Press release

The Teflon Coating Market is anticipated to reach USD 4.02 Billion by 2030

According to the report published by Virtue Market Research in Teflon Coating Market was valued at USD 2.84 Billion in 2024 and is anticipated to reach USD 4.02 Billion by 2030, with a strong CAGR of 5.1% during the forecast period 2025-2030.Request Sample Copy of this Report @ https://virtuemarketresearch.com/report/teflon-coating-market/request-sample

The Teflon coating market has been quietly shaping the way industries work, from cookware to aerospace. Its unique mix of low friction, high heat resistance, and chemical stability makes it a favorite choice across applications. One of the biggest long-term drivers behind this market is the growing demand for non-stick and corrosion-resistant surfaces in industrial manufacturing. Over the years, manufacturers have turned to Teflon coatings to improve product durability, reduce maintenance needs, and enhance operational efficiency. As industries such as automotive and chemical processing continue expanding, the importance of such coatings is only expected to rise. Companies are also leaning toward using Teflon as part of broader sustainability efforts since it extends product life and reduces waste, aligning with long-term environmental goals.

When the COVID-19 pandemic disrupted global trade, the Teflon coating market faced its share of challenges. Factories slowed down, logistics networks became tangled, and demand from certain end-use sectors-like automotive and construction-dropped sharply. However, the market also witnessed an unexpected turn as medical and food-grade applications gained attention. The need for sterile, easy-to-clean surfaces in healthcare environments pushed the adoption of Teflon coatings in medical devices and laboratory tools. Similarly, food packaging and kitchenware saw a spike in demand as people shifted toward home cooking and hygiene-focused products. The pandemic, while disruptive, ultimately revealed how adaptable Teflon coatings could be when global conditions suddenly changed.

In the short term, a major driver for the Teflon coating market comes from the surge in electronic component manufacturing. With devices becoming smaller, faster, and more heat-sensitive, coatings that can handle high temperatures and protect delicate surfaces are in demand. Teflon's dielectric properties make it a strong choice for insulating wires, circuit boards, and microchips. As the electronics industry continues to evolve, manufacturers are investing in new coating technologies that combine high performance with thin, uniform layering. This short-term momentum is not only boosting sales but also encouraging research into more efficient application techniques.

An important opportunity that is unfolding within the Teflon coating market lies in the renewable energy sector. Wind turbines, solar panels, and hydrogen fuel systems all require materials that can resist corrosion, heat, and chemical exposure. Teflon's characteristics make it ideal for protecting components exposed to outdoor or high-stress environments. As nations increase their investments in clean energy, the demand for such coatings is likely to expand. This opportunity is drawing attention from both established coating manufacturers and new entrants looking to specialize in advanced surface technologies. The alignment of performance with sustainability makes this an attractive growth area for the years ahead.

A trend that stands out in the Teflon coating market is the steady shift toward water-based and low-VOC formulations. Traditional solvent-based coatings have been criticized for releasing volatile organic compounds, which are harmful to the environment and human health. In response, manufacturers are re-engineering Teflon coatings to meet stricter environmental regulations while maintaining their signature properties. The push toward green chemistry is changing the way coatings are produced and applied, leading to innovations in curing processes and surface adhesion methods. These eco-friendly advancements not only improve safety during manufacturing but also enhance the public perception of coated products as sustainable and responsible choices.

Segmentation Analysis:

By Product Type: Virgin PTFE, Stainless Steel Filled PTFE, Bronze Filled PTFE, Glass Filled PTFE, and Others

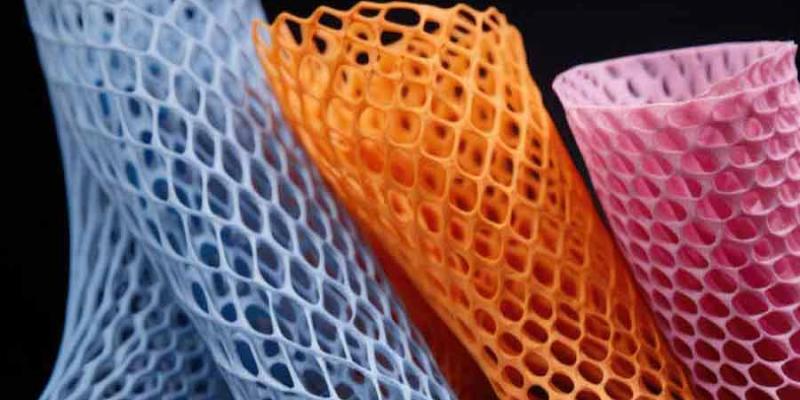

The Teflon Coating Market by product type displays diverse properties that fit many industrial needs. Virgin PTFE stands out as the largest segment due to its wide use in applications that need high purity, low friction, and superior chemical resistance. It is preferred in sectors like food processing and medical equipment, where contamination-free performance is essential. Bronze Filled PTFE, on the other hand, is the fastest growing during the forecast period. Its combination of enhanced wear resistance and improved thermal conductivity makes it popular in demanding mechanical and automotive parts. The addition of bronze particles provides strength without sacrificing Teflon's signature smoothness.

This shift toward more durable composite coatings reflects how industries are prioritizing longevity and efficiency over basic formulations. Stainless steel and glass-filled variants continue to serve specialized uses, especially where load-bearing or insulation performance is key. The overall diversity within this product segment shows that as application requirements grow more specific, manufacturers are turning to targeted PTFE blends that can meet precise operational and environmental standards without compromising reliability or safety.

By Form Type: Granular, Fine Powder, Dispersion, and Micronized

The Teflon Coating Market by form type represents a broad mix of physical formats designed for flexible application. Granular PTFE is the largest segment, primarily used in molding and extrusion processes for producing gaskets, linings, and seals. Its ease of processing and compatibility with mechanical shaping techniques make it essential for industries that demand precise geometries. Dispersion form, however, is the fastest growing during the forecast period.

It is widely adopted in coating applications where Teflon is applied as a liquid layer to surfaces like cookware, pipes, and fabrics. The rise in industrial spraying and dipping technologies has made dispersion forms highly sought after for uniform coverage and surface finishing. Fine powders and micronized PTFE continue to serve niche uses in lubricants, films, and non-stick coatings, where small particle size enhances adhesion and smoothness. The growing variety of processing methods across industries has increased demand for Teflon in forms that allow both structural integrity and high-performance coatings. This balance of usability and versatility keeps PTFE in steady demand across both traditional and evolving manufacturing settings worldwide.

By Application: Sheets, Coatings, Pipes, Films, and Others

The Teflon Coating Market by application shows its adaptability across both industrial and consumer goods sectors. Coatings dominate as the largest segment, given their widespread use in cookware, automotive parts, and industrial machinery. Their role in reducing friction, preventing corrosion, and improving energy efficiency keeps them indispensable across multiple fields. Films, however, are the fastest growing during the forecast period. These thin layers are finding increased use in electronics, solar panels, and packaging due to their insulation, non-stick, and temperature-resistant qualities.

Sheets and pipes continue to support construction and chemical industries, where mechanical stability and resistance to aggressive substances are essential. The constant improvement in coating and film technologies-driven by demands for lighter, cleaner, and more efficient products-has made these applications central to market expansion. Manufacturers are investing in newer application systems that ensure better adhesion and longer service life. The evolution of Teflon from a traditional coating into a multifunctional layer is reshaping its role in engineering and manufacturing, emphasizing precision, durability, and environmental adaptability across a wide range of modern products.

By End-Use Industry: Automotive, Aerospace, Electrical & Electronics, Industrial & Chemical Processing, Construction, and Others

The Teflon Coating Market by end-use industry captures its wide-scale adoption in varied operational environments. Industrial & Chemical Processing is the largest segment, as these facilities rely heavily on Teflon coatings for their resistance to acids, solvents, and extreme heat. Equipment such as tanks, valves, and pipelines benefit from extended service life and reduced maintenance needs when coated with PTFE. The Aerospace industry is the fastest growing during the forecast period due to the rising demand for lightweight, heat-tolerant, and low-friction materials. Teflon is being used in aircraft wiring, hydraulic systems, and bearings, where reliability under high stress is vital.

Automotive and electronics sectors also contribute strongly, leveraging Teflon's thermal and dielectric stability for both performance and safety. Construction applications continue to expand as modern buildings integrate Teflon-based materials for waterproofing and energy-efficient coatings. This broad presence across industries highlights how PTFE coatings are not just surface treatments but essential components that drive efficiency, safety, and performance improvements across high-value manufacturing sectors.

Read More @ https://virtuemarketresearch.com/report/teflon-coating-market

Regional Analysis:

The Teflon Coating Market by region shows significant geographical diversity. North America is the largest segment, driven by strong industrial infrastructure, established manufacturing bases, and high adoption in automotive, aerospace, and electronics sectors. The region's focus on technological innovation and performance-driven materials supports continuous demand for advanced coatings. Asia-Pacific, however, is the fastest growing during the forecast period. Rapid industrialization, expanding automotive production, and increasing investment in electronics manufacturing are fueling Teflon consumption across countries like China, India, and Japan. Europe maintains a steady position, emphasizing environmental compliance and sustainability in coating applications. South America and the Middle East & Africa are witnessing gradual growth due to expanding construction and oil-processing industries.

Regional differences reflect how local priorities-ranging from high-end engineering to infrastructure development-shape the usage and innovation around Teflon coatings, ensuring that the market's expansion aligns with both industrial maturity and emerging economic potential worldwide.

Latest Industry Developments:

• Sustainability-driven formulation shift: Manufacturers are increasingly moving toward water-based and low-VOC Teflon (PTFE) formulations to meet tightening environmental regulations and customer demand for greener coatings. The market is witnessing a clear trend where traditional solvent-based systems are being reformulated into waterborne or low-VOC variants that retain PTFE's non-stick and thermal properties while reducing emissions and worker exposure. This transition supports compliance with stricter air quality rules and aligns with downstream buyers seeking safer, more sustainable production chains. Adoption is accelerated by investment in new curing and dispersion technologies that preserve film integrity and adhesion, enabling broader use in food, medical, and consumer goods without sacrificing performance.

• Consolidation and strategic portfolio expansion: The industry is coalescing through targeted M&A, partnerships, and licensing deals to secure scale, specialized chemistries, and regional reach. A discernible consolidation trend is reshaping competitive dynamics as players pursue inorganic growth to capture niche segments and speed product development. Mid-sized vendors and technology specialists are being folded into larger portfolios to access distribution networks, application expertise, and regulatory know-how. Strategic alliances and licensing agreements shorten time-to-market for novel PTFE grades and application systems while pooling R&D risk. This concentration helps achieve economies of scale in raw materials procurement and coating lines, enabling more aggressive pricing and broader technical support for industrial customers across multiple end-use sectors.

• Process modernization and application customization: There is a growing emphasis on automation, digital process controls, and tailor-made coating systems to meet precise performance and efficiency requirements. Firms are investing in automated spray, dip, and curing lines plus digital monitoring to improve layer uniformity, reduce waste, and ensure reproducible properties across batches. Concurrently, demand for bespoke PTFE composites and application recipes-optimized for specific substrates, thicknesses, and service conditions-is rising, driven by sectors like electronics, aerospace, and renewables. Process modernization shortens lead times and lowers , while custom formulations enable differentiation through enhanced wear resistance, dielectric strength, or thermal stability. Together these developments boost customer retention by aligning coatings tightly with end-user performance targets.

customize the Full Report Based on Your Requirements @ https://virtuemarketresearch.com/report/teflon-coating-market/customization

contact Us:

Virtue Market Research

Kumar Plaza, #103, SRPF Rd, Ramtekadi, Pune, Maharashtra 411013, India

About Us:

"Virtue Market Research stands at the forefront of strategic analysis, empowering businesses to navigate complex market landscapes with precision and confidence. Specializing in both syndicated and bespoke consulting services, we offer in-depth insights into the ever-evolving interplay between global demand and supply dynamics. Leveraging our expertise, businesses can identify emerging opportunities, discern critical trends, and make decisions that pave the way for future success."

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release The Teflon Coating Market is anticipated to reach USD 4.02 Billion by 2030 here

News-ID: 4318468 • Views: …

More Releases from Virtue Market Research

The Global Vodka Seltzer Market is projected to reach a market size of USD 16.22 …

The Vodka Seltzer Market was valued at USD 9.4 billion in 2024 and is projected to reach a market size of USD 16.21 billion by the end of 2030. Over the forecast period of 2025-2030, the market is projected to grow at a CAGR of 8.1%.

Request Sample @ https://virtuemarketresearch.com/report/vodka-seltzer-market/request-sample

The vodka seltzer market has grown from a niche beverage choice into a mainstream favorite, supported by shifting consumer lifestyles and evolving…

The Global Telehealth Services Market and is projected to reach a market size of …

The Global Telehealth Services Market was valued at USD 126.1 billion and is projected to reach a market size of USD 302.49 billion by the end of 2030. Over the forecast period of 2025-2030, the market is projected to grow at a CAGR of 15.7%.

Request Sample @ https://virtuemarketresearch.com/report/telehealth-services-market/request-sample

The perennial shift towards patient-centric healthcare has been a pivotal long-term market driver for telehealth services. Over the years, the industry has witnessed…

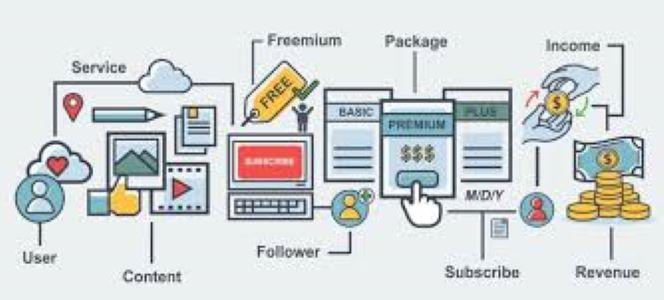

The Subscription Box/Subscription E-Commerce Market is projected to reach a mark …

The Subscription Box/Subscription E-Commerce Market is valued at USD 47.19 billion in 2024 and is projected to reach a market size of USD 97.73 billion by the end of 2030. Over the outlook period of 2025-2030, the market is anticipated to grow at a CAGR of 12.9%.

Request Sample @ https://virtuemarketresearch.com/report/subscription-e-commerce-market/request-sample

The subscription e-commerce market has grown into one of the most dynamic parts of the digital economy. It began as a…

The Global Aramid Fibre Reinforced Polymer Composites Market is projected to rea …

According to the report published by Virtue Market Research in Aramid Fibre Reinforced Polymer Composites Market was valued at USD 5.55 billion and is projected to reach a market size of USD 8.57 billion by the end of 2030. Over the forecast period of 2025-2030, the market is projected to grow at a CAGR of 7.5%.

Request Sample Copy of this Report @ https://virtuemarketresearch.com/report/aramid-fibre-reinforced-polymer-composites-market/request-sample

The Aramid Fibre Reinforced Polymer Composites…

More Releases for Teflon

Teflon Capacitor Market Size, In-Deep Analysis Details, Application, Regional De …

QY Research has recently published a new report, titled Teflon Capacitor Market Report, History and Forecast 2015-2026, Breakdown Data by Manufacturers, Key Regions, Types and Application. The report has been put together using primary and secondary research methodologies, which offer an accurate and precise understanding of the Teflon Capacitor market. Analysts have used a top-down and bottom-up approach to evaluate the segments and provide a fair assessment of their impact on…

Teflon Mesh Belt Market: Competitive Dynamics & Global Outlook 2025

LP INFORMATION recently released a research report on the Teflon Mesh Belt analysis, which studies the Electrical Cord Reels's industry coverage, current market competitive status, and market outlook and forecast by 2025.

Global “Teflon Mesh Belt 2020-2025” Research Report categorizes the global Teflon Mesh Belt by key players, product type, applications and regions,etc. The report also covers the latest industry data, key players analysis, market share,…

Teflon Thailand: Where There's Crisis There's Opportunity

Amazing Thailand. That is the official slogan for the Tourism Authority of Thailand because it's beauty and culture. Thailand is also amazing as it has bounced back from every modern economic setbacks and headwinds and emerged stronger, smarter and more powerful.

From the 1997 Asian Financial crisis, SARS, Boxing Day Tsunami 2004, 2006 coup, 2008 Financial Crisis, 2014 coup Thailand has recovered steady and successfully and…

Teflon Tape Market Size, Share, Development by 2024

Global Info Research offers a latest published report on Teflon Tape Market Analysis and Forecast 2019-2025 delivering key insights and providing a competitive advantage to clients through a detailed report. This report focuses on the key global Teflon Tape players, to define, describe and analyze the value, market share, market competition landscape, SWOT analysis and development plans in next few years.

To analyze the Teflon Tape with respect to individual growth…

Rubber Teflon Market 2017 Industry Analysis Report

Here comes the New Version of Rubber Teflon Market Research Report is a core market research report in this current market.

This report majorly discuss the global and regional market, major manufacturers and segment market details various classifications and mode of applications.

Do u Want Sample of report then visit at: https://www.1marketresearch.com/sample/?flag=rs&rep_id=3084&sku=1655

First and foremost, Rubber Teflon report gives the basic analytic scope of this industry like definition, classification, specification, industry policy,application and…

Global Teflon fabric Market 2016-2020- Research Report

“Global Teflon fabric Industry 2020 Market Research Report” Order This Report by calling ResearchnReports.com at +1-888-631-6977.

This market intelligence report is a comprehensive analysis of the situation of Teflon fabric market. A detailed investigation of the past progress, present market scenario, and future prospects has been offered in the report. It also gives accurate data of the main strategies, market share, and products of the leading companies in this market sector.

This…