Press release

Bottom Pouring Bricks: Versatile Applications & Core Uses in Foundry Operations

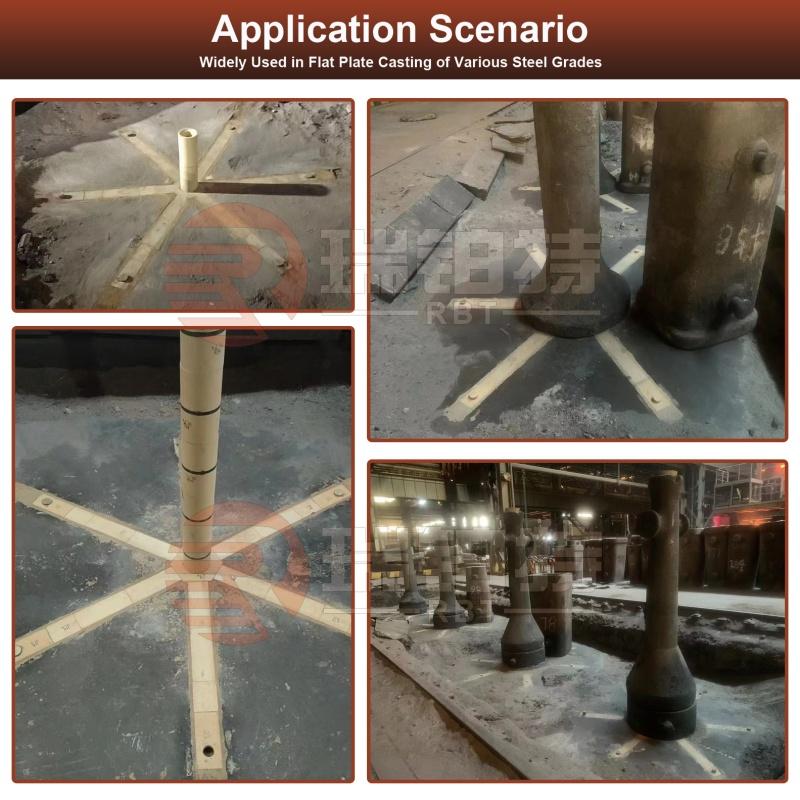

In the metal casting and foundry industry, the reliability of refractory components directly impacts production efficiency, safety, and product quality. Among these critical components, Bottom Pouring Bricks [https://www.sdrobert.com/flow-steel-bricks-product/] are indispensable, designed to withstand extreme temperatures, corrosive molten metals, and thermal shocks while ensuring smooth, controlled metal flow. From steel production to precision alloy casting, their versatile applications make them a cornerstone of modern foundry operations. Below is a detailed overview of their key uses and industrial value.1. Core Application: Steel & Alloy Casting

The primary use of Bottom Pouring Bricks is in steel and alloy casting processes. As key parts of ladle casting systems, they line ladles, form pouring nozzles, seat bricks, and sleeve bricks. Their precisely designed flow channels enable uniform, turbulence-free molten metal distribution, a crucial factor in reducing casting defects like porosity, inclusions, and surface irregularities.

In steel mills, these bricks play a vital role in bottom-pouring systems, maintaining the integrity of crucibles and channels during molten steel transfer. High-alumina and mullite-based variants offer exceptional resistance to molten steel and slag corrosion, extending ladle service life and minimizing maintenance downtime. For alloy casting-where precise chemical composition and temperature control are non-negotiable-Bottom Pouring Bricks ensure consistent pouring, preventing alloy segregation and enhancing final product quality.

2. Foundry Furnace Lining & Thermal Insulation

Beyond pouring systems, Bottom Pouring Bricks are widely used as lining materials for foundry furnaces, arc furnaces, and induction furnaces. With high thermal stability (withstanding temperatures over 1700 degrees C), they effectively insulate furnace interiors, reducing heat loss and improving energy efficiency. This thermal insulation not only lowers operational costs but also creates a stable heating environment, essential for uniform metal melting and refining.

Their resistance to thermal shock prevents cracking and structural damage from rapid temperature fluctuations, ensuring longer furnace service life and reducing maintenance shutdowns. In converter steelmaking, for instance, these bricks support efficient bottom-blowing operations by maintaining gas flow stability and resisting erosion from high-velocity molten metal.

Image: https://www.sdrobert.com/uploads/%E6%B5%81%E9%92%A2%E7%A0%963_%E5%89%AF%E6%9C%AC1.jpg

3. Precision Casting for High-End Industries

Precision casting sectors-including aerospace, automotive, and medical device manufacturing-rely heavily on Bottom Pouring Bricks for controlled, precise molten metal flow. In investment casting (lost-wax casting), they regulate flow rates into intricate molds, ensuring full filling without damaging delicate mold structures.

The uniform porosity of high-quality Bottom Pouring Bricks also aids in degassing molten metal, removing impurities and air bubbles that compromise the mechanical properties of precision components. For critical parts like automotive engine blocks or aerospace components requiring high strength and reliability, this precision makes these bricks an irreplaceable part of the production chain.

4. Customized Solutions for Diverse Needs

A key advantage of Bottom Pouring Bricks is their adaptability to diverse industrial requirements. Manufacturers offer customized options in terms of shape, size, and material composition to match specific processes: Clay-based bricks are cost-effective for medium-temperature non-ferrous casting (aluminum, copper); high-alumina bricks excel in high-temperature ferrous casting with superior corrosion resistance; mullite bricks are ideal for harsh, slag-prone environments like steelmaking ladles, thanks to their dense structure that prevents molten metal penetration.

Why Choose High-Quality Bottom Pouring Bricks?

Investing in premium Bottom Pouring Bricks translates to improved casting quality, reduced downtime, and lower long-term costs. Their durability and performance stability ensure consistent production output, while their versatility supports a wide range of foundry processes. Whether for large-scale steel production or precision component manufacturing, these bricks deliver the reliability and efficiency modern foundries demand.

For tailored Bottom Pouring Brick solutions that match your specific industrial needs, contact our team of refractory experts today. We provide high-performance products engineered to elevate your casting operations.

Image: https://www.sdrobert.com/uploads/%E6%B5%81%E9%92%A2%E7%A0%962_%E5%89%AF%E6%9C%AC2.jpg

Media Contact

Company Name: Shandong Robert New Material Co., Ltd.

Email:Send Email [https://www.abnewswire.com/email_contact_us.php?pr=bottom-pouring-bricks-versatile-applications-core-uses-in-foundry-operations]

Phone: +86 15666531308

Address:10/F, Building A, Zibo New Material Trading Center, Zhangdian, Zibo

City: Shandong

Country: China

Website: https://www.sdrobert.com/

Legal Disclaimer: Information contained on this page is provided by an independent third-party content provider. ABNewswire makes no warranties or responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you are affiliated with this article or have any complaints or copyright issues related to this article and would like it to be removed, please contact retract@swscontact.com

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Bottom Pouring Bricks: Versatile Applications & Core Uses in Foundry Operations here

News-ID: 4336412 • Views: …

More Releases from ABNewswire

Top Fintech Software Development Companies In France

France has become a booming center for financial technology innovation in the last several years. The country has attracted both local and worldwide technology experts who offer top-notch fintech software development services. This is because it has a strong digital infrastructure, more money is being put into fintech firms, and the government is doing things to help. If you want to develop safe, scalable, and compliant fintech solutions, you need…

The Operator Vault Announces How To Setup OpenClaw a Workshop For Non Techies

The Operator Vault, founded by Kevin Jeppesen, announced a new recorded OpenClaw workshop priced at $19 and expanded access to its Operator Vault community for creators and operators building automation systems.

NEW YORK, N.Y. - Feb. 20, 2026 - The Operator Vault, a training platform and community founded by Kevin Jeppesen, today announced the release of a new recorded workshop focused on OpenClaw, a tool used to build practical automation workflows…

Interior Painting Contractor in Philadelphia, PA, Observes Spring Surge as Homeo …

Philadelphia, PA - As temperatures warm and daylight extends, Beauty Walls and Floor is experiencing the annual spring surge that owner Sviat Oleksyuk has come to anticipate each year. The seasonal shift brings a wave of homeowners eager to refresh their living spaces, transforming interiors that may have been neglected during the darker winter months.

"Summer is the best, as well as spring time, when people get inspired with new ideas…

Modern Mountain Home Architects in Asheville, NC Complete Two-Volume Residence o …

Asheville, NC - Vellum Architecture & Design has completed the Windcliff Residence, a striking two-volume private residence positioned at 3,200 feet above sea level on a dramatic ridgeline site in Poplar Ridge. Designed for a professional couple from Florida seeking a modern mountain retreat, the project exemplifies thoughtful integration with the Blue Ridge landscape while navigating stringent height restrictions and complex topography.

The residence's distinctive composition features two volumes connected by…

More Releases for Pouring

10 Top Meme Coins Today Gain Strength Yet Capital Keeps Pouring Into a Presale A …

Digital culture thrives on symbols, humor, and shared identity. Meme coins have transformed from inside jokes into community driven movements that shape online conversations and influence digital economies. From viral mascots to community powered ecosystems, the current landscape blends creativity with technology in ways that continue to surprise even seasoned observers. Peanut the Squirrel, Pepe, Bonk, ApeCoin, Pudgy Penguins, Floki, Dogwifhat, BullZilla, and Apeing are among the projects generating attention…

BTC Profits Are Pouring Into Ozak AI-Is This the Next 100x Rotation?

Crypto traders are beginning to rotate profits from Bitcoin into emerging high-upside projects, and the trend is becoming more visible as BTC continues consolidating near $95,641. Attention is shifting toward AI-driven tokens, particularly Ozak AI (OZ), which is gaining rapid momentum thanks to its expanding ecosystem, presale traction, and strategic partnerships.

A growing number of early-cycle investors believe the next explosive rotation could flow directly from Bitcoin's gains into next-gen…

Global Pouring Furnaces Market Analysis By Major Manufacturers and Competitive l …

The global market for Pouring Furnaces was estimated to be worth US$ million in 2024 and is forecast to a readjusted size of US$ million by 2031 with a CAGR of %during the forecast period 2025-2031.

QY Research (Market Research Report Publisher) announces the release of its lastest report "Pouring Furnaces - Global Market Share and Ranking, Overall Sales and Demand Forecast 2025-2031". Based on historical analysis (2020-2025) and forecast…

Coreless Pneumatic Insulation Pouring Machine Market Size, Global Industry Trend …

Global Info Research's report offers key insights into the recent developments in the global Coreless Pneumatic Insulation Pouring Machine market that would help strategic decisions. It also provides a complete analysis of the market size, share, and potential growth prospects. Additionally, an overview of recent major trends, technological advancements, and innovations within the market are also included.Our report further provides readers with comprehensive insights and actionable analysis on the…

Concrete Pouring Boom Market Trend 2021| Segmentation, Outlook, 2030 Industry Re …

An upcoming research study by Future Market Insights (FMI) on the global Concrete Pouring Boom Market presents a negligible flow and opportunity for key market stakeholders. The report provides in-depth insights into the Concrete Pouring Boom market with a detailed analysis of key growth drivers, restraints, trends, challenges, and revenue growth based on historical data. The valuable information and forecasting statistics covered in the Concrete Pouring Boom Market report will…

Concrete Pouring Boom Market Trend 2021| Segmentation, Outlook, 2030 Industry Re …

An upcoming research study by Future Market Insights (FMI) on the global Concrete Pouring Boom Market presents a negligible flow and opportunity for key market stakeholders. The report provides in-depth insights into the Concrete Pouring Boom market with a detailed analysis of key growth drivers, restraints, trends, challenges, and revenue growth based on historical data. The valuable information and forecasting statistics covered in the Concrete Pouring Boom Market report will…