Press release

What Is a Regenerative Thermal Oxidizer (RTO)?

A Regenerative Thermal Oxidizer (RTO) is one of the most widely used technologies for controlling industrial emissions, especially Volatile Organic Compounds [https://www.yurcentrto.com/volatile-organic-compounds/] (VOCs). With its high thermal efficiency, stable performance, and ability to treat large airflows, the RTO has become a standard solution across printing, chemical, coating, and many other industries. This article provides a clear overview of what an RTO is, how it works, its core components, common types, and where it is typically applied.1. What Is a Regenerative Thermal Oxidizer?

A Regenerative Thermal Oxidizer (RTO) is an Air Pollution Control System [https://www.yurcentrto.com/air-pollution-control-system/] designed to destroy VOCs and other harmful organic pollutants through high-temperature oxidation. Typically operating around 800 degrees C, the RTO converts organic compounds into harmless substances such as carbon dioxide (CO) and water vapor (HO).

What makes the RTO unique is its regenerative heat recovery system. Inside the RTO, ceramic media stores thermal energy and uses it to preheat incoming exhaust gas. This allows the system to achieve thermal efficiencies above 95%, greatly reducing fuel consumption compared with traditional incinerators.

2. How Does a Regenerative Thermal Oxidizer Work?

The Regenerative Thermal Oxidizer works through repeated cycles of heating, oxidizing, and heat recovery:

Step 1: Preheating

A burner heats the ceramic media during startup until the system reaches operational temperature.

Step 2: Oxidation of VOCs

Exhaust gas enters one of the ceramic beds. As the gas passes through the hot ceramic media, it heats up rapidly and enters the combustion chamber.

At high temperatures, VOCs oxidize and break down into CO and water.

Step 3: Heat Recovery & Clean Gas Exhaust

The purified hot gas flows through a second ceramic bed, transferring its heat to the media. Once this bed becomes saturated with heat, flow direction switches, and the cycle repeats.

This regenerative process keeps operating costs low and efficiency high.

3. Main Components of a Regenerative Thermal Oxidizer

A typical RTO includes:

Combustion Chamber - Where VOC oxidation occurs at high temperatureCeramic Heat Recovery Beds - Store and release heat for regenerative operationSwitching Valves - Direct the airflow between chambersBurner System - Provides initial heating and supplemental heatFans, ducts, and stack - Support gas flow and exhaustPLC/Control System - Automates temperature, valves, and safety logic

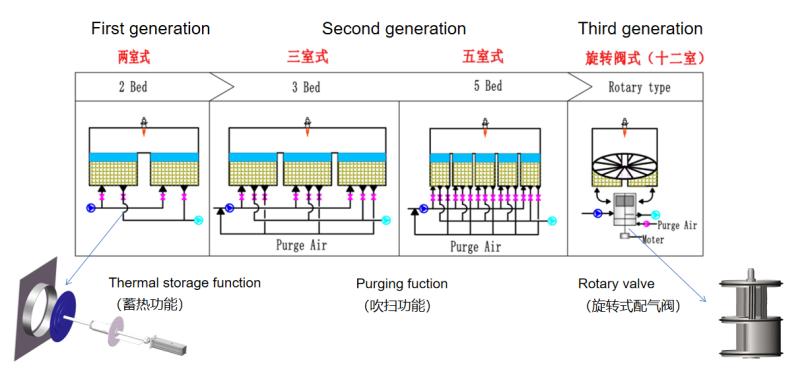

4. Common Regenerative Thermal Oxidizer Types in the Market

Two types of RTOs are widely used today:

1) Multi-Bed (Fixed-Bed) RTO

Usually designed with two-bed, three-bed, or multi-chamber layoutsUses multiple valves for switching airflowStable, highly effective pollutant removalSuitable for printing, coating, packaging, chemical production, etc.

2) Rotary RTO (Rotary Valve RTO)

Uses a rotating valve instead of multiple switching valvesLess mechanical wear, lower maintenanceSuitable for large airflow applications such as automotive painting, battery materials, polyester fiber, and electronics production

Image: https://ecdn6.globalso.com/upload/p/2910/image_other/2025-12/wechat-image_20251205145405_161_89.png

5. Applications of RTO Systems

RTOs are used in almost all industries involving VOC emissions, including:

* Printing & packaging

* Automotive & appliance coating

* Chemical and petrochemical processes

* Lithium battery materials and film coating

* Electronics manufacturing

* Plastic, rubber, and polyester fiber production

* Woodworking and furniture plants

Because of their high efficiency and reliability, RTOs remain a preferred technology for environmental compliance worldwide.

Media Contact

Company Name: Xi'an Yangling Yurcent Environmental Technology Co., Ltd.

Email:Send Email [https://www.abnewswire.com/email_contact_us.php?pr=what-is-a-regenerative-thermal-oxidizer-rto]

Country: China

Website: https://www.yurcentrto.com/

Legal Disclaimer: Information contained on this page is provided by an independent third-party content provider. ABNewswire makes no warranties or responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you are affiliated with this article or have any complaints or copyright issues related to this article and would like it to be removed, please contact retract@swscontact.com

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release What Is a Regenerative Thermal Oxidizer (RTO)? here

News-ID: 4331333 • Views: …

More Releases from ABNewswire

The Tabby Spot Redefines Online Shopping with Signature Editorial Curation and M …

The Tabby Spot is reshaping the online lifestyle retail experience by proving that shopping should feel inspiring, not overwhelming. With its signature purpleandgold aesthetic and commitment to handpicked premium products, the retailer is expanding its multichannel presence while preserving the curated approach that resonates with discerning shoppers nationwide.

In a digital landscape dominated by massmarket retailers and endless product listings, The Tabby Spot has emerged as a refreshing alternative. Built on…

HMRC Tax Software: Why UK Taxpayers Are Moving to Smarter Digital Filing Solutio …

HMRC requires online submissions to meet strict formatting and reporting standards. As a result, individuals and businesses are increasingly relying on dedicated tax software rather than manual forms or spreadsheets. Among the platforms gaining attention in 2026 is Pie, a UK fintech tax app designed to simplify HMRC-compliant filing for modern income earners.

LONDON, United Kingdom - February 13, 2026 - As digital reporting becomes standard across the UK tax system,…

Luxury Swiss Watches Are Getting the Direct-to-Consumer Treatment. Will Buyers B …

The direct-to-consumer model gutted the markup on everything from eyeglasses to mattresses. Now it's coming for one of retail's most markup-heavy categories: Swiss luxury watches.

The direct-to-consumer model gutted the markup on everything from eyeglasses to mattresses. Now it's coming for one of retail's most markup-heavy categories: Swiss luxury watches.

A growing number of startups are attempting to sell Swiss-made timepieces online-only, cutting out the jewelers, distributors, and retail showrooms that have…

Discover Red Oak Hospice and Palliative Care: Expert Hospice & Palliative Suppor …

Red Oak Hospice offers compassionate end-of-life care, providing expert support to families through hospice and palliative services during difficult times.

Red Oak Hospice and Palliative Care is proud to provide expert care services designed to offer comfort, support, and dignity to patients and their families during some of life's most challenging moments. With a compassionate approach and a team of experienced professionals, our team ensures that every patient receives the highest…

More Releases for RTO

Regenerative Thermal Oxidizer (RTO) Market Is Going to Boom |• Thermo Energy C …

The worldwide "Regenerative Thermal Oxidizer (RTO) Market" 2026 Research Report presents a professional and complete analysis of the Global Regenerative Thermal Oxidizer (RTO) Market in the current situation. This report includes development plans and policies along with Regenerative Thermal Oxidizer (RTO) manufacturing processes and price structures. The reports 2026 research report offers an analytical view of the industry by studying different factors like Regenerative Thermal Oxidizer (RTO) Market growth, consumption…

PRR - Guest Post - Maximising the Value of VET Resources in Your RTO

Investing in quality VET resources is only the first step in delivering effective and compliant training. To get the most value from your materials, your RTO needs to use them strategically-not just as course content, but as tools to improve learner engagement, streamline trainer workload, and ensure audit readiness.

In this blog, we'll explore practical ways to maximise the value of your VET learning resources, from integrating them into multiple delivery…

RTO Packaging Market to Reach USD 2.13 Billion by 2034

According to Exactitude Consultancy, the global RTO packings market is projected to grow from USD 1.21 billion in 2024 to USD 2.13 billion by 2034, at a CAGR of 5.6% over the forecast period. This expansion is underpinned by increased adoption in automotive, pharmaceuticals, chemicals, and food processing sectors, as well as advancements in structured and random packing technologies.

Download Full PDF Sample Copy of Market Report @ https://exactitudeconsultancy.com/request-sample/69351

Key Market Drivers

1.…

Regenerative Thermal Oxidizer (RTO) Market to Witness Growth Acceleration by 203 …

The Regenerative Thermal Oxidizer (RTO) market is witnessing significant growth, driven by increasing industrialization, stringent environmental regulations, and the rising demand for air pollution control solutions. This comprehensive article explores the key aspects of the RTO market, including its overview, growth prospects, segmentation, regional analysis, market dynamics, trends, and competitive landscape.

Regenerative Thermal Oxidizers are advanced pollution control systems designed to eliminate hazardous air pollutants (HAPs) and volatile organic compounds (VOCs)…

RTO Honeycomb Ceramic Regenerator Market Size,Volume,Revenue Trends Analysis Rep …

Global Info Research announces the release of the report "Global RTO Honeycomb Ceramic Regenerator Market 2023 by Manufacturers, Regions, Type and Application, Forecast to 2029" . The report is a detailed and comprehensive analysis presented by region and country, type and application. As the market is constantly changing, the report explores the competition, supply and demand trends, as well as key factors that contribute to its changing demands across many…

Japan Regenerative Thermal Oxidizer [RTO] Market to Develop Rapidly by 2031

Regenerative Thermal Oxidizer (RTO) Market: Introduction

Transparency Market Research delivers key insights into the global regenerative thermal oxidizer (RTO) market. In terms of revenue, the global regenerative thermal oxidizer (RTO) market is estimated to expand at a CAGR of ~5% during the forecast period, owing to numerous factors, regarding which TMR offers thorough insights and forecasts in its report on the global regenerative thermal oxidizer (RTO) market.

The global market for regenerative thermal oxidizer (RTO)…