Press release

CWL: Your Trusted Custom Precision Bearing Fabrication Supplier - Proven by Decades of Expertise and ISO9001

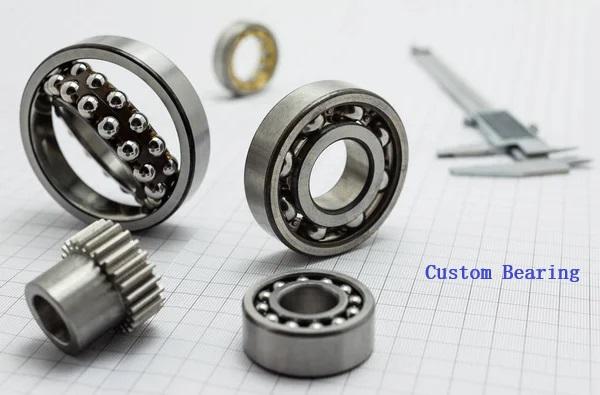

The Imperative of Customization: When Standard Bearings Fall ShortIn modern industrial engineering, machine efficiency, lifespan, and overall performance are often dictated by the precision of internal components. While catalogs offer a vast range of standard bearings, increasingly specialized and challenging applications-from high-vacuum semiconductor equipment to bespoke aerospace actuators-demand components that simply do not exist off-the-shelf. This is where the expertise of a Custom Precision Bearing Fabrication Supplier(https://www.cwlbearing.com/) becomes essential.

Custom precision bearings are not merely slightly modified standards; they are engineered solutions, designed from the ground up to meet unique, non-negotiable operational parameters, including extreme temperatures, unconventional load distribution, specific material requirements, or highly restricted mounting envelopes. For procurement professionals and design engineers, identifying a supplier with proven technical depth, validated by decades of expertise and rigorous quality systems like ISO9001, is paramount to mitigating project risk and ensuring long-term operational success.

Navigating the Custom Sourcing Process: Defining Your Precision Needs

When a standard bearing cannot fulfill the criteria-be it due to dimensional constraints, required rotational accuracy, or environmental factors like corrosion or heat-the buyer must pivot to a custom solution. The initial challenge for the purchaser is often translating complex machine requirements into actionable bearing specifications. Successfully sourcing a custom precision bearing relies on clearly defining several critical parameters, especially when off-the-shelf options have been exhausted:

1. Operational Parameters and Size Constraints

A buyer must meticulously document the complete operating profile. This includes the maximum and minimum speed (RPM), the precise static and dynamic load capacities (axial, radial, and moment loads), and the temperature range. More importantly, when the right size is elusive, the buyer needs to clearly specify the limiting dimensions: the absolute maximum Outer Diameter (OD), the minimum Inner Diameter (ID) needed for the shaft, and the available Width (W). A robust supplier will use these boundary conditions to design a bearing that maximizes capacity within the physical envelope.

2. Environmental and Material Requirements

Non-standard environments require non-standard materials. Is the application exposed to water, acids, magnetic fields, or a vacuum? These factors necessitate a material selection beyond standard bearing steel, potentially requiring ceramics, specialized stainless steel, or high-performance polymers. Buyers should outline the required material properties (e.g., non-magnetic, corrosion-proof, electrical insulation) rather than attempting to specify the material itself, leaving the ultimate engineering decision to the fabrication experts.

3. Required Precision and Tolerance Grades

Precision is defined by tolerance grades (e.g., ABEC-5, ABEC-7, or tighter). While high precision increases cost, it is non-negotiable for high-speed spindles, medical robotics, or ultra-accurate measuring equipment. Defining the required runout, parallelism, and radial/axial clearance is crucial. When the exact bearing dimensions are unknown, specifying the function and required accuracy of the machine component (e.g., "spindle must achieve 5-micron runout") is the most effective way to communicate the ultimate need to the fabrication supplier.

The Role of the Solutions Provider in Custom Fabrication

A truly capable Custom Precision Bearing Fabrication Supplier transcends the role of a simple manufacturer; they operate as a technical solutions provider. The complexity of custom work demands a collaborative, engineering-led approach, where the supplier's expertise is brought to bear on the client's design challenges.

Chengdu West Industry Co., Ltd (CWL)(https://www.cwlbearing.com/contact-us/) exemplifies this model. The company was founded by a group of experienced engineers and skilled export personnel, with most core members boasting over 10 years of experience in bearing technology. This foundation allows CWL to offer comprehensive custom services that minimize errors and optimize final performance:

Design Engineering: Custom fabrication begins with detailed design. CWL is equipped to handle bearing design, which includes analyzing client specifications, selecting appropriate internal geometry (e.g., contact angle, number and size of rolling elements), and specifying materials for rings, balls, and cages. This service is vital for applications requiring optimized performance within unique dimensional constraints.

Prototyping and Testing: Before mass production, custom solutions require rigorous validation. CWL maintains established test centers, allowing them to perform bearing tests to confirm that the prototype meets the required load, speed, and precision specifications under simulated operating conditions. This phase significantly de-risks the client's final assembly and prevents costly failures down the line.

End-to-End Customization: Beyond the bearing itself, the supplier provides services such as customized bearing marking and packing. For global exporters, efficient and secure packaging tailored to specialized bearings is a critical logistical advantage, ensuring the delicate precision components arrive ready for installation.

Core Competitiveness and Technical Assurance(https://www.cwlbearing.com/about-us/)

The credibility of a custom fabrication supplier rests upon its technical assurance systems and ability to handle high-complexity production consistently. CWL's core competitiveness is defined by its deep engineering experience, broad production capability, and unwavering commitment to quality control, all vital for a Custom Precision Bearing Fabrication Supplier.

The company's ability to export a vast inventory of over 5,000 items, ranging in size from 2 mm to 1200 mm, demonstrates a comprehensive understanding of diverse tolerance grades and special properties. This large scope of standard knowledge acts as a robust baseline for tackling custom challenges.

Quality Control and Certifications

In the precision industry, quality is non-negotiable. While the market features many suppliers, only those adhering to recognized international standards offer the requisite assurance. CWL's quality management system is underpinned by ISO9001 certification. This globally recognized standard dictates rigorous processes across the entire lifecycle, from design input validation and material procurement to production, final inspection, and documentation. For custom fabrication, ISO9001 is particularly important as it mandates traceable processes for non-standard work, ensuring that every bearing design variation is systematically documented, tested, and verified before shipment.

Summary

By combining decades of collective engineering experience with established quality procedures and dedicated testing capabilities, CWL positions itself as a reliable partner. They provide custom precision solutions that not only meet the immediate technical need but are also proven for consistent performance, offering customers peace of mind across their most demanding industrial and technological projects. This focus on technical assurance and problem-solving is what truly distinguishes a leading custom supplier in the global market.

For more information on custom precision bearing fabrication and technical services, please visit: https://www.cwlbearing.com

CHENGDU WEST INDUSTRY CO., LTD

D-704,Guanghua Center, No.98,Guanghua North 3rd road, Qingyang District, Chengdu, China

sales@cwlbearing.com

service@cwlbearing.com

CHENGDU WEST INDUSTRY CO., LTD (CWL) is export company for bearings.It is created by a group of experience engineer and skilled export persons. Mostly person is more than 10 years experience on bearings.

We are not just a exporter. We are solutions provider of bearing technology. We can dobearing design,bearing test, bearing mark and packing. CWL head office located in Chengdu along with established warehouses and test center.

CWL specializes in exporting all kinds of bearings and accessories, more than 5,000 items of high quality bearings ranging from 2 mm in bore diameter to 1200 mm in outside diameter with different tolerance grades and other special properties.

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release CWL: Your Trusted Custom Precision Bearing Fabrication Supplier - Proven by Decades of Expertise and ISO9001 here

News-ID: 4324393 • Views: …

More Releases from CHENGDU WEST INDUSTRY CO., LTD

CWL: Global Leading Turbocharger Bearing Manufacturer with Superior Product Qual …

In an era defined by stringent environmental standards and the relentless pursuit of thermal efficiency, the turbocharger has evolved from a performance-enhancing component into a non-negotiable part of modern powertrain architecture. At the core of this critical technology lies the turbocharger bearing(https://www.cwlbearing.com/turbocharger-bearings/), a small yet immensely vital component that dictates the system's reliability, durability, and overall engine performance. Chengdu West Industry Co., Ltd. (CWL)(https://www.cwlbearing.com/about-us/), a technology-driven company established by a…

CWL vs Competitors: Key Advantages of Choosing China Best Forklift Mast Bearing …

In the demanding field of material handling, the reliability of equipment is paramount to operational efficiency and safety. At the heart of every forklift's lifting mechanism is the forklift mast bearing-a component that facilitates the smooth, controlled vertical movement of the mast and carriage. These specialized bearings must endure significant, dynamic loads and operate reliably in often-harsh, dusty environments. Their function is non-negotiable; a failure directly translates into halted operations…

CWL Showcasing The Best Forklift Mast Bearing at China International Bearings an …

The global material handling sector is experiencing a period of transformative growth, driven by the acceleration of e-commerce, increasingly complex supply chains, and a heightened focus on operational efficiency and safety. At the core of this industry's machinery-the ubiquitous forklift-lies a critical, often-overlooked component: the forklift mast bearing. These bearings are essential for the smooth, precise, and reliable vertical movement of the mast and carriage, which directly impacts a forklift's…

Reliable Ceramic Bearing Supplier: How CWL Has Secured a Significant Position in …

The modern industrial landscape demands components that offer exceptional performance under challenging conditions. Within this context, Ceramic Bearings have emerged as a critical element in various high-speed, corrosive, and demanding applications, owing to their distinct material properties. These advanced bearings, often utilizing materials like silicon nitride (Si3N4) or zirconium dioxide (ZrO2), surpass traditional steel bearings in several key areas. Their inherent characteristics include significantly lower friction, which results in less…

More Releases for CWL

CWL: Global Leading Turbocharger Bearing Manufacturer with Superior Product Qual …

In an era defined by stringent environmental standards and the relentless pursuit of thermal efficiency, the turbocharger has evolved from a performance-enhancing component into a non-negotiable part of modern powertrain architecture. At the core of this critical technology lies the turbocharger bearing(https://www.cwlbearing.com/turbocharger-bearings/), a small yet immensely vital component that dictates the system's reliability, durability, and overall engine performance. Chengdu West Industry Co., Ltd. (CWL)(https://www.cwlbearing.com/about-us/), a technology-driven company established by a…

CWL vs Competitors: Key Advantages of Choosing China Best Forklift Mast Bearing …

In the demanding field of material handling, the reliability of equipment is paramount to operational efficiency and safety. At the heart of every forklift's lifting mechanism is the forklift mast bearing-a component that facilitates the smooth, controlled vertical movement of the mast and carriage. These specialized bearings must endure significant, dynamic loads and operate reliably in often-harsh, dusty environments. Their function is non-negotiable; a failure directly translates into halted operations…

CWL Showcasing The Best Forklift Mast Bearing at China International Bearings an …

The global material handling sector is experiencing a period of transformative growth, driven by the acceleration of e-commerce, increasingly complex supply chains, and a heightened focus on operational efficiency and safety. At the core of this industry's machinery-the ubiquitous forklift-lies a critical, often-overlooked component: the forklift mast bearing. These bearings are essential for the smooth, precise, and reliable vertical movement of the mast and carriage, which directly impacts a forklift's…

Reliable Ceramic Bearing Supplier: How CWL Has Secured a Significant Position in …

The modern industrial landscape demands components that offer exceptional performance under challenging conditions. Within this context, Ceramic Bearings have emerged as a critical element in various high-speed, corrosive, and demanding applications, owing to their distinct material properties. These advanced bearings, often utilizing materials like silicon nitride (Si3N4) or zirconium dioxide (ZrO2), surpass traditional steel bearings in several key areas. Their inherent characteristics include significantly lower friction, which results in less…

How Does CWL Provide Tailored Custom Bearing Solutions for Complex Industrial De …

The industrial landscape is undergoing a profound transformation, driven by demands for unprecedented efficiency, extreme performance, and specialized operating capabilities. As traditional manufacturing shifts towards high-precision automation and complex, challenging environments, the components at the core of heavy and delicate machinery-industrial bearings-are increasingly required to move beyond standardized specifications. It is within this dynamic market that specialized firms focused on engineering expertise are emerging as essential partners. Chengdu West Industry…

Top 10 Manufacturers of Agricultural Bearings in the World - CWL Shines at the B …

The agricultural sector is currently undergoing a significant transformation, driven by the imperative for higher productivity and sustainable farming practices. At the heart of the machinery enabling this revolution are agricultural bearings(https://www.cwlbearing.com/round-bore-agricultural-bearings/), critical components that ensure the reliability, efficiency, and longevity of equipment operating in some of the world's most challenging environments. These specialized bearings must withstand extreme conditions-from pervasive dust and abrasive materials to intense vibrations and moisture-while supporting…