Press release

The Global Multi-Tasking Industrial Robots Market is anticipated to reach a value of USD 49.28 Billion by 2030.

According to the report published by Virtue Market Research The Multi-Tasking Industrial Robots Market was estimated to be worth USD 24.96 billion in 2024 and is anticipated to reach a value of USD 49.27 billion by 2030, growing at a fast CAGR of 12% during the outlook period 2025-2030.Request Sample Copy of this Report @https://virtuemarketresearch.com/report/multi-tasking-industrial-robots-market/request-sample

The market for multi-tasking industrial robots is gaining steady momentum as industries continue to integrate automation for greater precision, efficiency, and productivity. One of the strongest long-term drivers shaping this market is the accelerating shift toward manufacturing automation across sectors such as automotive, electronics, and logistics. Companies are increasingly relying on robots capable of performing multiple tasks simultaneously, such as welding, assembly, and material handling, which helps them optimize production lines and reduce downtime. These multi-functional robots reduce operational costs and enhance throughput, allowing industries to meet the growing demands of mass customization and flexible production environments.

The impact of the COVID-19 pandemic on the multi-tasking industrial robots market was complex but ultimately transformative. During the early stages of the pandemic, supply chain disruptions and the temporary closure of manufacturing facilities slowed robot deployment and production. However, the crisis also revealed the vulnerabilities of human-dependent operations. As industries resumed production, many organizations adopted automation at an unprecedented rate to minimize human contact, ensure business continuity, and maintain operational resilience. The pandemic effectively accelerated the adoption of intelligent robotics as companies recognized the importance of self-sufficient systems capable of maintaining production under restrictive conditions.

This shift has now become a structural change, with automation strategies embedded into the long-term growth plans of most manufacturers.

In the short term, one of the key drivers for the market is the growing demand for compact and adaptive robotic systems in small and medium-sized enterprises (SMEs). Unlike traditional industrial robots that are often large and require extensive programming, multi-tasking robots are now being designed to be more intuitive, modular, and space-efficient. SMEs, which were once hesitant due to high costs and complexity, are increasingly investing in these systems to remain competitive against larger manufacturers. The integration of easy-to-program interfaces, plug-and-play functionalities, and collaborative capabilities is enabling smaller companies to embrace robotics at a faster pace. This trend is not only expanding the customer base for robot manufacturers but also diversifying the application scope of such technologies across industries previously untouched by automation.

An emerging opportunity within the multi-tasking industrial robots market lies in the convergence of robotics with artificial intelligence and machine learning. The combination of these technologies allows robots to not only perform multiple tasks but also adapt and optimize their operations based on data-driven insights. For instance, a robot equipped with advanced sensors and AI algorithms can adjust its movements in real time, detect potential errors, and even predict maintenance needs before failures occur. This integration is opening pathways for industries such as aerospace, pharmaceuticals, and food processing to adopt robots in environments where precision and adaptability are critical. The growing affordability of smart sensors, cloud computing, and AI toolkits further fuels this opportunity, as more businesses can now afford to automate complex workflows with high degrees of customization.

A significant trend shaping the future of the multi-tasking industrial robots market is the rise of human-robot collaboration in hybrid workplaces. Unlike traditional robots that function in isolated environments, modern systems are increasingly being developed to work safely alongside human operators. These collaborative robots, or cobots, are designed with built-in safety sensors and motion controls that allow them to share tasks with workers without posing risks. This approach enhances productivity by combining the creativity and problem-solving skills of humans with the precision and endurance of robots. The trend also supports workforce upskilling, as operators transition from manual labor to supervisory and programming roles, fostering a more symbiotic relationship between humans and machines.

As industries evolve toward more intelligent and interconnected production systems, the demand for multi-tasking industrial robots is expected to rise steadily. The long-term push for automation, accelerated by global disruptions like COVID-19, continues to reshape manufacturing priorities. In the near term, the accessibility of robotics to smaller enterprises, coupled with advancements in AI integration and collaborative functionality, is driving innovation and competition across the market. The future of industrial production will likely revolve around systems that can learn, adapt, and perform a diverse set of functions seamlessly-making multi-tasking robots not just a trend but a cornerstone of modern industrial transformation.

Segmentation Analysis:

By Type: Traditional Industrial Robots, Collaborative Robots

The Multi-Tasking Industrial Robots Market by type is evolving as industries demand advanced automation solutions to boost efficiency and flexibility. Traditional industrial robots dominate this segment due to their long-standing use in large-scale manufacturing processes where precision, speed, and heavy-duty performance are crucial. These robots are preferred for complex tasks like welding, assembling, and material handling, especially in high-volume production environments. However, collaborative robots are the fastest growing category during the forecast period. Their ability to safely operate alongside humans, ease of programming, and adaptability for small and medium enterprises make them an attractive choice for modern manufacturers. As industries move toward human-robot collaboration, cobots are increasingly being integrated into production lines to improve overall workflow, safety, and productivity. The growing focus on compact design, plug-and-play functionality, and flexible task execution is further accelerating their adoption.

By Industry: Automotive, Electrical And Electronics, Plastics, Rubber, And Chemicals, Metals, And Machinery, Food And Beverages, Others

The Multi-Tasking Industrial Robots Market by industry is witnessing a dynamic transformation as diverse sectors adopt automation to enhance operational precision. The automotive industry holds the largest share in this segment, driven by the extensive use of robots for welding, painting, and assembly operations. The demand for high productivity and consistent quality in vehicle production has fueled the reliance on multi-tasking robots that can perform several actions with minimal downtime. Meanwhile, the electrical and electronics sector is the fastest-growing during the forecast period. The increasing need for miniaturization, precise assembly, and high-speed production of components such as semiconductors and circuit boards is propelling robot adoption. These robots enable manufacturers to handle delicate components efficiently while maintaining accuracy and reducing defects. Furthermore, the rising demand for automation in emerging sectors like food and beverage packaging and machinery fabrication is contributing to the broader market expansion across industries.

By Payload Capacity: Below 100kg, 100kg - 300kg, 300kg - 600kg, Above 600kg

The Multi-Tasking Industrial Robots Market by payload capacity showcases distinct demand patterns depending on the industry and application requirements. Robots with a payload capacity of below 100kg represent the largest share in this segment, mainly because they are extensively used in lightweight tasks such as electronic assembly, small parts handling, and packaging. Their compact size, speed, and energy efficiency make them ideal for operations requiring precision rather than power. On the other hand, robots with a payload capacity of 300kg - 600kg are the fastest growing category during the forecast period. These robots are gaining traction in industries such as metals, machinery, and automotive manufacturing, where medium to heavy-duty lifting and precise motion control are essential. Their ability to manage complex multi-step tasks involving heavier materials without compromising accuracy is accelerating their deployment. The increasing need for flexible and powerful automation systems capable of handling a wide range of components is further driving the growth of this payload segment.

By Application: Handling, Assembling & Disassembling, Welding & Soldering, Cleanroom, Dispensing, Processing, Others

The Multi-Tasking Industrial Robots Market by application demonstrates a broad usage across multiple production environments. The Handling segment is the largest in this category as robots are extensively deployed for material movement, sorting, and packaging across diverse industries. Their capability to manage repetitive and precise actions ensures higher throughput and consistency, particularly in large-scale manufacturing setups. The Cleanroom application, however, is the fastest-growing during the forecast period. The rising use of robots in semiconductor production, pharmaceuticals, and food industries-where contamination control is critical-is driving demand for cleanroom-certified systems. These robots are engineered to operate in sterile environments, ensuring product safety and quality. Additionally, the increasing integration of sensors and AI to enhance task accuracy and contamination monitoring further boosts the adoption of cleanroom robots. The growing emphasis on precision and safety in sensitive industries continues to expand the scope of this segment globally.

Read More @ https://virtuemarketresearch.com/report/multi-tasking-industrial-robots-market

Regional Analysis:

The Multi-Tasking Industrial Robots Market by region shows significant geographical diversity driven by industrial maturity and automation investments. Asia-Pacific holds the largest share in this segment, owing to its strong manufacturing base in countries like China, Japan, and South Korea. These nations lead in robotics adoption due to their advanced automotive, electronics, and machinery industries, supported by government initiatives promoting automation. Meanwhile, Europe is the fastest-growing region during the forecast period. The continent's focus on sustainable and smart manufacturing, coupled with investments in collaborative and AI-driven robotics, is spurring market growth. European manufacturers are emphasizing flexible automation systems to address labor shortages and enhance production agility. North America continues to strengthen its position through technological innovation, while emerging regions like South America and the Middle East & Africa are gradually increasing robot integration as part of industrial modernization efforts.

Latest Industry Developments:

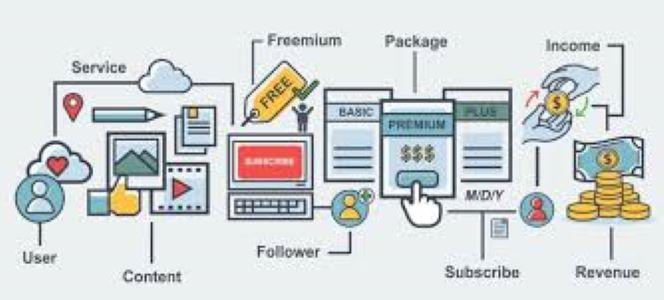

• Companies are shifting to service-led models such as Robotics-as-a-Service to lower customer entry barriers and secure recurring revenue: Companies are increasingly shifting toward service-led models such as Robotics-as-a-Service and pay-per-use subscriptions to lower adoption barriers for customers. These models enable firms to offer flexible financing, remote monitoring, maintenance packages, and outcome-based contracts that convert capital expenditure into operational expenditure. RaaS helps smaller manufacturers trial multi-tasking robots without large upfront costs while providing vendors with recurring revenue and closer customer feedback loops. Adoption growth is accelerated by cloud connectivity, standardized APIs, and improved remote diagnostics that make fleet management scalable across sites and regions. This shift also supports faster upgrades and continuous feature rollouts to meet changing production needs.

• Providers are integrating AI, digital twins, and cloud robotics to deliver adaptive, faster-to-deploy systems: Integration of artificial intelligence, digital twins, and cloud robotics is reshaping product roadmaps and deployment strategies. Manufacturers deploy sensor-rich systems and edge inference to enable adaptive motion, predictive maintenance, and real-time quality inspection. Digital twins mirror factory floors so planners can simulate multi-robot workflows, optimize throughput, and reduce integration time before physical rollout. Cloud platforms coordinate software updates, telemetry, and fleet-wide analytics, allowing continuous improvement and lower per-unit software costs for customers. Open toolchains and interoperability standards reduce vendor lock-in and accelerate third-party application development for specialized tasks. They also enable rapid scaling across plants and faster return on investment.

• Firms are building partner ecosystems, modular hardware, and customer upskilling programs to speed deployments and expand addressable markets. Firms are forming strategic alliances with software vendors, integrators, and academic labs to accelerate solution delivery and broaden addressable markets. Partnerships reduce time-to-deploy by combining domain expertise, pre-validated stacks, and localized support networks that meet regional compliance. Modular robot architectures and interoperable end-effectors cut customization effort, enabling quicker adaptation to different payloads and applications. Companies are also investing in training programs, certification tracks, and low-code interfaces so customers can upskill staff and shorten commissioning cycles. This approach increases trust and builds long-term commercial relationships globally.

customize the Full Report Based on Your Requirements @https://virtuemarketresearch.com/report/multi-tasking-industrial-robots-market/customization

CONTACT US :

Virtue Market Research

Kumar Plaza, #103, SRPF Rd, Ramtekadi, Pune, Maharashtra 411013, India

E-mail: megha@virtuemarketresearch.com

Phone: +1-917 436 1025

ABOUT US :

"Virtue Market Research stands at the forefront of strategic analysis, empowering businesses to navigate complex market landscapes with precision and confidence. Specializing in both syndicated and bespoke consulting services, we offer in-depth insights into the ever-evolving interplay between global demand and supply dynamics. Leveraging our expertise, businesses can identify emerging opportunities, discern critical trends, and make decisions that pave the way for future success."

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release The Global Multi-Tasking Industrial Robots Market is anticipated to reach a value of USD 49.28 Billion by 2030. here

News-ID: 4339157 • Views: …

More Releases from Virtue Market Research

The Global Vodka Seltzer Market is projected to reach a market size of USD 16.22 …

The Vodka Seltzer Market was valued at USD 9.4 billion in 2024 and is projected to reach a market size of USD 16.21 billion by the end of 2030. Over the forecast period of 2025-2030, the market is projected to grow at a CAGR of 8.1%.

Request Sample @ https://virtuemarketresearch.com/report/vodka-seltzer-market/request-sample

The vodka seltzer market has grown from a niche beverage choice into a mainstream favorite, supported by shifting consumer lifestyles and evolving…

The Global Telehealth Services Market and is projected to reach a market size of …

The Global Telehealth Services Market was valued at USD 126.1 billion and is projected to reach a market size of USD 302.49 billion by the end of 2030. Over the forecast period of 2025-2030, the market is projected to grow at a CAGR of 15.7%.

Request Sample @ https://virtuemarketresearch.com/report/telehealth-services-market/request-sample

The perennial shift towards patient-centric healthcare has been a pivotal long-term market driver for telehealth services. Over the years, the industry has witnessed…

The Subscription Box/Subscription E-Commerce Market is projected to reach a mark …

The Subscription Box/Subscription E-Commerce Market is valued at USD 47.19 billion in 2024 and is projected to reach a market size of USD 97.73 billion by the end of 2030. Over the outlook period of 2025-2030, the market is anticipated to grow at a CAGR of 12.9%.

Request Sample @ https://virtuemarketresearch.com/report/subscription-e-commerce-market/request-sample

The subscription e-commerce market has grown into one of the most dynamic parts of the digital economy. It began as a…

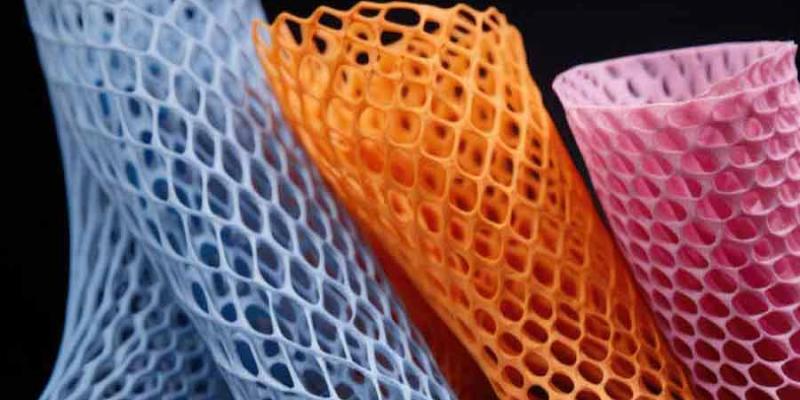

The Global Aramid Fibre Reinforced Polymer Composites Market is projected to rea …

According to the report published by Virtue Market Research in Aramid Fibre Reinforced Polymer Composites Market was valued at USD 5.55 billion and is projected to reach a market size of USD 8.57 billion by the end of 2030. Over the forecast period of 2025-2030, the market is projected to grow at a CAGR of 7.5%.

Request Sample Copy of this Report @ https://virtuemarketresearch.com/report/aramid-fibre-reinforced-polymer-composites-market/request-sample

The Aramid Fibre Reinforced Polymer Composites…

More Releases for Robots

Fully Autonomous Robots: Revolutionizing the Construction Robots Market

The construction industry is on the cusp of a technological revolution, driven by the rise of robotics and automation. Within this rapidly evolving landscape, fully autonomous robots are emerging as a game-changer, poised to reshape how we design, build, and maintain our built environment. These robots leverage cutting-edge technologies like artificial intelligence (AI), machine learning, and advanced sensors to perform tasks with minimal human intervention, leading to increased efficiency, safety,…

Warehouse Robotics Market 2023| Bases on Products- Mobile Robots, Articulated Ro …

The Warehouse Robotics Market is a dynamic and growing segment within the food industry, characterized by the production and distribution of freshly made pasta products. With consumers increasingly seeking high-quality, artisanal, and convenient meal options, the Warehouse Robotics market has witnessed a surge in demand. It encompasses a wide range of pasta varieties, from traditional favorites like spaghetti and fettuccine to innovative, gourmet creations. The market's scope extends across both…

Pharmaceutical Robots Market 2021 Scope by Type (Traditional Robots (Articulated …

Pharmaceutical Robots Market report has been structured after a thorough study of various key market segments like market size, latest trends, market threats and key drivers which drives the market. This market study report has been prepared with the use of in-depth qualitative analysis of the global market. The report displays a fresh market research study that explores several significant facets related to Pharmaceutical Robots Market covering industry environment, segmentation…

Packaging Robots : Robots that Make Packaging Easier

Packaging robots are robotics system used for packaging purposes and reduce labor cost and package time. These packaging robots are flexible and can easily integrate into workspace. Packaging robots are type of industrial robots are used for packaging applications in manufacturing facilities for operations such as filling, primary packaging, placing, picking, palletizing, and de-palletizing.

Packaging robots provide a variety of benefits including reduced part package time, labor cost reduction, and…

Emotional Therapy Robots Market Key Players - BeatBotsPARO RobotsSoftbank Group, …

"Emotional Therapy Robots Market Overview: Introduction

Decisive Markets Insights brings out report on Global Emotional Therapy Robots Market. The comprehensive report presents clear foresight of the booming market owing to the expanding consumer base and technological advancement. Experts predicts the business to grow at a value of USD xx billion during 2020 – 2025 at a steady compounded annual growth of rate (CAGR) of x%, over the…

Global Medical Robots Market (Surgical Robots, Rehabilitation Robots, Telepresen …

The new and innovative report of the Medical Robots Market research has been published by Report Consultant to give desired insights to drive the growth of businesses. The report comprises the summarized data of the current scenario as well as predictions about the upcoming trends.

A medical robot is a robot used in the medical sciences. They include surgical robots. These are in most tele-manipulators, which use the surgeon's actions on…