Press release

3D Printing Metal Market Size to Reach US$ 4.2 Bn by 2032 Driven by Aerospace & Industrial Adoption

Introduction: Evolution of the 3D Printing Metal MarketThe 3D printing metal market has emerged as one of the most transformative segments within advanced manufacturing, redefining how complex metal components are designed, produced, and deployed across industries. Unlike conventional subtractive manufacturing, metal additive manufacturing enables layer-by-layer fabrication of intricate geometries with minimal material waste and enhanced design flexibility. This capability has made 3D metal printing highly attractive for industries seeking lightweight, high-strength, and customized components. As digital manufacturing accelerates globally, metal-based additive manufacturing is transitioning from prototyping to full-scale production, marking a significant shift in industrial workflows and value chains.

According to the latest study by Persistence Market Research, the global 3D printing metal market was valued at US$ 1.2 billion in 2025 and is projected to reach US$ 4.2 billion by 2032, expanding at a robust CAGR of 19.8% during the forecast period from 2025 to 2032. This rapid growth is underpinned by rising adoption in aerospace, medical, automotive, and industrial equipment manufacturing, where performance optimization, rapid iteration, and cost efficiency are critical. The market's strong trajectory highlights its growing role as a core manufacturing technology rather than a niche innovation.

Get Your FREE Sample Report Instantly - Click Now: https://www.persistencemarketresearch.com/samples/33210

Key Market Drivers Accelerating Metal Additive Manufacturing

One of the primary drivers of the 3D printing metal market is the increasing demand for lightweight yet high-performance components, particularly in aerospace and automotive industries. Aircraft manufacturers are leveraging metal 3D printing to produce complex parts with reduced weight, which directly improves fuel efficiency and lowers emissions. Similarly, automotive manufacturers are adopting metal additive manufacturing to develop lightweight structural components, tooling, and functional prototypes that shorten development cycles and improve overall performance.

Another major growth driver is the ability of metal 3D printing to enable mass customization and rapid production. Traditional manufacturing methods often struggle with low-volume, high-complexity parts due to high tooling costs and long lead times. Metal additive manufacturing overcomes these limitations by allowing direct production from digital designs, making it ideal for customized medical implants, dental prosthetics, and specialized industrial components. This flexibility not only reduces time-to-market but also supports innovation across multiple end-use sectors.

Technological Advancements Shaping Market Growth

Technological innovation remains a cornerstone of growth in the 3D printing metal market. Advances in metal powders, printing accuracy, and post-processing techniques have significantly improved the mechanical properties and surface finish of printed components. Modern metal 3D printers now offer enhanced precision, repeatability, and scalability, enabling manufacturers to meet stringent industry standards, particularly in aerospace and medical applications where safety and reliability are paramount.

In addition, software integration and digital manufacturing ecosystems are playing a critical role in market expansion. Simulation tools, artificial intelligence, and digital twins are increasingly being used to optimize print parameters, predict defects, and reduce material waste. These advancements not only improve production efficiency but also lower operational costs, making metal additive manufacturing more accessible to small and medium-sized enterprises. As technology matures, the gap between traditional manufacturing and metal 3D printing continues to narrow.

Market Segmentation Analysis

By Metal Powder

Metal Powder

Metal Alloy Powder

By Shape

Spherical

Non-Spherical

By Production Process

Powder Bed Fusion

Directed Energy Deposition

Material Jetting

Binder Jetting

Metal Extrusion

Photo Polymerization

By End-user

Medical

Aerospace

Automotive

Electronics

Energy

Industrial Equipment

Education and Research

Others

By Region

North America

Europe

East Asia

South Asia and Oceania

Latin America

Middle East and Africa

This segmentation highlights the diversity of materials, technologies, and applications driving the market. Metal alloy powders are increasingly preferred due to their superior mechanical and thermal properties, while powder bed fusion remains the most widely adopted production process owing to its precision and compatibility with high-performance metals.

Get a Customized Market View in One Click: https://www.persistencemarketresearch.com/request-customization/33210

End-User Industry Adoption and Application Trends

The aerospace sector continues to dominate the 3D printing metal market due to its need for lightweight, high-strength, and geometrically complex components. Metal additive manufacturing allows aerospace manufacturers to consolidate multiple parts into single components, reducing assembly time and potential failure points. This capability has positioned 3D metal printing as a strategic technology for both commercial aviation and defense applications.

The medical industry is another significant end-user, leveraging metal 3D printing for patient-specific implants, orthopedic devices, and surgical instruments. Titanium and cobalt-chromium alloys are widely used due to their biocompatibility and strength. Beyond aerospace and medical sectors, industrial equipment and energy industries are increasingly adopting metal additive manufacturing for tooling, spare parts, and high-temperature components, further broadening the market's application landscape.

Regional Outlook and Market Expansion Opportunities

North America holds a leading position in the 3D printing metal market, driven by strong technological capabilities, high R&D investments, and early adoption across aerospace and defense industries. The presence of major additive manufacturing companies and supportive government initiatives has further strengthened the region's dominance. Europe follows closely, with countries such as Germany, the UK, and France focusing on advanced manufacturing and Industry 4.0 integration.

East Asia, particularly China and Japan, is emerging as a high-growth region due to rapid industrialization and increasing investments in advanced manufacturing technologies. Meanwhile, South Asia and Oceania are witnessing gradual adoption, supported by growing awareness and expanding industrial bases. As manufacturing ecosystems evolve globally, regional diversification is expected to play a key role in sustaining long-term market growth.

Challenges and Limitations Impacting Market Growth

Despite its strong growth outlook, the 3D printing metal market faces several challenges that could hinder widespread adoption. High initial investment costs for metal 3D printers, materials, and post-processing equipment remain a significant barrier, particularly for small and medium-sized enterprises. Additionally, the cost of metal powders and the need for skilled operators can further increase operational expenses.

Another challenge lies in standardization and certification, especially in regulated industries such as aerospace and medical. Ensuring consistent quality, material properties, and compliance with industry standards requires rigorous testing and validation. However, ongoing advancements in quality control systems, process monitoring, and regulatory frameworks are gradually addressing these concerns, paving the way for broader market acceptance.

Future Outlook and Strategic Opportunities

The future of the 3D printing metal market appears highly promising, with continued advancements expected in materials science, machine capabilities, and digital manufacturing integration. As production speeds increase and costs decline, metal additive manufacturing is likely to transition from specialized applications to mainstream manufacturing processes. Hybrid manufacturing models combining additive and subtractive techniques are also expected to gain traction, offering enhanced flexibility and efficiency.

Strategic collaborations between technology providers, material suppliers, and end-users will play a crucial role in shaping market dynamics. Investments in research and development, coupled with government support for advanced manufacturing initiatives, are expected to unlock new opportunities across emerging economies. With a projected CAGR of 19.8% through 2032, the market is well-positioned for sustained expansion and technological evolution.

For In-Depth Competitive Analysis, Buy Now: https://www.persistencemarketresearch.com/checkout/33210

Company Insights

The competitive landscape of the 3D printing metal market is characterized by the presence of established material suppliers, technology providers, and industrial manufacturers focusing on innovation and strategic partnerships. Key players operating in the market include

✦ Sandvik AB

✦ ATI Powder Metalsokj

✦ Advanced Metallurgical Group

✦ Rio Tinto

✦ American Axle & Manufacturing, Inc.

✦ Carpenter Powered Products

✦ Showa Denko Materials

✦ GKN PLC

✦ Praxair Surface Technologies Inc.

✦ Aubert & Duval

✦ Höganäs AB

These companies are actively investing in advanced metal powders, production technologies, and global expansion strategies to strengthen their market positions.

The 3D printing metal market is undergoing a significant transformation, driven by technological advancements, expanding industrial applications, and a growing emphasis on efficiency and customization. With market value expected to rise from US$ 1.2 billion in 2025 to US$ 4.2 billion by 2032, metal additive manufacturing is set to become a cornerstone of next-generation manufacturing. As challenges related to cost and standardization are gradually addressed, the market is poised to unlock new possibilities across aerospace, medical, automotive, and industrial sectors, shaping the future of global manufacturing.

Explore the Latest Trending Research Reports:

• Plastic Bag Market Overview - https://www.persistencemarketresearch.com/market-research/plastic-bag-market.asp

• Digital Label Printing Market Overview - https://www.persistencemarketresearch.com/market-research/digital-label-printing-market.asp

• Plastic Vials and Ampoules Market Overview - https://www.persistencemarketresearch.com/market-research/plastic-vials-and-ampoules-market.asp

Contact Us:

Persistence Market Research

Second Floor, 150 Fleet Street,

London, EC4A 2DQ, United Kingdom

USA Phone: +1 646-878-6329

UK Phone: +44 203-837-5656

Email: sales@persistencemarketresearch.com

Web: https://www.persistencemarketresearch.com

About Persistence Market Research:

At Persistence Market Research, we specialize in creating research studies that serve as strategic tools for driving business growth. Established as a proprietary firm in 2012, we have evolved into a registered company in England and Wales in 2023 under the name Persistence Research & Consultancy Services Ltd. With a solid foundation, we have completed over 3600 custom and syndicate market research projects, and delivered more than 2700 projects for other leading market research companies' clients.

Our approach combines traditional market research methods with modern tools to offer comprehensive research solutions. With a decade of experience, we pride ourselves on deriving actionable insights from data to help businesses stay ahead of the competition. Our client base spans multinational corporations, leading consulting firms, investment funds, and government departments. A significant portion of our sales comes from repeat clients, a testament to the value and trust we've built over the years.

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release 3D Printing Metal Market Size to Reach US$ 4.2 Bn by 2032 Driven by Aerospace & Industrial Adoption here

News-ID: 4326445 • Views: …

More Releases from Persistence Market Research

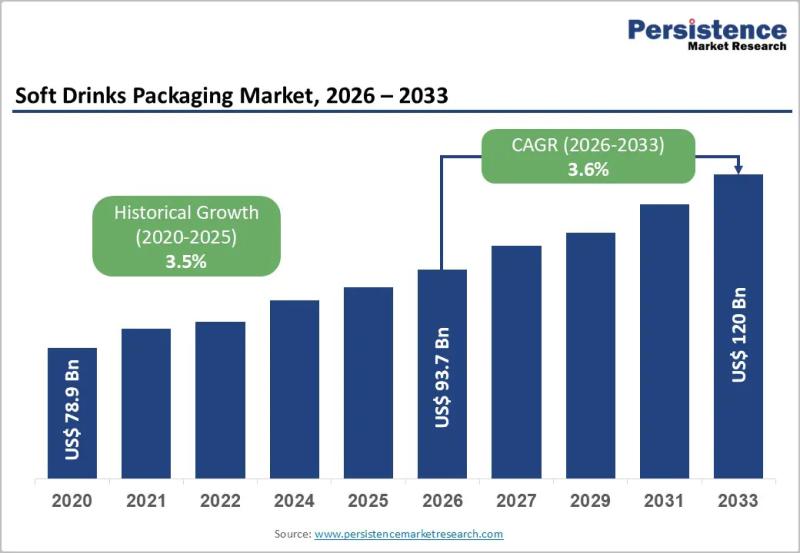

Soft Drinks Packaging Market to Reach US$120.0 Billion by 2033 - Persistence Mar …

The soft drinks packaging market plays a central role in the global beverage industry, serving carbonated drinks, juices, flavored water, energy drinks, and ready to drink teas and coffees. Packaging is no longer limited to containment and transportation; it has evolved into a critical component of branding, sustainability strategy, consumer convenience, and supply chain efficiency. Manufacturers are increasingly focusing on lightweight materials, recyclable packaging formats, and innovative designs that improve…

Christmas Tree Valves Market Size to Reach US$8.1 Billion by 2033 - Persistence …

The Christmas Tree Valves Market plays a critical role in the upstream oil and gas industry, serving as a central component in wellhead equipment systems. Christmas tree valves are installed on oil and gas wells to control pressure, regulate flow, and ensure safe extraction of hydrocarbons. These assemblies, commonly referred to as "Christmas trees," consist of multiple valves, spools, and fittings arranged in a structure that resembles a decorated tree.…

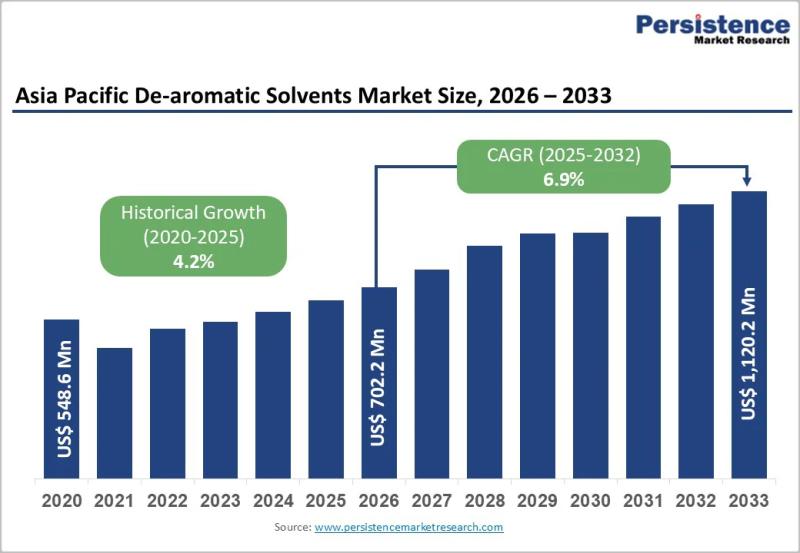

Asia Pacific De-aromatic Solvents Market to Reach US$1,120.2 Million by 2033 - P …

The Asia Pacific De-aromatic Solvents Market is gaining steady momentum as industries across the region increasingly shift toward low aromatic, high purity solvent formulations. De-aromatic solvents are hydrocarbon solvents that have significantly reduced aromatic content, making them suitable for applications requiring low odor, lower toxicity, and improved environmental performance. These solvents are widely used in paints and coatings, adhesives, inks, metalworking fluids, agrochemicals, and cleaning formulations. As regulatory scrutiny around…

Off-Highway Radiators Market to Reach US$ 7.2 Bn by 2033 as Leading Players Like …

The off-highway radiators market plays a vital role in ensuring efficient thermal management in heavy-duty equipment used across construction, agriculture, mining, and forestry sectors. These radiators regulate engine temperatures, prevent overheating, and support consistent equipment performance under extreme operating conditions. Growing mechanization and the expansion of infrastructure projects worldwide are increasing reliance on durable cooling systems. Equipment manufacturers are prioritizing high-performance radiators that offer reliability, longer service life, and resistance…

More Releases for Metal

Metal Roofing Companies Revolutionizing the Industry: Classic Metal Roofs Leads …

Classic Metal Roofs has established itself as a leading provider of durable and energy-efficient roofing systems in Southern New England. With over 20 years of experience, the company is known for high-quality installations, customer satisfaction, and sustainable metal roofing solutions.

As homeowners increasingly seek durable and energy-efficient solutions, metal roofing companies continue to provide top-tier roofing systems. Among the industry leaders, Classic Metal Roofs [http://business.bigspringherald.com/bigspringherald/markets/article/abnewswire-2025-2-15-classic-metal-roofs-expert-aluminum-shingle-metal-roof-installation-and-services/] stands out for its commitment to…

Rare Metal Raw Materials - Boron(B) Metal

Boron Powder [https://www.urbanmines.com/boron-powder-product/]

Short Description:

Boron [,%20a%20chemical%20element%20with%20the%20symbol%20B%20and%20atomic%20number%205,%20is%20a%20black/brown%20hard%20solid%20amorphous%20powder.%20It%20], a chemical element with the symbol B and atomic number 5, is a black/brown hard solid amorphous powder. It is highly reactiveand soluble in concentrated nitric and sulfuric acids but insoluble in water, alcohol and ether. It has a high neutro absorption capacity. UrbanMines specializes in producing high purity Boron Powder with the smallest possible average grain sizes. Our standard powderparticle sizes average in the…

Metal Polishing Services Market Trends and Leading Players 2023-2030 | Metal Pol …

With a CAGR of 6.1%, the Metal Polishing Services Market is expected to grow from USD 1.5 billion in 2023 to USD 2.3 billion by 2030, offering a gleaming finish to metal surfaces for aesthetic and functional purposes.

Market Overview:

The Metal Polishing Services market is poised for rapid growth, driven by several pivotal drivers. There is a continuous demand for metal finishing and polishing services that improve the appearance and…

Metal-to-metal Seal Market 2021 | Detailed Report

Metal-to-metal Seal Market Forecasts report provided to identify significant trends, drivers, influence factors in global and regions, agreements, new product launches and acquisitions, Analysis, market drivers, opportunities and challenges, risks in the market, cost and forecasts to 2027.

Get Free Sample PDF (including full TOC, Tables and Figures) of Metal-to-metal Seal Market @ https://www.reportsnreports.com/contacts/requestsample.aspx?name=5089735

The report provides a comprehensive analysis of company profiles listed below:

- Parker

- CPI

- HTMS

- American Seal &…

Metal Polishing Services Market Research Report 2020 Analysis: Enhanced Growth a …

Metal Polishing Services Market

Global Metal Polishing Services Market is providing the summarized study of several factors encouraging the growth of the market such as manufacturers, market size, type, regions and numerous applications. By using the report consumer can recognize the several dynamics that impact and govern the market. For any product, there are several companies playing their role in the market, some new, some established and some are planning to…

Worldwide Recycled Metal Market By Metal 2024 | Nucor, Steel Dynamics, Schnitzer …

The 2018-2024 report on global Recycled Metal market explores the essential factors of Recycled Metal industry covering current scenario, market demand information, coverage of active companies and segmentation forecasts.

North America recycled metal market was estimated close to USD 8.5 billion in 2017. This is mainly attributed to strong presence of transportation, electrical & electronics and defense industry which majorly constitute to the overall product demand. Moreover, strict laws formulated…