) Market Booming Worldwide

Prophecy Market Insights recently presented CNC Machine (CNC Machine Tools) market report which provides reliable and sincere insights related to the various segments and sub-segments of the market. The market study throws light on the various factors that are projected to impact the overall dynamics of the CNC Machine (CNC Machine Tools) market over the forecast period (2019-2029).

The CNC Machine (CNC Machine Tools) research study contains 100+ market data Tables,…

Desktop CNC Machines Market Research Analysis by Carbide3D, Stoney CNC, VELOX CN …

Desktop CNC Machines Market Share, Size, Trends, And Business Opportunity Analysis Report 2019 include historic data, with forecast data to 2023. Desktop CNC Machines Industry report is helpful for future strategy development, and to know about Market Drivers, Restraints, Opportunities, And Global market size, share, Growth, Trends, key players forecast to 2023.

The global desktop CNC machines market has witnessed tremendous growth in the last few years, owing to the growing…