Press release

Broaching Machines Market to Expand at 4.8% CAGR Through 2033 - Persistence Market Research

The manufacturing industry continues to evolve toward more precision-driven, automated, and high-productivity solutions, and broaching machines stand at the center of this transformation. As technological advancements redefine operational capabilities, broaching has become a key machining process for producing complex profiles with high repeatability, dimensional control, and surface finish quality. From automotive transmission components to turbine blades, gears, firearm parts, and industrial tools, broaching machines have secured their relevance in modern engineering environments. The global broaching machines market, supported by innovation, automation, and expansion across heavy engineering sectors, is witnessing a steady acceleration driven by demand for precision machining and productivity optimization.Download Free Sample & Check the Latest Market Analysis: https://www.persistencemarketresearch.com/samples/33229

According to industry estimates, the global broaching machines market size is expected to reach US$ 539.2 million in 2026 and further expand to US$ 747.3 million by 2033, registering a CAGR of 4.8% during the forecast period. This positive growth outlook is strongly supported by rising investment in automotive component manufacturing, modernization of industrial production lines, and widespread adoption of CNC-based broaching machines. The automotive sector currently leads the demand due to mass production needs for gear shafts, steering components, and engine parts. Regionally, Asia Pacific leads the global market, backed by thriving automotive hubs, large-scale industrialization, and strong machine tool production capacity in China, Japan, India, and South Korea. The region is expected to maintain dominance as manufacturers continue expanding production and upgrading to digital and automated systems.

Key Highlights from the Report

• Market projected to reach US$ 747.3 million by 2033.

• CAGR of 4.8% anticipated between 2026-2033.

• Automotive sector remains the leading end-use segment.

• Asia Pacific dominates due to strong manufacturing capacity.

• Rising adoption of CNC and automated broaching technologies.

• Demand boosted by growth in aerospace and defense machining.

Market Segmentation Overview

Market segmentation plays a pivotal role in analyzing how technological adoption, application areas, and product variations dictate the trajectory of the broaching machines industry. The market is primarily segmented based on product type, machine design (horizontal/vertical), operation mode (manual, semi-automatic, and automatic/CNC), and end-use industries.

In terms of product type, horizontal broaching machines currently hold a leading market share owing to their widespread use in high-volume production environments. They are preferred for internal and external surface finishing processes, particularly in automotive transmission gears, splines, and steering components. Vertical broaching machines, however, continue to gain traction due to compact design, reduced floor space requirement, and better suitability for complex geometrical finishing in aerospace and precision component manufacturing. The rising integration of servo controls and numerical programming in vertical broaching systems is making them increasingly efficient and desirable for multi-part production lines.

Considering technology and automation, CNC-controlled broaching systems remain the fastest-growing segment. Manufacturers today are inclined towards integrating broaching machines with robotic handling, tool monitoring systems, and digital machining platforms. These CNC models enable faster cycle times, higher repeat accuracy, reduced manpower dependency, and remote process control. Manual and hydraulic variants still hold demand in small machine shops and cost-sensitive industries but automation-oriented upgrades are gradually reshaping the customer preference pattern.

Get a Customized Market View in One Click : https://www.persistencemarketresearch.com/request-customization/33229

From the perspective of end-user segmentation, the automotive industry remains the dominant consumer of broaching machines. The rising global demand for electric vehicles, lightweight powertrain systems, and precision-engineered transmission components creates long-term opportunities for machine manufacturers. Aerospace and defense industries also represent a rapidly expanding application domain, driven by requirements for turbine disc broaching, landing gear parts, and firearm components. Meanwhile, industrial machinery, medical device manufacturing, oil & gas equipment production, and general engineering sectors contribute steadily to overall market revenue.

Regional Insights

Regionally, Asia Pacific stands as the most influential market, accounting for a substantial share of production and consumption. China and India have emerged as machine manufacturing hubs, driven by foreign investments, growing automotive exports, and increased demand for industrial tooling. Japan and South Korea continue to dominate high-precision machine tool innovation, benefiting from strong research capabilities and advanced robotics adoption. The region's economic growth, heavy engineering output, and expansion of EV manufacturing create numerous opportunities for broaching machine providers.

North America maintains strong growth led by aerospace, defense, and automobile component manufacturing. The United States, being a key center for aviation machining technologies, actively invests in advanced broaching tools for turbine engine parts, weapon systems, and high-strength alloy production. The rise of additive manufacturing hybridization with CNC machining is another trend boosting adoption.

Europe remains a stable and technologically mature market for broaching machines. Germany, Italy, and France host some of the world's leading machine tool manufacturers with exceptional capabilities in gear broaching systems, high-speed cutting environments, and Industry 4.0 retrofitting. Government-backed industrial automation policies, along with a focus on sustainable manufacturing, are supporting stable equipment demand across automotive and energy sectors. Meanwhile, the Middle East, Africa, and Latin America markets are gradually emerging, led by increasing industrialization and infrastructure development efforts.

Market Drivers

One of the primary drivers fueling demand is the increasing requirement for precision machining in automotive component manufacturing. Broaching remains unmatched for producing internal profiles like keyways, splines, and gear teeth with repeatable high tolerance, making it indispensable for mass component production. The transition towards EV and hybrid vehicles is further boosting the need for lightweight and efficient powertrain elements, indirectly increasing the utilization of broaching systems.

Another major driver is the rising adoption of CNC-integrated and automated broaching machines. Manufacturers are continuously focusing on productivity improvements, cost reduction, and faster turnaround times. CNC machines enhance surface finish accuracy, reduce tooling wear, and support digital workflow integration, aligning perfectly with Industry 4.0 standards. Additionally, expanding aerospace and defense procurement amplifies demand for broached components used in turbine assembly, artillery parts, and precision weaponry.

Market Restraints

Despite promising growth, the market faces certain restraints that require consideration. The high initial investment and maintenance cost of CNC broaching machines poses a challenge to small and mid-sized manufacturers. Manual broaching machines are cost-effective, but lack the automation features needed for next-generation production environments. Skilled labor shortage in machine operation and programming also contributes to slower adoption in underdeveloped industries.

Another barrier lies in tooling wear and replacement frequency. Broach tools are expensive, and dulling or deformation leads to quality defects, higher rates, and operational downtime. Industries working with hard materials such as titanium and nickel alloys in aerospace may face accelerated tool wear, increasing operational cost and maintenance efforts. Economic fluctuations and declining automotive production cycles can further soften market demand during recessionary phases.

Click to Purchase the Full Report & Start Exploring : https://www.persistencemarketresearch.com/checkout/33229

Market Opportunities

Looking ahead, substantial opportunities exist in the integration of smart, connected, and robotic-assisted broaching systems. Machine manufacturers are increasingly investing in digital monitoring, force feedback sensors, and real-time diagnostics to predict tool wear and optimize machining parameters. This transformation creates a strong future market for retrofitting and upgrading existing machines rather than complete replacement.

Emerging markets such as Southeast Asia, Eastern Europe, and Africa remain untapped pockets of growth where industrialization is accelerating. Local component manufacturers in these regions are likely to adopt broaching machines for gearing, agricultural equipment, railway spare parts, and mining machinery. Additionally, aerospace expansion, defense modernization, and commercial EV production offer long-term demand for highly efficient broaching machines.

Sustainability adoption presents another significant opportunity. The development of energy-efficient drives, coolant recycling, and eco-friendly machining fluids is in motion, allowing manufacturers to align with environmental compliance trends. The future of broaching machines is expected to shift toward hybrid intelligent systems capable of combining cutting technologies and enabling cost-efficient smart manufacturing.

Company Insights

Key players operating in the Broaching Machines Market include:

• Nachi-Fujikoshi Corporation

• Mitsubishi Heavy Industries Machine Tool Co., Ltd

• American Broach & Machine Company

• Colonial Tool Group Inc.

• Axisco Precision Machinery Co., Ltd

• Forst Technologie GmbH

• Pioneer Broach Company

• General Broach Company

• Broaching Machine Specialties (BMS)

• Varinelli S.r.l.

Recent Developments:

Leading manufacturers are launching CNC-enabled vertical broaching machines with smart sensors and servo-based feed systems to expand efficiency and intelligent machining capabilities.

Companies are investing heavily in Industry 4.0 retrofitting solutions and remote machine monitoring capabilities, enabling factory automation and predictive maintenance for high-volume production environments.

Related Reports:

https://www.persistencemarketresearch.com/market-research/hvac-packaged-units-market.asp

https://www.persistencemarketresearch.com/market-research/door-frame-market.asp

https://www.persistencemarketresearch.com/market-research/industrial-wastewater-management-market.asp

https://www.persistencemarketresearch.com/market-research/mechanical-seals-market.asp

https://www.persistencemarketresearch.com/market-research/photovoltaic-mounting-system-market.asp

https://www.persistencemarketresearch.com/market-research/sorting-machines-market.asp

Persistence Market Research

Second Floor, 150 Fleet Street, London, EC4A 2DQ, United Kingdom

USA Phone: +1 646-878-6329

UK Phone: +44 203-837-5656

Email: sales@persistencemarketresearch.com

Web:

https://www.persistencemarketresearch.com

About Persistence Market Research:

At Persistence Market Research, we specialize in creating research studies that serve as strategic tools for driving business growth. Established as a proprietary firm in 2012, we have evolved into a registered company in England and Wales in 2023 under the name Persistence Research & Consultancy Services Ltd. With a solid foundation, we have completed over 3600 custom and syndicate market research projects, and delivered more than 2700 projects for other leading market research companies' clients.

Our approach combines traditional market research methods with modern tools to offer comprehensive research solutions. With a decade of experience, we pride ourselves on deriving actionable insights from data to help businesses stay ahead of the competition. Our client base spans multinational corporations, leading consulting firms, investment funds, and government departments. A significant portion of our sales comes from repeat clients, a testament to the value and trust we've built over the years.

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Broaching Machines Market to Expand at 4.8% CAGR Through 2033 - Persistence Market Research here

News-ID: 4332330 • Views: …

More Releases from Persistence Market Research

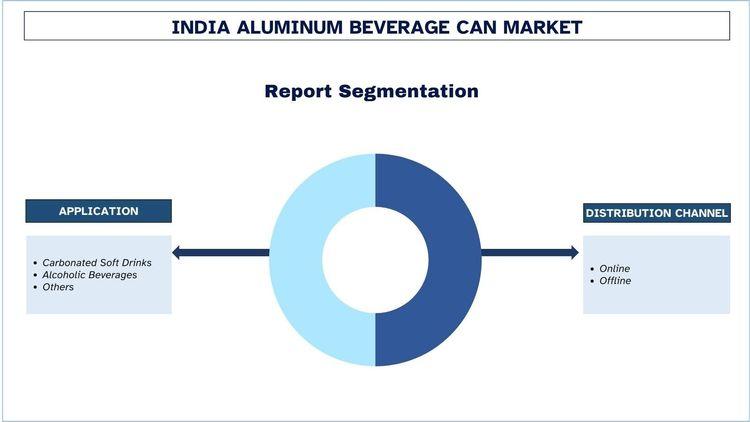

India Aluminum Beverage Can Market Size to Reach US$ 0.8 Bn by 2032 - Persistenc …

The India aluminum beverage can market is undergoing a significant transformation, driven by changing consumer lifestyles, rising urbanization, and a noticeable shift toward sustainable and convenient packaging formats. Aluminum beverage cans are increasingly preferred across carbonated soft drinks, energy drinks, sports beverages, alcoholic drinks, and ready-to-drink juices due to their lightweight structure, portability, fast chilling properties, and superior recyclability. In India, where on-the-go consumption is accelerating rapidly, aluminum cans are…

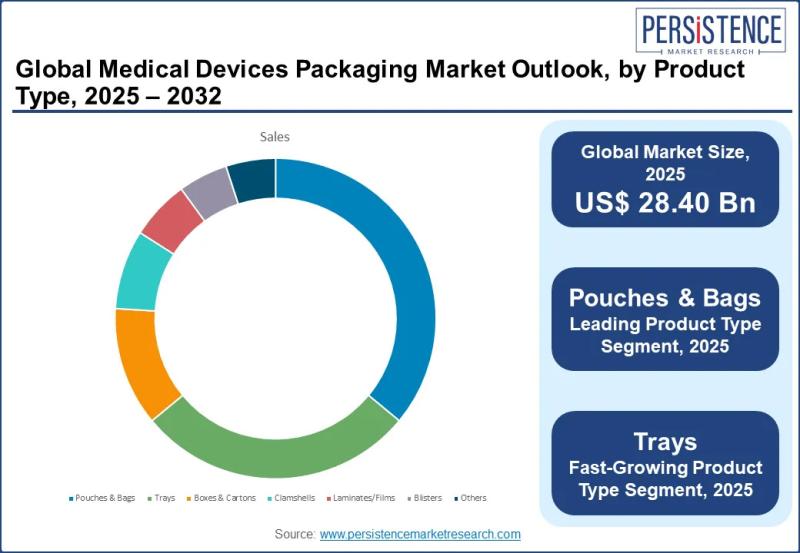

Medical Devices Packaging Market Size to Reach US$ 41.57 Billion by 2032 - Persi …

The medical devices packaging market plays a vital role within the global healthcare ecosystem, acting as a protective and regulatory bridge between manufacturers and end users. Medical device packaging refers to specialized materials and formats designed to safeguard medical instruments, implants, diagnostic tools, and consumables throughout storage, transportation, and clinical use. These packaging solutions are engineered to maintain sterility, prevent contamination, ensure ease of handling, and comply with strict regulatory…

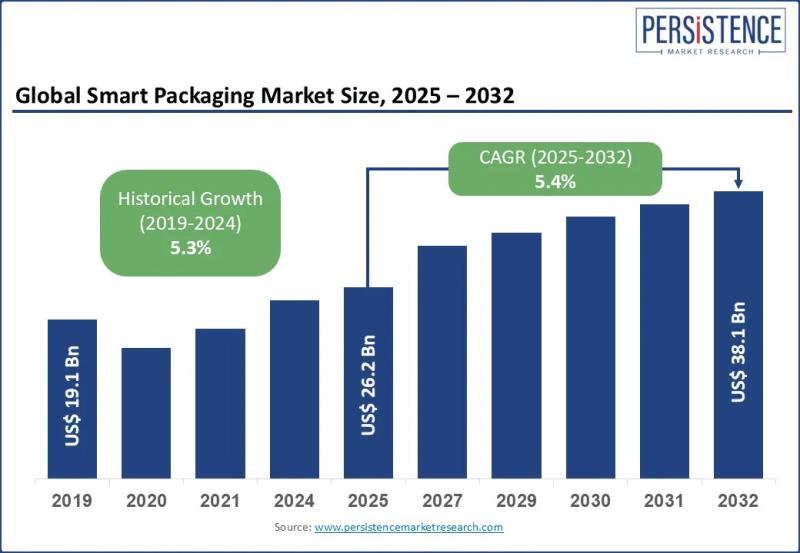

Smart Packaging Market Size Valued at US$ 26.2 Bn in 2025, Projected to Reach US …

The smart packaging market is rapidly transforming the global packaging landscape by integrating advanced technologies with traditional packaging materials to deliver enhanced functionality, traceability, and consumer engagement. Smart packaging refers to packaging systems embedded with features such as sensors indicators QR codes RFID tags and data tracking mechanisms that monitor product condition authenticity and movement across the supply chain. These solutions are increasingly adopted as businesses shift from passive containment…

Football Equipment Market Set for Strong Global Growth Through 2032

The global football equipment market continues to display resilient growth driven by rising participation in football across all age groups, expanding commercial opportunities, and technological advancements in sports gear. The industry is expected to grow from an estimated US$ 18.7 billion in 2025 to approximately US$ 24.1 billion by 2032, registering a compound annual growth rate (CAGR) of 3.7% over the forecast period.

➤ Download Your Free Sample & Explore Key…

More Releases for Broach

Broaching machines Market Is Booming Worldwide: Ekin, Apex Broaching Systems, Pi …

The latest study released on the Global Broaching machines Market by HTF MI evaluates market size, trend, and forecast to 2030. The Broaching machines market study covers significant research data and proofs to be a handy resource document for managers, analysts, industry experts and other key people to have ready-to-access and self-analyzed study to help understand market trends, growth drivers, opportunities and upcoming challenges and about the competitors.

Key Players in…

Automatic Broach Sharpening Machine Market Types and Applications, Drivers, Ongo …

The Automatic Broach Sharpening Machine Market Trends Overview 2024-2031:

A new Report by Worldwide Market Reports, titled "Automatic Broach Sharpening Machine Market: Industry Trends, Share, Size, Growth, Opportunity and Forecast 2024-2031," offers a comprehensive analysis of the industry, which comprises insights on the Automatic Broach Sharpening Machine market analysis. The report also includes competitor and regional analysis, and contemporary advancements in the market.

This report has a complete table of contents, figures,…

Automatic Broach Sharpening Machine Market to Set Remarkable Growth in Coming Ye …

Worldwide Market Reports published a "Automatic Broach Sharpening Machine Market Business Growth Forecast 2023-2030" report that sheds light on the key opportunities attributing to the growth of the market. This Insight Report offers a thorough study of the global Automatic Broach Sharpening Machine market and identifies significant trends in product/services segmentation, company formation, revenue, market share, recent advancements, and M&A activity. With a focus on Automatic Broach Sharpening Machine portfolios…

Broaching Machine Design Market Regional Demands, Future Trends and Competitive …

The Broaching Machine Design market research report is proficient and top to bottom research by specialists on the current state of the industry. This statistical surveying report gives the most up to date industry information and industry future patterns, enabling you to distinguish the items and end clients driving income development and benefit. It centres around the real drivers and restrictions for the key players and present challenge status with…

Broaching Machines Market In-Depth Qualitative Insights, Explosive Growth Opport …

The global broaching machines market was valued at US$ 0.8 billion in 2021 and it is anticipated to grow up to US$ 1.2 billion by 2031, at a CAGR of 4.0% during the forecast period.

A broaching machine is used to finish a surface by pulling or pushing a cutting tool called a brooch over the entire surface. The brooch has a series of cut teeth arranged side by side, with…

Broaching Machine Market 2019-2026 | Evolving Opportunities with Accu-Cut Diamon …

The automotive industry segment dominated the broaching machine market in 2018, contributing more than two-fifths of the market, owing to rise in trend of adoption of CNC broaching machine in the automotive industry. Moreover, the segment is estimated to manifest the fastest CAGR of 6.8% during the forecast period. The report includes an analysis of industrial machinery, precision engineering machine, and other segments.

Rise in production of vehicles from developing economies,…