Press release

Flow Chemistry Market to be Worth USD 5.9 Bn by 2035 - By Reactor Scale / By Reactor Type / By End-use Industry | U.S. • Germany • China • India

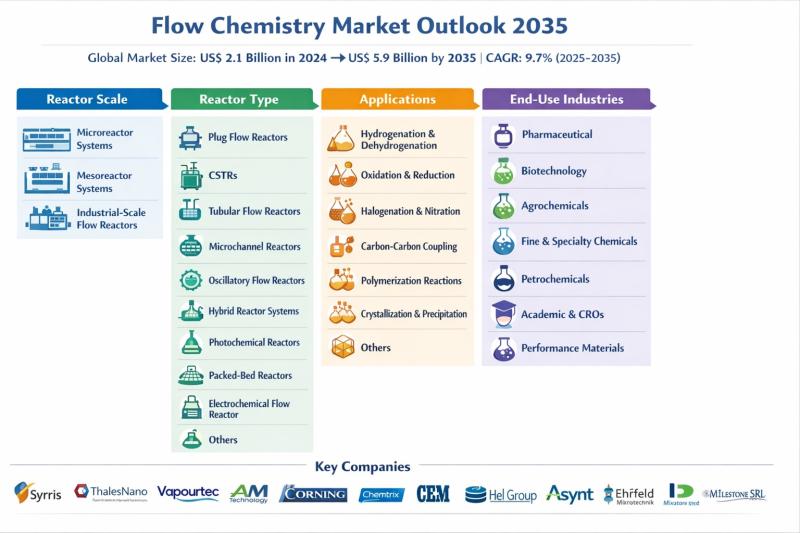

The global Flow Chemistry Market was valued at US$ 2.1 Billion in 2024 and is projected to reach US$ 5.9 Billion by 2035, expanding at a compound annual growth rate (CAGR) of 9.7% from 2025 to 2035. This strong growth trajectory reflects the increasing adoption of continuous manufacturing technologies across pharmaceuticals, fine and specialty chemicals, agrochemicals, and performance materials.Explore core findings and critical insights from our Report in this sample -

https://www.transparencymarketresearch.com/sample/sample.php?flag=S&rep_id=2058

Flow chemistry has transitioned from a niche laboratory technique to a commercially viable production platform, enabling manufacturers to improve yields, reduce costs, enhance safety, and meet stringent regulatory and environmental standards. As industries worldwide prioritize operational efficiency and sustainability, flow chemistry is emerging as a core technology shaping the future of chemical manufacturing.

Market Overview

Flow chemistry, also known as continuous-flow processing, involves conducting chemical reactions in a continuously flowing stream rather than traditional batch reactors. This approach enables precise control over reaction parameters such as temperature, pressure, residence time, and mixing, resulting in superior product consistency, enhanced safety, and higher process efficiency.

The technology is particularly advantageous for fast, highly exothermic, or hazardous reactions that are difficult to manage using batch systems. By minimizing in-process inventory and improving heat and mass transfer, flow chemistry significantly reduces operational risks while enabling higher throughput.

From a commercial perspective, flow chemistry supports process intensification, faster scale-up from laboratory to production, and reduced environmental footprint. These advantages make it a preferred choice for pharmaceutical manufacturers producing APIs and intermediates, as well as specialty chemical producers seeking flexibility and cost optimization. With ongoing advancements in reactor design, automation, and process analytical technology (PAT), flow chemistry is increasingly being deployed as a full-scale manufacturing solution rather than solely an R&D tool.

Key Market Growth Drivers

Rising Demand for Efficient, Sustainable & Continuous Chemical Processes

One of the primary drivers of the flow chemistry market is the global push toward efficiency, sustainability, and regulatory compliance. Traditional batch processes often suffer from high energy consumption, inconsistent quality, and significant waste generation. In contrast, continuous flow systems enable accurate control over reaction conditions, leading to improved yields, repeatability, and reduced environmental impact.

Manufacturers adopting flow chemistry have reported 20-40% reductions in solvent usage, 15-30% lower energy consumption, and up to 50% waste reduction in fine chemical reactions. These benefits align closely with ESG objectives and stricter environmental regulations, making flow chemistry a strategic investment for chemical producers worldwide.

Growth in Pharmaceutical and Specialty Chemical Production

The global pharmaceutical industry continues to expand, with API production growing at an estimated 6-8% annually. Flow chemistry has become a critical enabler for this growth by delivering 3-10× higher space-time yields and significantly shorter reaction times compared to batch processes.

Continuous flow processing has reduced typical API reaction times from 8-24 hours to just 30-120 minutes, directly improving plant productivity and scheduling efficiency. Additionally, precise process control has led to 20-40% yield improvements in multistep reactions, while hazardous transformations such as nitration, hydrogenation, and diazotization benefit from 70-90% lower in-process inventory, enhancing safety and regulatory compliance.

In specialty chemicals, steady-state operation and reduced downtime have resulted in 20-35% higher asset utilization and 15-25% lower unit production costs, further accelerating adoption.

Analysis of Key Players - Competitive Positioning and Market Influence

The flow chemistry market features a mix of established technology providers and specialized innovators offering scalable reactor platforms, automation solutions, and integrated process development capabilities.

ThalesNano Inc. is a leading global supplier of flow chemistry systems, with strong expertise in continuous hydrogenation and high-pressure reactions. Its scalable reactor platforms are widely used in pharmaceutical and fine chemical manufacturing, enabling 3-10× higher space-time yields while significantly improving process safety. ThalesNano's ability to support seamless scale-up from laboratory to commercial production strengthens its global market position.

Syrris Ltd. is recognized for its modular, automated flow chemistry systems extensively used in pharmaceutical and specialty chemical R&D. Its platforms enable reactions to be completed in 60-90% less time with 20-40% higher yields, driven by precise control over temperature and residence time. Syrris' compatibility with process analytics and its strong global distribution network position it as a trusted partner for continuous process development.

Vapourtec Ltd. has established itself as a key innovator in flow chemistry equipment, particularly for peptide synthesis and continuous processing applications. The company's emphasis on long-run stability, solvent recycling, and sustainability-focused solutions aligns closely with industry demands.

Other prominent players include AM Technology, Corning, Chemtrix, CEM Corporation, Hel Group, Asynt, Ehrfeld Mikrotechnik, Cambridge Reactor Design, Milestone SRL, Parr Instrument Company, Advion Interchim Scientific, and Asymchem, each contributing to the market through specialized reactor designs, scalable platforms, and regional expansion strategies.

Explore our report to gain an in-depth view of the key findings -

https://www.transparencymarketresearch.com/flow-chemistry-market.html

Market Challenges & Opportunities

Despite its strong growth outlook, the flow chemistry market faces several challenges. High initial capital investment, integration with existing batch infrastructure, and the need for specialized technical expertise can slow adoption, particularly among small and mid-sized manufacturers. Process development and optimization for continuous systems may also require longer validation cycles in regulated industries.

However, these challenges present significant opportunities. Increasing availability of modular, plug-and-play reactor systems, combined with CDMO support for continuous manufacturing, is lowering entry barriers. Regulatory agencies' growing acceptance of continuous processing, particularly in pharmaceuticals, further enhances market potential.

Emerging applications in electrochemical flow reactors, photochemical reactors, and hybrid systems also open new avenues for innovation and revenue growth.

Key Player Strategies

Key players in the flow chemistry market are focusing on:

• Integrated automation and PAT-enabled platforms to improve process monitoring and control

• Modular reactor architectures that simplify scale-up and multi-product flexibility

• Strategic partnerships with CDMOs and academic institutions to accelerate adoption

• Regional expansion and localized manufacturing support to meet reshoring and supply chain resilience trends

These strategies are enabling suppliers to differentiate themselves while supporting customers through the full lifecycle of process development, scale-up, and commercialization.

Recent Developments

• In 2025 Asymchem unveiled a new CE-certified flow capability at its Sandwich, UK location (facility acquired 2024). The extension offers a medical-scale center for small-molecule APIs, peptides and oligonucleotides through the use of a proprietary, CE-certified flow equipment. With this new regional CDMO capacity for the UK/EU customers, who are looking for quick clinical supply and safer handling of hazardous chemistries, the times for technology transfer are getting shortened and it is becoming easier to support localized supply chains amid reshoring trends.

• In 2025, Vapourtec included product activity such as Peptide-Builder demonstrations (continuous LPPS runs) and launches including the eBPR-GL and integrated solvent-recycling options. Several academic labs and pilot customers were able to witness demo runs of continuous peptide synthesis throughputs, thereby confirming long-run stability; Vapourtec staged these products as a means of supporting pharma peptide supply chains and making sustainability better by solvent reuse, thus assisting the reduction of both operating costs and solvent waste in peptide manufacture.

• Corning announced the launch of Advanced-Flow Reactor (AFR) application qualified lab with Ulsan Technopark in April 2024. The lab offers local access to AFR development means for Korean fine chemical and performance materials companies, thus, continuous process development is getting faster and scale-up cycles are getting shorter. The regional manufacturers, who are adopting process intensification for battery precursor and specialty polymer intermediates, will benefit from the initiative as it will reduce their development timelines and promote AFR usage in the Asia-Pacific region.

• Chemtrix BV announced in 2024 that it had become a part of the AGI Group to facilitate the scaling-up process from the laboratory to the pilot and industrial production level. The acquisition has opened up Chemtrix's way to more capital, increased manufacturing capacity, and new distribution channels. As a result, the company is now in a position to accelerate its scalable reactor portfolio to larger commercial projects and be the multi-tonne continuous production of fine chemicals and specialty pharmaceuticals. The strategic move by this firm is a solution to their clients' needs for easier technology transfer and numbering up to the production scale.

Investment Landscape and ROI Outlook

Investment in flow chemistry continues to rise as manufacturers seek long-term returns through cost efficiency and sustainability. Typical adopters report 15-25% lower unit production costs, 30-50% reductions in cycle time, and significantly improved asset utilization.

With growing regulatory support and increasing adoption across Asia Pacific, Europe, and North America, investors can expect strong ROI driven by recurring equipment demand, service contracts, and CDMO-led expansion of continuous manufacturing capacity.

Market Segmentations

By Reactor Scale

• Microreactor Systems

• Mesoreactor Systems

• Industrial-Scale Flow Reactors

By Reactor Type

• Plug Flow Reactors

• Continuous Stirred Tank Reactors

• Tubular Flow Reactors

• Microchannel Reactors

• Oscillatory Flow Reactors

• Hybrid Reactor Systems

• Photochemical Reactors

• Packed-Bed Reactors

• Electrochemical Flow Reactor

• Others

By End-use Industry

• Pharmaceutical

• Biotechnology

• Agrochemicals

• Fine and Specialty Chemicals

• Performance Materials & Polymers

• Petrochemicals

• Academic Institutions

• Contract Research Organizations

• Others

By Region

• North America (36% market share, leading region)

• Europe (27% share, strong regulatory support)

• Asia Pacific (26% share, fastest growth)

• Latin America

• Middle East & Africa

Why Buy This Report?

• Gain detailed insights into the global flow chemistry market outlook through 2035

• Understand technology, application, and regional growth dynamics

• Identify high-growth segments and investment opportunities

• Analyze competitive strategies and recent developments

• Support strategic decision-making with quantitative and qualitative insights

Buy this Premium Research Report to stay informed with key insights -

https://www.transparencymarketresearch.com/checkout.php?rep_id=2058<ype=S

FAQs

1. What is the current size of the flow chemistry market?

The market was valued at US$ 2.1 Billion in 2024.

2. What is the expected growth rate of the flow chemistry market?

The market is projected to grow at a CAGR of 9.7% from 2025 to 2035.

3. Which region dominates the flow chemistry market?

North America leads the market with a 36% revenue share.

4. Which reactor scale holds the largest market share?

Microreactor systems held the largest share, accounting for 40% in 2024.

5. What industries are driving demand for flow chemistry?

The primary drivers are pharmaceuticals, specialty chemicals, agrochemicals, and performance materials.

Explore Latest Research Reports by Transparency Market Research:

3D Printing Materials Market - https://www.transparencymarketresearch.com/3d-printing-materials-market.html

Coil Coating Market - https://www.transparencymarketresearch.com/coil-coating-market.html

Nanofiber Filter Media Market - https://www.transparencymarketresearch.com/nanofiber-filter-media-market.html

Epoxy Composites Market - https://www.transparencymarketresearch.com/epoxy-composites-market.html

About Transparency Market Research

Transparency Market Research, a global market research company registered at Wilmington, Delaware, United States, provides custom research and consulting services. Our exclusive blend of quantitative forecasting and trends analysis provides forward-looking insights for thousands of decision makers. Our experienced team of Analysts, Researchers, and Consultants use proprietary data sources and various tools & techniques to gather and analyses information.

Our data repository is continuously updated and revised by a team of research experts, so that it always reflects the latest trends and information. With a broad research and analysis capability, Transparency Market Research employs rigorous primary and secondary research techniques in developing distinctive data sets and research material for business reports.

Contact:

Transparency Market Research Inc.

CORPORATE HEADQUARTER DOWNTOWN,

1000 N. West Street,

Suite 1200, Wilmington, Delaware 19801 USA

Tel: +1-518-618-1030

USA - Canada Toll Free: 866-552-3453

Website: https://www.transparencymarketresearch.com

Email: sales@transparencymarketresearch.com

Follow Us: LinkedIn| Twitter| Blog | YouTube

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Flow Chemistry Market to be Worth USD 5.9 Bn by 2035 - By Reactor Scale / By Reactor Type / By End-use Industry | U.S. • Germany • China • India here

News-ID: 4329403 • Views: …

More Releases from Transparency Market Research

Photodynamic Therapy Market Outlook 2031: Industry to Expand at 7.9% CAGR Driven …

The global photodynamic therapy (PDT) market was valued at US$ 4.5 Billion in 2022 and is projected to grow at a compound annual growth rate (CAGR) of 7.9% from 2023 to 2031, reaching more than US$ 8.9 Billion by the end of 2031. Market growth is driven by increasing clinical validation of PDT, rising adoption of minimally invasive procedures, and expanding applications across oncology, dermatology, and other medical specialties.

Access key…

Mainframe Modernization Services Market to Reach USD 108.9 Billion by 2031, Driv …

Mainframe systems have long served as the backbone of enterprise IT, supporting high-volume transaction processing, data storage, and mission-critical operations. Industries such as banking, insurance, government, and telecommunications continue to depend on mainframes for reliability, security, and performance. However, as digital transformation accelerates, traditional mainframe environments are increasingly viewed as barriers to agility, innovation, and scalability. This shift has positioned the Mainframe Modernization Services Market as a vital enabler of…

Underwater Connectors Market Set to Grow from US$ 1.3 Billion to US$ 3.1 Billion …

The global underwater connectors market is gaining strong momentum as subsea operations become increasingly critical across offshore energy, marine research, defense, and underwater communication systems. The market was valued at US$ 1.3 billion in 2022 and is estimated to expand at a robust CAGR of 10.6% from 2023 to 2031, reaching US$ 3.1 billion by the end of 2031. This sustained growth reflects rising investments in deepwater exploration, subsea robotics,…

Global EV Charging Connector Market to Surge at 16.9% CAGR, Reaching US$ 545.9 M …

The global EV Charging Connector Market is witnessing remarkable momentum as electric mobility gains widespread acceptance across regions. Valued at US$ 93.0 million in 2024, the market is projected to expand at a robust compound annual growth rate (CAGR) of 16.9% from 2025 to 2035, reaching an estimated US$ 545.9 million by the end of 2035. This exceptional growth trajectory underscores the increasing importance of reliable, high-performance charging connectors as…

More Releases for Flow

Flow (FLOW) Price Prediction: Pepenode (PEPENODE) Gains Rapid Market Recognition

Market moves since early October have reshaped speculative flows. Bitcoin slid from roughly $126,080 to about $87,423, wiping nearly $1 trillion from total market value and pressuring Ethereum. That unwind pushed ETH down about 28% over 30 days and coincided with a $415M net outflow from spot funds in a single day.

Rising U.S. Treasury yields and shifting Federal Reserve expectations have nudged capital toward perceived safety and yield-bearing strategies. Institutional…

Flow Rate Liquid Flow Meters Market Size, Share and Growth Report, 2034

"The global liquid flow meter market was valued at approximately USD 4 billion in 2024 and is projected to reach around USD 6.5 billion by 2034, indicating a Compound Annual Growth Rate (CAGR) of about 5.2% over the forecast period from 2025 to 2034. "

Exactitude Consultancy., Ltd. released a research report titled "Flow Rate Liquid Flow Meters Market". This report covers the global Flow Rate Liquid Flow Meters market sales,…

Hybrid Flow Battery Market, By Type (Zinc Bromine Flow Batteries, Other Hybrid F …

Data Bridge Market Research analyses the hybrid flow battery market will exhibit a CAGR of 32.14% for the forecast period of 2022-2029 and is likely to reach USD 710.18 million by 2029.

View Detailed Analysis Report: https://www.databridgemarketresearch.com/reports/global-hybrid-flow-battery-market

The zinc-bromine flow battery (ZBFB) is the most well-known form of hybrid flow battery. Typically, a hybrid flow battery consists of a cell with 2 compartments separated by a microporous membrane. The battery has a…

Hybrid Flow Battery Market, By Type (Zinc Bromine Flow Batteries, Other Hybrid F …

Data Bridge Market Research analyses the hybrid flow battery market will exhibit a CAGR of 32.14% for the forecast period of 2022-2029 and is likely to reach USD 710.18 million by 2029.

View Detailed Report: https://www.databridgemarketresearch.com/reports/global-hybrid-flow-battery-market

The zinc-bromine flow battery (ZBFB) is the most well-known form of hybrid flow battery. Typically, a hybrid flow battery consists of a cell with 2 compartments separated by a microporous membrane. The battery has a conductor…

Hybrid Flow Battery Market, By Type (Zinc Bromine Flow Batteries, Other Hybrid F …

Data Bridge Market Research analyses the hybrid flow battery market will exhibit a CAGR of 32.14% for the forecast period of 2022-2029 and is likely to reach USD 710.18 million by 2029.

View Detailed Report: https://www.databridgemarketresearch.com/reports/global-hybrid-flow-battery-market

The zinc-bromine flow battery (ZBFB) is the most well-known form of hybrid flow battery. Typically, a hybrid flow battery consists of a cell with 2 compartments separated by a microporous membrane. The battery has a conductor…

Flow Cytometry Market Size 2020-26, Agilent Technologies, Apogee Flow Systems

The latest study on the Global Flow Cytometry market report represents a deep appraisal of the international industry. The research report on the worldwide Flow Cytometry market 2020-2026 sheds light on qualitative as well as quantitative insights, historical Flow Cytometry industry status and authorized projection related to the Flow Cytometry market size. Each and every segment exhibited in this report are discovered through verifiable research methods and techniques. It also…