Press release

Shaft Pulley: Essential Component for Efficient Power Transmission

In modern industrial machinery, Shaft Pulley [https://www.huishichuandong.com/shaft-pulley/]s play a pivotal role in power transmission systems. From Conveyor Belts to heavy-duty manufacturing equipment, these components ensure efficient energy transfer, precise speed control, and reliable operation. Selecting the right shaft pulley is critical for businesses aiming to maximize productivity, reduce maintenance costs, and maintain consistent performance across industrial applications.Shaft pulleys are widely used in mechanical systems where rotational motion and torque need to be transferred from one shaft to another, often through belts or chains. They are indispensable in industries ranging from automotive, packaging, and mining to material handling and HVAC systems.

Understanding Shaft Pulleys

A shaft pulley is a mechanical component mounted on a shaft to transfer rotational motion to a belt or chain. It serves as a link between power sources (such as motors) and driven machinery, enabling smooth motion and torque distribution.

Key features of shaft pulleys include:

High-strength materials, typically cast iron, steel, or aluminum

Precision-machined surfaces for minimal belt slippage

Compatibility with various belt types (V-belts, Timing Belt [https://www.huishichuandong.com/timing-belt/]s, flat belts)

Balanced construction to reduce vibration and wear

Corrosion-resistant coatings for long service life

By understanding these features, B2B buyers can make informed decisions when selecting pulleys for specific industrial applications.

Types of Shaft Pulleys

Shaft pulleys come in various designs to suit different power transmission requirements. The main types include:

V-Belt Pulleys: Designed for V-shaped belts, offering efficient torque transmission and reduced slippage

Timing Pulleys: Feature teeth that mesh with timing belts for synchronized motion in precision applications

Flat Belt Pulleys: Used for flat belts, ideal for long-distance power transmission with minimal maintenance

Step Pulleys: Provide multiple diameters on a single pulley for adjustable speed control in variable-speed machinery

Selecting the right type ensures optimal performance, efficiency, and durability in industrial systems.

Image: https://ecdn6.globalso.com/upload/p/3196/image_other/2025-12/gear-1-1.jpg

Material Selection and Manufacturing Considerations

Choosing the correct material and manufacturing process for a shaft pulley is crucial for long-term reliability.

Materials: Common options include cast iron, steel, aluminum, and reinforced plastics. Cast iron offers high strength and wear resistance, while aluminum provides lightweight solutions for high-speed applications

Heat Treatment: Proper heat treatment enhances strength, toughness, and wear resistance

Precision Machining: Ensures accurate diameter, flatness, and groove profile to prevent belt slippage and reduce vibration

Surface Coating: Protective coatings can resist corrosion, oxidation, and environmental wear, extending service life

B2B buyers should carefully evaluate material specifications and manufacturing quality when sourcing pulleys.

Benefits of Using High-Quality Shaft Pulleys

Investing in premium shaft pulleys provides multiple advantages for industrial operations:

Enhanced Efficiency: Smooth power transfer minimizes energy loss

Reduced Downtime: Durable construction decreases the frequency of maintenance and replacements

Improved Belt Life: Properly machined pulleys reduce belt wear and slippage

Precise Speed Control: Maintains consistent operation for production lines and machinery

Versatility: Compatible with a wide range of belts, shafts, and industrial systems

High-quality pulleys directly impact productivity and cost efficiency, making them a critical component for B2B procurement decisions.

Common Applications of Shaft Pulleys

Shaft pulleys are widely utilized across various industries, including:

Conveyor systems in manufacturing and logistics

Agricultural machinery and irrigation equipment

Automotive engine and accessory drives

Packaging, printing, and textile machinery

HVAC systems and industrial fans

Mining, construction, and material handling equipment

By understanding their application scope, B2B buyers can better match pulley specifications to operational needs.

Installation and Maintenance Tips

Proper installation and maintenance are essential to maximize the lifespan and performance of shaft pulleys:

Ensure pulleys are aligned correctly on the shaft to avoid belt misalignment

Use appropriate mounting hardware and keyways to secure the pulley firmly

Regularly inspect for wear, cracks, or corrosion

Lubricate bearings or shaft interfaces if applicable

Replace pulleys showing significant wear or deformation to prevent equipment failure

Adhering to these practices ensures safety, reliability, and uninterrupted industrial operations.

Summary

Shaft pulleys are indispensable components in industrial power transmission systems. Their proper selection, material quality, and installation significantly influence operational efficiency, safety, and maintenance costs. For B2B buyers, understanding pulley types, materials, and performance benefits is key to making informed procurement decisions. By investing in high-quality shaft pulleys, businesses can enhance productivity, reduce downtime, and ensure consistent performance across a wide range of industrial applications.

FAQ

What is a shaft pulley used for? Shaft pulleys transfer rotational motion and torque from a motor or drive shaft to a driven machine via belts or chains.

How do I choose the right type of shaft pulley? Consider belt type, load capacity, rotational speed, and precision requirements. Common types include V-belt, timing, flat, and step pulleys.

What materials are best for industrial shaft pulleys? Cast iron and steel are preferred for heavy-duty applications, while aluminum is suitable for lightweight or high-speed applications.

How can I extend the lifespan of a shaft pulley? Proper alignment, periodic inspection, maintenance, and selecting the right material and coating can significantly extend service life.

Media Contact

Company Name: Qingdao Huishi Transmission Equipment Co., Ltd.

Email:Send Email [https://www.abnewswire.com/email_contact_us.php?pr=shaft-pulley-essential-component-for-efficient-power-transmission]

Country: China

Website: https://www.huishichuandong.com/

Legal Disclaimer: Information contained on this page is provided by an independent third-party content provider. ABNewswire makes no warranties or responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you are affiliated with this article or have any complaints or copyright issues related to this article and would like it to be removed, please contact retract@swscontact.com

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Shaft Pulley: Essential Component for Efficient Power Transmission here

News-ID: 4325232 • Views: …

More Releases from ABNewswire

Otter Public Relations Awarded in the Excellence in Workplace Culture Award for …

ST. PETERSBURG, Fla. - Feb 23, 2026 - Otter Public Relations [https://otterpr.com/]was proudly awarded Excellence in Workplace Culture for Small Businesses for 2025.

Otter PR, founded by Scott Bartnick and Jay Feldman, is one of the nation's most highly rated and awarded PR firms. With over 300 years of combined experience, Otter PR is known for results-driven campaigns and securing valuable media coverage. Otter PR's team of publicists, writers, marketers, and…

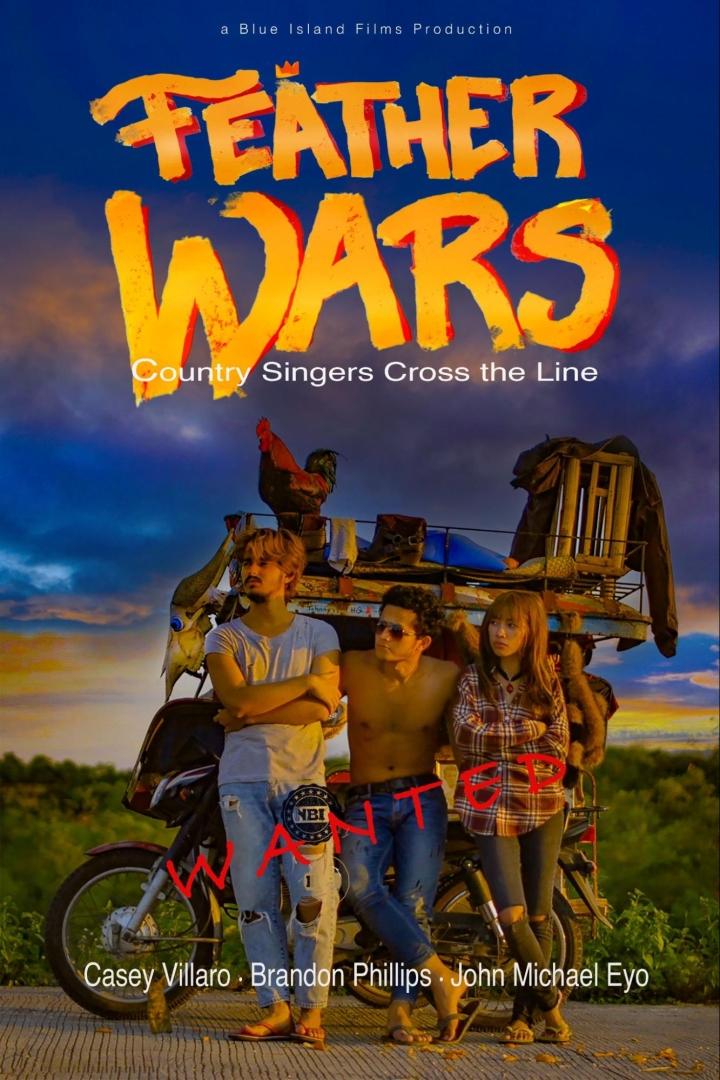

Philippine Coming-of-Age Film "Feather Wars" (2025) Wraps Production in Bohol, S …

Feather Wars is a 140-minute Filipino coming-of-age adventure comedy filmed in Bohol. Directed by Tim Fitzharris and produced by Jesse Fitzharris, it follows two teen musicians fleeing their abusive stepfather, funding their escape through underground cockfighting scams. Blending dark comedy, music, and family drama, the film highlights Filipino culture and earned international screenplay recognition before completing production in 2025.

BOHOL, PHILIPPINES - The Philippine independent film Feather Wars, a 140-minute coming-of-age…

BPOSeats Launches Flexible, Fully-Managed Office Solutions to Help BPOs and Star …

BPOSeats.com introduces plug-and-play office spaces designed for BPO companies, startups, and remote teams seeking cost-efficient, scalable, and fully managed workspace solutions across the Philippines.

Philippines - February 23, 2026 - BPOSeats.com, a leading provider of fully-managed office and seat leasing solutions, announces its continued expansion in supporting BPO companies, startups, and remote teams with flexible, scalable office infrastructure across the Philippines.

As businesses increasingly prioritize agility and cost efficiency, traditional long-term office…

Great Yarmouth Serviced Accommodation: QF Living Signs Pavilion Sands Apartment …

Two-bedroom coastal apartment near the seafront and River Yare, designed for leisure and business stays.

Image: https://www.abnewswire.com/upload/2026/02/d6ed430595914579b21c5f71bc16191e.jpg

Great Yarmouth, Norfolk - QF Living, a locally operated Great Yarmouth serviced accommodation provider, has expanded its portfolio with the signing of Pavilion Sands Apartment in Gorleston-on-Sea [https://qfliving.com/listing/pavilion-sands-apartment/], a newly launched two-bedroom coastal apartment located close to the seafront and near the mouth of the River Yare.

The addition strengthens QF Living's offering for leisure guests,…

More Releases for Shaft

Shaft Coupling Component Manufacturer | SUNG-IL MACHINERY

Line and multi-shaft coupling components from SUNG‐IL MACHINERY ensure efficient power transfer and protect mechanical systems.

Sung-Il Machinery Coupling:

A coupling is a vital mechanical component that transmits power and motion from a driving shaft to a driven shaft while compensating for misalignment and reducing mechanical stress. By connecting two rotating parts, couplings ensure smooth torque transmission, protect machinery from excessive loads, and help maintain the overall efficiency and reliability of industrial…

Marine Shaft Power Meter Market Size Analysis by Application, Type, and Region: …

According to Market Research Intellect, the global Marine Shaft Power Meter market under the Aerospace and Defense category is expected to register notable growth from 2025 to 2032. Key drivers such as advancing technologies, changing consumer behavior, and evolving market dynamics are poised to shape the trajectory of this market throughout the forecast period.

The marine shaft power meter market is experiencing steady growth due to the increasing need for fuel…

Wind Turbine Drive Shaft Market

The "Wind Turbine Drive Shaft Market" is expected to reach USD xx.x billion by 2031, indicating a compound annual growth rate (CAGR) of xx.x percent from 2024 to 2031. The market was valued at USD xx.x billion In 2023.

Growing Demand and Growth Potential in the Global Wind Turbine Drive Shaft Market, 2024-2031

Verified Market Research's most recent report, "Wind Turbine Drive Shaft Market: Global Industry Trends, Share, Size, Growth, Opportunity and…

Automotive Axle & Propeller Shaft Market : Single Piece Propeller Shaft to Surpa …

The global automotive axle & propeller shaft market was valued at $29.3 billion in 2020, and is projected to reach $45.3 billion by 2030, growing at a CAGR of 4.61% from 2021 to 2030.

Asia-Pacific is expected to dominate the automotive axle & propeller shaft market owing to increase in demand for passenger vehicles from China, Japan, and India. In January 2021, vehicle sales in China experienced rise of 29.5% as…

Automotive Axle & Propeller Shaft Market : Live Axle, Dead Axle, Tandem Axle, Si …

The automotive axle & propeller shaft market was valued at $29.3 billion in 2020, and is estimated to reach $45.3 billion by 2030, growing at a CAGR of 4.6% from 2021 to 2030.

Asia-Pacific is expected to dominate the automotive axle & propeller shaft market owing to increase in demand for passenger vehicles from China, Japan, and India. In January 2021, vehicle sales in China experienced rise of 29.5% as compared…

Automotive Balance Shaft Market - Global Industry Analysis

Automotive Balance Shaft Market was valued $10,489.0 million in 2020 and is projected to reach $16,691.3 million in 2030, registering a CAGR of 4.9%.

Balance shaft is a weighted shaft utilized for offsetting the vibrations in vehicle engine. A balance shaft system comprises two shafts having equal eccentric weights and revolves in opposite directions with twice the engine speed. The centrifugal forces generated by shafts cancel out…