Press release

Comparing Manual vs. Automatic Candy Production Line

Overview of Candy Production Processes [https://www.yuchomachine.com/candy-production-line/]Understanding Traditional Manual Candy MakingManual candy making is an intricate ballet of skill, patience, and instinct. Craftsmen meticulously boil, stretch, mold, and decorate each piece, often relying on generational knowledge rather than standardized protocols. The texture, flavor, and appearance of each confection bear the fingerprints of the artisan's personal touch, resulting in a product that feels alive and unique.

How Automatic Candy Production Lines [https://www.yuchomachine.com/automatic-hard-candy-depositing-production-line-from-yucho-product/] Revolutionized the Industry

The advent of automatic production lines [https://www.yuchomachine.com/gummy-production-line/] marked a seismic shift in the candy industry [https://www.yuchomachine.com/gummy-production-line/]. Mechanical precision replaced human variability, allowing for mass candy production [https://www.yuchomachine.com/gummy-production-line/] on a scale previously unimaginable. Machines now regulate temperature, shape products with uniformity, and package thousands of units within minutes, propelling confections from kitchens to global shelves with relentless speed.

Key Components of Manual and Automatic Systems

Manual systems hinge on hand tools: copper kettles, wooden paddles, silicone molds. Every step demands human intuition. Conversely, automatic systems integrate sophisticated machinery-extruders, cooling tunnels, enrobing machines-interwoven with programmable logic controllers (PLCs) that ensure consistency and minimize human intervention.

Manual Candy Production LinesThe Artistry Behind Manual Candy Making

Manual candy production is as much an art as it is a science. Each batch is an ephemeral masterpiece, shaped by variables like ambient humidity, subtle ingredient variations, and the nuanced techniques of the maker. There's an irreplaceable authenticity in handcrafted candy-imperfections are celebrated as hallmarks of genuine craftsmanship.

Benefits of Manual Candy Production: Customization, Craftsmanship, and Control

The flexibility of manual production enables unparalleled customization. Small-batch manufacturers can rapidly prototype new flavors, textures, and designs. Moreover, direct oversight empowers artisans to fine-tune recipes mid-production, ensuring an impeccable final product that resonates with niche audiences craving authenticity and exclusivity.

Challenges of Manual Lines: Labor-Intensive Work and Scalability Issues

However, manual production is not without its encumbrances. It demands a high degree of labor, skill, and endurance. Scaling up to meet surging demand without compromising quality proves a Herculean task. Production capacity is tethered to workforce availability and can be stymied by workforce fatigue or skill shortages.

Ideal Situations for Manual Production: Small Batches, Artisan Brands, and Specialty Products

Manual lines excel when exclusivity is paramount. Artisan brands, luxury confectioners, and seasonal specialty producers thrive on the manual model, leveraging the story and soul imbued in each piece to command premium pricing and forge deep connections with discerning customers.

Image: https://ecdn6.globalso.com/upload/p/1431/image_other/2025-04/photobank-3-1.jpg

Automatic Candy Production LinesHow Automation Transforms Candy Production Efficiency

Automation obliterates traditional bottlenecks. Complex operations-once executed in a painstaking, sequential manner-occur simultaneously across integrated systems. This synthesis results in staggering increases in throughput, allowing manufacturers to meet colossal orders with a fraction of the manpower.

Advantages of Automatic Lines: Speed, Consistency, and Cost-Effectiveness

The triad of speed, consistency, and economy underpins the allure of automatic production. Uniformity ensures that every piece of candy meets rigorous quality standards. Operational costs, though initially steep, are amortized over vast production volumes, drastically reducing the per-unit cost and enhancing profitability.

Common Hurdles in Automation: Initial Investment and Flexibility Limits

Yet, automation is not without formidable challenges. The upfront capital outlay for industrial-grade machinery can be staggering. Furthermore, automated systems often lack the flexibility of manual methods, requiring expensive retooling for new product lines or niche customizations.

Best Fit for Automation: Mass Production, High Demand, and Global Distribution

Automation is indispensable for enterprises targeting massive, homogenous markets. Companies supplying multinational retailers or dominating e-commerce platforms rely on automation to sustain consistent supply chains and satisfy the relentless appetite of global consumers.

Key Differences Between Manual and Automatic Candy ProductionProduction Speed and Volume: How They Stack Up

Manual production is inherently slow and intimate, suited to limited quantities. In contrast, automatic lines can churn out tons of candy daily, maintaining breakneck production speeds essential for mainstream retail and international markets.

Quality Control: Handcrafted Perfection vs. Machine Precision

While handcrafted candies exude personality, they are susceptible to minor inconsistencies. Automated lines, governed by precise tolerances, deliver unwavering uniformity-crucial for brands prioritizing predictability and minimizing customer complaints.

Flexibility and Product Variety: Adapting to Trends and Custom Orders

Manual systems outshine in flexibility, swiftly pivoting to produce avant-garde designs or trending flavors. Automatic systems, although capable of adaptation, often involve complex and costly modifications that deter rapid experimentation.

Cost Considerations: Short-Term vs. Long-Term Investments

Manual operations incur lower startup costs but higher ongoing labor expenses. Automation demands significant initial investment yet promises lower operational costs over time, culminating in superior long-term profitability for high-volume producers.

Workforce Requirements: Skilled Artisans vs. Machine Operators

Manual production is reliant on skilled artisans whose craftsmanship defines the product's essence. Automated lines, by contrast, depend on trained operators and technicians proficient in machine maintenance and system optimization, shifting the labor paradigm from artistry to engineering.

Choosing the Right Production Line for Your BusinessFactors to Consider: Budget, Brand Identity, and Growth Goals

Selecting between manual and automatic production demands a holistic evaluation of business aspirations. Budgetary constraints, brand positioning-whether premium or mainstream-and projected growth trajectories must align with the chosen production methodology.

Case Studies: Success Stories from Manual and Automated Candy Makers

Artisanal brands like Hammond's Candies have built loyal followings by embracing traditional techniques, while giants such as Haribo dominate through industrial automation. Each path offers a blueprint for success, contingent upon aligning production strategy with market expectations.

Future-Proofing Your Production Line: Trends in Candy Manufacturing

Emerging technologies like modular production lines, AI-driven quality control, and eco-friendly manufacturing are reshaping the industry. Savvy manufacturers are investing in adaptable systems that can evolve with shifting consumer tastes and regulatory landscapes.

Media Contact

Company Name: Shanghai Yucho Industrial Co., Ltd.

Email:Send Email [https://www.abnewswire.com/email_contact_us.php?pr=comparing-manual-vs-automatic-candy-production-line]

Country: China

Website: https://www.yuchomachine.com/

Legal Disclaimer: Information contained on this page is provided by an independent third-party content provider. ABNewswire makes no warranties or responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you are affiliated with this article or have any complaints or copyright issues related to this article and would like it to be removed, please contact retract@swscontact.com

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Comparing Manual vs. Automatic Candy Production Line here

News-ID: 4351513 • Views: …

More Releases from ABNewswire

McKayLawTx.com Named Top Choice Car Accident Attorney for Car Accident Victims A …

Local Personal Injury Firm's Deep Community Roots and Proven Track Record Set New Standard for Client Care in Sulphur Springs, Greenville, Paris, Longview, and Tyler

SULPHUR SPRINGS, TX - January 14, 2025 - McKay Law PLLC, a leading personal injury law firm serving East Texas communities, is being recognized as the premier choice for car accident victims across the region, with clients from Hopkins, Hunt, Lamar, Gregg, and Smith Counties citing…

Can Muslims Eat Marshmallows? Industry Trends and Best Practices

Beyond the Fluff: A Thoughtful Look at Marshmallows and the Muslim Table

To understand the dilemma, one must start with the ingredient that gives the modern marshmallow its signature bounce: gelatin. Derived typically from the collagen of animals, often pigs or non-ritually slaughtered cattle, gelatin sits at the heart of the issue. For a devout Muslim, consumption is not merely about physical sustenance but an act of spiritual integrity. The Quranic…

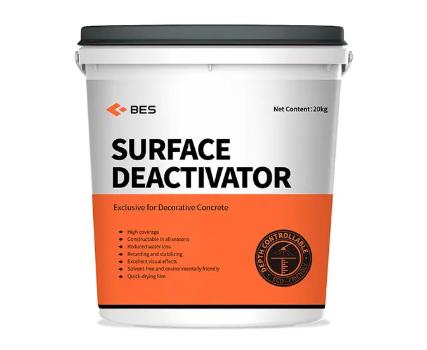

The Future of Concrete Surface Treatment: Eco-Friendly Passivators

In the construction industry, achieving both efficiency and sustainability is a constant challenge. With the rise of green building practices, innovative materials are revolutionizing traditional methods. One such advancement is the multi-functional eco-friendly passivator-a cutting-edge solution for concrete surface treatment.

Image: https://ecdn6.globalso.com/upload/p/44/image_product/2025-02/1-5.png

What Makes This Passivator Special?

Unlike conventional methods, BES Surface Deactivator [https://www.besdecorative.com/surface-deactivator-product/] offers multiple benefits in a single application:

Delays surface setting: Allows more time for intricate designs and custom textures.

No need…

Xiongqi Seal Refrigerated Truck Door Gasket: Ensuring Precision in the Cold Chai …

Introduction: The Critical Role of Sealing [https://www.xqsealingstrip.com/products/] in Cold Chain Integrity

In the global supply chain for perishable goods-from pharmaceuticals and fresh produce to frozen foods and sensitive chemicals-the refrigerated truck is a mobile, temperature-controlled sanctuary. Its performance hinges on one often-overlooked component: the door seal, or gasket. More than just a strip of rubber, it is the primary guardian of thermal efficiency, cargo safety, and operational compliance. The Xiongqi Seal…

More Releases for Manual

Emerging Trends Influencing The Growth Of The Manual Car Charger Market: Technol …

The Manual Car Charger Market Report by The Business Research Company delivers a detailed market assessment, covering size projections from 2025 to 2034. This report explores crucial market trends, major drivers and market segmentation by [key segment categories].

How Big Is the Manual Car Charger Market Size Expected to Be by 2034?

The manual car charger market has shown steady growth, projected to increase from $9.89 billion in 2024 to $10.29 billion…

Aerotaxis: 100% Autonomous or Manual Control?

Image: https://www.getnews.info/wp-content/uploads/2024/07/1720433314.jpeg

Embention stands out as a leading company in the autonomous aerial vehicle sector

Technological advancements in aviation have led to the development of aerotaxis, aerial vehicles designed for passenger transport in urban environments. These innovative means of transportation promise to significantly reduce travel times and alleviate ground traffic congestion. However, should aerotaxis be 100% autonomous or manually piloted?

Autonomous Aerotaxis

Autonomous aerotaxis offer a futuristic vision of urban air mobility. These self-piloted…

Manual Resuscitators Market

Global Manual Resuscitators Market analysis report encompasses the growth factors of the worldwide market based on end-users. Also, the industry changing factors for the market segments are explored in this report. The report forecasts the innovative applications of the product market on the basis of several estimations. This industry report also provides market price analysis and value chain features. The market research performed over here was provided for leading growth…

Manual Micromanipulator Market 2021 | Detailed Report

According to Market Study Report, Manual Micromanipulator Market provides a comprehensive analysis of the Manual Micromanipulator Market segments, including their dynamics, size, growth, regulatory requirements, competitive landscape, and emerging opportunities of global industry. An exclusive data offered in this report is collected by research and industry experts team.

Get Free Sample PDF (including full TOC, Tables and Figures) of Manual Micromanipulator Market @ https://www.reportsnreports.com/contacts/requestsample.aspx?name=5062782

The report provides a comprehensive analysis of…

Building Openings Construction Manual

Every architect has to reflect on building openings, since every house has windows and doors. They are the interface between indoor and outdoor spaces, essential functional and design elements of facades which provide light, ventilation and climate control. What sounds so simple has become a highly complex matter in times of energy planning. DETAIL is now publishing a comprehensive standard and reference work on the subject: the Building Openings Construction…

Manual soldering oven cleaning video

ZESTRON Europe, the global leading provider of high precision cleaning products, services and training solutions in the electronics manufacturing and semiconductor industries, has released a new instructional video on manual soldering oven cleaning on their YouTube channel. This video details how to use the water-based cleaning agent, VIGON® RC 303. This cleaning agent was developed specifically for manual removal of residues in reflow ovens and wave solder machines. It successfully…