Press release

Die Attach Materials Market to Reach US$ 4.5 Billion by 2033 - Persistence Market Research

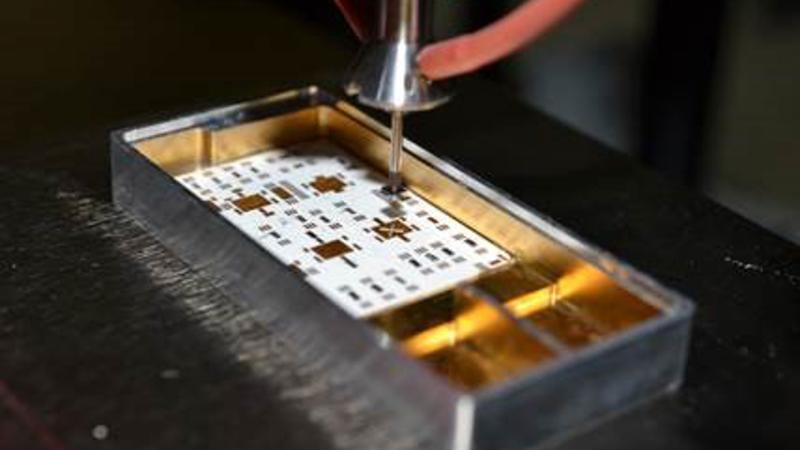

The die attach materials market is a critical segment within the global semiconductor and electronics manufacturing ecosystem. Die attach materials are specialized substances used to bond semiconductor dies to substrates or packages, ensuring mechanical stability, thermal conductivity, and electrical performance. These materials are essential in maintaining device reliability, especially as electronic components become smaller, more powerful, and more complex. Die attach materials are widely used across integrated circuits, power devices, light emitting diodes, radio frequency components, and advanced packaging technologies, making them indispensable to modern electronics.Discover Exclusive Data - Request Your Free Sample : https://www.persistencemarketresearch.com/samples/13234

The market has gained significant traction due to the rapid expansion of semiconductor manufacturing and the growing penetration of electronics across automotive, industrial, consumer, and energy applications. As manufacturers push toward higher performance and miniaturization, the role of die attach materials has evolved from basic bonding solutions to highly engineered materials designed to withstand extreme temperatures, high power densities, and long operational lifecycles. This evolution positions die attach materials as a foundational enabler of next generation electronic devices.

The global die attach materials market size is likely to be valued at US$ 2.0 billion in 2026, and is projected to reach US$ 4.5 billion by 2033, growing at a CAGR of 12.3% during the forecast period 2026 to 2033. This trajectory aligns with rising semiconductor packaging volumes, as well as growing requirements for high reliability electronics in segments such as automotive, industrial automation, and power management. As device architectures become more complex, die attach materials play a more critical role in ensuring mechanical integrity, electrical performance, and long term reliability under demanding operating conditions.

Market Statistics and Growth Drivers

Market statistics clearly indicate a robust growth outlook for die attach materials, supported by strong demand across multiple end use industries. Semiconductor manufacturers are scaling production capacities to meet global demand for chips used in electric vehicles, smart devices, industrial machinery, and data centers. Each of these applications requires advanced packaging solutions, directly increasing consumption of high performance die attach materials.

One of the most influential growth drivers is the electrification of the automotive sector. Electric vehicles rely heavily on power electronics such as inverters, converters, and battery management systems, all of which use power semiconductor devices. These devices operate under high thermal and electrical stress, necessitating die attach materials with superior thermal conductivity, mechanical strength, and resistance to fatigue.

Leading Market Segment and Dominant Geographical Region

Within the die attach materials market, conductive die attach materials represent the leading segment. These materials are widely used in power semiconductor devices due to their ability to provide efficient electrical and thermal pathways between the die and substrate. Silver based sintering materials and conductive epoxies are particularly prominent, as they support high power densities and elevated operating temperatures. Their widespread adoption in automotive electronics and industrial power modules positions conductive die attach materials as the dominant product category.

From a geographical perspective, Asia Pacific stands as the leading region in the global die attach materials market. This dominance is driven by the region's strong semiconductor manufacturing base, particularly in countries such as China, Japan, South Korea, and Taiwan. These nations host major foundries, packaging and assembly plants, and electronics manufacturing hubs that collectively account for a significant share of global semiconductor output. Government support for domestic chip production, combined with rising investments in electric mobility and renewable energy, further strengthens the region's leadership position.

Key Highlights from the Die Attach Materials Market Report

✦ The market is experiencing double digit growth due to expanding semiconductor packaging volumes across automotive and industrial sectors.

✦ Conductive die attach materials remain the most widely used segment owing to superior thermal and electrical performance.

✦ Electric vehicles and renewable energy systems are emerging as the fastest growing application areas for die attach materials.

✦ Asia Pacific dominates global demand due to its extensive semiconductor manufacturing ecosystem.

✦ Technological advancements are driving adoption of sintered silver and high temperature epoxy solutions.

✦ Increasing focus on device reliability and lifespan is encouraging the use of premium die attach materials.

Market Segmentation Analysis

The die attach materials market can be segmented based on material type, application, and end user industry. By material type, the market includes conductive adhesives, non conductive adhesives, solder based materials, and sintering materials. Conductive adhesives and sintering materials are gaining preference in high power applications due to their ability to manage heat efficiently and maintain stable electrical connections. Non conductive adhesives are commonly used in applications where electrical isolation is required, such as certain integrated circuits and sensors.

In terms of application, the market covers power devices, integrated circuits, light emitting diodes, radio frequency components, and optoelectronic devices. Power devices represent the largest application segment, driven by their extensive use in electric vehicles, industrial drives, and energy systems. Integrated circuits and light emitting diodes also contribute significantly, supported by strong demand from consumer electronics and lighting industries.

By end user industry, the market spans automotive, consumer electronics, industrial, telecommunications, healthcare, and energy sectors. Automotive and industrial end users collectively account for a substantial share due to increasing adoption of power electronics and automation technologies. Consumer electronics remain a high volume segment, while energy and healthcare applications are gaining momentum with advancements in medical devices and renewable infrastructure.

Make This Report Fit Your Needs - Customize Now : https://www.persistencemarketresearch.com/request-customization/13234

Regional Insights Across Key Markets

Asia Pacific continues to lead the die attach materials market, supported by high semiconductor production volumes, strong electronics exports, and ongoing investments in electric vehicle manufacturing. The presence of major chipmakers and packaging service providers ensures consistent demand for advanced die attach solutions.

North America holds a significant market share due to strong innovation in semiconductor design, power electronics, and advanced packaging technologies. The region benefits from increasing investments in electric mobility, aerospace electronics, and data center infrastructure, all of which rely on high reliability die attach materials.

Europe represents a rapidly growing market, driven by its leadership in automotive manufacturing and industrial automation. Stringent reliability and safety standards in automotive electronics encourage the adoption of advanced die attach materials capable of meeting long operational lifecycles.

Emerging regions such as Latin America and the Middle East are gradually contributing to market growth through expanding electronics assembly activities and renewable energy projects, although their overall share remains comparatively smaller.

Market Drivers Influencing Industry Expansion

The die attach materials market is driven by a combination of technological advancement and expanding end use applications. Increasing semiconductor integration and higher power densities require materials that can manage heat more effectively and maintain structural integrity. The transition toward wide bandgap semiconductors such as silicon carbide and gallium nitride further amplifies demand for high temperature die attach materials.

Rising adoption of electric vehicles and renewable energy systems is another major driver, as these applications demand power modules with exceptional reliability. Additionally, continuous miniaturization of electronic components places greater stress on bonding materials, making advanced die attach solutions essential for long term performance. Growing investments in smart manufacturing and industrial automation also support market growth by increasing demand for durable and efficient electronic components.

Market Restraints Impacting Growth Potential

Despite strong growth prospects, the die attach materials market faces certain restraints. High material costs, particularly for silver based sintering materials, can limit adoption among cost sensitive manufacturers. The complexity of processing advanced die attach materials may also require specialized equipment and expertise, increasing manufacturing expenses.

Supply chain volatility and fluctuating raw material prices pose additional challenges, especially during periods of global semiconductor shortages. Furthermore, stringent qualification requirements and long validation cycles in automotive and industrial applications can slow the introduction of new die attach materials into the market.

Ready to Dive Deep? Buy Full Report Today : https://www.persistencemarketresearch.com/checkout/13234

Market Opportunities Shaping the Future Outlook

Significant opportunities exist for market players as new semiconductor technologies and applications emerge. The growing use of silicon carbide and gallium nitride devices opens avenues for innovative die attach materials tailored to high voltage and high temperature environments. Expansion of electric vehicle charging infrastructure and renewable energy installations further increases demand for power modules and associated bonding materials.

Opportunities also arise from advancements in packaging technologies such as system in package and multi chip modules, which require precise and reliable die attach solutions. Manufacturers that invest in research and development to improve material performance, reduce costs, and enhance processing efficiency are well positioned to capitalize on these opportunities.

Reasons to Buy the Die Attach Materials Market Report

✔ Gain comprehensive insights into market size, growth trends, and future projections across key regions.

✔ Understand the impact of electric vehicles, renewable energy, and industrial automation on material demand.

✔ Identify leading market segments and emerging application areas with high growth potential.

✔ Analyze competitive dynamics and strategic developments among major industry players.

✔ Support informed decision making with data driven insights and expert analysis.

Company Insights and Competitive Landscape

The die attach materials market features a mix of global material suppliers and specialized chemical manufacturers focused on high performance electronic materials. These companies compete on factors such as thermal performance, reliability, processing compatibility, and cost efficiency. Continuous innovation and collaboration with semiconductor manufacturers are essential to maintain competitive advantage.

• Henkel AG and Company

• Dow Inc

• Sumitomo Chemical

• Indium Corporation

• Hitachi Chemical

• Shin Etsu Chemical

• Heraeus Holding

• Panasonic Industry

Recent developments in the market include increased investment in sintered silver die attach technologies to support wide bandgap semiconductors and strategic partnerships between material suppliers and automotive electronics manufacturers to develop customized high reliability bonding solutions. These developments highlight the industry's focus on meeting evolving performance requirements and capturing growth opportunities in high value applications.

Conclusion

The die attach materials market is poised for strong and sustained growth, driven by rapid advancements in semiconductor technology and expanding applications across automotive, industrial, and energy sectors. As electronic devices become more powerful and complex, the importance of reliable and high performance die attach materials continues to rise. With Asia Pacific leading global demand and conductive materials dominating the product landscape, the market offers significant opportunities for innovation and investment. Companies that align their strategies with emerging trends such as electric mobility, renewable energy, and advanced packaging are likely to shape the future of this dynamic and essential industry.

Read More Related Reports :

Luxury Packaging Market : https://www.persistencemarketresearch.com/market-research/luxury-packaging-market.asp

Semi-Chemical Wood Pulp Market: https://www.persistencemarketresearch.com/market-research/semi-chemical-wood-pulp-market.asp

Carbon Credit (Carbon Offset) Market: https://www.persistencemarketresearch.com/market-research/carbon-credit-carbon-offset-market.asp

Plastic Vials and Ampoules Market: https://www.persistencemarketresearch.com/market-research/plastic-vials-and-ampoules-market.asp

Contact Us:

Persistence Market Research

Second Floor, 150 Fleet Street,

London, EC4A 2DQ, United Kingdom

USA Phone: +1 646-878-6329

UK Phone: +44 203-837-5656

Email: sales@persistencemarketresearch.com

Web: https://www.persistencemarketresearch.com

About Persistence Market Research:

At Persistence Market Research, we specialize in creating research studies that serve as strategic tools for driving business growth. Established as a proprietary firm in 2012, we have evolved into a registered company in England and Wales in 2023 under the name Persistence Research & Consultancy Services Ltd. With a solid foundation, we have completed over 3600 custom and syndicate market research projects, and delivered more than 2700 projects for other leading market research companies' clients.

Our approach combines traditional market research methods with modern tools to offer comprehensive research solutions. With a decade of experience, we pride ourselves on deriving actionable insights from data to help businesses stay ahead of the competition. Our client base spans multinational corporations, leading consulting firms, investment funds, and government departments. A significant portion of our sales comes from repeat clients, a testament to the value and trust we've built over the years.

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Die Attach Materials Market to Reach US$ 4.5 Billion by 2033 - Persistence Market Research here

News-ID: 4332640 • Views: …

More Releases from Persistence Market Research

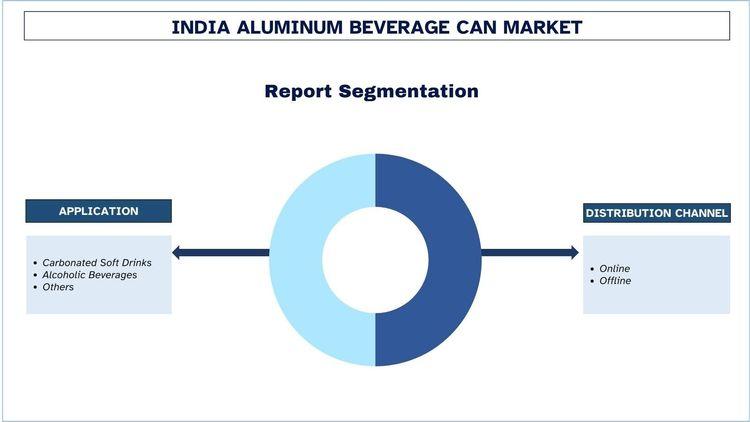

India Aluminum Beverage Can Market Size to Reach US$ 0.8 Bn by 2032 - Persistenc …

The India aluminum beverage can market is undergoing a significant transformation, driven by changing consumer lifestyles, rising urbanization, and a noticeable shift toward sustainable and convenient packaging formats. Aluminum beverage cans are increasingly preferred across carbonated soft drinks, energy drinks, sports beverages, alcoholic drinks, and ready-to-drink juices due to their lightweight structure, portability, fast chilling properties, and superior recyclability. In India, where on-the-go consumption is accelerating rapidly, aluminum cans are…

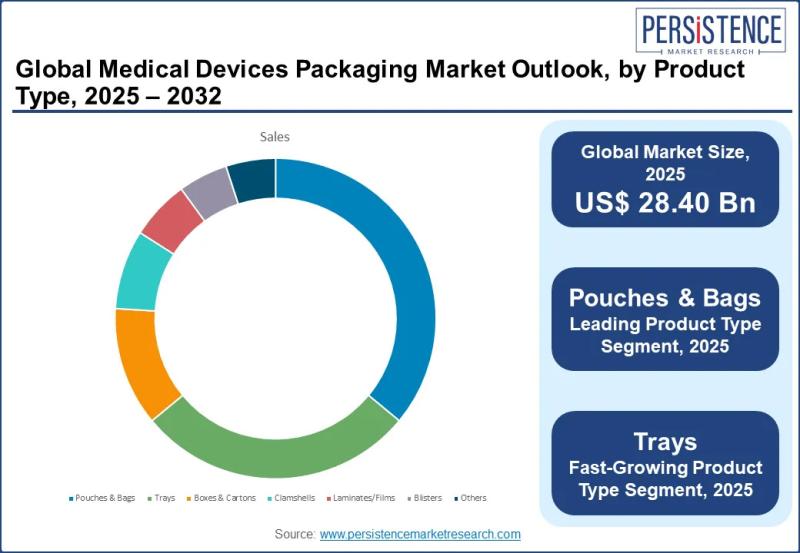

Medical Devices Packaging Market Size to Reach US$ 41.57 Billion by 2032 - Persi …

The medical devices packaging market plays a vital role within the global healthcare ecosystem, acting as a protective and regulatory bridge between manufacturers and end users. Medical device packaging refers to specialized materials and formats designed to safeguard medical instruments, implants, diagnostic tools, and consumables throughout storage, transportation, and clinical use. These packaging solutions are engineered to maintain sterility, prevent contamination, ensure ease of handling, and comply with strict regulatory…

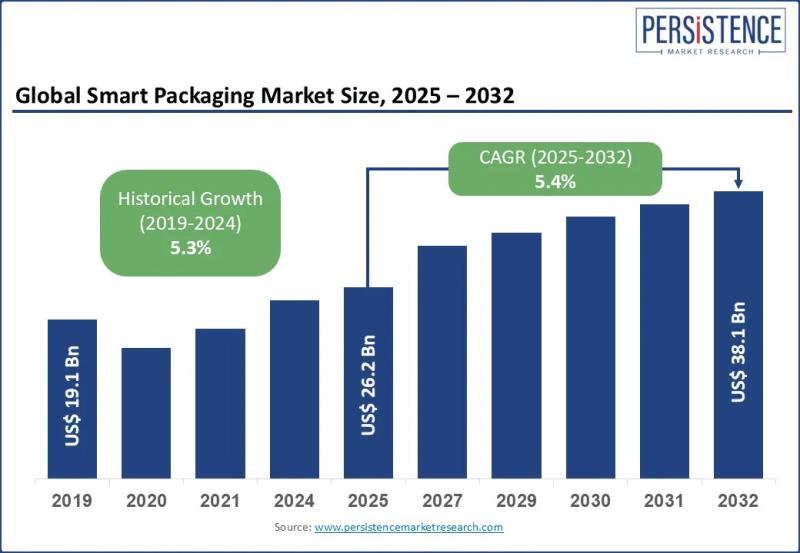

Smart Packaging Market Size Valued at US$ 26.2 Bn in 2025, Projected to Reach US …

The smart packaging market is rapidly transforming the global packaging landscape by integrating advanced technologies with traditional packaging materials to deliver enhanced functionality, traceability, and consumer engagement. Smart packaging refers to packaging systems embedded with features such as sensors indicators QR codes RFID tags and data tracking mechanisms that monitor product condition authenticity and movement across the supply chain. These solutions are increasingly adopted as businesses shift from passive containment…

Football Equipment Market Set for Strong Global Growth Through 2032

The global football equipment market continues to display resilient growth driven by rising participation in football across all age groups, expanding commercial opportunities, and technological advancements in sports gear. The industry is expected to grow from an estimated US$ 18.7 billion in 2025 to approximately US$ 24.1 billion by 2032, registering a compound annual growth rate (CAGR) of 3.7% over the forecast period.

➤ Download Your Free Sample & Explore Key…

More Releases for Die

U.S. Die Casting Market Set for Dynamic Growth with Key Players Ryobi Die Castin …

Coherent Market Insights has released a report titled "U.S. Die Casting Market: Industry Trends, Share, Size, Growth, Opportunity, and Forecast 2025-2032", which includes market percentage records and a thorough enterprise analysis. This report looks at the market's competition, geographic distribution, and growth potential. This comprehensive report encompasses industry performance, critical success factors, risk assessment, manufacturing prerequisites, project expenses, economic analysis, anticipated return on investment (ROI), and profit margins.

This comprehensive report…

Automotive Parts Die Casting Market Global outlook 2021 to 2026: Gibbs Die-casti …

The report presents an in-depth assessment of the Automotive Parts Die Casting Market including enabling technologies, key trends, market drivers, challenges, standardization, regulatory landscape, deployment models, operator case studies, opportunities, future roadmap, value chain, ecosystem player profiles and strategies. The report also presents SWOT Analysis and forecast for Automotive Parts Die Casting investments. The final report copy provides the impact analysis of novel COVID-19 pandemic on the Automotive Parts Die Casting market…

Automotive Parts Die Casting Market Global Outlook 2019-2025 | Leading Vendors- …

Up Market Research published a detailed report on “Automotive Parts Die Casting Market”. The report provides an in-depth overview of industry and competitive landscape, covering multiple market segments and elaborates market outlook and status to 2025.

Get Sample Copy Of This Report @

https://www.upmarketresearch.com/home/requested_sample/109602

The report contains 115 pages which highly exhibit on current market analysis scenario, upcoming as well as future opportunities, revenue growth, pricing and profitability.

Automotive Parts Die Casting…

Automotive Parts Die Casting Market 2019 Global Key Country Analysis: Alcast Com …

Automotive Parts Die Casting Market Research Report, by Production Process Type (Pressure, Vacuum, Squeeze and Semi-Solid), Raw Material Type (Aluminum, Zinc, Magnesium and Others), By Application Type, Vehicle Type, and by Regions - Forecast till 2023

The Key Players In Automotive Parts Die Casting Market Are:

Alcast Company (U.S.), Dynacast, LLC (U.S.), Endurance Technologies Limited (India), Gibbs Die Casting Corp (U.S.), and Rockman Industries (India). Ryobi Die Casting Inc. (U.S.), Kinetic Die…

Automotive Parts Aluminium & Magnesium Die Casting Market Report 2018: Segmentat …

Global Automotive Parts Aluminium & Magnesium Die Casting market research report provides company profile for Magic Precision Inc, Kinetic Die Casting Company, Texas Die Casting, Endurance Group, Sandhar technologies limited, Meridian Lightweight Technologies Inc, Sunbeam Auto Pvt. Ltd, Dynacast, Rockman Industries Ltd, Castwel Autoparts Pvt Ltd. and Others.

This market study includes data about consumer perspective, comprehensive analysis, statistics, market share, company performances (Stocks), historical analysis 2012 to 2017, market…

Global Automotive Parts Aluminium Die Casting Market Forecasat 2017 Texas Die Ca …

Automotive Parts Aluminium Die Casting Market

A market study ” Global Automotive Parts Aluminium Die Casting Market ” examines the performance of the Automotive Parts Aluminium Die Casting market 2017. It encloses an in-depth Research of the Automotive Parts Aluminium Die Casting market state and the competitive landscape globally. This report analyzes the potential of Automotive Parts Aluminium Die Casting market in the present and the future prospects from various angles…