Press release

Wire Extrusion Machine Market to Reach US$ 2.5 Bn by 2033, Says Persistence Market Research

The global wire extrusion machine market has emerged as a critical segment in the industrial machinery and cable manufacturing ecosystem. Wire extrusion machines are specialized equipment used to coat, insulate, and finish metal wires with polymeric or thermoplastic materials, ensuring durability, electrical insulation, and resistance to environmental factors. These machines are integral to the production of wires and cables for sectors such as power generation, telecommunications, automotive, construction, and renewable energy. With technological advancements and rising demand for high-performance cables, wire extrusion machines are evolving to provide higher precision, speed, and energy efficiency.Download Free Sample & Check the Latest Market Analysis: https://www.persistencemarketresearch.com/samples/24781

The global wire extrusion machine market size was valued at US$ 1.4 billion in 2026 and is expected to reach US$ 2.5 billion by 2033, growing at a CAGR of 8.7% from 2026 to 2033. This growth is fueled by the expanding need for durable and high-performance wiring solutions, particularly in renewable energy infrastructure, including solar and wind power grids. The accelerating adoption of electric vehicles (EVs) is another major factor, driving demand for extrusion machines capable of producing lightweight, high-voltage wiring harnesses with tight tolerances and robust insulation. Furthermore, Industry 4.0 integration and automation in cable manufacturing have enhanced the use of high-precision, energy-efficient extrusion equipment, enabling manufacturers to meet stringent quality standards and reduce operational costs.

From a product perspective, single-screw and twin-screw wire extrusion machines dominate the market, with twin-screw machines gaining traction for their superior mixing capabilities and ability to process high-performance polymers. Geographically, Asia Pacific leads the market due to its strong manufacturing base, rapid industrialization, and large-scale investments in renewable energy and automotive sectors. Countries such as China, India, and Japan benefit from a concentration of cable manufacturers and favorable government policies, which collectively drive demand for sophisticated extrusion equipment.

Key Highlights from the Wire Extrusion Machine Market Report

• The global wire extrusion machine market is projected to reach US$ 2.5 billion by 2033, growing at a CAGR of 8.7%.

• Rising investments in renewable energy infrastructure are driving demand for high-quality cable production.

• Accelerating electric vehicle adoption is increasing the need for advanced wire extrusion machines.

• Industry 4.0 integration and automation are enhancing efficiency and precision in extrusion operations.

• Expansion of fiber-optic and 5G telecommunications networks is fueling demand for specialized extrusion technologies.

• Asia Pacific dominates the market due to its large manufacturing base, growing industrialization, and government incentives.

Market Segmentation

The wire extrusion machine market can be segmented based on machine type, material compatibility, end-user industry, and automation level, reflecting distinct operational and performance requirements. By machine type, the market primarily consists of single-screw extrusion machines and twin-screw extrusion machines. Single-screw machines are widely used for standard insulation processes and cost-sensitive applications, providing reliable throughput and consistent quality. Twin-screw machines, in contrast, offer enhanced mixing, precise temperature control, and the ability to process high-performance polymers, making them suitable for demanding applications in renewable energy, automotive, and specialty cable manufacturing.

Based on material compatibility, extrusion machines are designed to process PVC, polyethylene (PE), polypropylene (PP), TPE, and specialty high-performance polymers. PVC and PE dominate due to their widespread use in general-purpose wiring and electrical insulation, while specialty polymers are increasingly used for high-voltage, lightweight, and fire-resistant cables required in EVs, aerospace, and industrial automation.

End-user segmentation includes power cable manufacturers, automotive wire producers, telecommunications cable manufacturers, and industrial wiring suppliers. Power cable manufacturers represent the largest segment due to the global expansion of renewable energy infrastructure, grid modernization, and increasing electricity demand. Automotive wire producers are witnessing high growth as EV adoption accelerates, requiring lightweight, durable, and high-voltage cables. Telecommunications, particularly fiber-optic and 5G networks, are also creating substantial demand for advanced extrusion equipment with precise diameter control and minimal defects.

Automation level is another key segment, ranging from semi-automatic machines to fully automated Industry 4.0-enabled extrusion lines. Fully automated machines are gaining momentum due to their ability to optimize process parameters in real-time, reduce human error, minimize material waste, and increase throughput, meeting the quality expectations of high-value applications.

Get a Customized Market View in One Click : https://www.persistencemarketresearch.com/request-customization/24781

Regional Insights

Asia Pacific dominates the global wire extrusion machine market, supported by a robust industrial ecosystem, strong infrastructure development, and rising demand from renewable energy and automotive sectors. China, India, and Japan are key contributors, with large-scale investments in cable manufacturing, renewable power generation, and electric vehicle infrastructure. Government incentives for industrial modernization and renewable energy adoption further reinforce the region's leadership in the market.

North America is another significant market, driven by technological advancement, high-quality manufacturing standards, and a well-established automotive and telecommunications industry. The United States, in particular, is witnessing increasing demand for high-performance wire extrusion machines to support EV production, 5G network expansion, and grid modernization projects. Advanced R&D capabilities and strong aftermarket services for machinery enhance market growth in this region.

In Europe, the market is shaped by strict quality standards, environmental regulations, and growing renewable energy investments. Germany, France, and Italy are key contributors, with a focus on energy-efficient and environmentally friendly extrusion technologies. Waterborne and low-emission processing systems are gaining traction due to regional sustainability requirements.

Latin America and Middle East & Africa represent emerging markets, experiencing gradual growth as industrialization and infrastructure development expand. Brazil, Mexico, and GCC countries are increasingly investing in power grid expansion, EV adoption, and industrial cable networks, driving demand for advanced extrusion machines despite lower overall market penetration.

Market Drivers

The wire extrusion machine market is primarily driven by the rapid expansion of renewable energy infrastructure, including solar, wind, and smart grids. High-performance, durable cables are essential for transmitting electricity efficiently, and reliable extrusion machines are critical to meet these demands. Manufacturers require machines capable of producing precise, defect-free insulation to ensure safety, reliability, and longevity of power transmission systems.

The accelerating adoption of electric vehicles (EVs) is another key driver. EVs require specialized wiring harnesses that are lightweight, high-voltage capable, and heat-resistant. Wire extrusion machines equipped with advanced process controls are necessary to produce these cables at scale while maintaining strict quality standards.

Additionally, the growing integration of Industry 4.0 and automation in cable manufacturing is enhancing productivity, precision, and efficiency. Smart extrusion machines with real-time monitoring, predictive maintenance, and energy optimization features are becoming essential for manufacturers aiming to reduce operational costs and ensure consistent quality.

The expansion of telecommunications networks, including fiber-optic and 5G infrastructure, also fuels demand. These networks require high-precision cables with exact dimensions and low defect rates, making advanced extrusion machinery indispensable.

Market Restraints

Despite robust growth, the wire extrusion machine market faces certain challenges. One of the key restraints is the high capital investment required for advanced extrusion equipment, particularly for twin-screw, fully automated, or Industry 4.0-enabled machines. Small and medium-sized manufacturers often find it difficult to invest in such high-cost machinery, which can limit adoption in price-sensitive markets.

Additionally, stringent environmental regulations on emissions, energy consumption, and material handling in regions like Europe and North America can increase compliance costs for manufacturers. This can slow the deployment of older, less-efficient machines and require continuous innovation and investment in cleaner technologies.

The complexity of operation and maintenance for advanced extrusion machines is another potential barrier. Highly automated and high-precision equipment requires skilled operators, regular calibration, and preventive maintenance, which can challenge manufacturers in regions with a limited skilled workforce.

Click to Purchase the Full Report & Start Exploring : https://www.persistencemarketresearch.com/checkout/24781

Market Opportunities

The wire extrusion machine market presents significant opportunities, particularly in the renewable energy sector. As solar farms, wind turbines, and smart grids proliferate globally, manufacturers will require high-performance cables, driving demand for specialized extrusion equipment. Machines capable of processing advanced polymers for high-voltage, durable insulation will see increased adoption.

The EV market also offers substantial growth potential. The rising adoption of electric cars, buses, and commercial vehicles globally is driving demand for lightweight, high-voltage wiring harnesses. Manufacturers investing in advanced extrusion technologies to produce these cables can capitalize on this growing segment.

Digitalization and smart factory integration present additional opportunities. The adoption of Industry 4.0 solutions, such as predictive maintenance, IoT-enabled monitoring, and automated process optimization, enables manufacturers to increase efficiency, reduce material waste, and meet stringent quality requirements. Companies offering smart, energy-efficient, and modular extrusion machines are well-positioned to gain a competitive edge in the evolving market.

Company Insights: Key Players and Competitive Landscape

The wire extrusion machine market is competitive and includes several multinational industrial machinery manufacturers that focus on technological innovation, service support, and global distribution. Leading companies are investing in advanced extrusion technologies, automation, and smart factory solutions to meet growing demand from high-value applications.

• Reifenhäuser Group

• Davis-Standard, LLC

• JSW Extrusion Co., Ltd.

• SIKORA AG

• Battenfeld-Cincinnati GmbH

• Milacron Holdings Corp.

• Bausano & Figli S.p.A.

• The Japan Steel Works, Ltd.

• KraussMaffei Berstorff GmbH

• Welex, Inc.

Recent developments highlight market innovation and expansion. One notable development is the launch of energy-efficient twin-screw extrusion machines designed for high-performance polymer wire insulation, which reduces energy consumption while improving product quality. Another is the expansion of regional service and R&D centers in Asia Pacific, aimed at supporting growing demand for advanced extrusion machines and providing localized maintenance and training services to manufacturers.

Technological Advancements

Technological innovation is transforming the wire extrusion machine market. Modern extrusion machines feature real-time process monitoring, precision temperature control, and automated adjustments to ensure consistent insulation thickness, smooth surfaces, and minimal defects. The use of high-performance polymers, flame-retardant materials, and lightweight composites in cable production necessitates machines capable of processing complex materials reliably.

The integration of Industry 4.0, IoT, and predictive maintenance allows manufacturers to optimize machine performance, reduce downtime, and monitor key operational parameters remotely. Smart extrusion lines enhance energy efficiency, minimize material waste, and support rapid changeovers for different cable sizes or materials.

UV-assisted curing, hot-die technology, and modular extruder designs are additional innovations that improve productivity, precision, and scalability. Manufacturers adopting these technologies are better positioned to meet the demands of EV wiring, renewable energy cables, and telecommunications networks.

Future Outlook

The wire extrusion machine market is poised for continued growth, driven by global trends in electrification, renewable energy, and telecommunications expansion. Manufacturers that invest in smart, automated, and energy-efficient extrusion technologies will gain a competitive advantage, especially in high-growth regions such as Asia Pacific and North America.

The increasing demand for lightweight, high-voltage, and fire-resistant cables for EVs and industrial applications will continue to shape product development. Furthermore, governments' push for sustainable manufacturing practices and energy-efficient equipment will create opportunities for innovation and differentiation in the market.

Related Reports:

https://www.persistencemarketresearch.com/market-research/mortar-fire-control-computer-market.asp

https://www.persistencemarketresearch.com/market-research/fire-pump-market.asp

https://www.persistencemarketresearch.com/market-research/security-screening-equipment-market.asp

https://www.persistencemarketresearch.com/market-research/pneumatic-valves-and-accessories-market.asp

https://www.persistencemarketresearch.com/market-research/hydraulic-fluid-connector-market.asp

https://www.persistencemarketresearch.com/market-research/north-america-manufactured-housing-market.asp

https://www.persistencemarketresearch.com/market-research/industrial-control-panel-market.asp

Persistence Market Research

Second Floor, 150 Fleet Street, London, EC4A 2DQ, United Kingdom

USA Phone: +1 646-878-6329

UK Phone: +44 203-837-5656

Email: sales@persistencemarketresearch.com

Web:

https://www.persistencemarketresearch.com

About Persistence Market Research:

At Persistence Market Research, we specialize in creating research studies that serve as strategic tools for driving business growth. Established as a proprietary firm in 2012, we have evolved into a registered company in England and Wales in 2023 under the name Persistence Research & Consultancy Services Ltd. With a solid foundation, we have completed over 3600 custom and syndicate market research projects, and delivered more than 2700 projects for other leading market research companies' clients.

Our approach combines traditional market research methods with modern tools to offer comprehensive research solutions. With a decade of experience, we pride ourselves on deriving actionable insights from data to help businesses stay ahead of the competition. Our client base spans multinational corporations, leading consulting firms, investment funds, and government departments. A significant portion of our sales comes from repeat clients, a testament to the value and trust we've built over the years.

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Wire Extrusion Machine Market to Reach US$ 2.5 Bn by 2033, Says Persistence Market Research here

News-ID: 4347298 • Views: …

More Releases from Persistence Market Research

Off-Highway Radiators Market to Reach US$ 7.2 Bn by 2033 as Leading Players Like …

The off-highway radiators market plays a vital role in ensuring efficient thermal management in heavy-duty equipment used across construction, agriculture, mining, and forestry sectors. These radiators regulate engine temperatures, prevent overheating, and support consistent equipment performance under extreme operating conditions. Growing mechanization and the expansion of infrastructure projects worldwide are increasing reliance on durable cooling systems. Equipment manufacturers are prioritizing high-performance radiators that offer reliability, longer service life, and resistance…

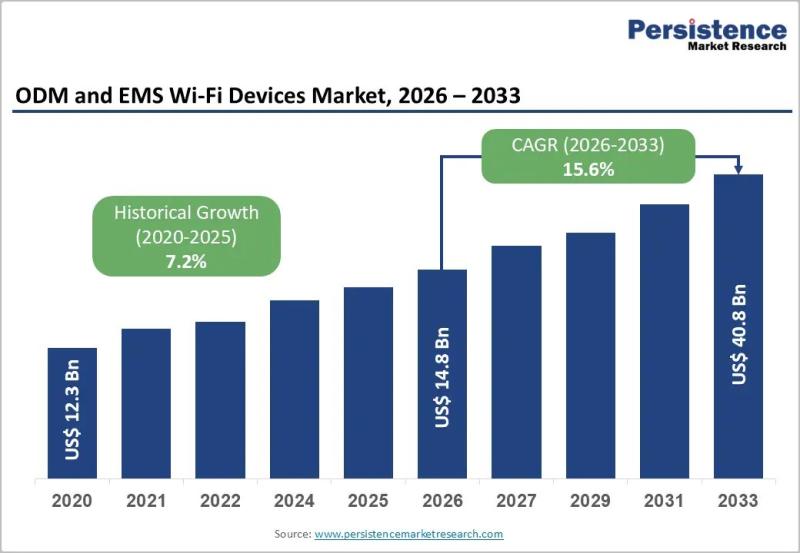

ODM and EMS Wi-Fi Devices Market to Reach US$ 40.8 Billion by 2033 at 15.6% CAGR

The global ODM and EMS Wi-Fi devices market is projected to be valued at US$ 14.8 billion in 2026 and is forecast to surge to US$ 40.8 billion by 2033, registering a robust CAGR of 15.6% between 2026 and 2033. This rapid growth reflects the accelerating demand for advanced wireless connectivity solutions across residential, enterprise, and industrial environments. The expansion of 5G infrastructure, enterprise digital transformation strategies, and large-scale IoT…

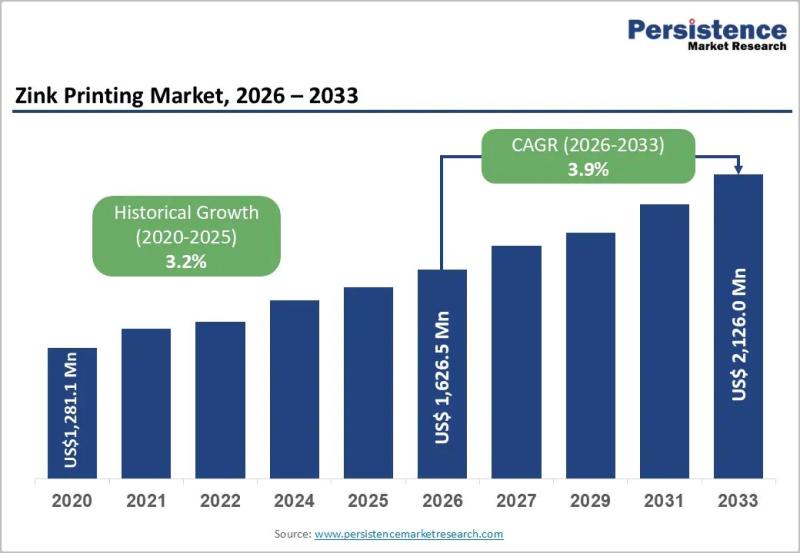

Zink Printing Market to Reach US$ 2,126.0 Million by 2033 at 3.9% CAGR

Zink Printing Market Size and Trends Analysis

The global Zink printing market is projected to be valued at US$ 1,626.5 million in 2026 and is expected to reach US$ 2,126.0 million by 2033, expanding at a CAGR of 3.9% between 2026 and 2033. Zink (Zero Ink) printing technology eliminates the need for ink cartridges by using heat-activated color crystals embedded within specialized paper. This innovation has positioned Zink printers as a…

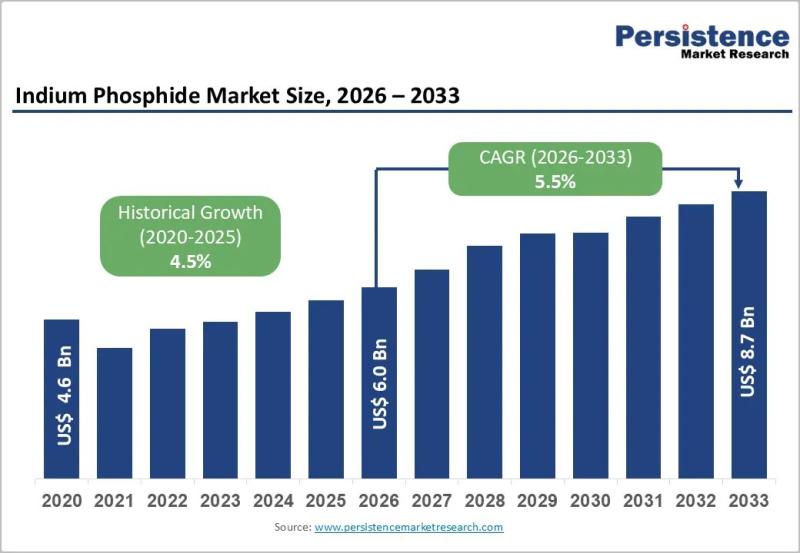

Indium Phosphide Market to Reach US$ 8.7 Billion by 2033 at 5.5% CAGR

The global Indium Phosphide (InP) market is poised for steady expansion, with its valuation expected to reach US$ 6.0 billion by 2026 and further grow to US$ 8.7 billion by 2033, registering a CAGR of 5.5% between 2026 and 2033. Indium phosphide, a high-performance compound semiconductor material, is widely used in optoelectronics, high-frequency electronics, and photonic integrated circuits (PICs). The market growth is largely fueled by the accelerating deployment of…

More Releases for Wire

Understanding Wire Electrical Discharge Machining (Wire EDM)

Wire Electrical Discharge Machining (Wire EDM) is a highly accurate and reliable method for cutting electrically conductive materials. Favored in industries like aerospace, automotive, medical device manufacturing, and mold making, this process allows for extremely precise cuts that are nearly impossible to achieve with traditional mechanical methods.

What Is Wire EDM?

Wire EDM-short for wire electrical discharge machining-is a non-contact machining process that uses a thin, electrically charged wire to cut through…

Steel Wire Rod and Wire Market

Market Overview:

The global steel wire rod and wire market was valued at USD 174.5 billion in 2022 and is projected to rise at a compound annual growth rate (CAGR) of 5.6% to reach USD 269.5 billion by 2030.

The increasing popularity of electric vehicles presents a new market for steel wire. EVs require specific steel wire materials for applications including electric motors, charging stations, and battery components. As EV usage continues…

Steel Wire Market 2021 Analysis by Global Manufacturers – Heico Wire Group, Al …

The "Steel Wire" Market report offers qualitative and quantitative insights and a detailed analysis of market size & growth rate for all possible segments in the market. The Global Steel Wire Industry presents a market overview, product details, classification, and market concentration. The report also provides an in-depth survey of key players in the market which is based on various competitive intelligence parameters like company profiles, product picture and specification,…

Global Specialty Wire Sales Market 2018:2025 - MWS Wire, Torpedo Specialty Wire, …

The Specialty Wire Sales market research report is a comprehensive emphasizing study of the industry

The Global Specialty Wire Sales market 2018-2025 report offers a extensive and precise estimates and forecasts study of Specialty Wire Sales industry along with the analysis of essential features providing key industry insights to the readers. The Specialty Wire Sales market research report further delivers an methodical outlook of the industry by studying key components impacting…

- 3M, Alpha Wire, Amphenol, Belden Wire $ Cable

Global Multiconductor Cable Sales Market 2018-2025 Research Report

The Global Multiconductor Cable Sales Market 2018 Report contains in depth information major manufacturers, opportunities, challenges, and industry trends and their impact on the market forecast. Multiconductor Cable Sales market also provides data about the company and its operations. This report also provides information on the Pricing Strategy, Brand Strategy, Target Client, Distributors/Traders List offered by the company

The Multiconductor Cable Sales research report…

Specialty Wire 2017 Global Market Key Players – MWS Wire, Torpedo Specialty Wi …

Specialty Wire SWOT Analysis And Forecast 2022

This report studies Specialty Wire in Global market, especially in North America, China, Europe, Southeast Asia, Japan and India, with production, revenue, consumption, import and export in these regions, from 2012 to 2016, and forecast to 2022.

This report focuses on top manufacturers in global market, with production, price, revenue and market share for each manufacturer, covering

MWS Wire

Torpedo Specialty Wire

Specialty Wire and Cable (SWC)

LANOCO Specialty…