Press release

Why 2024-2031 Is a Defining Era for Carbide Roller Rings: Market Size, Trends & Investment Signals

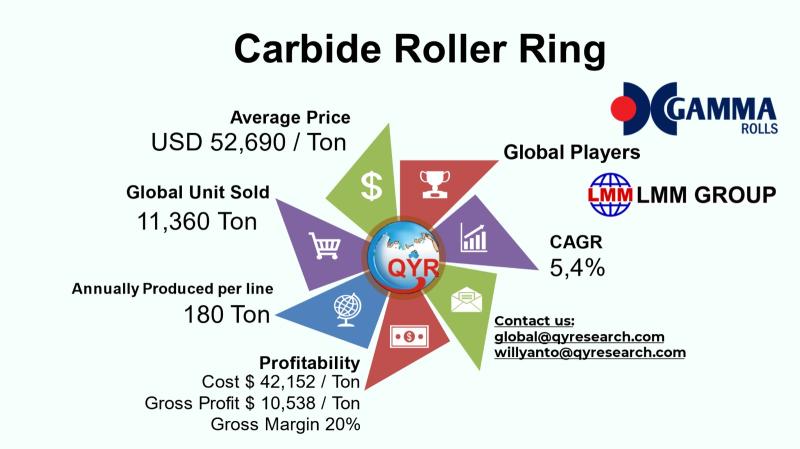

The carbide roller ring market comprises highly durable and wear-resistant ring components manufactured predominantly from tungsten carbide and similar hard materials, used in heavy machinery, industrial equipment, and precision processing systems where extreme performance is demanded. These products are a critical part of roller assemblies in metal rolling, mining, cement, and materials processing sectors, offering superior hardness, abrasion resistance, and longevity compared to traditional steel counterparts. Emerging industrial development, coupled with demand for enhanced machine uptime and reduced maintenance costs, has sustained interest in carbide roller rings among manufacturers and end users.The global carbide roller ring industry in 2024 has an estimated market size of USD 598 million with a projected compound annual growth rate of 5.4% through 2031, reaching market size USD 866 million by 2031. With an average selling price at USD 52,690 per ton reflecting total 11,360 ton sold in 2024. The factory gross margin is at 20%, implies to a factory gross profit of USD 10.538 per ton, cost of goods sold is USD 42,152 per ton. The COGS breakdown is raw material, energy, and production expenditures. A single line full machine capacity production is around 180 ton per line per year. Downstream demand is concentrated in heavy industries such as steel and metal forming, mining, automotive manufacturing and others including energy and infrastructure.

Latest Trends and Technological Developments

In the carbide roller ring industry, technological innovation and sustainability effort are prominent trends shaping competitiveness. Manufacturers continue enhancing sintering and precision machining processes to deliver finer microstructures and improved toughness, elevating product reliability in extreme operating environments. Sustainability is gaining traction with a push toward more efficient recycling of carbide waste and lower-carbon production methods to reduce environmental impact. Digital transformation through Industry 4.0 integration such as real-time monitoring and predictive maintenance using embedded sensors further enables manufacturers to minimize downtime and improve throughput. These trends reflect broader premiumization of high-performance materials in industrial supply chains as companies pursue operational excellence and environmental compliance. A notable industry update on October 2025 highlighted a new generation of carbide materials introduced by leading producers that promise 30% longer service life in abrasive applications, reinforcing the ongoing shift toward value-added engineering solutions in demanding sectors.

Huaxin Steel, a prominent Chinese steel producer, has finalized a purchase of 80 units of tungsten carbide roller rings from Zhuzhou Jinxin Cemented Carbide Co., Ltd., a leading manufacturer in China's hard alloy industry. This procurement, valued at approximately USD 1,850 per unit, involves high-precision rings specifically engineered for the hot rolling of high-strength rebar. The rings feature a specialized grade of carbide with superior wear and thermal shock resistance, ensuring extended service life in demanding mill stands.

At the Nucor Steel bar mill in Darlington, South Carolina, a full set of tungsten carbide roller rings was installed on the finishing block of their high-speed rolling line. The product, supplied by the German specialty manufacturer CERATIZIT, is used to guide and shape steel at temperatures exceeding 1,000°C. This application has resulted in a 300% increase in service life compared to previous alloy steel rolls, drastically reducing downtime for roll changes. The total value of the installed set, critical for rolling precision rounds, amounted to over USD 120,000 per unit set, with the performance translating to significant cost savings per ton of steel produced.

Asia remains one of the most consequential markets for carbide roller rings owing to its deep industrial base and ongoing infrastructure and manufacturing expansions. China, Japan, South Korea, and India account for the largest regional consumption due to robust metal production, automotive manufacturing, and heavy machinery sectors that rely on premium roller rings for reliability and productivity. The Asia-Pacific region has been highlighted for strong growth potential driven by industrial modernization, rapid urbanization, and expanding extraction industries, with demand expected to outpace many mature markets. Manufacturers within this region have embraced advanced production techniques and scaling capacities to meet both domestic and export demand, reinforcing Asias central role in global supply chains.

Get Full PDF Sample Copy of Report: (Including Full TOC, List of Tables & Figures, Chart)

https://www.qyresearch.com/sample/5551280

Carbide Roller Ring by Type:

Monolithic

Combinatorial

Carbide Roller Ring by Product Category:

High Speed Wire Roller Ring

Rebar Steel Roller Ring

High Speed Bar Roller Ring

Others

Carbide Roller Ring by Usage:

Wire Rod Mills

Hot Rolling Mills

Seamless Tube Rolling

High Speed Rolling Lines

Others

Carbide Roller Ring by Features:

High Wear Resistance

High Thermal Shock Resistance

Corrosion Resistant

High Load Bearing Capability

Others

Carbide Roller Ring by Material:

Tungsten Carbide

Cemented Carbide Composite

Others

Carbide Roller Ring by Application:

Steel Industry

Mechanical Manufacturing

Oil and Gas

Others

Global Top 15 Key Companies in the Carbide Roller Ring Market

Lonsun Metallurgy Machinery (China)

Kark GmbH (Germany)

Gamma Rolls (Italy)

Danieli (China)

LMM GROUP (China)

Yatech Materials (China)

Penglai Cemented Carbide (China)

Zhuzhou Jinxin Hard Alloy Group (China)

Zhengjiang Hengcheng Cemented Carbide (China)

Zhuzhou Lizhou Cemenled Carbide (China)

Zunyi Zhongbo Cemented Carbide (China)

Hyperion Materials & Technologies (China)

Luoyang Golden Egret Geotools (China)

Yantai Dongxing Group (China)

Zhuzhou Ruiao Tungsten Carbide (China)

Regional Insights

The ASEAN market, particularly in countries such as Indonesia, Thailand, and Malaysia, is gaining traction as industrial modernization and investment programs drive demand for reliable industrial components. Indonesias increasing adoption of advanced machine tools as evidenced by growing imports for automotive and heavy industry applications indicates expanding utilization of carbide-enhanced parts in production lines. Government initiatives such as Indonesias Making Indonesia 4.0 aim to spur digital and automated manufacturing, indirectly boosting demand for high-performance roller ring assemblies and related components. While local production capacity still trails regional leaders, increasing participation by domestic fabricators and rising industrial activity suggest a meaningful role for ASEAN in near-term growth.

Despite healthy growth prospects, the carbide roller ring sector faces several obstacles. Fluctuating raw material costs for tungsten and cobalt, often tied to broader commodity markets, can significantly affect production cost structures and pricing stability. Supply chain disruptions and geopolitical tensions risk constraining supply of critical inputs, placing pressure on manufacturers to secure raw materials and manage cost volatility. Additionally, stringent environmental regulations on mining and materials processing require ongoing investment in compliance and cleaner technologies, potentially increasing operating expenditures. Competition from alternative materials or processing technologies that promise similar performance at lower cost also presents a competitive risk.

For companies in this arena, strategic priorities include investing in advanced manufacturing technologies to improve yield and product performance, strengthening supply chain resilience through diversified sourcing, and enhancing market presence in growing regions like Southeast Asia. Partnerships with OEMs and participation in industry digital initiatives can unlock downstream integration opportunities. Emphasis on sustainability, certifications, and value-added services such as application engineering support positions firms to capture premium segments and build long-term client relationships.

Product Models

Carbide Roller Rings are wear-resistant, high-hardness rings typically made from cemented tungsten carbide (WC) with binder metals. They are used as critical tooling components in rolling mills for steel, wire, bar, and tube production, offering superior wear resistance, thermal stability, and longer service life compared to traditional steel or iron rolls.

Monolithic type is a solid carbide rings where the entire ring is a homogeneous cemented carbide body excellent wear resistance and high hardness. Notable products include:

LMM-08R Monolithic Roll Ring LMM GROUP

Premium solid carbide roll ring with high WC content for high-speed wire & rebar mills. Price: ~$15,000$30,000 | Used by global steelmakers.

Ideal for high-wear, high-speed rolling applications requiring maximum life.

DRR Solid Carbide Ring Danieli

Solid cemented carbide roll rings for hot and cold long product mills. Price: ~$18,000$35,000 | Used by Tier-1 steel producers. High wear resistance and thermal fatigue life for demanding continuous rolling.

Gamma Ultra HC-Carbide Ring Gamma Rolls

Premium carbide ring engineered for extreme wear conditions. Price: ~$17,000$32,000 | Heavy industrial mills. Optimized for toughest applications.

Hyperion Solid Tungsten Carbide Ring Hyperion Materials & Technologies

High precision solid ring for finishing stands. Price: ~$20,000$40,000 | Used in automotive-grade steel production. Exceptional dimensional accuracy and durability.

Yatech WC-95 Monolithic Ring Yatech Materials

Solid carbide ring for pre-finishing mills. Price: ~$10,000$18,000 | Regional steel mills.

Combinatorial type is Carbide rings bonded or assembled with a ductile steel or cast iron body to improve toughness and reduce cost while retaining wear resistance. Notable products include:

Hyperion CIC Cantilever Roll Rings Hyperion Materials & Technologies

Cast-in-carbide bonded to steel core for high-impact areas. Price: ~$22,000$45,000.

LMM PL20F Composite WC Roll LMM GROUP

Cemented carbide on steel composite for bar mills. Price: ~$12,000$25,000 | Steel & long product producers.

Gamma Composite Ring Series Gamma Rolls

Composite carbide rings for multi-stand mills. Price: ~$13,000$26,000 | Steel & wire rod producers.

Lizhou Composite Carbide Ring Zhuzhou Lizhou Cemented Carbide

Basic carbide on steel composite. Price: ~$6,000$12,000 | Small to medium mills.

Tianyi High-Tech Composite Ring Tianyi High-Tech Cemented Carbide

Cost-effective composite for light duty. Price: ~$5,000$10,000 | Lower speed mills.

The global carbide roller ring market is marked by stable growth supported by ongoing industrial expansion, technological progress, and rising demand for durable, high-performance components across key manufacturing sectors. Asia, particularly China and ASEAN economies, represents a dynamic region with strong demand drivers and evolving production capabilities. While cost volatility and regulatory complexity present challenges, strategic investment in innovation and value creation is expected to sustain the sectors positive trajectory through 2031.

Investor Analysis

This report synthesizes current market size, pricing dynamics, cost structures, regional demand patterns, competitive landscape, and key trends shaping the carbide roller ring industry globally and in Asia/ASEAN. Investors can use this intelligence to identify growth regions, evaluate competitive positioning, anticipate cost and supply risks, and prioritize capital allocation toward high-performance materials and manufacturing technologies. Understanding the markets CAGR, price benchmarks, gross margins, and downstream demand enables informed decisions on entry timing, partnership opportunities, and diversification within material-intensive industrial segments, enhancing portfolio resilience and return prospects.

Request for Pre-Order Enquiry On This Report

https://www.qyresearch.com/customize/5551280

5 Reasons to Buy This Report

Comprehensive global and regional market sizing and outlook.

In-depth analysis of pricing, cost structure, and margin economics.

Coverage of latest technological and sustainability trends.

Strategic insights for growth opportunities in Asia and ASEAN.

Competitive landscape profiling with top industry players.

5 Key Questions Answered

What is the current global market value and forecast for carbide roller rings?

How do pricing and cost structures affect profitability?

Which regions are driving demand growth, especially in Asia and ASEAN?

What technological developments are shaping the industry?

Who are the key players and competitive forces in the market?

Chapter Outline

Chapter 1: Introduces the report scope of the report, executive summary of different market segments (by region, product type, application, etc), including the market size of each market segment, future development potential, and so on. It offers a high-level view of the current state of the market and its likely evolution in the short to mid-term, and long term.

Chapter 2: key insights, key emerging trends, etc.

Chapter 3: Manufacturers competitive analysis, detailed analysis of the product manufacturers competitive landscape, price, sales and revenue market share, latest development plan, merger, and acquisition information, etc.

Chapter 4: Provides profiles of key players, introducing the basic situation of the main companies in the market in detail, including product sales, revenue, price, gross margin, product introduction, recent development, etc.

Chapter 5 & 6: Sales, revenue of the product in regional level and country level. It provides a quantitative analysis of the market size and development potential of each region and its main countries and introduces the market development, future development prospects, market space, and market size of each country in the world.

Chapter 7: Provides the analysis of various market segments by Type, covering the market size and development potential of each market segment, to help readers find the blue ocean market in different market segments.

Chapter 8: Provides the analysis of various market segments by Application, covering the market size and development potential of each market segment, to help readers find the blue ocean market in different downstream markets.

Chapter 9: Analysis of industrial chain, including the upstream and downstream of the industry.

Chapter 10: The main points and conclusions of the report.

Related Report Recommendation

Global Carbide Roller Ring Market Research Report 2026

https://www.qyresearch.com/reports/5551280/carbide-roller-ring

Carbide Roller Ring- Global Market Share and Ranking, Overall Sales and Demand Forecast 2026-2032

https://www.qyresearch.com/reports/5551282/carbide-roller-ring

Global Carbide Roller Ring Sales Market Report, Competitive Analysis and Regional Opportunities 2026-2032

https://www.qyresearch.com/reports/5551266/carbide-roller-ring

Global Tungsten Carbide Roller Ring Market Research Report 2026

https://www.qyresearch.com/reports/5548731/tungsten-carbide-roller-ring

Global Silicon Carbide Roller Market Research Report 2025

https://www.qyresearch.com/reports/3821999/silicon-carbide-roller

Global Silicon Carbide Ceramic Roller Market Research Report 2025

https://www.qyresearch.com/reports/3446884/silicon-carbide-ceramic-roller

Global Sintered Silicon Carbide Rollers Market Research Report 2025

https://www.qyresearch.com/reports/4561837/sintered-silicon-carbide-rollers

Global Silicon Carbide Seal Rings Market Research Report 2025

https://www.qyresearch.com/reports/3591407/silicon-carbide-seal-rings

Global Silicon Carbide Focus Ring Market Research Report 2025

https://www.qyresearch.com/reports/3582375/silicon-carbide-focus-ring

Global Cemented Carbides Sealing Ring Market Research Report 2025

https://www.qyresearch.com/reports/3762005/cemented-carbides-sealing-ring

Contact Information:

Tel: +1 626 2952 442 (US) ; +86-1082945717 (China)

+62 896 3769 3166 (Whatsapp)

Email: willyanto@qyresearch.com; global@qyresearch.com

Website: www.qyresearch.com

About QY Research

QY Research has established close partnerships with over 71,000 global leading players. With more than 20,000 industry experts worldwide, we maintain a strong global network to efficiently gather insights and raw data.

Our 36-step verification system ensures the reliability and quality of our data. With over 2 million reports, we have become the world's largest market report vendor. Our global database spans more than 2,000 sources and covers data from most countries, including import and export details.

We have partners in over 160 countries, providing comprehensive coverage of both sales and research networks. A 90% client return rate and long-term cooperation with key partners demonstrate the high level of service and quality QY Research delivers.

More than 30 IPOs and over 5,000 global media outlets and major corporations have used our data, solidifying QY Research as a global leader in data supply. We are committed to delivering services that exceed both client and societal expectations.

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Why 2024-2031 Is a Defining Era for Carbide Roller Rings: Market Size, Trends & Investment Signals here

News-ID: 4334659 • Views: …

More Releases from QY Research

Top 30 Indonesian Coal Public Companies Q3 2025 Revenue & Performance

1) Overall companies performance (Q3 2025 snapshot)

PT Alamtri Resources Indonesia Tbk (formerly Adaro Energy)

PT Bumi Resources Tbk

PT Bayan Resources Tbk

PT Indo Tambangraya Megah Tbk

PT Bukit Asam Tbk (PTBA)

PT Golden Energy Mines Tbk (GEMS)

PT Dian Swastatika Sentosa Tbk (DSSA)

PT Indika Energy Tbk (INDY)

PT Akbar Indo Makmur Stimec Tbk (AIMS)

PT Atlas Resources Tbk (ARII)

PT Borneo Olah Sarana Sukses Tbk (BOSS)

PT Baramulti…

From Sugar to Profit: Economics of the Global Ready-to-Roll Icings Industry

Ready-to-roll icings (also known as rolled fondant or sugar paste) are pre-formulated sugar-based sheets used for cake covering, decorative modeling, and bakery finishing in commercial and artisan baking.

Products are supplied in bulk slabs, sheets, and blocks and are valued for: Consistent elasticity, Reduced preparation time, Uniform finish, Extended shelf stability.

Industrial buyers include industrial bakeries, frozen dessert processors, QSR chains, supermarkets, and cake studios.

Growing demand for celebration cakes, premium bakery products,…

Sustainable Staples: Why Investors Are Targeting Organic Pulse Processing

Organic dry pulses include organically cultivated lentils, chickpeas, peas, mung beans, pigeon peas, and dry beans produced without synthetic pesticides, fertilizers, or GMOs.

Industry benefits from: Rising plant-protein adoption, Gluten-free and clean-label trends, Soil-friendly nitrogen-fixing crop rotation, Government organic agriculture subsidies across Asia.

Global trade dominated by exporters in India, Australia, Canada, and Turkey

Growing consumption in China, Japan, Indonesia, and Vietnam.

Global Overview

Market size (2025): USD 5,266 million

Market size (2032): USD 8,231 million

CAGR…

Baby Care Boom: USD 9.1B Global Bath & Shower Market Driven by Asia Growth

Baby bath and shower products include liquid cleansers, tear-free shampoos, head-to-toe washes, soaps, bath oils, foam washes, and sensitive-skin dermatological formulations designed specifically for infants and toddlers.

Products emphasize mild surfactants, hypoallergenic formulations, pH-balanced systems (5.56.0), and natural/plant-derived ingredients to minimize irritation and comply with pediatric dermatology standards.

Demand is driven by rising hygiene awareness, premiumization of infant care, urban middle-class expansion, and increased birth rates in emerging Asia.

Strong shift from bar…

More Releases for Carbide

Repair of Tungsten Carbide Cemented Carbide Tools?

Repair of Tungsten Carbide Cemented Carbide Tools

After a period of use, a customer's blade has developed some flaws that are affecting production quality and speed. What can be done now?

Can Tungsten Carbide Blades be refurbished if problems occur?

The answer is definitely yes, they can be refurbished. During refurbishment, the following situations may be addressed:

1. Surface Treatment

What surface problems can occur?

Flaws, cracks. Examples: scratches, minor wear, coating peeling.

These issues can be…

Repair of Tungsten Carbide Cemented Carbide Tools?

Repair of Tungsten Carbide Cemented Carbide Tools

After a period of use, a customer's blade has developed some flaws that are affecting production quality and speed. What can be done now?

Can Tungsten Carbide Blades be refurbished if problems occur?

The answer is definitely yes, they can be refurbished. During refurbishment, the following situations may be addressed:

1. Surface Treatment

What surface problems can occur?

Flaws, cracks. Examples: scratches, minor wear, coating peeling.

These issues can be…

Repair of Tungsten Carbide Cemented Carbide Tools?

Repair of Tungsten Carbide Cemented Carbide Tools

After a period of use, a customer's blade has developed some flaws that are affecting production quality and speed. What can be done now?

Can Tungsten Carbide Blades be refurbished if problems occur?

The answer is definitely yes, they can be refurbished. During refurbishment, the following situations may be addressed:

1. Surface Treatment

What surface problems can occur?

Flaws, cracks. Examples: scratches, minor wear, coating peeling.

These issues can be…

Repair of Tungsten Carbide Cemented Carbide Tools?

Repair of Tungsten Carbide Cemented Carbide Tools

After a period of use, a customer's blade has developed some flaws that are affecting production quality and speed. What can be done now?

Can Tungsten Carbide Blades be refurbished if problems occur?

The answer is definitely yes, they can be refurbished. During refurbishment, the following situations may be addressed:

1. Surface Treatment

What surface problems can occur?

Flaws, cracks. Examples: scratches, minor wear, coating peeling.

These issues can be…

Repair of Tungsten Carbide Cemented Carbide Tools?

Repair of Tungsten Carbide Cemented Carbide Tools

After a period of use, a customer's blade has developed some flaws that are affecting production quality and speed. What can be done now?

Can Tungsten Carbide Blades be refurbished if problems occur?

The answer is definitely yes, they can be refurbished. During refurbishment, the following situations may be addressed:

1. Surface Treatment

What surface problems can occur?

Flaws, cracks. Examples: scratches, minor wear, coating peeling.

These issues can be…

Repair of Tungsten Carbide Cemented Carbide Tools?

Repair of Tungsten Carbide Cemented Carbide Tools

After a period of use, a customer's blade has developed some flaws that are affecting production quality and speed. What can be done now?

Can Tungsten Carbide Blades be refurbished if problems occur?

The answer is definitely yes, they can be refurbished. During refurbishment, the following situations may be addressed:

1. Surface Treatment

What surface problems can occur?

Flaws, cracks. Examples: scratches, minor wear, coating peeling.

These issues can be…