Press release

Starting a Saccharin Production Plant: 2025 Project Report & Business Plan

IMARC Group's "Saccharin Production Plant Project Report 2025" provides a comprehensive roadmap for saccharin production plant setup, covering process technology, plant infrastructure, capital investment, operating costs, and market outlook.The global saccharin industry continues to show stable growth, driven by increasing demand for high-intensity, low-calorie sweeteners across food & beverages, pharmaceuticals, personal care, and industrial applications. Saccharin is one of the oldest artificial sweeteners, valued for its strong sweetness, thermal stability, long shelf life, and cost efficiency.

Industry Overview: Why Saccharin Matters:

• Saccharin is approximately 300-500 times sweeter than sucrose, requiring very small dosages.

• It is widely used in sugar-free beverages, bakery products, confectionery, and tabletop sweeteners.

• The pharmaceutical industry uses saccharin as a taste-masking agent in syrups, tablets, and oral drugs.

• Personal care products such as toothpaste, mouthwash, and oral hygiene solutions rely on saccharin for sweetness and stability.

• Rising health awareness related to diabetes, obesity, and calorie reduction continues to support global saccharin demand.

See the Data First: Download Your Sample Report: https://www.imarcgroup.com/saccharin-manufacturing-plant-project-report/requestsample

Is Saccharin Production Profitable?

Saccharin production can be a profitable specialty chemical business when supported by efficient synthesis routes, optimized operating costs, and consistent demand from food and pharmaceutical industries. Its high sweetness intensity, low production cost per unit sweetness, and wide application base ensure stable revenue potential.

Profitability improves further with scale, export-oriented production, and compliance with food- and pharma-grade standards. A well-planned saccharin production plant setup offers strong margins and long-term commercial sustainability.

Saccharin Production Process:

Core Process: Chemical synthesis of saccharin through controlled reactions of aromatic intermediates, followed by purification and crystallization.

Key Production Steps:

• Preparation of aromatic intermediates

• Sulfonation and oxidation reactions

• Cyclization to form saccharin

• Filtration and crystallization

• Drying, milling, grading, and packaging

Raw Material and Utility Considerations:

Key inputs include toluene derivatives, sulfuric acid, oxidizing agents, solvents, water, steam, and electricity. Reliable utilities and consistent raw material quality are essential for efficient saccharin manufacturing.

Plant Setup Requirements:

Infrastructure:

Land for reaction and processing units, crystallization and drying sections, raw material and finished product storage, utilities, effluent treatment plants, and quality control laboratories.

Equipment & Machinery:

Chemical reactors, centrifuges, filtration units, crystallizers, dryers, pulverizers, dust collection systems, storage tanks, and automated packaging machines are essential for a saccharin production plant.

Manpower:

Chemical engineers, plant operators, quality assurance staff, maintenance technicians, safety officers, and packaging personnel are required for smooth and compliant operations.

Regulatory Compliance:

Compliance with food safety regulations, pharmaceutical excipient standards, chemical handling laws, environmental emission norms, and occupational safety guidelines is mandatory for saccharin plant setup and operation.

Cost Structure & Financials:

Capital Expenditure (CapEx):

Includes land acquisition, civil construction, processing equipment, utilities, pollution control systems, laboratory setup, and automation infrastructure.

Operating Expenditure (OpEx):

Covers raw materials, utilities, labor, maintenance, packaging, transportation, waste treatment, and regulatory compliance costs.

Profitability Analysis:

The project report provides detailed financial metrics including ROI, IRR, NPV, payback period, and break-even analysis. Fixed and variable cost assessments help investors evaluate feasibility and pricing strategies for saccharin production.

Market Demand & Growth Drivers:

Food & Beverage Industry:

Increasing consumption of sugar-free and low-calorie products drives saccharin demand.

Pharmaceutical Applications:

Growth in oral liquid medicines and chewable formulations supports usage.

Personal Care Sector:

Expansion of oral hygiene and cosmetic products increases saccharin consumption.

Industrial Uses:

Applications in electroplating and specialty chemical formulations add to demand.

Regional Outlook:

Asia-Pacific leads global saccharin production due to strong chemical manufacturing capabilities, while North America and Europe focus on regulated food- and pharma-grade consumption.

Risks and Challenges:

• Volatility in raw material prices can affect operating margins.

• Strict regulatory scrutiny regarding food additive approvals and labeling.

• Competition from newer artificial and natural sweeteners in certain markets.

Strategic Insights for Investors:

• Select plant location with access to chemical raw materials and logistics infrastructure.

• Adopt efficient and environmentally compliant synthesis technology.

• Focus on food-grade and pharmaceutical-grade saccharin to achieve premium pricing.

• Scale production capacity in line with domestic demand and export opportunities.

• Conduct detailed techno-economic and market feasibility studies before finalizing the saccharin production plant setup.

Request a Customized Project Report for Your Capacity: https://www.imarcgroup.com/request?type=report&id=18140&flag=C

Conclusion:

The saccharin production plant setup represents a strategic and profitable opportunity within the global artificial sweeteners and specialty chemicals market. Supported by steady demand from food, pharmaceutical, and personal care industries, saccharin manufacturing offers stable growth and attractive long-term returns. With efficient process design, regulatory compliance, and strong market insights, investors and entrepreneurs can successfully establish and scale a competitive saccharin manufacturing facility.

How IMARC Group Supports Plant Setup:

IMARC Group helps investors and entrepreneurs establish a manufacturing plant by providing detailed market research, technical guidance, and financial feasibility analysis. Their reports outline process flow, machinery requirements, raw materials, project cost, profitability, and regulatory needs, offering a complete roadmap for setup. With expert consulting and customized solutions, IMARC ensures smoother planning, reduced risks, and faster project execution.

Contact Us:

IMARC Group

134 N 4th St., Brooklyn, NY 11249, USA

Email: sales[@]imarcgroup.com

Tel No:(D) +91 120 433 0800

United States: (+1-201971-6302)

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Starting a Saccharin Production Plant: 2025 Project Report & Business Plan here

News-ID: 4320644 • Views: …

More Releases from IMARC Group

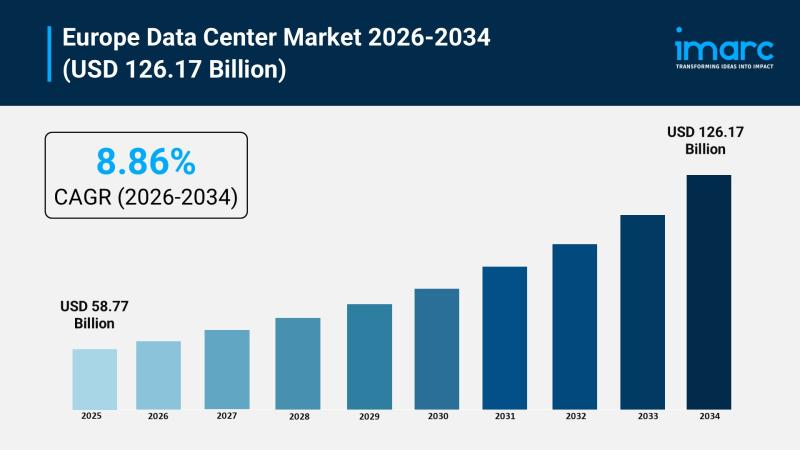

IMARC Group Forecasts 8.86% CAGR for Europe Data Center Market Amidst AI and Clo …

The Europe data center market is experiencing a critical phase of infrastructure evolution, having reached a valuation of USD 58.77 Billion in 2025. Propelled by the accelerating digitalization of the region's economy and sovereign cloud ambitions, the market is projected to reach USD 126.17 Billion by 2034. This growth trajectory represents a solid Compound Annual Growth Rate (CAGR) of 8.86% during the forecast period of 2026-2034.

Key Market Trends &…

Hot Sauce Manufacturing Plant DPR & Unit Setup - 2026: Demand Analysis and Proje …

Setting up a hot sauce manufacturing plant positions investors within one of the fastest-growing and flavor-driven segments of the global condiment industry, fueled by rising consumer appetite for spicy, bold, and ethnic flavors, increasing demand for clean-label and premium condiment products, and expanding utilization of hot sauce across food service, retail, and food processing applications. Made primarily from chili peppers, vinegar, salt, and complementary flavoring ingredients, hot sauce is recognized…

Glyoxylic Acid Prices Q4 2025: US Stable While Europe Remains High Price Trend

The Glyoxylic Acid Price Trend Analysis indicates dynamic shifts in global supply-demand balance, feedstock volatility, and regional trade flows. In 2026, Glyoxylic Acid Prices are reflecting fluctuations in raw material costs and downstream demand from pharmaceuticals, cosmetics, and agrochemicals. Market participants closely track the Glyoxylic Acid price index and forecast data to understand pricing momentum, risk exposure, and procurement strategies across key global regions.

Glyoxylic Acid Current Glyoxylic Acid Price Movements:

Recent…

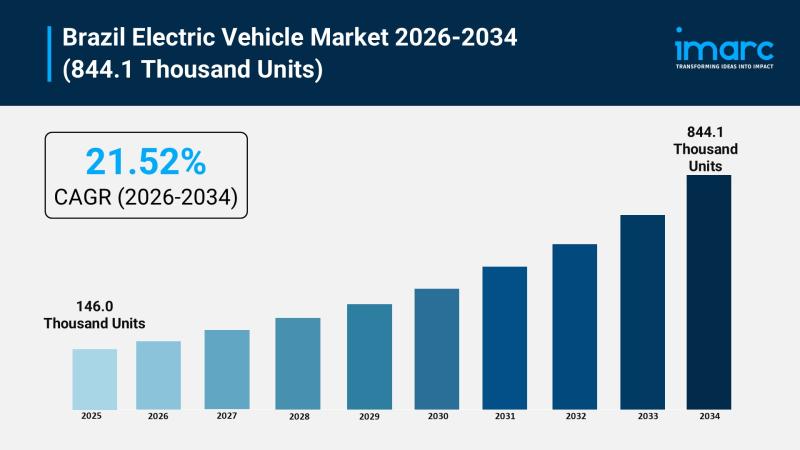

IMARC Group Forecasts 21.52% CAGR for Brazil EV Market as BYD and GWM Ramp Up Lo …

The Brazil electric vehicle (EV) market is currently witnessing an unprecedented surge, having reached a volume of 146.0 Thousand Units in 2025. Fueled by a combination of stringent environmental policies and a strategic shift toward domestic production by global automakers, the market is projected to reach 844.1 Thousand Units by 2034. This rapid expansion represents a robust Compound Annual Growth Rate (CAGR) of 21.52% during the forecast period of 2026-2034.

Key…

More Releases for Saccharin

Leading Companies Enhancing Their Presence in the Saccharin Market

The saccharin market is gradually gaining traction as consumer preferences shift toward healthier and low-calorie alternatives. Driven by multiple industrial applications and evolving demand patterns, this sector is expected to experience steady growth through the coming years. Let's explore the market size projections, key players, emerging trends, and segment breakdowns shaping the saccharin industry landscape.

Steady Growth Expected in the Saccharin Market Size by 2030

The saccharin market is forecasted…

Saccharin Industry Report 2025-2034: Market Dynamics, Trends, And Forecasts

The Saccharin Market Report by The Business Research Company delivers a detailed market assessment, covering size projections from 2025 to 2034. This report explores crucial market trends, major drivers and market segmentation by [key segment categories].

What Is the Expected Saccharin Market Size During the Forecast Period?

The saccharin industry has seen consistent growth over recent years. The market size, which is expected to rise from $1.42 billion in 2024 to $1.46…

Saccharin Market Analysis, Trends, Growth, Research And Forecast 2033

The Business Research Company has updated its global market reports, featuring the latest data for 2024 and projections up to 2033

The Business Research Company offers in-depth market insights through Saccharin Global Market Report 2024, providing businesses with a competitive advantage by thoroughly analyzing the market structure, including estimates for numerous segments and sub-segments.

Market Size And Growth Forecast:

The saccharin market size has grown steadily in recent years. It will grow…

Global High Purity Saccharin Industry Professional Market Analysis by 2020-2025

This report also researches and evaluates the impact of Covid-19 outbreak on the COVID-19 High Purity Saccharin industry, involving potential opportunity and challenges, drivers and risks. We present the impact assessment of Covid-19 effects on COVID-19 High Purity Saccharin and market growth forecast based on different scenario (optimistic, pessimistic, very optimistic, most likely etc.).

Global COVID-19 High Purity Saccharin Market Overview:

The latest report on the global COVID-19 High Purity Saccharin market suggests a positive growth rate in…

Saccharin Market Growth Factors, Technological Advancement and Trends by Manufac …

Global saccharin market is expected to register a steady CAGR of 4.38% in the forecast period of 2019-2026. The report contains data from the base year of 2018 and the historic year of 2017. This rise in market value can be attributed to the growing concerns regarding diabetes, obesity and health of the individuals.

For In depth Information Get Sample Copy of this Report@https://www.databridgemarketresearch.com/request-a-sample/?dbmr=global-saccharin-market&DK

Global Saccharin Market By Form (Dry, Liquid), Product…

Global Saccharin Sodium Market - Foodchem, Kaifeng Xinghua Fine Chemical, Anhui …

A New fresh research report presented by KD Market Insights provides a detailed analysis of “Saccharin Sodium Market – By Product Type (Food Grade Sodium Saccharine, Pharma Grade Sodium Saccharine, Industrial Grade Sodium Saccharine), By Application (Food Industry, Pharmaecutical, Cosmetics, Others) & Global Region - Market Size, Share, Trends and Forecast 2018-2023” research report will include all the major trends and technologies that play an important role in market growth…