Press release

Phenanthrene Production Plant Setup | Cost Machinery & Investment Analysis

Setting up a Phenanthrene Production Plant requires comprehensive market assessment along with a detailed understanding of technical, operational, and financial parameters. Investors must evaluate factors such as raw material availability, production technology, plant capacity planning, utility requirements, environmental compliance, skilled manpower, logistics, and long-term cost optimization to ensure a commercially viable and scalable operation.IMARC Group's report titled "Phenanthrene Production Plant Project Report 2025: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue" offers a structured and data-driven guide for establishing a phenanthrene manufacturing facility. The report covers product overview, manufacturing routes, plant infrastructure, machinery selection, and detailed financial modeling to support informed investment decisions.

Request for a Sample Report: https://www.imarcgroup.com/phenanthrene-manufacturing-plant-project-report/requestsample

What is Phenanthrene Production?

Phenanthrene production involves the extraction and purification of phenanthrene, a polycyclic aromatic hydrocarbon, primarily derived from coal tar fractions or petroleum-based feedstocks. Phenanthrene is widely used as an intermediate in the manufacture of pharmaceuticals, agrochemicals, dyes, explosives, resins, and specialty chemicals.

The production process typically includes distillation, crystallization, solvent extraction, and purification steps to achieve high-purity phenanthrene suitable for industrial applications. Due to its importance in chemical synthesis, phenanthrene plays a crucial role in downstream value chains across multiple industries.

What is Driving the Phenanthrene Market?

The phenanthrene market is driven by rising demand from the pharmaceutical and agrochemical sectors, where it serves as a key intermediate for active ingredients and specialty compounds. Growth in dyes, pigments, and resin manufacturing is further supporting market expansion. Increasing chemical production in emerging economies, coupled with expanding applications in research and advanced material development, is positively influencing demand.

Additionally, the availability of coal tar derivatives from steel and metallurgical industries ensures a steady supply of raw materials, supporting long-term production feasibility. Technological improvements in purification processes and increasing investments in specialty chemicals are expected to sustain market growth in the coming years.

Key Steps Required to Set Up a Phenanthrene Production Plant:

1. Market Analysis:

The report provides in-depth insights into the global phenanthrene industry, including market size, demand trends, and competitive landscape. It also offers segment-wise and region-wise analysis to help stakeholders identify high-growth markets. Price trends of raw materials and profit margin analysis are included to support strategic planning.

• Segment Breakdown

• Regional Insights

• Pricing Analysis and Trends

• Market Forecast

2. Product Manufacturing: Detailed Process Flow:

Detailed information related to the phenanthrene production process and unit operations is explained in the report. These processes are designed to ensure efficiency, product purity, and regulatory compliance.

Key operational aspects covered include:

• Land, Location, and Site Development

• Plant Layout

• Plant Machinery

• Raw Material Procurement

• Packaging and Storage

• Transportation

• Quality Inspection

• Utilities

• Human Resource Requirements and Wages

• Marketing and Distribution

3. Project Requirements and Cost:

The report provides a detailed evaluation of project requirements, covering plant location selection, environmental considerations, and associated setup costs for a phenanthrene production facility. It also analyzes plant layout design and factors influencing capital and operating efficiency. Expenditures related to machinery, raw materials, utilities, packaging, transportation, and manpower are comprehensively assessed.

Machinery and Equipment:

• List of machinery required for phenanthrene production

• Estimated machinery costs and supplier insights

Raw Material Costs:

• Coal tar fractions or petroleum-based feedstocks

• Sourcing strategies and cost dynamics

Utilities and Overheads

• Power, water, fuel, labor, and maintenance expenses

4. Project Economics:

A detailed assessment of project economics is included to evaluate the financial feasibility of setting up a phenanthrene production plant. This section covers investment analysis, operating costs, revenue projections, and long-term profitability metrics.

Capital Expenditure (CAPEX):

• Land, civil construction, machinery, and infrastructure costs

Operating Expenditure (OPEX):

• Raw materials, utilities, labor, maintenance, and overheads

Revenue Projections

• Expected income based on production capacity, pricing strategy, and end-use demand

Taxation

Depreciation

Financial Analysis

• Liquidity Analysis

• Profitability Analysis

• Payback Period

• Net Present Value (NPV)

• Internal Rate of Return (IRR)

• Profit and Loss Account

Uncertainty Analysis

Sensitivity Analysis

Economic Analysis

Speak to Analyst for Customized Report: https://www.imarcgroup.com/request?type=report&id=11551&flag=C

5. Legal and Regulatory Compliance

• Licenses and Permits

• Environmental and Safety Regulations

• Chemical Handling and Storage Compliance

• Certification and Quality Standards

6. Hiring and Training

• Total manpower requirements

• Salary and wage structure analysis

• Training programs for plant operations and safety compliance

The report also highlights key success factors and potential risks affecting the phenanthrene production industry. Strategic recommendations are provided to enhance operational efficiency, regulatory compliance, and market competitiveness. Additionally, a real-world case study of a successful chemical manufacturing venture is included, offering practical insights and best practices that can serve as a valuable reference for entrepreneurs and investors entering the phenanthrene production market.

How IMARC Group Supports Plant Setup:

IMARC Group helps investors and entrepreneurs establish a manufacturing plant by providing detailed market research, technical guidance, and financial feasibility analysis. Their reports outline process flow, machinery requirements, raw materials, project cost, profitability, and regulatory needs, offering a complete roadmap for setup. With expert consulting and customized solutions, IMARC ensures smoother planning, reduced risks, and faster project execution.

Contact Us:

IMARC Group

134 N 4th St., Brooklyn, NY 11249, USA

Email: sales[@]imarcgroup.com

Tel No:(D) +91 120 433 0800

United States: (+1-201971-6302)

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Phenanthrene Production Plant Setup | Cost Machinery & Investment Analysis here

News-ID: 4320889 • Views: …

More Releases from IMARC Group

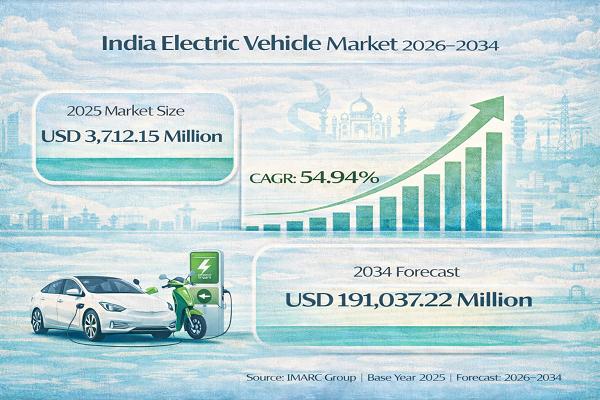

India Electric Vehicle Market Set to Reach USD 191,037.22 Million by 2034, Expan …

India Electric Vehicle Market : Report Introduction

According to IMARC Group's report titled "India Electric Vehicle Market Size, Share, Trends and Forecast by Vehicle Type, Price Category, Propulsion Type, and Region, 2026-2034" the report offers a comprehensive analysis of the industry, including market share, growth, trends, and regional insights.

Free Sample Download PDF (Exclusive Offer on Corporate Email) : https://www.imarcgroup.com/india-electric-vehicle-market/requestsample

India Electric Vehicle Market Overview

The India electric vehicle market size was valued at…

United States Revenue Cycle Management Market Size, Trends, Growth and Forecast …

IMARC Group has recently released a new research study titled "United States Revenue Cycle Management Market Size, Share, Trends and Forecast by Type, Component, Deployment, End User, and Region, 2026-2034", offers a detailed analysis of the market drivers, segmentation, growth opportunities, trends and competitive landscape to understand the current and future market scenarios.

Connect with a Research Analyst Now:

https://www.imarcgroup.com/united-states-revenue-cycle-management-market/requestsample

United States Revenue Cycle Management Market Summary:

The United States revenue cycle…

LED Chip Manufacturing Plant Cost Report 2026: Demand Analysis, CapEx/OpEx & ROI …

Setting up an LED chip manufacturing plant involves strategic planning, substantial capital investment, and comprehensive understanding of semiconductor fabrication technologies. These high-performance components power everything from general illumination and displays to automotive lighting and consumer electronics. Success requires careful site selection, advanced epitaxial growth processes, sophisticated cleanroom facilities, reliable raw material sourcing, and compliance with stringent quality and environmental regulations to ensure profitable and sustainable operations.

IMARC Group's report, "LED Chip…

Eyewear Manufacturing Plant DPR & Unit Setup - 2026: Machinery Cost, CapEx/OpEx, …

Setting up an eyewear manufacturing plant positions investors within a strategically important segment of the global optical and fashion accessories industry, driven by increasing demand for vision correction solutions, rising awareness of eye health, and growing fashion consciousness. As modern lifestyles advance, digital device usage expands, and the need for protective and corrective eyewear grows, eyewear continues to gain traction across prescription glasses, sunglasses, safety eyewear, and fashion accessories worldwide.…

More Releases for Phenanthrene

Phenanthrene(CAS83-32-9) Market Witnesses Rapid Expansion with Rising Adoption i …

New Jersey, US State: "The global Phenanthrene(CAS83-32-9) market in the Chemicals and Materials category is projected to reach USD 1.8 billion by 2031, growing at a CAGR of 5.5% from 2025 to 2031. With rising industrial adoption and continuous innovation in Chemicals and Materials applications, the market is estimated to hit USD 1.2 billion in 2024, highlighting strong growth potential throughout the forecast period."

Phenanthrene (CAS 83-32-9) Market Size & Forecast…

Phenanthrene Manufacturing Plant Project Report 2023: Industry Trends, Investmen …

IMARC Group's report titled "Phenanthrene Manufacturing Plant Project Report 2023: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue" provides a comprehensive guide for establishing a phenanthrene manufacturing plant. The report covers various aspects, ranging from a broad market overview to intricate details like unit operations, raw material and utility requirements, infrastructure necessities, machinery requirements, manpower needs, packaging and transportation requirements, and more.

In addition to the operational…

Miconazole Manufacturing Plant Project Report 2023: Industry Trends, Raw Materia …

IMARC Group's report titled "Miconazole Manufacturing Plant Project Report 2023: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue" provides a comprehensive guide for establishing a miconazole manufacturing plant. The report covers various aspects, ranging from a broad market overview to intricate details like unit operations, raw material and utility requirements, infrastructure necessities, machinery requirements, manpower needs, packaging and transportation requirements, and more.

In addition to the operational…

Phenanthrene(CAS83-32-9) Market Size,Share,Recent Study By 2028|Cato Research Ch …

LOS ANGELES, United States: QY Research has recently published a new report, titled Global Phenanthrene(CAS83-32-9) Market Outlook 2022 This report offers an in-depth analysis of the global Phenanthrene(CAS83-32-9) market taking into account market dynamics, segmentation, geographical expansion, and competitive landscape, and various other key aspects. The market analysts who have prepared the report have thoroughly studied the global Phenanthrene(CAS83-32-9) market and have offered reliable and accurate data. They understand the needs of…

The Global Buprenorphine Hydrochloride Market, Growth Analysis, Latest Trends an …

Buprenorphine Hydrochloride is the hydrochloride salt of buprenorphine, a narcotic analgesic synthetic phenanthrene. In 2020, the global Buprenorphine Hydrochloride market size was US$ 136.4 million and it is expected to reach US$ 155.5 million by the end of 2027, with a CAGR of 1.9% during 2021-2027.

Request Sample Copy of Buprenorphine Hydrochloride Market Report: https://www.infinitybusinessinsights.com/request_sample.php?id=614142

Top Key Players Included in Buprenorphine Hydrochloride Market Report: Siegfried, Sanofi, Johnson Matthey, Mallinckrodt, Noramco, Unichemlabs, Arevipharma,…

Benzenoid Market Leading Key Players BASF SE (Germany), Sigma-Aldrich Co. LLC. ( …

Benzenoid Market Overview to 2023

Benzenoids belong to a special class of aromatic organic compound which contain one or more benzene ring such as naphthalene, anthracene, phenanthrene, pyridine, and others. Naturally, they are found in leaves & flowers, oil, and wood & bark. They are widely utilized in numerous application such as cosmetics & personal care, soap & detergent, household products, food & beverage, and others, owing to its aroma and…