Press release

Sheet Metal Bending Calculation: All Factors Explained

In sheet metal fabrication, https://proleantech.com/sheet-metal/ bending a sheet metal part influences its dimensions and thickness. The final piece may end up larger than the measurements on the original drawing if bending effects are not taken into account. This usually occurs because the metal stretches along the bend, a process known as elongation. The stretching appears as the neutral axis of the material shifts toward the inside of the bend.The neutral axis is an invisible line in the sheet where the material does not change length during bending. Material on the outer side of this line stretches under tension, while the material on the inner side is compressed. Along the neutral axis, the material stays the same length. If the neutral axis moves too far inward, more material is pushed outward than compressed inward, which causes springback after bending.

Knowing how the neutral axis affects material behaviour is essential for accurate sheet metal bending. This article explains the calculations, formulas, and technical considerations required for precise bending.

What is Sheet Metal Bending?

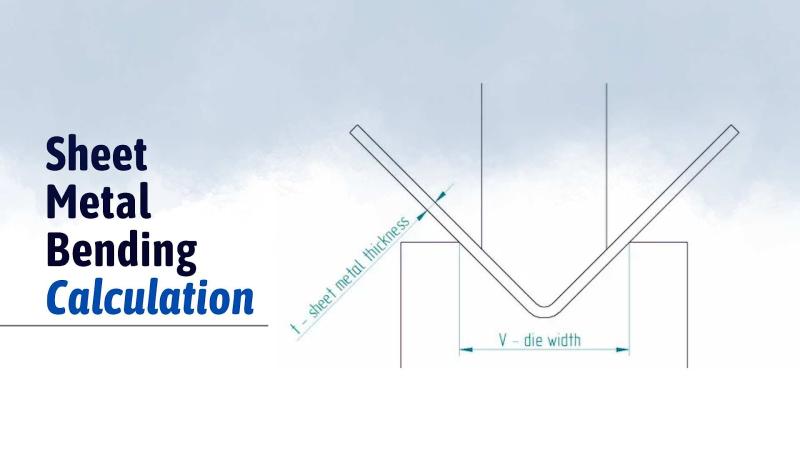

Metal sheets can be shaped by various techniques, including bending to form an angle or curve. Bending utilizes a punch and die in a press brake or bending machine to deform the metal to the desired angle, while retaining the overall strength of the metal. However, bending will require adjustments to accommodate the fact that the metal will stretch on the outside of the bend while compressing on the inside of the bend. If these adjustments are not considered, then inaccuracies may occur, such as incorrect measurements or spring back.

Standard Methods of Sheet Metal Bending

Here are the common methods of sheet metal bending.

Air Bending

Air bending forces the sheet into a V-shaped die, but does not fully push it down into the die. Only a few areas of the sheet come into contact with the die. It uses less pressure and allows for flexibility in bending angles, resulting in minimal cost to create new dies. It also provides versatility for small batch products and/or products with frequent design changes.

Bottoming

Bottoming forces the sheet into the die until the sheet is flush with the die. It creates exact and repeatable angles, which makes it optimal for continuous production. Since the entire surface of the sheet contacts the die, more pressure is required. In addition, special care should be taken to minimise any slight cracking and stress lines that may develop with harder metals.

Roll Bending

Roll Bending is a bending method where the sheet is passed through a set of rollers to produce curved and cylindrical pieces. Roll bending is typically used for making pipes/tubes and large panels. It is well-suited for thicker and longer materials; however, it can be challenging if the rollers do not pass evenly over the material. This may result in warped or twisted curves. By adjusting the space between the rollers and the roller speed, roll bending produces even and consistent shapes.

Sheet Metal Bending Calculation https://proleantech.com/sheet-metal-bending-calculation-explain/ : How to Calculate Bends

As you bend sheet metal, the material will experience both compression and tension. As such, you must determine how much the material expands/contracts so that you can produce the accurate final product size. There are different design programs available today that have a Bend Calculation feature to assist with this calculation. This feature indicates the amount of adjustment that must be made to the flat sheet so that the bent product matches your original drawing.

K-Factor

K-Factor is a number that describes where the neutral axis of the material lies between the inside and outside of the bend. The K-Factor helps determine how far the material will expand. The K-Factors can be found in a table for the most common materials. Most commonly, the K-Factor is simply entered as a value to perform the bend calculations.

Formula for bending sheet metal (K-Factor)

Mathematically, the K-Factor is defined as follows:

K-Factor is the distance from the Neutral Axis to/Material Thickness

Bend Allowance

Bend allowance is the amount of expansion that occurs on the outside of the bend. Bend allowances are used to determine the flat length of the sheet for bending. Bend allowance calculations can be particularly helpful in obtaining an accurate final product dimension, especially when your material behaves predictably.

Bend allowance formula

Typical formulas for Bend Allowance include:

BA=π/180×R×(A+B)

Where,

● BA = Bend Allowance (inches or mm) R = Bend Radius (inches or mm)

● A = Angle of Bend (degrees)

● B = Material Thickness (inches or mm)

Bend Deduction

Bend deduction represents the difference between the flat sheet length and the neutral line after bending. Bend deductions can be beneficial when the size of the inside bend is critical. They allow you to anticipate the final size, ensuring the part fits properly into an assembly or attaches to other components.

The formula for Bend Deduction is:

BD=(A×B)+(BA×2)

Where,

● BD = Bend Deduction A = Angle of Bend

● B = Material Thickness BA = Bend Allowance

Sheet Metal Bending Design Tips

Careful planning is required when designing sheet metal parts that will be bent. Errors in the design can result in low-quality bends, distortion, or misaligned features. The following list identifies some of the significant considerations to take into consideration when designing for bending to make bending easier and increase the accuracy of the part.

Minimum Flange Length

Each flange on a bent sheet metal part has a minimum length that depends upon the thickness of the material. Refer to a Bend Allowance chart to determine the appropriate die width. Designing flanges that are smaller than the minimum standards for your material can make the part difficult to assemble, hinder bending, and may also result in a low-quality edge. Ensure that the flange length is at least equal to the minimum standard for your material.

Chamfered Edges

When adding chamfers to flanges, leave enough material adjacent to the bend line. Do not extend the chamfer to the bend line because this can compromise the strength of the edge and affect the angle of the bend. Combining adequate flange length with proper chamfering techniques will result in a clean bend, and the part will remain true to the intended shape.

Hole Position Relative to Bend

Holes located too close to a bend, particularly those with irregular shapes, can cause warping or improper alignment of the bolt fitting. Keep holes at a sufficient distance from the bend line and follow the minimum flange length recommendations in bending force charts to ensure proper alignment and prevent deformation during bending.

Symmetry in Design

Parts designed to be symmetrical around a bend will be easier to bend and will reduce the potential for errors when bending. When possible, design parts to be symmetrical around the bend. In cases where a design cannot be symmetrical, provide clear visual indications or directions to guide the operator to ensure that the bend is made in the correct direction and that the finished shape is as intended.

Small Flanges on Large Parts

It can be difficult to bend small flanges on large panels due to their size and weight. Handling large panels manually can result in increased costs and an increased potential for errors. Redesign or modify the panel layout to simplify bending and minimize complexity, thereby improving productivity and reducing strain on operators.

Summary

This article has covered the key concepts, calculations, methods, and design tips for effective sheet metal bending, including K Factor, bend allowance, bend deduction, bending techniques, and best practices to ensure accurate and high-quality bends.

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Sheet Metal Bending Calculation: All Factors Explained here

News-ID: 4352545 • Views: …

More Releases from Publiera

Best Crypto to Buy Now in January 2026: Solargy Presale Compared With Top Altern …

As January 2026 begins, more investors are starting to look beyond established cryptocurrencies and toward early-stage opportunities that are still developing. Market volatility has pushed many participants to rethink their strategies, especially after a year marked by uneven performance across major assets. As a result, discussions around the best crypto to buy now https://solargy.io/ are increasingly centered on presale projects that offer early exposure before wider market adoption.

Crypto presales have…

Buy Old Gmail Accounts - 100% Verified & Aged for Reliability

In today's digital landscape, having a reliable email account is essential for both personal and professional communication. With the growing need for online presence, many individuals and businesses are turning to old Gmail accounts https://usaallit.com/product/buy-old-gmail-accounts/ as a practical solution. But what exactly makes these aged accounts so appealing? If you've ever wondered whether it's worth investing in an old Gmail account or how to go about acquiring one, you're…

The Essential Role of MEP Design Consultants in Modern Construction Projects

The Essential Role of MEP Design Consultants in Modern Construction Projects

In the intricate world of building design and construction, MEP Design Consultants https://www.aha-engineers.com/service/mep-fp-design/ serve as the specialized experts who bring mechanical, electrical, plumbing, and fire protection systems to life. These professionals ensure that buildings function efficiently, safely, and sustainably-from high-performance labs and data centers to healthcare facilities, educational campuses, and commercial offices.

As we progress through 2026, with stricter energy codes,…

Mjolnex Highlights the Shift Toward Operational Discipline in Modern Trading Pla …

As financial platforms continue to evolve, a noticeable shift is taking place across the industry: operational discipline is increasingly valued alongside speed and accessibility. Market participants are paying closer attention to how platforms are structured internally, how processes are governed, and how reliably systems perform under varying conditions. Mjolnex offers a relevant case study in how this shift is being reflected in platform design and operational priorities.

From Feature Expansion to…

More Releases for Bend

Bend or Break: From Empires to Algorithms

ISBN: 979-8266536050

FOR IMMEDIATE RELEASE

1st October 2025

Newly-published: Bend or Break: From Empires to Algorithms - Lessons from History on How to Make Today's Societies More Resilient

About the book:

Why do some societies crumble under pressure while others rise stronger?

What can the past teach us about surviving the shocks of the future?

And how can humanity adapt in the age of AI?

From the fall of empires to the dawn of algorithms,…

Cut And Bend Equipment Market Size Analysis by Application, Type, and Region: Fo …

According to Market Research Intellect, the global Cut And Bend Equipment market under the Internet, Communication and Technology category is expected to register notable growth from 2025 to 2032. Key drivers such as advancing technologies, changing consumer behavior, and evolving market dynamics are poised to shape the trajectory of this market throughout the forecast period.

Due to the growing need for accurate and efficient steel processing in the construction industry, the…

Bend Insensitive Fiber Market - Industry Trends and Forecast to 2032

𝐓𝐡𝐞 𝐠𝐥𝐨𝐛𝐚𝐥 𝐁𝐞𝐧𝐝 𝐈𝐧𝐬𝐞𝐧𝐬𝐢𝐭𝐢𝐯𝐞 𝐅𝐢𝐛𝐞𝐫 𝐦𝐚𝐫𝐤𝐞𝐭 𝐰𝐚𝐬 𝐯𝐚𝐥𝐮𝐞𝐝 𝐚𝐭 𝐚𝐩𝐩𝐫𝐨𝐱𝐢𝐦𝐚𝐭𝐞𝐥𝐲 𝐔𝐒𝐃 𝟏𝟑.𝟑𝟓 𝐛𝐢𝐥𝐥𝐢𝐨𝐧 𝐢𝐧 𝟐𝟎𝟐𝟑 𝐚𝐧𝐝 𝐢𝐬 𝐩𝐫𝐨𝐣𝐞𝐜𝐭𝐞𝐝 𝐭𝐨 𝐫𝐞𝐚𝐜𝐡 𝐚𝐫𝐨𝐮𝐧𝐝 𝐔𝐒𝐃 𝟐𝟑.𝟔𝟒 𝐛𝐢𝐥𝐥𝐢𝐨𝐧 𝐛𝐲 𝟐𝟎𝟑𝟐, 𝐰𝐢𝐭𝐡 𝐚 𝐜𝐨𝐦𝐩𝐨𝐮𝐧𝐝 𝐚𝐧𝐧𝐮𝐚𝐥 𝐠𝐫𝐨𝐰𝐭𝐡 𝐫𝐚𝐭𝐞 (𝐂𝐀𝐆𝐑) 𝐨𝐟 𝐚𝐩𝐩𝐫𝐨𝐱𝐢𝐦𝐚𝐭𝐞𝐥𝐲 𝟔.𝟓𝟓% 𝐝𝐮𝐫𝐢𝐧𝐠 𝐭𝐡𝐞 𝐟𝐨𝐫𝐞𝐜𝐚𝐬𝐭 𝐩𝐞𝐫𝐢𝐨𝐝.

𝐁𝐞𝐧𝐝 𝐈𝐧𝐬𝐞𝐧𝐬𝐢𝐭𝐢𝐯𝐞 𝐅𝐢𝐛𝐞𝐫 𝐌𝐚𝐫𝐤𝐞𝐭 𝐎𝐯𝐞𝐫𝐯𝐢𝐞𝐰

The bend insensitive fiber market is witnessing steady growth due to increasing demand for high-speed data transmission and reliable connectivity solutions. These fibers are designed to…

Demand Analysis of Cut and Bend Equipment Market from 2027

Cut & bend equipment has numerous applications in the construction industry based on its different shapes, size, and quantities. Cut & bend equipment is used for cutting and bending purposes. The equipment helps in managing the inventory better which not only reduces the space requirement for keeping the rebars but also assists in saving costs associated with labor and wastage. Demand for integrated equipment for reinforcing processes is expected to…

Global Bend Fixtures Market Analysis by 2020-2025

Scope of the Report:

The global Bend Fixtures market size is expected to gain market growth in the forecast period of 2020 to 2025, with a CAGR of xx%% in the forecast period of 2020 to 2025 and will expected to reach USD xx million by 2025, from USD xx million in 2019.

Market segmentation

Bend Fixtures market is split by Type and by Application. For the period 2015-2025, the growth among segments…

Cut and Bend Equipment Market Size, Share, Development by 2024

Global Info Research offers a latest published report on Cut and Bend Equipment Market Analysis and Forecast 2019-2025 delivering key insights and providing a competitive advantage to clients through a detailed report. This report focuses on the key global Cut and Bend Equipment players, to define, describe and analyze the value, market share, market competition landscape, SWOT analysis and development plans in next few years.

To analyze the Cut and Bend…