Press release

Nachos Manufacturing Plant Cost: Setup Requirements, Economics & Revenue Forecast

IntroductionNachos are a popular Mexican-inspired snack consisting of tortilla chips topped with melted cheese and various complementary ingredients such as jalapeños, beans, meat, guacamole, salsa, and sour cream. Originally created in the 1940s in Mexico, nachos have evolved into a versatile dish served in casual dining, fast food outlets, and at home. They are enjoyed both as an appetizer and a main snack, appealing to a wide range of consumers due to their bold flavors, convenience, and shareable nature. Modern variations include loaded nachos with multiple toppings, healthier baked versions, and fusion styles incorporating international flavors. Their portability and adaptability make nachos a staple in parties, sports events, and quick-service restaurant menus.

Market Drivers and Outlook

The nachos market is witnessing strong growth driven by increasing demand for ready-to-eat and convenience foods among busy consumers, especially in urban areas. Rising popularity of casual dining restaurants, fast-food chains, and food trucks offering Mexican and Tex-Mex cuisine is expanding the market. Consumer preference for flavorful, customizable, and shareable snacks is fueling innovation in toppings, sauces, and healthier options like low-fat or baked nachos. Additionally, the growth of online food delivery platforms and the rise of snacking culture are making nachos more accessible. The influence of social media food trends and international culinary exposure is encouraging experimentation with nachos, attracting younger consumers. Moreover, rising disposable income and the inclination towards experiential dining are further boosting demand for this versatile snack globally.

Nachos Manufacturing Plant Report Overview:

IMARC's new report titled "Nachos Manufacturing Plant Project Report 2025: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue," provides a complete roadmap for setting up a nachos manufacturing plant. The study covers all the requisite aspects that one needs to know while entering the nachos industry. It provides a comprehensive breakdown of the nachos manufacturing plant setup cost, offering detailed insights into initial capital requirements and infrastructure planning. This report is a must-read for entrepreneurs, investors, researchers, consultants, business strategists, and all those who have any kind of stake in the nachos industry. Additionally, the report analyzes the nachos manufacturing plant cost, helping stakeholders evaluate the overall financial feasibility and long-term profitability.

Key Steps:

Manufacturing Process and Technical Workflow

This report provides an in-depth overview of the process flow and unit operations involved in a nachos manufacturing plant. It includes comprehensive details on raw material requirements, mass balance calculations, and step-by-step production procedures. Additionally, the report highlights essential technical tests, quality assurance standards, and control measures to ensure product consistency and safety.

Aspects Covered

• Product Overview and Specifications

• Detailed Unit Operations and Process Flow

• Mass Balance and Raw Material Requirements

• Quality Assurance Standards and Guidelines

• Essential Technical and Safety Tests

Infrastructure and Setup Requirements

This section delivers a detailed analysis of the critical factors for setting up a nachos manufacturing facility. It examines optimal land selection, site development considerations, strategic importance of location, and environmental compliance requirements, including land acquisition costs. The report further outlines the proposed plant layout and key design considerations. Operational needs and associated costs-including machinery, packaging, utilities, transportation, raw materials, and workforce requirements-are also thoroughly detailed.

• Land, Location Selection, and Site Development Costs

• Plant Layout Design and Workflow Optimization

• Machinery Requirements and Capital Costs

• Raw Material Sourcing and Cost Analysis

• Packaging Materials and Costs

• Transportation Infrastructure and Expenses

• Utilities and Power Requirements

• Human Resource Needs and Associated Costs

Financial Projections and Economic Viability

This section delivers a thorough economic assessment for setting up a nachos manufacturing plant. It covers detailed evaluations of capital expenditure (CapEx), operational expenditure (OpEx), taxation, and depreciation. The report also provides a comprehensive profitability analysis, including payback period calculation, net present value (NPV) assessment, projected income statements, cash flow analysis, and liquidity evaluation. Furthermore, it explores financial risk factors, uncertainty analysis, and sensitivity assessments to help investors make informed decisions regarding the economic feasibility of the project.

• Capital Investments and Setup Costs

• Operating Expenses and Overheads

• Expenditure Projections and Cost Breakdowns

• Revenue Projections and Sales Forecasts

• Taxation, Depreciation, and Compliance Costs

• Profitability and Return on Investment (ROI)

• Comprehensive Financial Analysis and Risk Assessment

Frequently Asked Questions

• What are the raw material requirements for nachos production?

• What is the estimated cost to establish a nachos manufacturing plant?

• Which machinery and equipment are required for nachos production?

• Are nachos manufacturing a profitable venture in 2025?

Key Considerations for Plant Design and Operations

• Production Capacity: The selection of machinery and plant layout should correspond to the intended scale of production, whether small, medium, or large-scale operations, ensuring efficient utilization of space, resources, and output potential.

• Automation Levels: The degree of automation should reflect labor availability, budget considerations, and technical expertise, ranging from semi-automated to fully automated systems to optimize efficiency and investment.

• Location Strategy: The plant should be strategically located to access target markets, raw material sources, skilled labor, and comply with local regulations, enhancing operational efficiency and minimizing logistics costs.

• Product Flexibility: Equipment and processes should allow production of multiple product variations, enabling quick adaptation to changing market preferences and customer demands.

• Sustainability Measures: Incorporate energy-efficient machinery, renewable energy sources, and effective waste management systems to meet environmental standards and support long-term operational sustainability.

• Raw Material Sourcing: Establish a robust supply chain strategy to ensure consistent, cost-effective, and quality raw material availability, taking into account regional supply dynamics and supplier reliability.

• Safety and Compliance: Design operations to comply with industrial safety standards, hygiene norms, and regulatory requirements, reducing risks and ensuring a safe working environment for employees.

Supply Chain and Raw Material Sourcing

Efficient supply chain management and reliable raw material sourcing are critical for the consistent production of high-quality nachos. A robust strategy ensures uninterrupted availability of ingredients such as corn, oil, seasonings, and packaging materials while optimizing costs and maintaining product standards. Close coordination with trusted suppliers, strategic inventory management, and timely logistics are essential to minimize production delays and enhance overall operational efficiency.

• Identification of reliable raw material suppliers

• Procurement planning and cost optimization

• Inventory management and storage solutions

• Logistics and transportation planning

• Quality checks and supplier audits

• Risk management and contingency planning

• Ensuring sustainability and compliance in sourcing

About Us:

IMARC Group is a leading global market research and management consulting firm. We specialize in helping organizations identify opportunities, mitigate risks, and create impactful business strategies.

Our expertise includes:

• Market Entry and Expansion Strategy

• Feasibility Studies and Business Planning

• Company Incorporation and Factory Setup Support

• Regulatory and Licensing Navigation

• Competitive Analysis and Benchmarking

• Procurement and Supply Chain Research

• Branding, Marketing, and Sales Strategy

Contact Us:

IMARC Group

134 N 4th St. Brooklyn, NY 11249, USA

Email: sales@imarcgroup.com

Tel No:(D) +91 120 433 0800

United States: (+1-201971-6302)

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Nachos Manufacturing Plant Cost: Setup Requirements, Economics & Revenue Forecast here

News-ID: 4322224 • Views: …

More Releases from IMARC Group

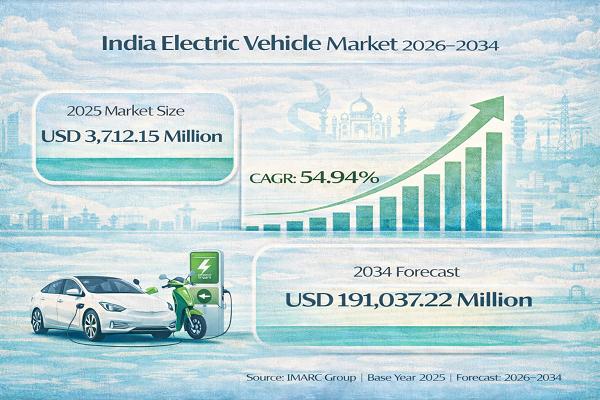

India Electric Vehicle Market Set to Reach USD 191,037.22 Million by 2034, Expan …

India Electric Vehicle Market : Report Introduction

According to IMARC Group's report titled "India Electric Vehicle Market Size, Share, Trends and Forecast by Vehicle Type, Price Category, Propulsion Type, and Region, 2026-2034" the report offers a comprehensive analysis of the industry, including market share, growth, trends, and regional insights.

Free Sample Download PDF (Exclusive Offer on Corporate Email) : https://www.imarcgroup.com/india-electric-vehicle-market/requestsample

India Electric Vehicle Market Overview

The India electric vehicle market size was valued at…

United States Revenue Cycle Management Market Size, Trends, Growth and Forecast …

IMARC Group has recently released a new research study titled "United States Revenue Cycle Management Market Size, Share, Trends and Forecast by Type, Component, Deployment, End User, and Region, 2026-2034", offers a detailed analysis of the market drivers, segmentation, growth opportunities, trends and competitive landscape to understand the current and future market scenarios.

Connect with a Research Analyst Now:

https://www.imarcgroup.com/united-states-revenue-cycle-management-market/requestsample

United States Revenue Cycle Management Market Summary:

The United States revenue cycle…

LED Chip Manufacturing Plant Cost Report 2026: Demand Analysis, CapEx/OpEx & ROI …

Setting up an LED chip manufacturing plant involves strategic planning, substantial capital investment, and comprehensive understanding of semiconductor fabrication technologies. These high-performance components power everything from general illumination and displays to automotive lighting and consumer electronics. Success requires careful site selection, advanced epitaxial growth processes, sophisticated cleanroom facilities, reliable raw material sourcing, and compliance with stringent quality and environmental regulations to ensure profitable and sustainable operations.

IMARC Group's report, "LED Chip…

Eyewear Manufacturing Plant DPR & Unit Setup - 2026: Machinery Cost, CapEx/OpEx, …

Setting up an eyewear manufacturing plant positions investors within a strategically important segment of the global optical and fashion accessories industry, driven by increasing demand for vision correction solutions, rising awareness of eye health, and growing fashion consciousness. As modern lifestyles advance, digital device usage expands, and the need for protective and corrective eyewear grows, eyewear continues to gain traction across prescription glasses, sunglasses, safety eyewear, and fashion accessories worldwide.…

More Releases for Cost

Steel Production Cost - Process Economics, Raw Materials, and Cost Drivers

Steel is the backbone of modern industry, and its production cost is one of the most closely tracked indicators across construction, infrastructure, automotive, and manufacturing sectors. Unlike niche chemicals or APIs, steel economics are driven by scale, energy intensity, and raw material volatility.

Here's the thing: steel production cost isn't just about iron ore prices. It's a layered equation involving coking coal, electricity, labor, emissions compliance, logistics, and technology choice. A…

Egg Powder Manufacturing Plant Setup Cost | Cost Involved, Machinery Cost and In …

IMARC Group's report titled "Egg Powder Manufacturing Plant Project Report 2024: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue" provides a comprehensive guide for establishing an egg powder manufacturing plant. The report covers various aspects, ranging from a broad market overview to intricate details like unit operations, raw material and utility requirements, infrastructure necessities, machinery requirements, manpower needs, packaging and transportation requirements, and more.

In addition to…

Glucose Manufacturing Plant Cost Report 2024: Requirements and Cost Involved

IMARC Group's report titled "Glucose Manufacturing Plant Project Report 2024: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue" provides a comprehensive guide for establishing a glucose manufacturing plant. The report covers various aspects, ranging from a broad market overview to intricate details like unit operations, raw material and utility requirements, infrastructure necessities, machinery requirements, manpower needs, packaging and transportation requirements, and more.

In addition to the operational…

Fatty Alcohol Production Cost Analysis: Plant Cost, Price Trends, Raw Materials …

Syndicated Analytics' latest report titled "Fatty Alcohol Production Cost Analysis 2023-2028: Capital Investment, Manufacturing Process, Operating Cost, Raw Materials, Industry Trends and Revenue Statistics" includes all the essential aspects that are required to understand and venture into the fatty alcohol industry. This report is based on the latest economic data, and it presents comprehensive and detailed insights regarding the primary process flow, raw material requirements, reactions involved, utility costs, operating costs, capital…

Corn Production Cost Analysis Report: Manufacturing Process, Raw Materials Requi …

The latest report titled "Corn Production Cost Report" by Procurement Resource, a global procurement research and consulting firm, provides an in-depth cost analysis of the production process of the Corn. Read More: https://www.procurementresource.com/production-cost-report-store/corn

Report Features - Details

Product Name - Corn Production

Segments Covered

Manufacturing Process: Process Flow, Material Flow, Material Balance

Raw Material and Product/s Specifications: Raw Material Consumption, Product and Co-Product Generation, Capital Investment

Land and Site Cost: Offsites/Civil Works, Equipment Cost, Auxiliary Equipment…

Crude Oil Production Cost Analysis Report: Manufacturing Process, Raw Materials …

The latest report titled "Crude Oil Production Cost Report" by Procurement Resource, a global procurement research and consulting firm, provides an in-depth cost analysis of the production process of the Crude Oil. Read More: https://www.procurementresource.com/production-cost-report-store/crude-oil

Report Features - Details

Product Name - Crude Oil

Segments Covered

Manufacturing Process: Process Flow, Material Flow, Material Balance

Raw Material and Product/s Specifications: Raw Material Consumption, Product and Co-Product Generation, Capital Investment

Land and Site Cost: Offsites/Civil Works, Equipment Cost,…