Press release

Cutting Oils Market Size US$ 2.3 Billion by 2033 Driven by Rising Metal Machining Demand across Automotive & Aerospace

Introduction to the Cutting Oils MarketThe cutting oils market plays a critical role in modern manufacturing and metalworking industries, acting as an essential support system for machining processes that demand precision, efficiency, and durability. Cutting oils, also known as metalworking fluids, are primarily used to lubricate and cool metal surfaces during operations such as drilling, milling, grinding, and machining. By reducing friction and heat generation, these oils enhance tool life, improve surface finish, and ensure dimensional accuracy. As global manufacturing activity continues to expand, particularly in automotive, aerospace, and defense sectors, the demand for high-performance cutting oils is steadily increasing.

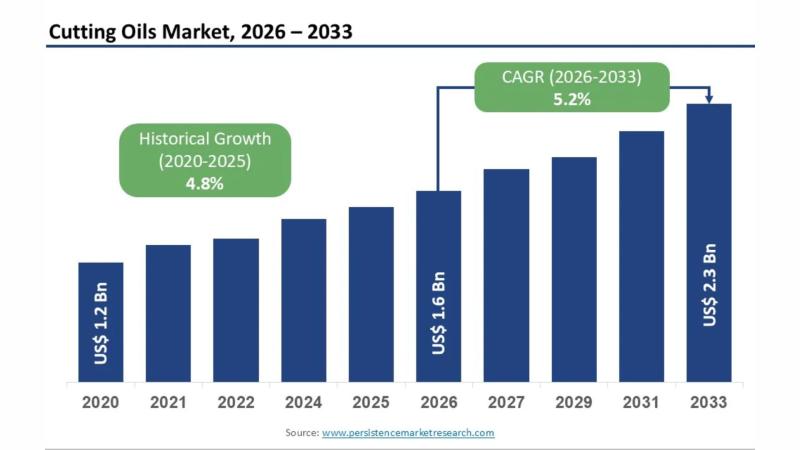

According to the latest study by Persistence Market Research, the global cutting oils market size is likely to be valued at US$ 1.6 billion in 2026 and is projected to reach US$ 2.3 billion by 2033, growing at a CAGR of 5.2% during the forecast period 2026-2033. This growth reflects the rising need for advanced lubrication solutions capable of supporting high-speed machining, harder alloys, and automated manufacturing systems. The market is also benefiting from technological advancements in fluid formulations that emphasize efficiency, sustainability, and worker safety.

Get Your FREE Sample Report Instantly - Click Now: https://www.persistencemarketresearch.com/samples/21175

Market Growth Drivers and Industry Dynamics

One of the primary drivers of growth in the cutting oils market is the steady expansion of the global automotive industry. With increasing vehicle production, especially in emerging economies, manufacturers are investing heavily in advanced machining operations that require reliable cutting fluids. Cutting oils help improve productivity by minimizing tool wear and reducing machine downtime, which is crucial in high-volume automotive manufacturing environments. Additionally, the growing adoption of electric vehicles is indirectly supporting market growth, as EV components require high-precision machining.

Another important growth factor is the rising demand from the aerospace and defense industries. These sectors rely heavily on high-performance materials such as titanium alloys, superalloys, and hardened steels, which generate excessive heat during machining. Cutting oils play a vital role in maintaining thermal stability and ensuring superior surface quality when working with such materials. Furthermore, increased defense spending across several regions and the recovery of commercial aviation are strengthening demand for advanced cutting oils designed for extreme operating conditions.

Technological Advancements and Product Innovation

Technological innovation is reshaping the cutting oils market, with manufacturers focusing on developing formulations that offer superior lubrication, cooling, and corrosion protection. Modern cutting oils are increasingly engineered to perform under high-speed and high-pressure machining conditions, enabling manufacturers to improve operational efficiency while maintaining quality standards. Additive technologies, such as extreme pressure additives and anti-wear agents, are being incorporated to enhance oil performance and extend tool life.

At the same time, environmental and regulatory pressures are encouraging the development of eco-friendly cutting oils. Traditional mineral oil-based products are gradually being complemented or replaced by bio-based and semi-synthetic alternatives that reduce environmental impact and improve workplace safety. These newer formulations generate less mist and fumes, lowering health risks for machine operators. As sustainability becomes a strategic priority across industries, the demand for low-toxicity, biodegradable cutting oils is expected to grow steadily.

Market Segmentation Overview

The cutting oils market is segmented based on product type, application, end-user industry, and region. Each segment plays a crucial role in shaping market demand and determining growth opportunities.

Market Segmentation

By Product Type

Neat Cuttings Oils

Water-Soluble Cuttings Oils

By Application

Machining

Grinding

Milling

Drilling

By End-User

Automotive

Aerospace

Defense

By Region

North America

Europe

East Asia

South Asia & Oceania

Latin America

Middle East & Africa

This segmentation highlights the diverse use cases of cutting oils across multiple industries and regions, reflecting the market's broad industrial relevance and adaptability.

Get a Customized Market View in One Click: https://www.persistencemarketresearch.com/request-customization/21175

Application-Based Demand Trends

Among applications, machining accounts for a significant share of the cutting oils market due to its widespread use across manufacturing industries. Machining operations generate high friction and heat, making effective lubrication essential for maintaining tool integrity and production quality. Cutting oils used in machining help achieve smoother finishes and tighter tolerances, which are increasingly demanded by high-precision industries.

Grinding, milling, and drilling also represent important application segments, each requiring specialized cutting oil formulations. Grinding operations, in particular, require oils with excellent cooling properties to prevent thermal damage to workpieces. Milling and drilling processes benefit from cutting oils that provide both lubrication and chip removal efficiency. As manufacturers continue to adopt multi-axis CNC machines and automated production lines, the need for application-specific cutting oils is expected to rise.

End-User Industry Insights

The automotive sector remains the dominant end-user of cutting oils, driven by large-scale production volumes and continuous innovation in vehicle design. From engine components to transmission systems, automotive manufacturing involves extensive metalworking operations that rely heavily on cutting oils. As automakers focus on lightweight materials and complex geometries, advanced cutting fluids become indispensable in maintaining efficiency and quality.

The aerospace and defense sectors, while smaller in volume compared to automotive, demand premium cutting oils due to stringent quality and safety requirements. Aerospace components often require machining of high-strength alloys with minimal tolerance for defects. Cutting oils used in these industries must deliver consistent performance under extreme conditions, making them high-value products within the overall market. Growth in defense manufacturing and aircraft production is therefore expected to positively influence cutting oil demand.

Regional Market Outlook

Regionally, North America and Europe represent mature markets for cutting oils, supported by well-established manufacturing industries and high adoption of advanced machining technologies. These regions also lead in terms of regulatory compliance and innovation, driving demand for high-performance and environmentally friendly cutting oils. The presence of major automotive and aerospace manufacturers further strengthens market stability in these regions.

East Asia and South Asia & Oceania are emerging as high-growth regions, fueled by rapid industrialization, expanding automotive production, and increasing foreign investments in manufacturing. Countries such as China and India are witnessing strong demand for cutting oils as they become global manufacturing hubs. Latin America and the Middle East & Africa, while relatively smaller markets, offer long-term growth potential due to infrastructure development and gradual industrial expansion.

Challenges and Market Constraints

Despite positive growth prospects, the cutting oils market faces several challenges. One of the key concerns is the environmental and health impact associated with conventional cutting oils. Improper disposal and exposure to harmful additives can pose risks to both the environment and workers. This has led to stricter regulations, which may increase compliance costs for manufacturers.

Another challenge is price volatility of raw materials, particularly mineral oils and additives. Fluctuations in crude oil prices can directly impact production costs and profit margins for cutting oil manufacturers. Additionally, the growing adoption of dry machining and minimum quantity lubrication (MQL) techniques may limit demand growth in certain applications, as these approaches aim to reduce or eliminate the use of cutting fluids.

Company Insights and Competitive Landscape

The cutting oils market is moderately competitive, with several global and regional players focusing on product innovation, strategic partnerships, and geographic expansion. Leading companies are investing in research and development to introduce advanced formulations that meet evolving industry requirements and regulatory standards.

Key players operating in the cutting oils market include

✦ Quaker Houghton

✦ Fuchs Petrolub SE

✦ BP Castrol

✦ TotalEnergies

✦ Chevron Corporation

✦ Shell Lubricants

✦ Indian Oil Corporation Limited

✦ Blaser Swisslube AG

✦ PETROFER Chemie

✦ Cimcool Industrial Products

✦ Henkel AG

✦ Exxon Mobil Corporation

✦ Sinopec Lubricant Company

✦ Master Chemical Corporation

These companies compete on factors such as product performance, sustainability, brand reputation, and global distribution networks.

For In-Depth Competitive Analysis, Buy Now: https://www.persistencemarketresearch.com/checkout/21175

Future Outlook of the Cutting Oils Market

Looking ahead, the cutting oils market is expected to witness steady growth driven by advancements in manufacturing technologies and increasing demand for precision machining. The integration of Industry 4.0 and smart manufacturing systems will further emphasize the need for high-quality cutting oils that ensure consistent performance and equipment longevity. Manufacturers that focus on innovation, sustainability, and customer-specific solutions are likely to gain a competitive edge.

With the global market projected to grow from US$ 1.6 billion in 2026 to US$ 2.3 billion by 2033 at a CAGR of 5.2%, the cutting oils market presents attractive opportunities for stakeholders across the value chain. As industries continue to evolve and demand higher efficiency, cutting oils will remain a vital component of modern manufacturing ecosystems.

Explore the Latest Trending Research Reports:

• Glass Reinforced Vinyl Ester Market Overview - https://www.persistencemarketresearch.com/market-research/glass-reinforced-vinyl-ester-market.asp

• Concrete Resurfacer Market Overview - https://www.persistencemarketresearch.com/market-research/concrete-resurfacer-market.asp

• Wood Preservative Chemicals And Coatings Active Ingredients Market Overview - https://www.persistencemarketresearch.com/market-research/wood-preservative-chemicals-and-coatings-active-ingredients-market.asp

Contact Us:

Persistence Market Research

Second Floor, 150 Fleet Street,

London, EC4A 2DQ, United Kingdom

USA Phone: +1 646-878-6329

UK Phone: +44 203-837-5656

Email: sales@persistencemarketresearch.com

Web: https://www.persistencemarketresearch.com

About Persistence Market Research:

At Persistence Market Research, we specialize in creating research studies that serve as strategic tools for driving business growth. Established as a proprietary firm in 2012, we have evolved into a registered company in England and Wales in 2023 under the name Persistence Research & Consultancy Services Ltd. With a solid foundation, we have completed over 3600 custom and syndicate market research projects, and delivered more than 2700 projects for other leading market research companies' clients.

Our approach combines traditional market research methods with modern tools to offer comprehensive research solutions. With a decade of experience, we pride ourselves on deriving actionable insights from data to help businesses stay ahead of the competition. Our client base spans multinational corporations, leading consulting firms, investment funds, and government departments. A significant portion of our sales comes from repeat clients, a testament to the value and trust we've built over the years.

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Cutting Oils Market Size US$ 2.3 Billion by 2033 Driven by Rising Metal Machining Demand across Automotive & Aerospace here

News-ID: 4340811 • Views: …

More Releases from Persistence Market Research

Ropes Market Set to Reach US$ 31.5 Billion by 2033, Expanding at 7.8% CAGR

The global ropes market continues to serve as a critical component across numerous industrial, commercial, and recreational sectors worldwide. Ropes, manufactured from natural fibers, synthetic materials, and steel wire, play an essential role in construction, marine operations, logistics, energy exploration, mining, and adventure sports. As infrastructure development accelerates and safety standards become more stringent, the demand for durable and high-performance ropes is rising steadily.

➤ Download Your Free Sample & Explore…

Disposable Cutlery Market Set to Reach USD 24.8 Billion by 2033: Driven by Susta …

The global disposable cutlery market has emerged as a resilient segment within the broader foodservice disposables industry, propelled by evolving consumer preferences, rising food delivery trends, and increased demand for convenience products. According to recent market estimates, the global disposable cutlery market size is likely to be valued at US$ 18.2 billion in 2026 and is projected to reach US$ 24.8 billion by 2033, growing at a CAGR of 4.5%…

Bamboo Market Set for Robust Global Growth through 2032 - Persistence Market Res …

The global bamboo market is on a strong upward trajectory as demand for sustainable, renewable materials continues to reshape industries worldwide. The market is projected to expand from an estimated US$ 74.5 billion in 2025 to US$ 102.8 billion by 2032, representing a compound annual growth rate (CAGR) of 4.7% over the forecast period.

This upward momentum is being propelled by several macroeconomic, environmental, and technological trends that are driving greater…

Parental Control Software Market Poised for Strong Growth as Digital Parenting B …

Market Overview and Growth Outlook

The global Parental Control Software Market is projected to reach US$ 1.8 billion in 2026 and is expected to expand to US$ 3.9 billion by 2033, registering a CAGR of 11.5% during the forecast period. Between 2020 and 2025, the market grew at a CAGR of 8.2%, reflecting increasing awareness around children's online safety and digital behavior management. Rising internet penetration and growing device ownership among…

More Releases for Cutting

Comparing CO2 Laser Cutting to Other Fabric Cutting Methods

Choosing the Right Tool for Precision and Efficiency

Choosing the correct focal length for your CO2 laser is crucial for achieving precise cuts, especially when working with laser cutting fabric. The focal length determines the laser beam's spot size and depth of focus, directly impacting cutting quality. Shorter focal lengths (e.g., 1.5" to 2") are ideal for fine details on thin materials, while longer focal lengths (e.g., 4" to 5") suit…

Cutting Edge Solutions: Analyzing the Booming Cutting Fluid Market

The global cutting fluid industry is poised for significant growth, with projections indicating a Compound Annual Growth Rate (CAGR) of 4.1% from 2023 to 2033. By 2033, the market is expected to achieve a valuation of USD 16.3 billion, underscoring its critical role in industrial manufacturing and machining processes.

Cutting fluids, often referred to as coolants or lubricants, play a pivotal role in industrial metalworking. These fluids are designed to reduce…

Is Die Cutting The Same As Cricut? What Is The Difference Between Die Cutting An …

Die cutting and Cricut are related but not exactly the same. Die cutting is a general term for the process of using a die to cut out shapes from various materials, such as paper, fabric, or metal. This can be done manually with a die cutting machine or press, or with the help of electronic die cutting machines like the Cricut.

Cricut is a brand of electronic die cutting machines that…

Profboard launches cutting-edge cutting board on Kickstarter

Image: https://www.getnews.info/wp-content/uploads/2024/06/1718783865.png

Revolutionizing Kitchen Safety and Convenience for Home Chefs

Profboard, the premier manufacturer of innovative cutting board systems, is proud to announce the launch of the Profboard Private edition. Since 2006, Profboard has been a trusted name among chefs and culinary enthusiasts worldwide. Now, the same professional-grade quality and innovation can be experienced in home kitchens.

Profboard sets a new standard with its cutting-edge cutting board system designed to revolutionize your kitchen.…

Fiber Laser Metal Cutting Machines Market Cutting-Edge Technology for Efficient …

Global Fiber Laser Metal Cutting Machines Market Overview:

The Fiber Laser Metal Cutting Machines market is a broad category that includes a wide range of products and services related to various industries. This market comprises companies that operate in areas such as consumer goods, technology, healthcare, and finance, among others.

In recent years, the Fiber Laser Metal Cutting Machines market has experienced significant growth, driven by factors such as increasing consumer demand,…

Metal Cutting Fluids Market Report 2018: Segmentation by Type (Emulsion Metal Cu …

Global Metal Cutting Fluids market research report provides company profile for Blaser, Idemitsu Kosan, Daido Chemical Industry, COSMO Oil, Master, Exxon Mobil Corporation, Houghton (Gulf Oil), BP, Fuchs, Yushiro Chemical, Quaker and Others.

This market study includes data about consumer perspective, comprehensive analysis, statistics, market share, company performances (Stocks), historical analysis 2012 to 2017, market forecast 2018 to 2025 in terms of volume, revenue, YOY growth rate, and CAGR for…