Press release

Pioneering Innovation: LST's Advanced Automatic Chocolate Tempering Machine Sets Industry Standards

In the intricate world of chocolate manufacturing, precision, consistency, and efficiency are not just desirable traits; they are fundamental pillars of success. As consumer palates become more refined and demand for diverse, high-quality chocolate products continues to surge globally, the role of advanced chocolate machinery [www.lst-machine.com] has never been more critical. At the heart of this evolution stands the tempering process-a delicate balance of temperature control that dictates the final product's snap, sheen, and shelf life. For years, manufacturers have sought solutions that can elevate this crucial step from an art form to a science, ensuring flawless results with every batch.Against this backdrop, Chengdu LST Technology Co., Ltd. (LST Machine), a comprehensive enterprise dedicated to providing complete solutions for chocolate food manufacturing and packaging, has emerged as a frontrunner. With a steadfast commitment to innovation and engineering excellence, LST is not merely participating in the industry; it is actively shaping its future, particularly through its state-of-the-art automatic chocolate tempering machine. This article delves into the evolving landscape of chocolate production, the challenges faced by manufacturers, and how LST's pioneering innovations are setting new benchmarks for quality, efficiency, and versatility across the global confectionery industry.

Image: https://www.abnewswire.com/upload/2025/12/d01fcba6465a34ae90ad800f59abb2a4.jpg

The Evolving Landscape of Chocolate ProductionThe Art and Science of Chocolate Manufacturing

Chocolate, a universally cherished indulgence, is the result of a complex interplay between raw materials and sophisticated processing. From the initial fermentation and roasting of cocoa beans to the final molding and packaging, each stage contributes to the unique flavor, aroma, and texture that defines a premium product. Key processes such as grinding, conching, and refining are essential, but it is tempering that truly elevates chocolate from a simple confection to an exquisite culinary experience.

Tempering is the controlled crystallization of cocoa butter, a polymorphic fat that can solidify into six different crystal forms. Achieving the desired Type V crystal structure is paramount for chocolate to possess its characteristic glossy finish, firm snap, smooth melt-in-your-mouth texture, and resistance to fat bloom. Traditionally, this was a labor-intensive process, often relying on the skilled hands and keen eye of experienced chocolatiers. However, modern industrial demands necessitate a more scientific, automated approach to ensure scalability and consistency.

Industry Challenges and the Drive for Automation

The contemporary chocolate industry faces a multitude of challenges that drive the relentless pursuit of advanced chocolate machinery [www.lst-machine.com]:

* Consistency and Quality: Maintaining uniform quality across large production volumes is a perennial challenge. Imperfect tempering leads to unsightly fat bloom, poor snap, and undesirable textures, resulting in product waste and reputational damage.

* Efficiency and Throughput: Global demand for chocolate products requires manufacturers to operate at peak efficiency. Manual processes are slow and prone to human error, hindering throughput and increasing labor costs. Automation is key to scaling operations without compromising quality.

* Flexibility and Product Diversification: The market constantly craves novelty. Consumers expect a wide array of chocolate types-solid bars, filled pralines, two-tone creations, and those infused with nuts, biscuits, or other inclusions. Production lines must be adaptable to accommodate rapid changeovers and diverse product specifications.

* Food Safety and Hygiene: Stringent food safety regulations and heightened consumer awareness demand machinery that is easy to clean, made from food-grade materials, and designed to prevent contamination.

* Global Supply Chains and Support: As manufacturers expand their reach, they require reliable machinery partners who can offer comprehensive sales, installation, and long-term technical support across different continents.

The Role of Advanced Chocolate Machinery

Modern chocolate machinery is designed to address these challenges head-on. From sophisticated refiners that use a chocolate ball machine to achieve micron-level particle sizes, to versatile chocolate depositor machine lines that can create intricate shapes and fillings, technology is transforming every aspect of production. However, it is the automatic chocolate tempering machine that remains one of the most vital pieces of equipment, ensuring the foundational quality of the chocolate itself.

LST's Vision: Redefining Chocolate Production

Established in 2009, Chengdu LST Technology Co., Ltd. has rapidly ascended to a prominent position in the global confectionery equipment market. LST's core business revolves around providing comprehensive, end-to-end solutions for chocolate food production and packaging. This encompasses a wide array of equipment, including feeding systems, ball mills, coating machines, tempering machines, depositing and decorating machines, and fully automatic production lines for various chocolate products.

LST's commitment to innovation is evidenced by its dedicated R&D team and a proactive goal of implementing three new high-tech advancements annually. This forward-thinking approach, coupled with stringent quality standards, comprehensive global after-sales support, and a focus on operational efficiency and user-centric design, positions LST as a pivotal player in the industry. The company's unique value proposition lies in its ability to deliver advanced, reliable, and cost-effective solutions that empower manufacturers to meet the evolving demands of the global chocolate market.

The Heart of Innovation: LST's Advanced Automatic Chocolate Tempering Machine

LST's range of automatic chocolate tempering machines stands as a testament to its pioneering innovation, directly addressing the industry's need for precision, consistency, and versatility.

Precision Engineering for Unmatched Quality

LST's tempering solutions are engineered to master the delicate science of cocoa butter crystallization. Their industrial/commercial TW-TP series (available in 25L, 60L, and 100L capacities, with production rates from 60-80 kg/hour to 200-300 kg/hour) embodies this precision:

* Advanced Control Systems: Equipped with PLC (Programmable Logic Controller) and HMI (Human-Machine Interface) touch screen controls, these machines offer unparalleled accuracy in temperature management. This allows for precise adjustments to the heating and cooling cycles, ensuring optimal Type V crystal formation every time. The ability to preset and store different process temperatures (e.g., melting at 55, storing/supplying at 38) eliminates guesswork and guarantees repeatable results.

* Automated Dosing and Flow Control: Features like automatic quantitative dosing, intermittent dosing, and adjustable chocolate flow rates provide manufacturers with granular control over their production. This is crucial for consistent product weight and efficient molding or coating applications.

* Enhanced Durability and Maintenance: The inclusion of two independent motors (one for the pump, one for the stirrer) in models like the CHOCO-D1 extends motor life. Removable food-grade plastic auger stirrers simplify cleaning and allow for quick chocolate changeovers, adhering to stringent hygiene standards.

* Operational Flexibility: A "night mode" feature keeps chocolate melted at reduced power consumption during non-operational hours, saving energy and preparation time. The adjustable speed of the auger pump and stirrer further enhances process control.

These sophisticated features directly tackle the challenge of consistency, ensuring that every piece of chocolate produced has the desired snap, gloss, and melt. By automating and optimizing the tempering process, LST's machines significantly reduce the risk of fat bloom and enhance product quality, thereby truly setting new industry standards for chocolate perfection.

Scalability and Versatility Across the Spectrum

LST's tempering solutions cater to a broad spectrum of manufacturers, from artisanal chocolatiers to large-scale industrial producers:

* Compact Solutions for Artisans: The CHOCO-D1 (5.5L) is a perfect example, designed for ice cream shops and smaller chocolate boutiques. It offers user-friendly features for decorating, small-batch molding, and dessert toppings, demonstrating LST's understanding of diverse market needs.

* Industrial Powerhouses: The TW-TP series provides the robust capacity and control required for high-volume manufacturing. These industrial chocolate machines can be equipped with various attachments for coating, depositing, and vibrating, allowing for diverse production capabilities such as molded chocolates, coated confections, hollow figures, and truffle products. This modularity enables manufacturers to diversify their product portfolio without significant additional investment, a critical advantage in a dynamic market.

Beyond Tempering: LST's Integrated Solutions for a Complete Ecosystem

LST's commitment to setting industry standards extends beyond individual machines. The company offers a holistic suite of chocolate machinery designed to integrate seamlessly into a complete, highly automated production ecosystem.

Comprehensive Product Portfolio

* Chocolate Depositor Machine: LST's full automatic chocolate depositing lines (e.g., LST-S1000/LST-D1000/LST-T1000) are marvels of automation. Capable of producing pure solid, filled, double-color, and nut-mixed chocolates, these lines can also integrate biscuit or wafer feeding units. Features like PLC control, automatic frequency conversion, human-machine touch interface, servo mold lifting, and high-precision cam rotor pumps ensure precise material mixing and consistent product quality. The ability to change chocolate colors and product types within 15 minutes highlights their exceptional flexibility.

* Chocolate Ball Machine (Grinding Mill): Essential for achieving the ultra-fine particle size critical for smooth chocolate, LST offers chocolate ball mills in various capacities (50kg, 300kg, 500kg, 1000kg, and 50L). Made from AISI 304 stainless steel, these machines refine and homogenize chocolate ingredients to micron-level dimensions, enhancing flavor, texture, and consistency.

* Chocolate Coating Machines: Rotary drum chocolate/sugar coating machines (LST-500L/LST-1000L) provide fully automatic loading, coating, unloading, spraying, dedusting, and cleaning for a variety of confectionery products.

* Chocolate Cooling Tunnels: LST's cooling tunnels feature advanced multi-stage cooling designs for energy efficiency and rapid solidification. Made entirely of stainless steel, they adhere to food hygiene standards. Notably, the vertical cooling tunnels offer significant space savings, addressing a common practical challenge for manufacturers with limited floor space. Precision digital temperature control (Delta PLC) and imported compressors ensure stability and durability.

* Other Specialized Chocolate Machinery: LST's extensive portfolio also includes chocolate cluster tunnels, desktop depositors, chocolate grinding machines, fat melting tanks, hollow chocolate rotating machines, and sugar cooking pots, demonstrating their capability to furnish every conceivable component for a complete chocolate production line.

LST's Commitment to Excellence and Global Partnership

LST's leadership in the chocolate machinery [www.lst-machine.com] sector is underpinned by several core competitive advantages:

* Innovation at Its Core: LST's professional R&D team is driven by a goal to implement three new high-tech advancements annually, consistently integrating advanced control systems (PLC/HMI), automatic frequency conversion, and sensor-controlled processes. The use of imported components, such as US compressors and Delta PLC, further underscores their commitment to cutting-edge technology.

* Unwavering Quality and Safety: A foundational principle for LST is the delivery of "high-quality, safe, reliable chocolate production machinery." This is substantiated by the exclusive use of AISI 304 stainless steel for food contact parts, adherence to stringent food hygiene standards, and multiple CE certifications, which are crucial for market access and demonstrating compliance with European safety directives.

* Global Reach and Unparalleled Support: LST offers comprehensive "global lifetime after-sales service" and "lifetime free professional English technical support," alongside remote debugging and on-site assistance. This level of enduring support significantly reduces customer risk, minimizes downtime, and fosters long-term partnerships, setting a high bar for customer commitment in the industrial machinery sector.

* Operational Efficiency and User-Centric Design: LST's machines are designed for high automation, from automatic loading and cleaning in coating machines to precise dosing in tempering units. Ease of installation, disassembly, and cleaning, coupled with intuitive touch screen controls and space-saving designs like vertical cooling tunnels, highlight a deep understanding of practical operational needs.

* Versatility and Customization: The modular design of LST's depositors allows for easy product diversification, while full automatic lines can handle a vast array of chocolate types. The ability to customize entire production lines, machine capacities, and even branding elements like logos and packaging, offers unparalleled flexibility to clients.

* Competitive Value Proposition: Positioned as a "factory direct supplier" benefiting from "economies of scale," LST provides advanced equipment at competitive prices. This strategy makes high-end automation accessible to a broader market, from emerging economies to established manufacturers seeking cost-effective upgrades.

* Market Leadership and Trust: Since its inception in 2009, LST has garnered "2,563 satisfied customers" and boasts a robust global sales network spanning Europe, Asia, North and South America, Africa, and Oceania. External validations, such as high Alibaba store ratings (4.9/5 and 5.0/5) and a 95.9% on-time delivery rate, provide objective evidence of customer satisfaction and operational reliability, solidifying LST's reputation as a trusted market leader.

Key Takeaways: Why LST Sets the Standard

LST Machine's advanced automatic chocolate tempering machine and comprehensive suite of chocolate machinery are redefining industry benchmarks through:

* Unrivaled Precision & Automation: Achieving perfect chocolate quality and consistency through advanced PLC/HMI controls, automated processes, and fine-tuned temperature management.

* Scalability & Versatility: Offering solutions for every scale of operation, from artisanal to industrial, with adaptable machines capable of producing a wide range of chocolate products.

* Comprehensive End-to-End Solutions: Providing a complete ecosystem of integrated chocolate machinery, from refining (chocolate ball machine) and tempering to depositing (chocolate depositor machine), coating, and cooling.

* Global Lifetime Support: Offering an industry-leading commitment to customer success with lifetime technical support, remote debugging, and on-site services worldwide.

* Uncompromising Quality & Safety: Adhering to the highest standards with food-grade materials, robust construction, and international certifications (CE).

* Exceptional Value: Combining cutting-edge technology with competitive pricing, making advanced chocolate production accessible to a broader global market.

Conclusion

The chocolate manufacturing industry is in a perpetual state of evolution, driven by technological advancements and shifting consumer preferences. In this dynamic environment, LST Machine stands out as a beacon of innovation, particularly with its advanced automatic chocolate tempering machine. By integrating precision engineering, robust automation, and a deep understanding of industry needs, LST is not just meeting the current demands of chocolate producers but is actively anticipating and shaping future trends.

LST's comprehensive product portfolio, unwavering commitment to quality, unparalleled global support, and strategic focus on customer success firmly establish its position as a pioneer. For manufacturers seeking to elevate their production capabilities, ensure consistent product quality, and achieve greater operational efficiency, LST Machine offers the definitive solutions that are setting new standards across the global confectionery landscape.

To explore how LST Machine can elevate your chocolate production capabilities and to view their full range of innovative chocolate machinery, visit www.lst-machine.com today.

Media Contact

Company Name: Chengdu LST Technology Co.,Ltd

Contact Person: Suzy

Email:Send Email [https://www.abnewswire.com/email_contact_us.php?pr=pioneering-innovation-lsts-advanced-automatic-chocolate-tempering-machine-sets-industry-standards]

Country: China

Website: https://www.lst-machine.com/

Legal Disclaimer: Information contained on this page is provided by an independent third-party content provider. ABNewswire makes no warranties or responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you are affiliated with this article or have any complaints or copyright issues related to this article and would like it to be removed, please contact retract@swscontact.com

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Pioneering Innovation: LST's Advanced Automatic Chocolate Tempering Machine Sets Industry Standards here

News-ID: 4329873 • Views: …

More Releases from ABNewswire

Cruelty.Farm Publishes Expansive Editorial Series Reframing Veganism as a Univer …

Cruelty.Farm's editorial series reframes veganism as a universal ethical responsibility rather than a political identity. Through articles on myth-busting, documentaries, athletes, beauty, and "Veganism Beyond Politics," the platform presents evidence-based insights showing how plant-based living can reduce animal suffering, support environmental sustainability, and improve public health - inviting inclusive, informed engagement beyond ideology.

A major new editorial series published on Cruelty.Farm presents veganism not as a political identity, but as a…

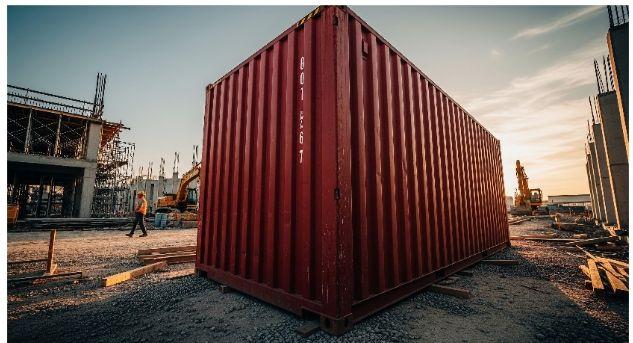

Storage Containers for Jobsites: A Practical Playbook for Construction Teams

Image: https://www.abnewswire.com/upload/2026/02/3383b50aa2f095c7d44c6caacaac4801.jpg

Construction schedules leave little room for friction. When you bring storage containers onto a site, success comes down to four things: delivery and placement, permits and compliance, security, and spec/cost fit. This playbook gives project managers and supers a clean, defensible approach that keeps crews productive and protects the schedule-without adding administrative drag.

Delivery & Placement: Prevent Redeliveries Before They Happen

Failed drops chew up time and budget. Before you order,…

Thailand Trademark Protection with an Intellectual Property Expert in Thailand

Trademarks are a serious issue for your business. This is true, especially if you want to protect your brand. Trademark protection in Thailand is a legal tool. It can help to safeguard your business name. To achieve long-term success, it is definitely necessary to understand how to protect your trademark. The registration of trademarks doesn't just provide protection for your brand. It also allows you to sue against infringement.

Why Trademark…

ERA-co Brings a Global Placemaking Perspective to MIPIM 2026 in Cannes

CANNES, FRANCE - ERA-co [https://era-co.com/], the world's leading placemaking and destination strategy firm, will bring its integrated, systems-driven approach to urban development to MIPIM 2026 [https://www.mipim.com/en-gb.html], taking place March 9-13 at the Palais des Festivals in Cannes.

Representing ERA-co at this year's conference are Paolo Testolini, USP Global Director, Urban Design and Masterplanning, and Taras Kashko, Global Leader, Urban Design and Masterplanning, both based in the firm's Dubai home studio.

MIPIM is…

More Releases for LST

Leading Manufacturer LST: Innovative Chocolate Machine Lines for Versatile Confe …

CHENGDU, CHINA - In the dynamic world of confectionery, where precision, innovation, and versatility are paramount, one name stands out as a beacon of excellence: Chengdu LST Science & Technology Co., Ltd. [https://www.lstchocolatemachine.com/](LST Machine). Established in 2009, LST has rapidly ascended to become a leading manufacturer, offering an unparalleled suite of advanced chocolate machinery that empowers confectioners worldwide to transform their creative visions into delectable realities. This press release delves…

Leading Manufacturer LST: Innovative Chocolate Machine Lines for Versatile Confe …

CHENGDU, CHINA - In the dynamic world of confectionery, where precision, innovation, and versatility are paramount, one name stands out as a beacon of excellence: Chengdu LST Science & Technology Co., Ltd. (LST Machine) (https://www.lstchocolatemachine.com/). Established in 2009, LST has rapidly ascended to become a leading manufacturer, offering an unparalleled suite of advanced chocolate machinery that empowers confectioners worldwide to transform their creative visions into delectable realities. This press release…

LST Machine's Versatile Depositors Redefine Global Confectionery Production

The Versatility Mandate: Why Multi-Functional Equipment is the Future of Chocolate Manufacturing

The global chocolate and confectionery machinery market is undergoing a rapid transformation, driven by consumer demand for novelty, personalization, and higher quality. Manufacturers are no longer content with producing a single line of products; success now hinges on the ability to swiftly pivot, innovate, and master diverse product categories-all while maintaining operational efficiency and cost-effectiveness. This new operating environment…

LST Machine's Versatile Depositors Redefine Global Confectionery Production

The Versatility Mandate: Why Multi-Functional Equipment is the Future of Chocolate Manufacturing

The global chocolate and confectionery machinery market is undergoing a rapid transformation, driven by consumer demand for novelty, personalization, and higher quality. Manufacturers are no longer content with producing a single line of products; success now hinges on the ability to swiftly pivot, innovate, and master diverse product categories-all while maintaining operational efficiency and cost-effectiveness. This new operating environment…

LST Machine Unveils Cutting-Edge Chocolate Tempering Innovations for Global Conf …

November 6, 2025 - Chengdu, China - In a move poised to reshape the confectionery manufacturing landscape, Chengdu LST Technology Co., Ltd. (LST Machine) (https://www.lstchocolatemachine.com/)has introduced groundbreaking advancements in chocolate tempering technology. These innovations promise unprecedented precision, efficiency, and versatility for chocolate producers worldwide, addressing the evolving demands of an industry projected to reach $250 billion by 2030.

The Booming Confectionery Equipment Sector: Trends Driving Innovation

The global chocolate and confectionery machinery…

LST Equipment: Multi-Functional Design Breaks Production Barriers

The Sweet Future: Global Trends Driving the Chocolate Machinery Market

The global chocolate industry is undergoing a profound transformation, moving beyond traditional mass production toward customization, health consciousness, and ethical sourcing. This shift is placing unprecedented pressure and opportunity on the machinery sector that equips this multi-billion-dollar market. For manufacturers like Chengdu LST Science and Technology Co., Ltd. (LST Machine), understanding and meeting these dynamic needs is key to maintaining market…