Press release

Aerospace Cold Forgings: The Strong, Silent Force Behind Modern Aircraft

Introduction: Why Aerospace Cold Forgings Matter More Than EverAerospace cold forgings might not sound thrilling, but this stuff is crucial for keeping planes in the air safely. We're talking about high-strength, lightweight, fatigue-resistant parts that go into critical aircraft and spacecraft components. The market was worth USD 4.1 billion last year, should hit USD 4.3 billion in 2025, and is headed toward USD 6.68 billion by 2035-growing about 5.1% annually. Commercial flying is bouncing back, defense budgets keep growing, and aircraft makers are obsessed with fuel efficiency. Cold forging has become the preferred way to make precision components like engine shafts, landing gear parts, fasteners, and structural pieces while barely wasting any material.

Download sample report here: https://www.meticulousresearch.com/download-sample-report/cp_id=6245

Aerospace Cold Forgings Market Size and Forecast

The numbers show steady growth. From USD 4.1 billion in 2024 to USD 4.3 billion this year, eventually reaching USD 6.68 billion by 2035 at 5.1% yearly. It won't make headlines with explosive growth, but that's the point-this market is built on reliable, long-term manufacturing needs, not whatever's trendy this quarter.

What Are Aerospace Cold Forgings?

Cold forging means shaping metal at room temperature to create components with incredible strength, perfect dimensions, and resistance to fatigue. Unlike machining or casting, it actually improves the metal's internal grain structure and mechanical properties-crucial when you're making parts that absolutely cannot fail. These components end up in engines and turbines, landing gear, structural airframe pieces, and hydraulic and fuel systems.

Key Drivers Fueling Growth in the Aerospace Cold Forgings Market

Aircraft makers constantly try to shave off weight without compromising strength. Cold forging helps aluminum and titanium alloys achieve amazing strength-to-weight ratios, translating to better fuel efficiency and performance.

Browse in Depth: https://www.meticulousresearch.com/product/aerospace-cold-forgings-market-6245

Titanium alloys like Ti-17 can handle yield strengths over 1,150 MPa, perfect for turbine shafts and engine parts. Airlines love this because it means burning less fuel and producing fewer emissions. Air travel just keeps growing-we had 4.8 billion passengers in 2024, beating pre-pandemic numbers. The world's aircraft fleet is expected to jump from 31,000 planes today to over 41,100 by 2034. Boeing, Airbus, and other major manufacturers increasingly count on cold-forged components for performance, durability, and safety. The technology itself has gotten way more sophisticated with CNC-controlled presses, AI systems inspecting quality, and advanced die materials. These improvements mean factories work more efficiently, create more complex shapes, and waste less material.

Recent Developments Accelerating Market Momentum

Last year, Rolls-Royce announced they're manufacturing lightweight aerospace components using advanced titanium cold forging techniques. Their new alloys cut engine weight while staying just as strong, directly improving fuel efficiency and reducing emissions. Around the same time, GKN Aerospace rolled out an advanced cold forging method using high-strength aluminum alloys that wastes less material and makes parts more durable-good for both cost savings and the environment.

Market Restraints and Challenges

The big barrier is upfront cost. Cold forging requires serious investment in specialized equipment and tooling. Sure, you save money long-term, but that initial capital requirement can shut out smaller suppliers. There are also technical limitations-cold forging doesn't work for every metal alloy or really large components. When that happens, manufacturers fall back on alternatives like hot forging. For example, massive titanium bulkheads in military aircraft usually get hot-forged because they're too big for cold forging processes.

Regional Analysis:

Where Demand Is Strongest

North America dominates, thanks to heavy defense spending, major aircraft manufacturers, and expertise in advanced materials. Manufacturers make critical components for fighter jets, transport planes, and space systems. Europe comes second, with aerospace hubs in France, Germany, and the UK driving demand. Companies supplying programs like the Airbus A350 XWB and Rafale fighter jet use more cold-forged titanium and aluminum parts to meet efficiency targets. The U.S. specifically benefits from steady production of both commercial planes and defense aircraft-programs like the 737 MAX and KC-46 Pegasus tanker create consistent demand for cold-forged engine shafts, landing gear, and structural assemblies.

Segment Analysis: Materials and Applications

Aluminum alloys grab 40-45% of the market because they're light, easy to shape when cold, and get incredibly strong after heat treatment. The 7000-series aluminum alloys like 7075 and 7050 show up everywhere in fuselage frames, wing ribs, and landing gear components. Engine components make up 30-40% of demand because those parts have to survive extreme temperatures and stresses. Cold-forged compressor blades and discs handle 40-50% more fatigue than the same parts made by casting or machining-a huge advantage when failure isn't an option.

Buy the Complete Report with an Impressive Discount:

https://www.meticulousresearch.com/view-pricing/1562

Competitive Landscape: Key Players Shaping the Market

The market's run by established manufacturers who really know advanced materials and precision engineering. The big names are Precision Castparts, Arconic, ATI, VSMPO-AVISMA, and Bharat Forge. These companies focus on developing advanced alloys, automating processes, and building long-term partnerships with aircraft manufacturers to lock in steady business.

Conclusion: A Reliable Growth Market for Aerospace Manufacturing

The aerospace cold forgings market isn't flashy, but it's fundamental to how we build aircraft and spacecraft. Growth is steady, but demand for lightweight, high-strength components keeps climbing, aircraft fleets keep expanding, and technology keeps improving. For manufacturers, suppliers, and investors, you get stable demand, high barriers protecting profit margins, and perfect alignment with the industry's push toward fuel efficiency and sustainability. As aircraft designs evolve and we keep building more planes globally, cold forging will remain the reliable, precise manufacturing method keeping everything safe and efficient in the sky.

Related Reports:

Aerospace 3D Printing Market: https://www.meticulousresearch.com/product/aerospace-3d-printing-market-6244

Aerospace and Defense C-Class Parts Market: https://www.meticulousresearch.com/product/aerospace-and-defense-c-class-parts-market-6168

About Us:

We are a trusted research partner for leading businesses worldwide, empowering Fortune 500 organizations and emerging enterprises with actionable market intelligence tailored to drive revenue transformation and strategic growth. Our insights reveal forward-looking revenue opportunities, providing our clients with a competitive edge through a diverse suite of research solutions-syndicated reports, custom research, and direct analyst engagement.

Each year, we conduct over 300 syndicated studies and manage 60+ consulting engagements across eight key industry sectors and 20+ geographic markets. With a focus on solving the complex challenges facing global business leaders, our research enables informed decision-making that propels sustainable growth and operational excellence. We are dedicated to delivering high-impact solutions that transform business performance and fuel innovation in the competitive global marketplace.

Contact Us:

Meticulous Market Research Pvt. Ltd.

1267 Willis St, Ste 200 Redding,

California, 96001, U.S.

Email- sales@meticulousresearch.com

USA: +1-646-781-8004

Europe: +44-203-868-8738

APAC: +91 744-7780008

Visit Our Website: https://www.meticulousresearch.com/

For Latest Update Follow Us:

LinkedIn- https://www.linkedin.com/company/meticulous-research

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Aerospace Cold Forgings: The Strong, Silent Force Behind Modern Aircraft here

News-ID: 4348725 • Views: …

More Releases from Meticulous Research®

Global High-Barrier Films Market for Food Packaging: Trends, Applications, and G …

The global high-barrier films market for food packaging has experienced notable growth over the past several years, driven by evolving consumer preferences, technological advancements, and increasing demand for packaged food products. In 2025, the market was valued at approximately USD 25.2 billion. High-barrier films, designed to provide superior protection against oxygen, moisture, light, and other environmental factors, are essential for preserving the flavor, texture, and nutritional value of food products.…

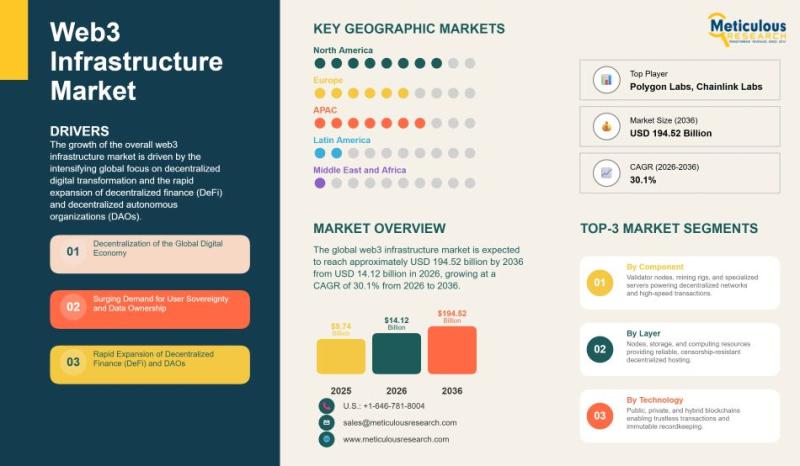

Global Web3 Infrastructure Market Analysis and Forecast (2026-2036)

The global web3 infrastructure market is experiencing rapid growth, driven by a shift toward decentralized digital transformation and the increasing adoption of decentralized finance (DeFi) and decentralized autonomous organizations (DAOs). In 2025, the market was valued at approximately USD 9.74 billion, and it is expected to grow to around USD 14.12 billion in 2026. By 2036, the market is projected to reach USD 194.52 billion, expanding at a compound annual…

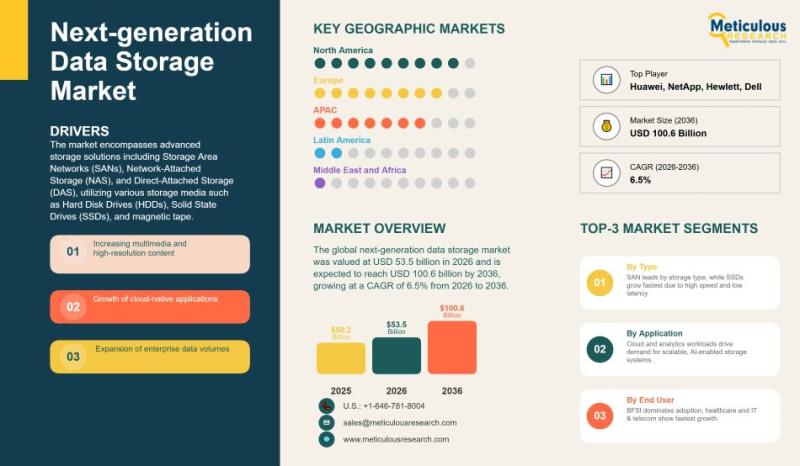

Global Next-Generation Data Storage Market Forecast 2026-2036: Trends, Drivers, …

The global next-generation data storage market is witnessing substantial growth as organizations increasingly grapple with massive volumes of digital information and the need for efficient, scalable storage solutions. In 2026, the market was valued at USD 53.5 billion and is expected to reach USD 100.6 billion by 2036, growing at a compound annual growth rate of 6.5%. This market includes a variety of advanced storage technologies, such as Storage Area…

Global Natural Sausage Casings Market 2026-2036: Trends, Growth Drivers, Applica …

The market for natural sausage casings has been growing steadily over the past few years, and it doesn't seem to be slowing down anytime soon. In 2025, it was worth about USD 2.61 billion, and estimates show it could hit USD 3.36 billion by 2036. Even in 2026, the market is expected to be around USD 2.67 billion, growing at a slow but steady pace of roughly 2.3% a year.…

More Releases for Aerospace

Aerospace Wiring Harness Market will reach $4.1 billion by 2032: Amphenol Aerosp …

The Latest published market study on Global Aerospace Wiring Harness Market provides an overview of the current market dynamics in the Aerospace Wiring Harness space, as well as what our survey respondents- all outsourcing decision-makers- predict the market will look like in 2032. The study breaks the market by revenue and volume (wherever applicable) and price history to estimate the size and trend analysis and identify gaps and opportunities. Some…

Aerospace Composites Market Future Growth Insight And Competitive Outlook 2025 | …

The Global Aerospace Composites Market is expected to reach USD 57.04 billion by 2025, from USD 26.90 billion in 2017, growing at a CAGR of 9.4% during the forecast period of 2018 to 2025. The upcoming market report contains data for historic years 2015 & 2016, the base year of calculation is 2017 and the forecast period is 2018 to 2025.Global Aerospace Composites Market, By Fibre Type (Carbon, Glass, Ceramic),…

Aerospace Evacuation Market 2025 By Top Key Players UTC Aerospace Systems, Zodia …

Asia Pacific will witness a significant growth rate in the aerospace evacuation market place over the forecast timeframe. This is attributed to the increasing air travel coupled with investments in aviation industry across the region. International Air Transport Association (IATA) estimates that the region will have around 3.5 billion passengers by 2036.

Europe aircraft evacuation market holds substantial share with the expansion of airlines. In August 2018, Wizz Air announced expansion…

Aircraft Evacuation Market 2025 | UTC Aerospace Systems, GKN Aerospace, Zodiac A …

Asia Pacific aircraft evacuation market share will witness a significant growth owing to increasing demand for air travel. Further, as per IATA, the region is witnessing an annual increase of around 5.5% passenger traffic. Continuous investments by industry players for setting up of manufacturing facilities are further supporting the regional growth till 2025.

Europe aircraft evacuation market holds substantial share with the expansion of airlines. In August 2018, Wizz Air announced…

Aerospace Lavatory System Market Outlook to 2027 - Percival Aviation, Zodiac Aer …

The Aerospace Lavatory System Market research report analyzes factors affecting market from both demand and supply side and further evaluates market dynamics affecting the market during the forecast period i.e., drivers, restraints, opportunities, and future trend. The report also provides exhaustive Poter's five forces analysis.

Factors responsible to drive the growth of aerospace lavatory system is increase in the number of passengers has raised the demand for more commercial aircraft equipped…

Aerospace Control Surface Market - Spirit AeroSystems, Aernnova Aerospace, GKN A …

North America aerospace control surface market size is expected to lead owing to presence of key manufacturers in the region. Europe led by Germany, France, UK and Russia is estimated to witness significant growth in aerospace control surface market during the forecast timeframe. Advancement in technology with implementation of light weight composites allowing improved efficiency of aircraft will support the overall industry demand.

Aerospace control surface market can be segmented based…