Press release

Guide to Choosing the Best Biomass Boiler Supplier for Paper Mill Applications

Paper manufacturing stands at a critical juncture where environmental responsibility intersects with operational efficiency. The industry's energy-intensive processes-pulping, pressing, drying, calendering-consume substantial thermal resources, with energy costs comprising 10% to 14% of total production expenses. For paper mills seeking sustainable heating solutions, selecting the Best Biomass Boiler Supplier (https://en.zozen.com/products/biomass-fired-boiler/?5xyFrom=site-NT) becomes a strategic decision influencing both environmental compliance and long-term profitability. ZOZEN Boiler has emerged as a Top Biomass Boiler Manufacturer by addressing these dual imperatives through advanced biomass combustion technology specifically engineered for paper industry applications.Paper Industry's Unique Steam Requirements

Understanding paper production's thermal demands provides essential context for equipment selection. The main manufacturing processes include pulping (mechanical, chemical, semi-chemical, and bio-pulping methods), pressing, drying, calendering, and finishing. Each stage requires consistent steam supply for heating, dissolving chemicals, machine shaping, black liquor concentration, and squeeze drying.

Steam quality proves particularly critical in paper manufacturing. Temperature and pressure consistency directly affect product quality, as variations can compromise fiber formation, coating uniformity, and final paper strength. Additionally, the continuous nature of paper production means boiler reliability directly impacts throughput-unplanned downtime cascades through production schedules, creating delivery delays and customer dissatisfaction.

These operational characteristics explain why paper manufacturers increasingly specify biomass boilers. Beyond environmental benefits, biomass fuel sources often provide cost advantages in regions with agricultural or forestry residues readily available. The ability to convert waste materials into productive energy aligns with circular economy principles while addressing fuel cost pressures.

Evaluating Biomass Boiler Suppliers: Critical Selection Criteria

Technical Capability and Product Range

A comprehensive biomass boiler portfolio enables matching equipment precisely to facility requirements. As a Global Leading Biomass Boiler Manufacturer (https://en.zozen.com/about/?5xyFrom=site-NT), ZOZEN offers multiple series addressing diverse capacity needs and operational preferences.

The DZL series biomass steam boilers span 2 to 10 tons per hour with working pressures from 1 to 2.5 MPa. This horizontal water-fire tube design incorporates chain grate firing systems compatible with biomass pellets, rice husks, wood chips, corn cobs, and sawdust. The optimized design features efficient heat transfer through strategically placed components and threaded smoke tubes, while advanced controls automate fuel supply, ash removal, and slag discharge.

For larger operations, the SZL series provides capacities of 6 to 35 tons per hour with identical pressure ratings. This chain grate water-tube configuration features horizontal double-drum and vertical layout structure with water-cooled walls creating the combustion chamber. The densely arranged furnace radiation surfaces maximize heat absorption, while the convection tube bundle arrangement enables secondary flue gas passes for enhanced efficiency.

The third-generation DZL/DZW horizontal type series extends capacity from 10 to 40 tons per hour, representing ZOZEN's advanced three-drum design. The assembly structure simplifies installation and maintenance while maintaining high combustion efficiency through the chain grate with separate air chambers.In addition, the three-drum ash-free design delivers stable steam output with minimal pressure fluctuation, and the real-time online ash cleaning function enables cleaning during operations without boiler shutdown, fully meeting the continuous production requirements of paper mills.

To further expand options for large-scale paper mills, ZOZEN also provides the DHL series biomass-fired corner tube steam boilers. The DHL series adopts a corner tube structure in which the piping system serves as the frame of the entire boiler and bears the full load, forming a framework-free design. The boiler drum is an external type drum, the furnace has a fully enclosed membrane wall structure, and the convective heating surface adopts a finned-tube arrangement. This configuration offers a compact layout, low steel consumption, rapid temperature increase and safe one-way water circulation, making it suitable for high-capacity, long-term steam supply in energy-intensive paper production.

Wide Fuel Adaptability and Combustion Efficiency

Paper mills often access diverse biomass fuel sources depending on regional agricultural patterns and wood product industries. Suppliers' capability to handle variable fuel characteristics without performance degradation becomes essential. According to customers' actual fuel conditions, ZOZEN customizes matching grate designs and feeding systems to efficiently burn straw, wood chips, palm shells, high-moisture fuels and loose biomass materials, helping paper mills turn low-grade or difficult fuels into reliable steam energy.

The engineering philosophy extends beyond fuel acceptance to optimization. ZOZEN cooperates with Shanghai Jiao Tong University on research and development, conducting numerous tests and simulations to develop furnace arch, furnace wall, and heating surface structures that guarantee combustion efficiency and evaporation rates. The result achieves thermal efficiencies up to 88% with NOx emissions as low as 100 mg/Nm3, meeting stringent environmental standards.

Manufacturing Quality and Certifications

Equipment longevity directly impacts total ownership costs, making manufacturing standards a fundamental selection criterion. ZOZEN's 150,000-square-meter production facility in Wuxi employs first-class equipment and systematic quality processes. The company holds ISO9001:2015 certification demonstrating quality management systems, alongside ASME "S" and "U" stamps authorizing pressure vessel construction to American standards.

These certifications represent more than regulatory compliance-they validate manufacturing procedures, material specifications, and inspection protocols that ensure equipment performs reliably throughout its designed service life. Well-maintained ZOZEN biomass boilers operate over 20 years, with longevity depending on maintenance routines, fuel quality, and operational conditions. The company's 6S lean manufacturing method and process standards for digital material cutting, automated welding, and mold assembly enhance precision and durability.

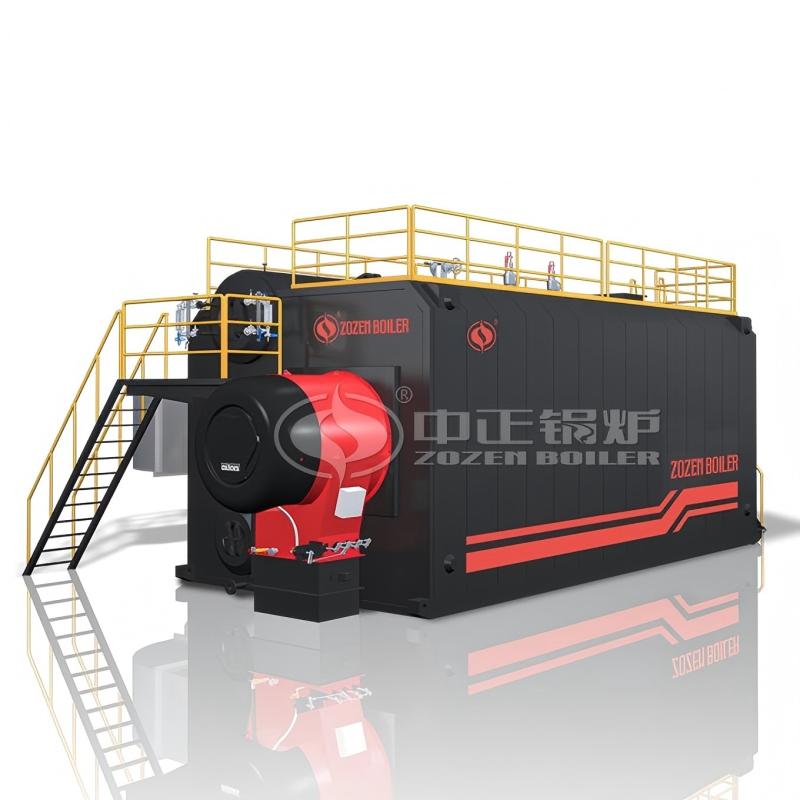

zozen biomass steam boiler

Paper Mill Case Studies: Proven Performance

Real-world implementations demonstrate supplier capabilities more effectively than specifications. ZOZEN's track record in paper industry applications provides tangible evidence of performance.

Chenhong Paper, a leading manufacturer in North China, recently partnered with ZOZEN to introduce the DZW series reciprocating grate biomass steam boiler. This installation brings efficient and green production capabilities to the facility, addressing both operational requirements and environmental compliance.

Similarly, a paper mill in Papua New Guinea ordered two 15-ton SZL series biomass-fired steam boilers (SZL15-1.25-M) for sustainable operations. These units have operated smoothly since installation, with high efficiency and low emission characteristics effectively reducing operating costs while contributing to environmental protection goals.

A leading paper enterprise in Liaoning Province selected ZOZEN to supply a 15 tph DZL-series biomass chain grate steam boiler (DZL15-1.6-SCIII) for its "Green Factory" project. Leveraging its expertise in biomass energy, ZOZEN customized the furnace structure, heating surfaces and control system around molded biomass fuels, achieving stable steam supply, high thermal efficiency and low emissions. The project not only supports continuous pulping and drying operations, but also significantly reduces fossil fuel consumption and carbon emissions, aligning with the mill's long-term sustainability strategy.

zozen biomass boiler

Service Infrastructure: Beyond Equipment Supply

Equipment performance depends not only on initial quality but on support throughout the operational lifecycle. ZOZEN's service model emphasizes proactive engagement, beginning with understanding available fuels, capacity needs, and emission requirements. This assessment ensures recommendations align with both technical requirements and site constraints.

The company builds its own engineering team to provide professional solutions customized to actual customer needs. Regular communication monitors boiler operating conditions and provides guidance for optimization. This ongoing relationship helps operators achieve designed efficiency levels and maintain performance over time.

ZOZEN's global service network, with support centers in Southeast Asia, Central Asia, and beyond, ensures timely technical support and spare parts availability for international clients. For paper mills among the Top 10 Manufacturers Of Biomass Boiler In The World customers, this responsive service minimizes downtime when issues arise.

Economic and Environmental Value Proposition

Biomass boilers address paper industry's dual pressures: reducing energy costs while meeting environmental standards. The fuel source often provides cost advantages over fossil alternatives, particularly when mills access agricultural residues or wood waste from nearby sources. Transportation costs factor into fuel economics, making local biomass availability a key consideration.

Environmental compliance represents another economic factor. As emission regulations tighten globally, equipment meeting current standards provides protection against future compliance costs. ZOZEN's advanced combustion technology and emission control systems position installations to satisfy evolving regulatory requirements without expensive retrofitting.

The Leading Biomass Boiler Company distinction reflects ZOZEN's ability to deliver these combined benefits through engineering that prioritizes both efficiency and environmental performance. The company's commitment to sustainability manifests not only in product design but in comprehensive client support from initial consultation through ongoing operation.

Making the Selection Decision

Choosing the optimal biomass boiler supplier requires evaluating technical capabilities, manufacturing quality, service infrastructure, and proven industry experience. ZOZEN's comprehensive product range spanning 2 to 75 tons per hour, multiple fuel compatibility, international certifications, and documented paper industry installations position the company to address diverse facility requirements.

For detailed information about ZOZEN's biomass boiler solutions, technical specifications, and paper industry applications, visit https://en.zozen.com/

Paper mills transitioning to sustainable energy sources need suppliers offering more than equipment-they require partners understanding industry-specific demands and providing solutions balancing efficiency, reliability, and environmental responsibility. ZOZEN's position as Best Biomass Boiler Supplier reflects decades of engineering development, proven installations across paper manufacturing facilities worldwide, and service commitment extending throughout equipment lifecycles. For paper industry operations planning long-term energy infrastructure, ZOZEN delivers the technical capability and application expertise to support sustainable production goals.

Addr: No. 777 Jianzhu West Road, Binhu District, Wuxi, China

Email: info@zozen.com

ZOZEN is one of the best modern boiler manufacturers in China, our products include steam boilers, hot water boilers and thermal oil heaters. ZOZEN boiler is located in Wuxi, covers 150 thousand square meters of production area, equipped with first-class production equipment, passed the ISO9001:2015 international quality system certification. The company gained the " S " and " U " steel seal from ASME of US.

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Guide to Choosing the Best Biomass Boiler Supplier for Paper Mill Applications here

News-ID: 4333239 • Views: …

More Releases from ZOZEN

ZOZEN: Top Water Tube Boiler Manufacturer Showcases Eco-Power at HEAT&POWER EXPO …

The industrial heating sector's premier gathering is approaching as manufacturers and technology providers prepare for HEAT&POWER EXPO 2026, the international exhibition dedicated to industrial boiler equipment, heat exchange systems, and power generation technologies. Among the exhibitors converging on Moscow's Crocus Expo Exhibition Center, ZOZEN Boiler stands out as a Top Water Tube Boiler Manufacturer (https://en.zozen.com/products/?5xyFrom=site-NT), bringing decades of engineering innovation to an audience seeking advanced thermal solutions that balance performance…

How ZOZEN Becomes a Top Firetube Boiler Manufacturer for Food Processing Plant?

For modern food processing plants, selecting the right boiler partner can determine whether production runs smoothly or constantly suffers from interruptions. Behind every sterilization line, blancher, dryer or CIP system is a need for clean, reliable and energy-efficient steam. In this context, ZOZEN has grown into a Top Firetube Boiler Manufacturer (https://en.zozen.com/products/thermal-fluid-heater/?5xyFrom=site-NT) for food processing plants, combining mature firetube boiler technology with deep food industry experience and a broad range…

ZOZEN: Best Industrial Thermal Oil Heater Manufacturer for Food Safety

Food processing demands unwavering commitment to safety, quality, and precision. Every heating system operating within food production facilities must deliver consistent thermal performance while maintaining the hygienic standards that protect consumer health. From thermal processing and material heating to oil refining and sterilization, industrial thermal oil heaters provide the controlled, high-temperature heating essential for modern food manufacturing. ZOZEN Boiler has established itself as the Best Industrial Thermal Oil Heater Manufacturer…

Why Leading Chemical Companies Choose ZOZEN as a Reliable Steam Boiler Exporter …

Chemical manufacturing operates under extraordinary constraints where process precision, safety protocols, and regulatory compliance converge. Steam boilers provide the temperature control essential for polymerization, condensation, drying, melting, and molding processes that define chemical production. When leading chemical enterprises select thermal equipment suppliers, they prioritize manufacturers demonstrating proven international standards through rigorous certification. ZOZEN Boiler has earned recognition as a Reliable Steam Boiler Exporter With CE and EAC Certifications (https://en.zozen.com/products/?5xyFrom=site-NT), positioning…

More Releases for Biomass

Biomass Pellets Market is Going to Boom | Major Giants Drax Biomass, Enviva Biom …

HTF MI recently introduced Global Biomass Pellets Market study with 143+ pages in-depth overview, describing about the Product / Industry Scope and elaborates market size (2025-2032). The market Study is segmented by key regions which is accelerating the marketization. At present, the market is developing its presence.

Major Companies in Biomass Pellets Market are: Drax Biomass (United States), International WoodFuels LLC (United States), Enviva Biomass (United States), Westervelt Renewable Energy…

Biomass Briquettes Market Transforming the Growth Landscape | Big Opportunities …

Biomass Briquettes Market Overview and Insights:

IMR posted new studies guide on Biomass Briquettes Market Insights with self-defined Tables and charts in presentable format. In the Study you may locate new evolving Trends, Drivers, Restraints, Opportunities generated via targeting market related stakeholders. The boom of the Biomass Briquettes marketplace became specifically driven with the aid of the growing R&D spending internationally.

Some of the Top Leading Key Players: Agro Energy (India)Biomass Power…

Biomass Briquette Market Statistical Forecast, Trade Analysis 2024 -Enviva, Shij …

DataM Intelligence has published a new research report on "Biomass Briquette Market Size 2024". The report explores comprehensive and insightful Information about various key factors like Regional Growth, Segmentation, CAGR, Business Revenue Status of Top Key Players and Drivers. The purpose of this report is to provide a telescopic view of the current market size by value and volume, opportunities, and development status.

Get a Free Sample Research PDF -…

Biomass Pellets Market Current Scenario and Future Prospects (2024-2030): Drax B …

The latest study released on the Global Biomass Pellets Market by HTF MI evaluates market size, trend, and forecast to 2030. The Biomass Pellets market study covers significant research data and proofs to be a handy resource document for managers, analysts, industry experts and other key people to have ready-to-access and self-analyzed study to help understand market trends, growth drivers, opportunities and upcoming challenges and about the competitors.

Key Players in…

Biomass Steam Boiler Market Is Booming Worldwide|Uniconfort, Ashwell Biomass, LO …

The latest study released on the Global Biomass Steam Boiler Market by AMA Research evaluates market size, trend, and forecast to 2030. The Biomass Steam Boiler market study covers significant research data and proofs to be a handy resource document for managers, analysts, industry experts and other key people to have ready-to-access and self-analyzed study to help understand market trends, growth drivers, opportunities and upcoming challenges and about the competitors.

Download…

Biomass Pellets Market Worth Observing Growth | Drax Biomass, International Wood …

Keep yourself up-to-date with latest market trends and maintain a competitive edge by sizing up with available business opportunity in Biomass Pellets Market various segments and emerging territory. The research report presents a comprehensive assessment of the Biomass Pellets Market and contains thoughtful insights, facts, historical data, and statistically supported and industry validated market data. It also contains projections using a suitable set of assumptions and methodologies. The research report…