Press release

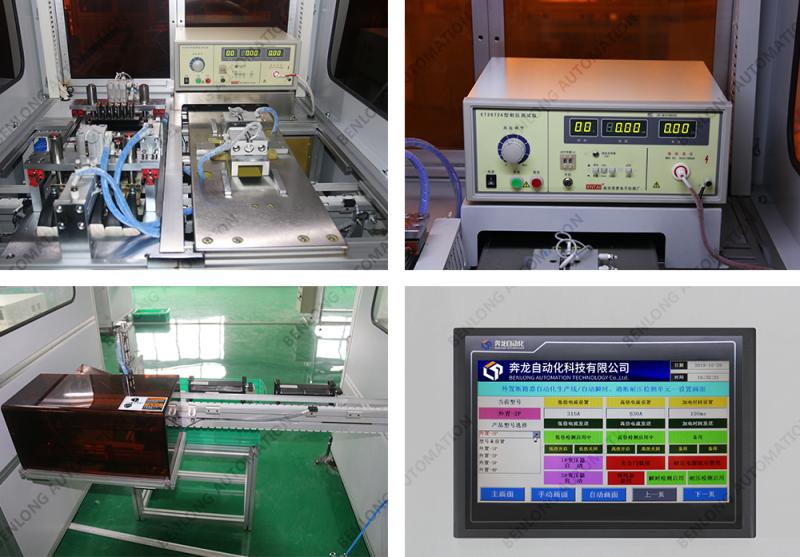

Benlong Unveils New Integrated Magnetic Trip & High-Voltage Testing Solution

In the competitive landscape of low-voltage electrical manufacturing, space optimization and cost control are just as critical as production speed. Traditionally, MCB (Miniature Circuit Breaker) assembly lines have required separate stations for Magnetic Trip (Instantaneous) testing and On-Off/High Voltage verification. While effective, this setup often leads to increased equipment costs and a larger factory footprint.Benlong Automation is proud to announce a game-changing solution: The Integrated Magnetic Trip & On-Off/High Voltage Testing Unit.

This innovative machine consolidates two of the most critical quality control processes into a single, robust frame. By combining the magnetic flux generation required for instantaneous tripping tests with the precision probes needed for dielectric strength and continuity checks, we have created a powerhouse station that streamlines the entire backend of the production line.

Breaking the Cycle Time Barrier A common concern with integrated stations is the potential for bottlenecks. Our engineering team has addressed this by optimizing the internal mechanical indexing system. The unit performs high-current magnetic testing and high-voltage isolation checks in a synchronized parallel sequence. The result? A combined operation that fits perfectly within the standard high-speed line cycle time, ensuring zero impact on your overall daily capacity.

Key Benefits for Manufacturers:

Reduced Capital Expenditure (CAPEX): Investing in one integrated machine is significantly more cost-effective than purchasing two separate units with their own feeding systems.

Space Saving: Free up valuable factory floor space for other operations or logistics.

Uncompromised Accuracy: Powered by advanced PLC controls and high-precision sensors, the unit adheres strictly to international IEC standards for MCB performance.

At Benlong Automation, we are committed to engineering solutions that make manufacturing smarter and leaner. This integrated testing unit represents our dedication to helping our global clients stay ahead of the curve.

For detailed technical specifications or to discuss how this unit can fit into your existing line, please contact our sales team today.

Image: https://ecdn6.globalso.com/upload/p/5095/image_other/2026-01/2-23.jpg

Media Contact

Company Name: Benlong Automation Technology Co., Ltd.

Email:Send Email [https://www.abnewswire.com/email_contact_us.php?pr=benlong-unveils-new-integrated-magnetic-trip-highvoltage-testing-solution]

Country: China

Website: https://www.benlongkj.com/

Legal Disclaimer: Information contained on this page is provided by an independent third-party content provider. ABNewswire makes no warranties or responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you are affiliated with this article or have any complaints or copyright issues related to this article and would like it to be removed, please contact retract@swscontact.com

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Benlong Unveils New Integrated Magnetic Trip & High-Voltage Testing Solution here

News-ID: 4344574 • Views: …

More Releases from ABNewswire

The Boston Brown Coffee Company Launches Lifestyle Merchandise Line Celebrating …

The Boston Brown Coffee Company introduces a premium merchandise collection featuring the brand's distinctive logo on high-quality apparel. The line includes t-shirts, hats, hoodies, and sweatshirts, allowing coffee enthusiasts to express their appreciation for exceptional beverage culture through stylish, comfortable clothing.

The Boston Brown Coffee Company has launched a thoughtfully designed merchandise collection that transforms its brand identity into wearable expressions of coffee culture appreciation. Featuring the company's beautifully crafted logo,…

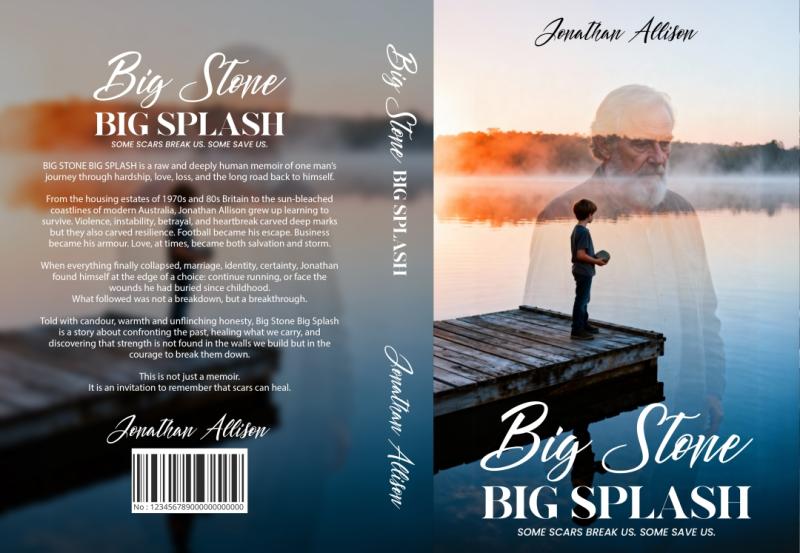

A Raw, Unflinching Memoir Big Stone Big Splash by Jonathan Allison Confronts Abu …

Australia - Feb 18, 2026 - The memoir Big Stone Big Splash by Jonathan Allison is a powerful new book that gives a very clear monologue of childhood abuse, addiction, violence, redemption, and self-understanding, which is a long road. Jonathan Allison follows his path with ruthless honesty and emotional clarity from a little boy in 1970s England who suffered from trauma to a man who is very resolute to eliminate…

The Boston Brown Coffee Company Brings World-Class Coffee Selection to Discernin …

The Boston Brown Coffee Company announces its expertly curated collection of exceptional coffees sourced from premier growing regions across the globe. Each selection offers distinct character and flavor profiles designed to match every coffee lover's unique preferences, from bold and robust to smooth and comforting varieties.

The Boston Brown Coffee Company has established itself as a destination for coffee enthusiasts seeking more than just their morning caffeine fix. By partnering with…

Chingu Vibe LLC Redefines Sustainable Fashion with Ethically Produced Apparel an …

Chingu Vibe LLC announces its emergence as a global lifestyle brand dedicated to connection and responsible living through ethically produced, sustainable apparel. The brand combines eco-conscious materials with transparent sourcing to create modern fashion that prioritizes environmental impact without sacrificing style or comfort.

Chingu Vibe LLC is transforming the fashion landscape with a bold commitment to sustainability, ethical production, and community connection. As consumers increasingly demand transparency and environmental responsibility from…