Press release

Top 10 Comprehensive Guide to Glass Door Fittings for Modern Spaces

Image: https://statics.mylandingpages.co/static/aaanxdmf26c522mpaaaaz2wwe7ppkact/image/54441a9027364e3ea502f1ad46f66a45.webpSelecting the right Glass Door Fittings [https://www.hzdiecasting.com/glass-door-fittings/] is crucial for modern aesthetics and functionality. Informed choices ensure lasting quality, safety, and style in contemporary spaces. The market for these fittings is robust, valued at USD 2.5 billion in 2023 and projected to reach USD 4.3 billion by 2030, demonstrating significant industry growth. Therefore, careful consideration guides decision-making for optimal results.

Key Takeaways

* Glass door fittings are important for modern buildings. They make doors look good and work well.

* Modern fittings are simple and strong. They use materials like stainless steel and aluminum.

* Different fittings help doors in different ways. Hinges help doors swing, and patch fittings hold glass panels.

* Sliding door systems save space. They let in more light and make rooms feel bigger.

* Locks keep glass doors safe. Electronic locks offer smart ways to get in.

* Seals and gaskets make doors work better. They stop drafts, noise, and water.

* Good materials and proper installation make fittings last longer. They also keep people safe.

* Clean fittings regularly. Check them often to fix small problems before they become big ones.

Understanding Essential Glass Door Fittings

Image: https://statics.mylandingpages.co/static/aaanxdmf26c522mpaaaaz2wwe7ppkact/image/d70a45c8e29a41c7b4eacb4737d97b69.webp

Modern architectural design demands hardware that complements its sleek lines and functional efficiency. Modern Glass Door Fittings represent a significant evolution from traditional hardware. They prioritize minimalist aesthetics and robust performance.

What Defines Modern Glass Door Fittings?Core Components for Contemporary Glass Doors

Contemporary glass doors rely on fittings that offer both structural integrity and visual discretion. These components often feature clean lines and understated profiles. They integrate seamlessly into the overall design.

Beyond Basic Hardware: Integrated Design

Modern hardware transcends mere functionality; it becomes an integral part of the design narrative. It emphasizes precision, clarity, and quiet sophistication. This contrasts sharply with the ornate nature of traditional hardware.

CHARACTERISTIC

TRADITIONAL HARDWARE (VINTAGE)

MODERN HARDWARE (CONTEMPORARY)

Materials

Hand-cast metal, antique brass, crystal, antique glass

Stainless steel, aluminum, chrome, matte black finishes

Designs

Layered, soulful, full of stories, artisanal feel, decorative, ornate

Minimalism, efficiency, function-driven style, clean lines, ergonomic, sculptural, minimalist silhouettes, subtle curves or sharp edges

Finishes

Antique brass, various finishes for crystal/glass

Brushed nickel, polished chrome, matte black

Feel

Emphasizes artistry, timeless sophistication, tells stories of the past

Sleek, streamlined, durable, prioritizes efficiency and minimalism, precision, clarity, quiet sophistication, longevity

Application

Adds depth and charm, suitable for homes seeking a layered, soulful aesthetic

Modern kitchens (flat-panel cabinetry), minimalist interiors, industrial lofts, Scandinavian design, unified look (blends into cabinetry)

Key Focus

Artistry, historical narrative, decorative embellishment

Functionality, simplicity, visual impact, durability, seamless integration

The Impact of Glass Door Fittings Selection

The choice of fittings significantly influences a glass door system's overall success. Careful selection ensures both visual appeal and long-term reliability.

Elevating Modern Aesthetics

Fittings contribute directly to a space's visual harmony. Sleek, well-chosen hardware enhances the minimalist aesthetic of modern interiors. It creates a cohesive and sophisticated look.

Ensuring Optimal Functional Performance

Functional performance is paramount for any door system. High-quality fittings ensure smooth operation and longevity. Track-based sliding doors, for example, achieve a 150,000 cycle durability rating. This guarantees consistent, reliable movement. Frame technologies also play a crucial role. uPVC frames offer a thermal break of 0.22 W/mK and a lifespan of 25 years. Aluminum frames provide a thermal break of 0.28 W/mK and exceed 40 years in lifespan. Frameless systems, while aesthetically minimal, typically have a 15-year lifespan. Glass engineering further enhances performance. Laminated glass with a 1.52mm PVB interlayer meets EN 12600 Class 1 impact standards. Low-E glass achieves U-values as low as 0.15 with a triple silver coating, reducing heat transfer. Tempered glass is four times stronger than annealed glass, adhering to ASTM C1048 standards. Key performance metrics include the U-Factor, which measures heat loss, and the Solar Heat Gain Coefficient (SHGC), indicating solar heat transmission. Air Leakage (AL) quantifies air infiltration, with ENERGY STAR requiring 0.30 or less for certification.

Prioritizing Safety and Durability

Safety and durability are non-negotiable aspects of glass door systems. Robust fittings provide essential security and structural integrity. Hinged variants can feature a 3-point locking system. This system surpasses ANSI/BHMA Grade 1 standards, offering superior protection. Durable materials and precise engineering ensure the fittings withstand daily use and environmental factors.

Top 10 Glass Door Fittings for Modern Architectural Designs

Modern architectural designs demand precision-engineered components that blend seamlessly with minimalist aesthetics and robust functionality. The right Glass Door Fittings are paramount for achieving these goals. This section explores the top ten categories of fittings essential for contemporary glass door systems.

1. Hinges for Glass Door Systems

Hinges form the foundational mechanism for swinging glass doors, dictating their movement and stability. Modern hinges offer advanced features for enhanced performance and aesthetic integration.

Pivot Hinges for Seamless Movement

Pivot hinges allow doors to rotate on a vertical axis, creating a clean, frameless appearance. They are often concealed, contributing to an uninterrupted visual flow. These hinges support the door's weight from the top and bottom, distributing stress effectively.

Patch Hinges for Frameless Designs

Patch hinges attach directly to the glass panel, eliminating the need for a full frame. They are ideal for frameless glass doors, providing a sleek, minimalist look. These hinges are commonly used in shower enclosures and interior glass partitions.

Floor Springs and Overhead Closers for Controlled Operation

Floor springs and overhead closers provide controlled opening and closing actions for glass doors. They ensure smooth, safe operation, preventing doors from slamming. Many models offer adjustable closing speeds and hold-open functions, enhancing user convenience.

Selecting the appropriate hinge involves considering the door's weight and usage frequency. High-quality hinges ensure long-term reliability.

FEATURE

WATERSON GLASS DOOR HINGES

Load Capacity (3 hinges)

Up to 260 lbs

Load Capacity (4 hinges)

Up to 330 lbs

Material

304 or 316 grade Stainless Steel

Durability Rating

5-year warranty

Corrosion Resistance

Excellent (304) to Superior (316)

Closing Mechanism

Soft Closing, Adjustable Speed

Opening Force

Low (ADA-friendly)

Hold-Open Options

90 degrees , 110 degrees , 120 degrees , 135 degrees , 180 degrees

Installation

No floor cutting required

Compliance

UL-listed, fire-rated glass entry sets

Replacement

Swappable with bracket kits; retrofit-friendly

Different hinge grades cater to various load and frequency requirements.

HINGE GRADE

LOAD CAPACITY

FREQUENCY CATEGORY

Commercial Grade Heavy-Duty (LL)

Up to 1000 lbs

Low-frequency

Commercial Grade Heavy-Duty

Up to 200 lbs

High-frequency

Commercial Grade Heavy-Duty

Around 400 lbs

Medium-frequency

Commercial Grade Heavy-Duty

600 lbs

Low-frequency

Residential Grade - Standard Duty

200 lbs

Medium-frequency

Residential Grade - Standard Duty

Less than 200 lbs

Standard

Heavy-duty hinges feature enhanced construction for superior durability.

FEATURE

STANDARD HINGE

HEAVY-DUTY HINGE

Bearing Type

Plain or washer-based

Ball bearing or concealed bearing

Leaf Thickness

2-2.5 mm

3-5 mm

Pin Design

Simple fixed pin

Reinforced non-loosening pin

Load Distribution

Centralized stress

Evenly distributed stress zones

Durability

Moderate

Superior under heavy use

Material (Corrosion Resistance)

SUS304 (Excellent for indoor/moderate outdoor)

SUS316 (Superior for coastal/industrial/high-humidity)

Lubrication System

Less precise

Precision-engineered for minimal metal-to-metal contact, heat dissipation

Rigidity

Less rigid

Thicker plates reduce flexing, maintain alignment

2. Patch Glass Door Fittings

Patch fittings are small, discreet components that secure glass panels without extensive framing. They are crucial for creating transparent and open environments.

Corner Patch Fittings for Structural Integrity

Corner patch fittings secure glass panels at their corners, providing essential structural integrity for frameless systems. They are vital for maintaining alignment and stability in glass partitions and doors.

Overpanel Patch Fittings for Extended Glass Panels

Overpanel patch fittings connect glass doors to fixed glass panels above them. They extend the visual height of the glass system, creating a grander entrance or partition.

Transom Patch Fittings for Overhead Support

Transom patch fittings provide support for glass panels positioned above a door opening. They integrate the door into a larger glass facade, ensuring stability and a cohesive design.

Patch fittings offer significant design benefits for modern spaces.

* Applications: Shower enclosures, glass doors, partitions, commercial spaces, residential projects.

* Design Benefits:

* Versatility: They integrate seamlessly into different environments, adapting to various designs and configurations.

* Enhanced Safety and Security: Robust materials and secure holding of glass panels increase stability and reduce the risk of movement.

* Ease of Installation and Maintenance: Installation involves minimal disruption, and the process is quick and efficient, reducing labor costs. Cleaning is straightforward.

* Aesthetic Appeal: Their minimalist design creates a sleek and contemporary look. They are unobtrusive, allowing the beauty of glass to shine through. This seamless integration with surrounding architecture creates an open and airy environment.

Material selection for patch fittings impacts their performance and aesthetic.

MATERIAL TYPE

PROS

CONS

Stainless Steel

- High strength and durability.- Excellent corrosion resistance.- Modern and sleek appearance.- Suitable for high-traffic areas and various environments.

- Higher cost compared to other materials.- Can be heavy, requiring robust support structures.

Aluminum

- Lightweight.- Corrosion-resistant.- Cost-effective.- Versatile in design and finishes.

- Less strong than stainless steel, not suitable for heavy-duty applications.- May dent or scratch more easily.

Brass

- Classic and elegant appearance.- Good corrosion resistance.- Durable.- Can be polished to a high shine or given an antique finish.

- Higher cost than aluminum.- Requires regular maintenance to prevent tarnishing.- Not as strong as stainless steel.

Zinc Alloy

- Cost-effective.- Easy to cast into complex shapes.- Good strength for light to medium applications.

- Lower corrosion resistance than stainless steel or aluminum.- Not suitable for heavy-duty or outdoor use.- Finishes may not be as durable.

Plastic/Nylon

- Very lightweight.- Non-corrosive.- Inexpensive.- Suitable for very light-duty or temporary applications.

- Low strength and durability.- Limited aesthetic appeal.- Not suitable for structural or high-traffic applications.

Chrome Plated

- Aesthetically pleasing, shiny finish.- Enhanced corrosion resistance over the base metal.- Can be applied to various base metals (brass, Zinc Alloy).

- Durability of the plating can vary.- Prone to chipping or scratching if not properly maintained.- Cost depends on the base metal.

Satin Anodized

- Durable and corrosion-resistant finish (for aluminum).- Matte, elegant appearance.- Resistant to fingerprints and smudges.

- Limited to aluminum as a base material.- Can be more expensive than standard aluminum finishes.

Powder Coated

- Wide range of colors and finishes.- Durable and chip-resistant.- Good corrosion protection.- Can be applied to various metals.

- Can be more expensive than some other finishes.- If chipped, the underlying metal can be exposed to corrosion.

Oil Rubbed Bronze

- Unique, antique, and rustic appearance.- Durable finish.- Hides fingerprints and water spots well.

- Limited color options.- Can be more expensive.- Finish may wear over time, revealing the base metal.

3. Sliding Glass Door Systems

Sliding glass door systems offer an elegant and space-saving solution for modern interiors and exteriors. They enhance natural light and provide seamless transitions between spaces.

Top Hung Sliding Systems for Minimalist Appeal

Top hung systems suspend the glass door from an overhead track, leaving the floor clear. This design creates a minimalist aesthetic and facilitates easy cleaning. They are ideal for interior partitions and light-duty applications.

Bottom Rolling Sliding Systems for Heavy Doors

Bottom rolling systems support the door's weight on rollers at the bottom, making them suitable for heavier glass panels. These systems are robust and often used for large patio doors or commercial entrances.

Soft-Close Mechanisms for Enhanced User Experience

Soft-close mechanisms integrate into sliding systems, ensuring doors close gently and quietly. This feature prevents slamming, reduces wear and tear, and significantly enhances the user experience.

Sliding glass doors offer distinct advantages in modern architectural contexts.

* Space-Saving Design: Unlike hinged doors, sliding doors glide along a track, eliminating the need for swing space. This allows for more flexible furniture arrangements and makes rooms feel more open and less cluttered, especially beneficial for compact homes.

* Enhanced Natural Light: Large glass panels bring abundant natural light into the home, providing unobstructed views and reducing the need for artificial lighting during the day. This creates a bright, welcoming environment and can help lower energy bills.

Various types of sliding glass doors cater to different design needs.

* Traditional Sliding Glass Doors:

* Description: These consist of two panels, one fixed and one sliding.

* Advantages: They are space-saving, maximize light and views, generally more affordable, and available in various standard sizes (5-10 feet). They are ideal for standard openings.

* French Sliding Doors:

* Description: These combine the classic aesthetic of French doors with sliding functionality.

* Advantages: They offer a timeless design with modern space-saving benefits. They are suitable for homes desiring a blend of classic looks and contemporary convenience.

* 3 Panel Sliding Patio Doors:

* Description: These feature three panels, with either one or two panels designed to slide.

* Advantages: They are excellent for larger areas, enhancing views and access, and creating an ultimate indoor-outdoor living experience. They are best for homes with extensive patios or decks.

* Double Sliding Patio Doors:

* Description: Both panels are designed to slide, allowing access from either side.

* Advantages: They provide enhanced airflow and flexible access, making movement between indoor and outdoor spaces easier. They offer better control over ventilation and access. They are ideal for versatile door access and creating seamless indoor-outdoor transitions in wide openings.

* Sliding Glass Patio Doors with Blinds:

* Description: These doors have blinds sealed between the glass panes.

* Advantages: They offer easy control over light and privacy, a sleek and modern appearance, protection of blinds from dust and damage, and improved energy efficiency by regulating indoor temperatures. They also reduce indoor allergens. They are perfect for homeowners seeking a clean, low-maintenance, and durable option with a modern aesthetic.

4. Handles and Pulls for Glass Doors

Handles and pulls serve as crucial interface points for glass doors. They combine functionality with aesthetic appeal, significantly influencing the user experience and the door's overall design.

Lever Handles for Ergonomic Access

Lever handles offer ergonomic access, providing an easy grip and smooth operation. Their design allows for quick and effortless opening, making them a popular choice for both residential and commercial settings. Manufacturers produce lever handles in various finishes and styles, ensuring compatibility with diverse interior designs.

Pull Handles for Bold Statements

Pull handles make bold statements, often featuring larger dimensions and distinctive designs. Architects frequently specify these handles for main entrances or grand interior doors where they wish to create a strong visual impact. They come in many forms, from sleek, minimalist bars to more elaborate, sculptural pieces, allowing for significant design flexibility.

Flush Pulls for Integrated Aesthetics

Flush pulls provide integrated aesthetics, recessing into the door panel. This design creates a seamless, minimalist look, particularly favored for sliding glass doors where protruding hardware could obstruct movement. Flush pulls offer a clean line, contributing to an uncluttered and contemporary appearance.

5. Locks and Latches for Glass Door Security

Security remains a paramount concern for any door system. Locks and latches for glass doors offer various levels of protection and convenience, tailored to specific needs.

Deadbolt Locks for Enhanced Protection

Deadbolt locks provide enhanced protection, offering superior security compared to standard spring latches. They operate independently of the handle, extending a solid metal bolt deep into the door frame. Many deadbolts feature robust construction from materials like steel and brass, which resist tampering, cutting, and shearing. Some models incorporate anti-bump technology and pick-resistant pin mechanisms, further deterring forced entry. For the highest security, architects often specify deadbolts meeting ANSI Grade 1 [https://www.dkhardware.com/blog/how-to-choose-the-best-door-and-window-locks-for-maximum-home-security/] standards, typically for commercial use. Residential properties commonly use ANSI Grade 2 locks, offering good security.

FEATURE/RATING

DESCRIPTION

ANSI Grade 1

Highest security, typically for commercial use, highly resistant to tampering.

ANSI Grade 2

Good security, commonly used in residential properties.

ANSI Grade 3

Low security, suitable for interior doors or situations not requiring high security.

Steel & Brass

Highly durable, resistant to tampering, cutting, and shearing.

Zinc Alloy

Less durable than steel or brass, often used in lower-cost locks.

Nickel-Plated

Offers protection against rust and corrosion, suitable for harsh weather.

Anti-Bump Technology

Prevents locks from being bypassed by the bumping method.

Pick-Resistant Pin Mechanism

High-quality pin mechanisms make locks difficult to pick, enhancing break-in protection.

Weatherproof Coatings

Zinc or chrome-plated finishes to prevent rust and maintain condition in harsh environments.

Rubber Gaskets

Prevents moisture from entering the lock mechanism, reducing rust.

Multi-point locking systems significantly enhance security by engaging the door into the jamb at multiple points. These systems typically include a central deadbolt, a live bolt, and at least two hook bolts, with some designs adding bolts to the top and bottom frames for extra stability. This distributes forced entry pressure across the door's full length, making it much harder to force open compared to a single deadbolt.

Latch Locks for Everyday Convenience

Latch locks offer everyday convenience, commonly integrating with the Door Handle. They provide quick and easy access, suitable for interior doors or areas where high security is not the primary concern. Many latch locks are made from durable stainless steel or zinc alloy, ensuring reliable performance for daily use. AGlass Door Knob Lock represents a traditional manual option for wardrobes or cabinets.

Electronic Locks for Smart Access Control

Electronic locks provide smart access control, offering keyless entry through various methods. These include passwords, fingerprints, or RFID cards. They integrate seamlessly with modern smart home security systems, allowing for remote monitoring and control. Smart locks, such as the Yale Assure lock, can indicate if a door is closed, locked, or unlocked, providing peace of mind. Magnetic or Electromagnetic Locks are often utilized for automation and access control systems in commercial environments. When selecting electronic locks, consider:

* Security Levels: Assess needs (basic, intermediate, high-security) based on location, asset value, and foot traffic.

* Lock Types: Explore deadbolts, mortise, and electronic/smart locks, evaluating their security, ease of use, and compatibility.

* Durability: Opt for locks made from high-quality materials like stainless steel or reinforced alloys from reputable brands.

* Integration: Select locks compatible with existing access control systems, such as key card readers, biometric scanners, or smartphone apps.

* Key Management: Implement systems like master keys or keyless entry for controlled access.

* Emergency Exit: Prioritize safety with locks equipped with emergency exit devices and panic hardware, ensuring compliance with fire safety regulations.

6. Door Rails and Clamps for Glass Door Stability

Door rails and clamps are essential components that provide structural support and stability to glass door assemblies. They ensure the glass panels remain securely in place and function correctly.

Top and Bottom Rails for Structural Support

Top and bottom rails provide critical structural support for glass doors. They encapsulate the edges of the glass, distributing weight and reinforcing the panel against impact and torsion. These rails come in various profiles and materials, including aluminum and stainless steel, to match specific design requirements and glass thicknesses. For example, Rapid Dry Set Door Rails feature profiles like tapered and square, available in heights such as 2 1/4 ", 4 1/4 ", 6", and 10 1/8", accommodating glass thicknesses from 3/8" to 3/4 ". They offer effortless installation, eliminating wet glazing with precision bolt assembly systems. Wet Set Door Rails provide a strong, durable one-piece bond using high-strength compression cement for secure application.

Side Clamps for Panel Integration

Side clamps facilitate panel integration, securely attaching glass panels to adjacent walls or other glass sections. They offer a minimalist solution for creating seamless glass partitions and enclosures. Manufacturers produce side clamps in various sizes and finishes, ensuring a cohesive look with other hardware.

U-Channels for Edge Protection

U-channels provide essential edge protection for glass panels. They fit over the exposed edges of the glass, shielding them from chips and impacts while also offering a finished aesthetic. These channels are particularly useful in shower enclosures and glass partitions, where they also help to contain water. Rapid Dry Set Sidelite Rails use setting tracks and EPDM compression vinyl for precise fits and easy installation, avoiding cement. They are available in profiles and finishes that coordinate with door rail series.

When working with glass door assemblies, meticulous planning and hardware selection are crucial:

* Accurate Measurements and Planning:Meticulously measure the door opening and glass panels, including height, width, and thickness. Account for any irregularities in the opening and plan for clearance space for hardware like Glass Clips and seals.

* Selecting the Right Hardware: Choose hardware compatible with the glass type and application, considering load-bearing capacity, corrosion resistance, and design compatibility to ensure durability and performance.

* Dealing with Irregular Openings: Use shims or adjustable hardware to compensate for minor discrepancies. For significant irregularities, consult a structural professional.

For Total Vision System (TVS) Euro door patch fittings, design considerations include their slim profiles for entirely transparent panic systems and suitability for heavy all-glass passage doors. These fittings use aluminum and stainless steel fasteners for strength and accommodate most standard opening conditions, but a thorough design assessment remains crucial.

7. Shower Glass Door Fittings

Shower glass door fittings require specialized design and materials due to constant exposure to moisture and humidity. These components ensure safety, functionality, and a sleek appearance in wet environments.

Shower Hinges for Wet Environments

Shower Hinges must withstand corrosive conditions while providing reliable door movement. Manufacturers typically construct them from materials offering high resistance to rust and degradation.

MATERIAL

PROS

CONS

IDEAL FOR

Stainless Steel

Highly corrosion-resistant; Extremely strong and durable; Modern, sleek aesthetic

Higher price point; Limited finish variety

Luxury or high-traffic bathrooms

Brass (Solid/Plated)

Excellent resistance to rust and corrosion; Classic, upscale look; Accepts wide range of finishes

Softer metal-may dent or wear; Can tarnish if not protected

Elegant, decorative bathrooms

Aluminum

Lightweight and affordable; Corrosion-resistant (when anodized); Available in many colors

Less durable than steel or brass; Can scratch or dent more easily

Budget-conscious or semi-frameless systems

Zinc Alloy

Cost-effective; Can mimic higher-end materials

Less corrosion-resistant; Shorter lifespan

Temporary or low-use installations

Corrosion resistance is crucial in wet environments. Strength and weight support are necessary for long-term stability. Finish compatibility helps integrate with the overall bathroom design. Shower enclosure glass must be safety glazing. It meets the impact requirement of the federal standard, Cat II of CPSC 16 CFR 1201. Frameless enclosures typically use monolithic tempered glass a minimum of 3/8-inch or thicker. Laminated glass may also be used if glass retention after breakage is desired, with consideration for its structural properties and durability in wet and humid conditions.

Shower Door Pulls for Functional Elegance

Shower door pulls offer both functional elegance and ease of use. They come in various designs, from simple knobs to elongated bar pulls, complementing diverse bathroom aesthetics. Designers select materials like stainless steel or brass for their durability and resistance to moisture.

Shower Door Seals for Water Containment

Shower door seals are vital for preventing water leakage and maintaining a dry bathroom floor. These seals, often made from clear vinyl or silicone, fit along the edges of the glass door. They create a barrier against water spray.

* Approved Materials: Use tempered and certified glass panels to withstand impacts and ensure user safety.

* Glass Thickness: Maintain glass thickness typically ranging from 3/8 to 1/2 inch for optimal performance.

* Anchoring Techniques: Securely attach the enclosure to the wall using high-quality anchors and stainless-steel hardware to prevent displacement and leaks. Ensure the enclosure is plumb.

* Hinges and Handles: Install hinges and handles that are tested for strength and durability.

* Sealing Methods: Employ silicone sealants approved for wet environments to prevent water damage and mold growth. Meticulously seal any gaps between the glass and the substrate and regularly inspect for wear.

Building codes also mandate specific requirements for shower enclosures.

* Safety Glazing (Tempered Glass): Tempered or approved safety glass is required. It bears a permanent certification mark (e.g., ANSI Z97.1 or CPSC 16 CFR 1201).

* Glass Thickness and Structural Integrity: Typically requires 3/8-inch (10 mm) to 1/2-inch (12 mm) thick glass for stability. Walls must support the glass panel weight.

* Edge Treatment: Glass edges must be polished, seamed, or smoothed to eliminate sharp edges.

* Structural Support and Anchorage: Hinges and brackets must securely fasten to wall studs or reinforced backing (e.g., plywood or steel plates) to handle glass weight. Manufacturer specifications for load-bearing capacity and installation must be followed.

* Door Clearance and Operation: Outward swinging doors are required for safety, with openings typically greater than or equal to 22 inches.

* Referenced Standards: Compliance with ANSI Z97.1/CPSC 16 CFR 1201 safety glazing standards is mandatory.

* Local Amendments: Always verify local building codes for additional requirements.

8. Standoffs and Spiders for Glass Door Facades

Standoffs and spiders create striking, transparent glass facades by minimizing visible hardware. They offer structural support while maintaining an open aesthetic.

Glass Standoffs for Architectural Glazing

Glass standoffs are cylindrical fasteners that hold glass panels away from a mounting surface. They create a floating effect, commonly seen in railings, canopies, and interior partitions. Architects use them to achieve a clean, modern look.

Spider Fittings for Point-Fixed Systems

Spider fittings are multi-armed metal components that secure glass panels at specific points. They attach to a primary structural framework, typically steel or aluminum. Glass panels are custom-fabricated with pre-drilled holes that align precisely with the point supports. Bolts or other hardware then fasten the glass to these supports, with gaskets ensuring a weather-tight seal. This precise engineering is crucial for load distribution and structural stability.

Point Fixed Glazing for Transparent Structures

Point fixed glazing systems utilize spider fittings and standoffs to create large, uninterrupted glass surfaces. Aesthetically, these systems offer maximum transparency and minimal visual obstruction. This design maximizes daylighting within the building, supporting biophilic design goals and potentially reducing the need for artificial lighting, thereby lowering energy consumption.

9. Connectors and Brackets for Glass Door Assemblies

Connectors and brackets are essential for assembling multiple glass panels and securing them to surrounding structures. They ensure stability and seamless integration.

Glass-to-Glass Connectors for Seamless Panels

Glass-to-glass connectors join adjacent glass panels, creating continuous, frameless partitions or enclosures. These connectors come in various angles and configurations, allowing for flexible design layouts. They maintain the transparent aesthetic by minimizing visible hardware. Patch fittings secure glass panels at the base, wall, or corner without requiring bulky frames. They are suitable for store entrances, office doors, or hotel corridors, offering glass-to-wall, glass-to-glass, and floor connector options.

Glass-to-Wall Brackets for Secure Mounting

Glass-to-wall brackets securely mount glass panels to solid walls or structural elements. These brackets provide robust support, crucial for fixed glass partitions, shower screens, and balustrades. Manufacturers design them for strength and durability, often using stainless steel.

Support Bars for Added Reinforcement

Support bars provide additional reinforcement for larger or heavier glass panels. They distribute weight and enhance stability, particularly in shower enclosures or expansive glass partitions. These bars often feature sleek designs that complement the minimalist aesthetic of modern glass installations.

10. Seals and Gaskets for Glass Door Performance

Seals and gaskets are critical components for optimizing glass door performance. They enhance comfort, energy efficiency, and overall functionality. These often-overlooked fittings play a vital role in environmental control and user experience.

Weather Seals for Environmental Protection

Weather seals create a crucial barrier against external elements. They protect interiors from harsh weather conditions. High-quality weather seals exhibit strong resistance to UV radiation, extreme temperatures, and moisture. They maintain their integrity even under direct sunlight, fluctuating temperatures, and constant moisture exposure. This ensures a consistent seal over time.

Durability is a key characteristic of effective weather seals. They offer long-lasting flexibility and durability. These seals retain their shape and sealing ability despite repeated door movements and frequent use. This makes them ideal for entry points that open and close often. Silicone seals, for example, are molded, flexible profiles. They provide long-lasting sealing against air, moisture, and temperature changes. These seals are suitable for permanent or heavy-duty installations. This differs from traditional weather stripping, which often serves for quick or temporary fixes. Proper weather sealing contributes significantly to a building's energy efficiency by preventing drafts and heat loss or gain.

Acoustic Seals for Sound Dampening

Acoustic seals are essential for creating quieter indoor environments. They effectively reduce the transmission of external noise. This provides acoustic insulation, contributing to more peaceful and productive spaces. Modern acoustic seals are engineered for high performance.

For instance, specialized products like Schall-Ex Registered GS H-8/12 offer impressive sound reduction. This concealed seal for new doors achieves 43dB sound reduction over a 7mm gap and 41dB over a 10mm gap. It also features smoke resistance, accessibility compliance, and a self-levelling system. Its gasket material is flame-retardant and self-extinguishing silicone. Similarly, the Schall-Ex Registered GS-A, a surface-mounted option, provides comparable sound reduction. It also resists smoke, sound, and fire, includes a self-levelling mechanism, and is easily adjustable. These advanced seals ensure optimal sound dampening for various applications.

Brush Seals for Dust and Draft Control

Brush seals and other gasketing solutions effectively control dust and drafts. They help maintain a cleaner and healthier indoor environment. These seals resist dust, mold, and mildew. They prevent unwanted outdoor elements like dust and pollen from entering a space. This contributes to better indoor air quality.

Various types of seals address specific dust and draft control needs:

* Bubble gaskets stop leaks and drafts. Manufacturers use them for door surround weather seals and UPVC door gaskets.

* Weather stripping and gasketing tape made from closed-cell foam provide barrier protection from moisture and air. They offer excellent resistance to weather and oxidation. These are common for UPVC door weather strips.

* UPVC sealing strips dampen vibration and noise. They also provide excellent resistance to acid, ozone, and oxidation. These strips are ideal for door and window sealing.

* Round cord gaskets resist ozone, weathering, moisture, and aging. They are perfect for outside sealing applications, sound insulation, and marine uses.

These seals require minimal maintenance. They ensure long-term performance in keeping interiors clean and comfortable.

Applications of Glass Door Fittings in Modern Design

Image: https://statics.mylandingpages.co/static/aaanxdmf26c522mpaaaaz2wwe7ppkact/image/5ef325cbd7b2419687ee05fe200ce1cc.webp

Modern design frequently incorporates glass doors, leveraging their transparency and aesthetic appeal. The specific Glass Door Fittings chosen significantly influence both the functionality and visual impact of these installations across various environments.

Residential Spaces

Glass doors enhance residential spaces by creating open, light-filled interiors. They offer versatile solutions for dividing areas and improving aesthetics.

Shower Enclosures and Wet Rooms

Shower enclosures and wet rooms benefit greatly from glass doors. These installations create distinct bathing areas while maintaining an open feel. Fittings ensure water containment and smooth operation in high-moisture environments.

Interior Partitions and Room Dividers

Glass partitions and room dividers effectively segment residential spaces. They divide halls into zones or allocate guest corners. These doors designate hallway areas without creating narrow corridors. Homeowners can hide staircases behind partitions or create separate rooms from larger ones. They also isolate kitchen areas, preventing cooking odors from spreading. Glass doors even create winter gardens for enjoying plants from indoors. These applications divide space, act as decoration, increase light flow, and visually expand a room. They increase natural light, modernize dark interiors, and make spaces feel more open. This promotes health by boosting productivity and aligning circadian rhythms. Glass doors save energy by reducing the need for artificial lighting. They enable flexible hybrid spaces, supporting multi-functional designs. Ultimately, they transform and elevate spaces, increasing property value.

Patio and Balcony Access Doors

Patio and balcony access doors frequently feature glass. These doors provide seamless transitions between indoor and outdoor living areas. They maximize natural light and offer expansive views.

Commercial and Public Projects

Commercial and public projects utilize glass doors for their durability, aesthetic versatility, and ability to manage high traffic.

Hotel Bathrooms and Spas

Hotel bathrooms and spas often feature glass doors. These doors create luxurious and contemporary aesthetics. They also provide privacy while maintaining an open, airy feel.

Office Partitions and Entrance Systems

Office partitions and entrance systems widely use glass doors. Sliding glass doors, manually operated, maximize space utilization in conference rooms or retail settings. They provide easy access and flexible space allocation, offering a modern aesthetic. Automatic glass doors suit high-traffic areas like hospitals and airports. They offer convenience, enhance accessibility, and reduce germ spread through hands-free operation. Swinging (hinged) glass doors are versatile for restaurants and corporate offices. They provide wide design options and a classic, professional look. Revolving glass doors efficiently manage traffic flow in hotels and large office buildings. They conserve energy and enhance security, adding a sophisticated design element. Custom glass doors offer unique statements with etched patterns or logos.

Retail Storefronts and Display Cases

Retail storefronts and display cases rely on glass doors for visibility and security. Panic bar glass doors [https://vallisco.com/commercial-glass-doors/] feature built-in panic hardware for quick exits. They use safety-rated tempered or laminated glass and reinforced frames. These doors are code-compliant for fire, safety, or ADA requirements. They are best for hotel emergency exits, office fire escape routes, and public hallways. Businesses must match the door to its location, checking safety and building codes. Long-term durability requires stronger frames and thicker glass for high-traffic areas. Balancing design with function ensures usability.

Key Factors for Choosing the Right Glass Door Fittings

Selecting appropriate Glass Door Fittings requires careful consideration of several critical factors. These factors ensure the chosen hardware meets aesthetic, functional, and safety requirements for any modern space.

Material Considerations for Glass Door Fittings

The material composition of glass door fittings directly impacts their durability, appearance, and suitability for specific environments.

Stainless Steel (304 vs. 316) for Durability

Stainless steelstands as a premier choice for glass door fittings due to its exceptional durability and corrosion resistance. It forms a protective shield against rust, making it highly reliable. D&D HARDWARE, for instance, utilizes solid stainless steel grades 304 and 316 for many Glass Door Hinges, highlighting their suitability for wet environments. Rust-proof hinges, including those made from stainless steel, brass, and aluminum, ensure longer durability in wet areas like bathrooms and kitchens.

MATERIAL

LOAD CAPACITY

APPROXIMATE TENSILE STRENGTH

RECOMMENDED APPLICATIONS

Stainless Steel

High

500-850 MPa

Outdoor equipment, marine applications, heavy doors, gates, industrial applications

Carbon Steel

Very High

N/A

Heavy doors, gates, industrial equipment

Titanium

High

N/A

Aerospace, weight-sensitive high-load applications

Steel

N/A

400-700 MPa

Medium to heavy doors, commercial uses

For high cycle count applications, designers consider hardened steels with appropriate lubrication, bearing-grade bronze, self-lubricating polymers, and stainless steel with hardened pins. For moderate use applications, standard grades of stainless steel, brass, aluminum, and engineering polymers suffice. Stainless steel with PTFE coatings, self-lubricating polymers, bearing-grade materials, and ball-bearing hinge designs offer minimal friction.

Brass and Bronze for Classic Appeal

Brass and bronze offer a warm, classic appearance, providing an aesthetically pleasing option that contains no iron, making them rust-resistant. However, brass hinges exhibit lower fatigue resistance compared to steel. This makes them susceptible to stress cracks or wear at pivot points in high-traffic applications. They are also prone to deformation under repeated stress, leading to sagging or play at the pin over time. Brass hinges require regular cleaning to prevent tarnish, using specialized cleaners or natural solutions. Protective lacquers on brass hinges have limitations; they wear off, can be damaged by cleaners, may need complete reapplication, and can yellow over time, typically lasting only 1-3 years. Repairing brass hinges often proves more complex than with other materials, as brass is harder to weld and may require custom-fabricated replacement parts. Brass hinges also pose a risk of galvanic corrosion when in contact with certain other metals. Furthermore, brass expands and contracts more readily with temperature changes, which can lead to seasonal sticking or binding as dimensions change, increased wear at contact points due to thermal expansion, and potential loosening of mounting screws as the material cycles through temperature changes. These effects are particularly noticeable in outdoor or unregulated environments with significant temperature fluctuations.

MATERIAL

LOAD CAPACITY

APPROXIMATE TENSILE STRENGTH

RECOMMENDED APPLICATIONS

Brass

Medium

310-550 MPa

Furniture, decorative applications, light doors, cabinets, decorative boxes

Bronze

N/A

250-350 MPa

Decorative applications, marine environments

Initial material costs vary significantly. Carbon steel is generally the lowest, followed by aluminum (moderate), stainless steel (moderate to high), and brass/bronze (moderate to high). Titanium is the most expensive. Brass hinges typically have a premium price due to higher raw material costs and manufacturing processes. For large projects, the cost difference between brass and steel can be substantial. Lifetime expenses for brass hinges include ongoing maintenance costs such as cleaning supplies, polishes, periodic reapplication of protective coatings, potential replacement costs due to premature failure, and labor for regular maintenance. These ongoing costs can make brass hinges significantly more expensive than alternatives like certain stainless steel grades that require minimal maintenance.

Aluminum for Lightweight Solutions

Aluminum provides a lightweight solution for glass door fittings. It is immune to rust and creates a protective shield against corrosion. For applications where weight is critical, designers consider aluminum alloys for their excellent strength-to-weight ratio.

MATERIAL

LOAD CAPACITY

APPROXIMATE TENSILE STRENGTH

RECOMMENDED APPLICATIONS

Aluminum

Medium

N/A

Light doors, electronic enclosures

Reinforced Polymers

Low to Medium

N/A

Electronic devices, light-duty applications

Finishes and Coatings for Aesthetic Versatility

Finishes and coatings offer aesthetic versatility, allowing fittings to complement various design schemes. Stainless steel provides a modern, clean look. Anodized aluminum allows for various color options. These finishes not only enhance appearance but also add an extra layer of protection against wear and environmental factors.

Safety Standards and Compliance for Glass Door Fittings

Adhering to safety standards and compliance certifications is paramount for glass door installations, ensuring user protection and structural integrity.

Load Bearing Capacity for Structural Integrity

Each patch fitting has a specified load-bearing capacity. It is crucial to select fittings that can safely support the weight of the glass panel, especially for large or heavy doors. This ensures the structural integrity of the entire glass door system.

Impact Resistance for User Protection

Safety glazing materials must meet rigorous impact resistance standards to protect users.

STANDARD

DESCRIPTION

IMPACT TEST CATEGORIES/CLASSES

CPSC 16 CFR 1201

Mandatory federal safety regulation for Architectural Glazing Materials.

Category I: 100 lb. bag from 18 drop height (approx. 150 ft/lb impact), for glazing up to 9 sq ft. Category II: 100 lb. bag from 48 drop height (approx. 400 ft/lb impact), for glazing over 9 sq ft.

ANSI Z97.1-2004

Voluntary safety performance specification and test method.

Class A: Comparable to CPSC Category II (48-inch drop height). Class B: Comparable to CPSC Category I (18-inch drop height). Size criteria: 'U' for Unlimited, 'L' for Limited.

IBC Code (Section 2406 Safety Glazing)

Building code that dictates when and where safety glazing materials must be used, referencing CPSC and ANSI standards.

Requires all glazing in fire doors in hazardous locations to be safety rated per Category I and II, withdrawing previous exemptions for wire glass.

ADA Standards (2010 ADA Standards for Accessible Design)

Standards for accessible design, including requirements for vision panel placement in doors.

Vision lights in doors, gates, and adjacent side lights must have the bottom of at least one glazed panel 43 inches (1090 mm) maximum above the finish floor, with exceptions for panels above 66 inches (1676 mm).

Fire Ratings for Building Code Adherence

Fire ratings ensure glass door systems comply with building codes, providing critical protection in case of fire. Fire-rated glass undergoes rigorous testing according to standards such as UL 263, NFPA, and other relevant codes. These tests evaluate performance under fire conditions, including exposure to heat, impact, and hose stream testing.

STANDARD

DESCRIPTION

RATINGS/CRITERIA

NFPA-80-2013 (4.4.3.1)

Standard for fire doors and other opening protectives.

For new wood doors, glazing materials in vision panels must be installed in labeled glass light kits or according to fire door listing and inspection service procedures.

US/Canadian Fire Test Standards (UL & WHI)

Standards for fire and hose stream testing of steel and wood door assemblies.

Ratings (e.g., 20, 45, 60, 90, 180 minutes) based on fire and hose stream tests. Products require certification labels and follow-up inspections by UL or Warnock Hersey. Ratings are based on maximum visible lite area.

British Standard (BSI or BS EN)

Fire test standards for timber and steel doors, without a hose stream test.

E-Integrity: Ability to keep back flames, smoke, and fumes. EW-Partial Radiation: Limits radiant heat on the non-fire side. Ratings (e.g., 30, 60, 120 minutes) based on door aperture. No labels required; products are 'assessed' every five years.

European Standard (EN 1634)

Fire resistance tests for door shutter assemblies, without a hose stream test.

EI-Integrity and Insulation: Limits average temperature rise on the non-fire side to 140 degrees C and maximum to 180 degrees C above ambient. Ratings (e.g., EI-30, EI-60, EI-90 minutes) based on temperature rise measurement.

Organizations like UL (Underwriters Laboratories), the National Glass Association, and AIA (American Institute of Architects) provide certifications and standards for fire-rated glass products. These certifications ensure product performance and compliance.

Installation Requirements for Glass Door Fittings

Proper installation is crucial for the optimal performance, safety, and longevity of glass door systems.

Professional Installation for Optimal Performance

Professional installation ensures optimal performance. Experts possess the knowledge and tools to handle glass safely and accurately. They guarantee correct alignment and secure mounting of all components.

Compatibility with Glass Thickness and Type

Patch fittings are designed for specific glass thicknesses, typically ranging from 8mm to 12mm. Using fittings with incompatible glass thickness can compromise safety and stability. Patch fittings are generally suitable for tempered glass, which is stronger and safer.

Structural Support for Secure Mounting

High-quality fittings are manufactured to withstand repeated use and environmental factors, ensuring long-term performance and minimal maintenance. They must comply with relevant safety standards and building codes, especially for public or commercial installations. The design and finish of the patch fittings should complement the overall architectural style and interior design of the space. For applications requiring fire safety, ensure that the patch fittings, along with the glass, meet the necessary fire-resistance ratings. For doors requiring enhanced security, consider fittings that can integrate with locking mechanisms or offer additional security features. Ensure that the patch fittings are compatible with other door hardware, such as hinges, locks, and handles, for a cohesive and functional system. Smooth, non-porous finishes are easier to clean and maintain hygiene, which is important in certain environments like healthcare facilities. For exterior applications or areas exposed to direct sunlight, fittings with UV-resistant properties will prevent discoloration or degradation over time.

REQUIREMENT

DETAIL

Load-Bearing Capacity

Each patch fitting has a specified load-bearing capacity. It's crucial to select fittings that can safely support the weight of the glass panel, especially for large or heavy doors.

Material and Finish

Common materials include stainless steel (304 or 316 grade for corrosion resistance), brass, and aluminum. Finishes like polished stainless steel, satin stainless steel, chrome, and powder-coated options are available to match aesthetic requirements.

Corrosion Resistance

For installations in humid or corrosive environments (e.g., bathrooms, coastal areas), fittings made from 316-grade stainless steel or with appropriate protective coatings are recommended.

Adjustability

Some patch fittings offer adjustability features, allowing for minor alignment corrections during installation. This can be particularly useful for achieving perfect door closure and alignment.

Durability and Longevity

High-quality fittings are manufactured to withstand repeated use and environmental factors, ensuring long-term performance and minimal maintenance.

Safety Standards

Ensure that the chosen patch fittings comply with relevant safety standards and building codes, especially for public or commercial installations.

Installation Requirements

Consider the complexity of installation and whether specialized tools or expertise are required. Some fittings are designed for easier installation than others.

Maintenance

Low-maintenance fittings are preferable, especially for high-traffic areas. Stainless steel fittings generally require minimal maintenance.

Aesthetics

The design and finish of the patch fittings should complement the overall architectural style and interior design of the space.

Type of Glass

Consider the type of glass being used (e.g., tempered, laminated). Patch fittings are generally suitable for tempered glass, which is stronger and safer.

Environmental Conditions

Extreme temperatures, humidity, and exposure to chemicals can affect the performance and lifespan of fittings. Select materials and finishes appropriate for the specific environment.

Manufacturer's Warranty

A good warranty indicates the manufacturer's confidence in their product's quality and durability.

Cost-Effectiveness

Balance the cost of the fittings with their quality, durability, and aesthetic appeal to ensure a cost-effective solution over the long term.

Acoustic Performance

While not a primary feature, some fittings might contribute to or detract from the acoustic insulation of a glass partition.

Fire Resistance

For applications requiring fire safety, ensure that the patch fittings, along with the glass, meet the necessary fire-resistance ratings.

Security Features

For doors requiring enhanced security, consider fittings that can integrate with locking mechanisms or offer additional security features.

Compatibility with Other Hardware

Ensure that the patch fittings are compatible with o

Legal Disclaimer: Information contained on this page is provided by an independent third-party content provider. ABNewswire makes no warranties or responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you are affiliated with this article or have any complaints or copyright issues related to this article and would like it to be removed, please contact retract@swscontact.com

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Top 10 Comprehensive Guide to Glass Door Fittings for Modern Spaces here

News-ID: 4339550 • Views: …

More Releases from ABNewswire

Self Employed Tax Software UK: Why Freelancers and Sole Traders Are Switching to …

With Many individuals are seeking software that simplifies tax filing while ensuring full compliance with HMRC requirements. Manual spreadsheets and paper-based calculations are being replaced by real-time, automated systems that give users visibility over their tax position throughout the year. Among the platforms gaining traction is Pie, a UK-based digital tax app built specifically to support self-employed individuals with modern income needs.

LONDON, United Kingdom - February 19, 2026 - Demand…

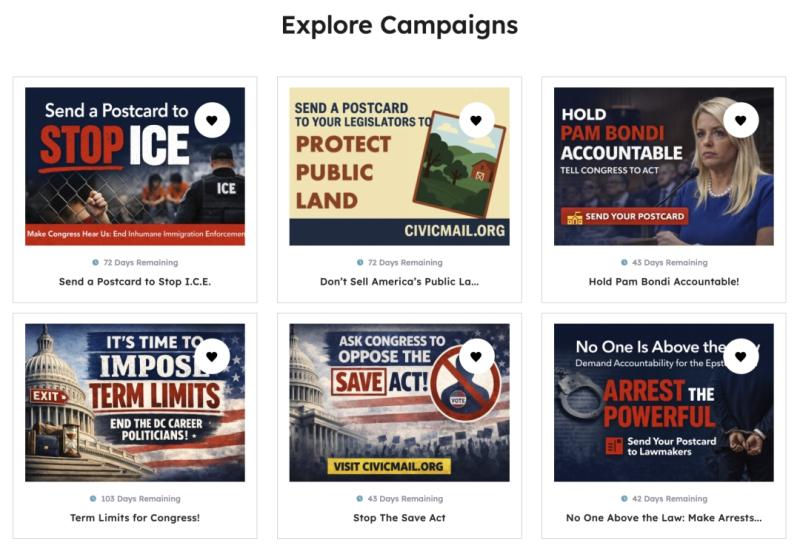

CivicMail.org Reinvents Postcard Campaigns for Grassroots Advocacy

CivicMail.org aims to bring civic engagement back to basics through the power of pen, paper, and postage.

Image: https://www.abnewswire.com/upload/2026/02/2addd1e9e0381d7e2262e1edbb064123.jpg

CivicMail.org [https://civicmail.org/] has announced its launch to help Americans send real, physical postcards to their elected officials with just a few clicks, delivering personalized messages directly to the desks of decision-makers at the local, state, and federal levels.

Research shows [https://www.concordia.ca/news/stories/2021/09/24/personalized-messages-are-more-likely-to-get-a-response-from-politicians-new-research-finds.html] that physical mail carries more weight with elected officials than petitions, emails, or…

New Children's Story: The Story of Sharin' Bear

A Heartfelt Message Of Courage, Kindness, And The True Meaning Of Giving

A pleasant new story for children, The Story of Sharin' Bear by Sharon Woods , introduces families to a lovable little cub whose journey of bravery and compassion changes him into a representation of sharing for children globally.

Entrenched in adventure, innocence, and emotional growth, this uplifting tale offers an unforgettable reminder that even the smallest acts of kindness can…

Fast-Growing Newman's Brew Combines Organic Coffee Excellence with Abandoned Ani …

Newman's Brew is experiencing rapid expansion by delivering on dual commitments that resonate with today's conscious consumers: exceptional fresh-roasted organic coffee and meaningful support for abandoned animals. The company's growing inventory and ethical business practices demonstrate that quality and social responsibility can drive sustainable business success in the competitive specialty coffee market.

Newman's Brew is riding a wave of growth that reflects fundamental shifts in how consumers approach coffee purchasing decisions.…

More Releases for Glass

Depression Glass Market 2023- Industry Revenue and Price | Hazel-Atlas Glass Com …

The Depression Glass market research report is proficient and top to bottom research by specialists on the current state of the industry. This statistical surveying report gives the most up to date industry information and industry future patterns, enabling you to distinguish the items and end clients driving income development and benefit. It centres around the real drivers and restrictions for the key players and present challenge status with development…

Auto Glass Market Is Booming Worldwide | Fuyao Glass, Webasto, Xinyi Glass, Asah …

Advance Market Analytics published a new research publication on "Auto Glass Market Insights, to 2028" with 232 pages and enriched with self-explained Tables and charts in presentable format. In the Study you will find new evolving Trends, Drivers, Restraints, Opportunities generated by targeting market associated stakeholders. The growth of the Auto Glass market was mainly driven by the increasing R&D spending across the world. Some of the key players profiled…

Recycled Glass Market 2023 Business Strategies - Cap Glass, Glass Recycled Surfa …

Newly added by Fior Markets study on Global Recycled Glass Market 2023 contains a detailed analysis of data through industrial dynamics which has a major impact on the growth of the market. The report categorizes the global Recycled Glass market by segmented top key players, type, application, marketing channel, and regions. The report provides a complete understanding of the market in the coming years. It looks over the market with…

Glass Easy-clean Glass Market 2019| Pilkington Glass, PPG Industries, Ravensby W …

The global market status for Easy-clean Glass is precisely examined through a smart research report added to the broad database managed by Market Research Hub (MRH). This study is titled “Global Easy-clean Glass Market” Research Report 2019, which tends to deliver in-depth knowledge associated to the Easy-clean Glass market for the present and forecasted period until 2025. Furthermore, the report examines the target market based on market size, revenue and…

Insulated Glass Market Analysis: Top Companies Includes (Cardinal Glass Industri …

Insulated glass refers to two or more lites of glass sealed around the edges with an air space between, to form a single unit.

Insulating glass is a very effective way to reduce air-to-heat transfer through the glazing. When used in conjunction with low-E and/or reflective coatings, IG units perform even better for conserving energy and complying with local codes. The most common configuration of IG units for commercial building is…

Global Ground Glass Market 2017- CSG, XINYI Glass, JINJING Glass, SYP Glass, Yao …

The market research report by QY Research provides detailed study on the overall Ground Glass market size, its financial positions, its unique selling points, key products, and key developments. This research report has segmented the Ground Glass market based on the segments covering all the domains in terms of type, country, region, forecasting revenues, and market share, along with analysis of latest trends in every sub-segment.

CLICK HERE to Request Sample…