Press release

Revolutionizing Cryogenic Gas Distribution Across High-Tech Industries with HL Cryogenics

At HL Cryogenics, we've got one goal: to raise the bar for fluid transfer in extreme temperature environments. Our thing? Advanced vacuum insulation tech. We're all about the tough engineering it takes to move liquefied gases-liquid nitrogen, oxygen, argon, LNG-without losing their chill. And we don't just talk about quality. You'll see it in everything we build, starting with our core products: the Vacuum Insulated Pipe [https://www.hlcryo.com/vacuum-insulated-pipe-series-product/] and the Vacuum Insulated Flexible Hose [https://www.hlcryo.com/vacuum-insulated-flexible-hose-series-product/].These aren't just pipes and hoses; they're engineered thermal systems that keep cryogenic liquids stable over long distances. That matters a lot in places like semiconductor factories, bio-banks, and LNG terminals. When we design our pipe systems, we use a double-walled build. The inner pipe carries the cryogen, and a high-vacuum space separates it from the outer pipe. In that gap, we pack in layers of insulation that bounce radiant heat away, cutting thermal loss way down compared to old-school foam pipes. So, when you use our Vacuum Insulated Pipe, you get better thermal efficiency, less boil-off gas, and more reliability-key for labs and medical setups where precision isn't negotiable.

But not every facility can run on rigid pipes alone. That's where our Vacuum Insulated Flexible Hose comes in. Some layouts are tricky; maybe you need to hook up portable dewars in a hospital, or deal with equipment that moves around in a chip factory. Rigid pipes just can't flex like that. Our cryogenic hose fills the gap, giving you the flexibility you need without sacrificing insulation. We build every hose to the same vacuum standards as our rigid pipe, so you still get a frost-free, safe surface and steady flow. The combo of our pipes and hoses means you have a complete cryogenic transfer network that won't ice up or create safety problems for your team.

Image: https://www.hlcryo.com/uploads/Phase-Separator13.jpgImage: https://www.hlcryo.com/uploads/20180903_1151481.jpg

Longevity and reliability matter, especially in big operations. That's why we developed the Dynamic Vacuum Pump System [https://www.hlcryo.com/dynamic-vacuum-pump-system-product/]. Unlike static vacuums that lose their seal over time, our system keeps an eye on the vacuum level and actively maintains it. This is huge for places like LNG terminals or busy bio-banks, where you just can't afford downtime. By constantly evacuating the insulation space, the Dynamic Vacuum Pump keeps the thermal barrier strong for years, giving facility managers real peace of mind.

We don't stop at pipes and hoses. Our Vacuum Insulated Valve technology handles flow control and isolation with the same attention to detail. Standard valves tend to act like heat magnets, causing ice and leaks. Ours are wrapped in a vacuum jacket that fits right into our pipe and hose lines, minimizing heat transfer. That way, you keep your cryogen in liquid form and regulate flow with the precision labs and research teams expect.

Keeping the liquid pure matters too. Even the best insulation lets in a little heat, which boils off some of the liquid into gas. If that gas ends up in sensitive equipment, you could get cavitation or instability. Our Vacuum Insulated Phase Separator [https://www.hlcryo.com/vacuum-insulated-phase-separator-series-product/] takes care of that. It pulls unwanted vapor out of the liquid nitrogen or oxygen stream and vents it safely, so only pure liquid gets downstream. This is vital for high-stability processes-think molecular beam epitaxy in chip making or fast freezing in food processing.

And for smaller jobs or when you need local storage, we've got the Mini Tank. It uses the same high-efficiency vacuum insulation as our big systems, just scaled down for more flexible, local use.

Image: https://www.hlcryo.com/uploads/vacuum-insulated-flexible-hose1.jpgImage: https://www.hlcryo.com/uploads/phase-separator.jpg

Media Contact

Company Name: Chengdu Holy Cryogenic Equipment Co., Ltd.

Email:Send Email [https://www.abnewswire.com/email_contact_us.php?pr=revolutionizing-cryogenic-gas-distribution-across-hightech-industries-with-hl-cryogenics]

Phone: +86 28-85370666

Country: China

Website: https://www.hlcryo.com/

Legal Disclaimer: Information contained on this page is provided by an independent third-party content provider. ABNewswire makes no warranties or responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you are affiliated with this article or have any complaints or copyright issues related to this article and would like it to be removed, please contact retract@swscontact.com

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Revolutionizing Cryogenic Gas Distribution Across High-Tech Industries with HL Cryogenics here

News-ID: 4317934 • Views: …

More Releases from ABNewswire

Self Employed Tax Software UK: Why Freelancers and Sole Traders Are Switching to …

With Many individuals are seeking software that simplifies tax filing while ensuring full compliance with HMRC requirements. Manual spreadsheets and paper-based calculations are being replaced by real-time, automated systems that give users visibility over their tax position throughout the year. Among the platforms gaining traction is Pie, a UK-based digital tax app built specifically to support self-employed individuals with modern income needs.

LONDON, United Kingdom - February 19, 2026 - Demand…

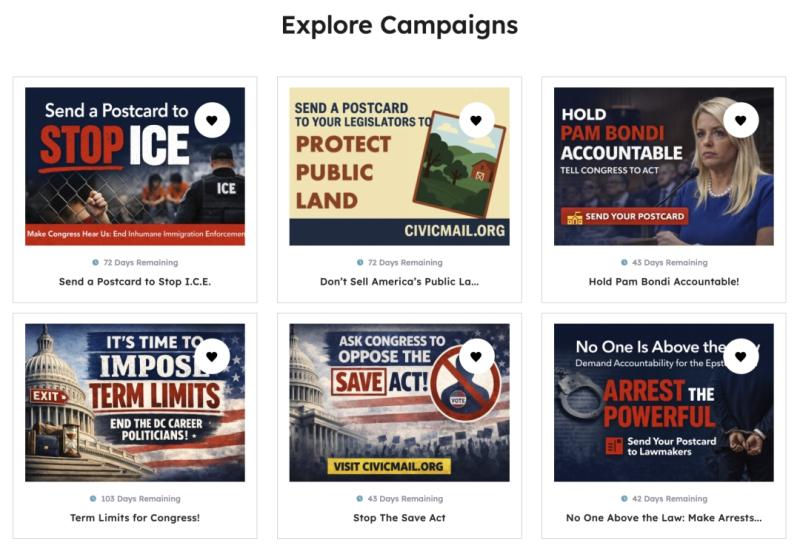

CivicMail.org Reinvents Postcard Campaigns for Grassroots Advocacy

CivicMail.org aims to bring civic engagement back to basics through the power of pen, paper, and postage.

Image: https://www.abnewswire.com/upload/2026/02/2addd1e9e0381d7e2262e1edbb064123.jpg

CivicMail.org [https://civicmail.org/] has announced its launch to help Americans send real, physical postcards to their elected officials with just a few clicks, delivering personalized messages directly to the desks of decision-makers at the local, state, and federal levels.

Research shows [https://www.concordia.ca/news/stories/2021/09/24/personalized-messages-are-more-likely-to-get-a-response-from-politicians-new-research-finds.html] that physical mail carries more weight with elected officials than petitions, emails, or…

New Children's Story: The Story of Sharin' Bear

A Heartfelt Message Of Courage, Kindness, And The True Meaning Of Giving

A pleasant new story for children, The Story of Sharin' Bear by Sharon Woods , introduces families to a lovable little cub whose journey of bravery and compassion changes him into a representation of sharing for children globally.

Entrenched in adventure, innocence, and emotional growth, this uplifting tale offers an unforgettable reminder that even the smallest acts of kindness can…

Fast-Growing Newman's Brew Combines Organic Coffee Excellence with Abandoned Ani …

Newman's Brew is experiencing rapid expansion by delivering on dual commitments that resonate with today's conscious consumers: exceptional fresh-roasted organic coffee and meaningful support for abandoned animals. The company's growing inventory and ethical business practices demonstrate that quality and social responsibility can drive sustainable business success in the competitive specialty coffee market.

Newman's Brew is riding a wave of growth that reflects fundamental shifts in how consumers approach coffee purchasing decisions.…

More Releases for Vacuum

Semiconductor Screw Vacuum Pump Market Industry Trends - Atlas Copco (Edwards Va …

MarketQuest.biz proclaims the addition of another new report titled Global Semiconductor Screw Vacuum Pump Market which is a well-synchronized synopsis of the market. The report offers broad insights extracted by thoroughly analyzing historical and current developments in the market. The report outlines the distinguishable players in the global Semiconductor Screw Vacuum Pump market with a clear-cut end goal to give an intelligent standpoint of the forces of the market, while…

Roots Vacuum Pumps Market SWOT Analysis by Key Players: Pfeiffer, Leybold, ANLET …

Roots vacuum pumps, or vacuum boosters, are dry vacuum pumps that are used together with backing pumps in a wide range of applications where large pumping speeds are required. Vacuum boosters operate completely contact-free and without sealing fluids such as oil or water in the working chamber, although with most models the two gearwheels of the synchromesh gearing and the bearings for the impeller shafts are lubricated with oil. Some…

Vacuum Coating Machines Market 2018 Global Key Country Analysis: Denton Vacuum, …

Vendor Landscape

Tetra Technologies, Inc., (U.S.), BP P.L.C. (U.K.), Statoil ASA (Norway), DNV GL (Norway), TechnipFMC PLC (U.K.), AF Gruppen ASA (Norway), Ramboll Group A/S (Denmark), and Aker Solutions ASA (Norway) are some of the key companies operating in the market. Amec Foster Wheeler (U.K.), John Wood Group Plc. (Scotland), Claxton Engineering Services (U.K.), Allseas group SA (Switzerland), and DeepOcean Group (Netherlands) among others.

Market Research Future’s (MRFR) latest study reveals that…

Global Rotary Vane Vacuum Pumps Market- Pfeiffer Vacuum, Tuthill, Osaka Vacuum, …

Global Rotary Vane Vacuum Pumps Market report 2017 is an in-depth research on the current situation of the Rotary Vane Vacuum Pumps industry.

The Scope of the Rotary Vane Vacuum Pumps research report:

The Global Rotary Vane Vacuum Pumps Market primarily includes a basic overview of the Rotary Vane Vacuum Pumps industry. It also includes Rotary Vane Vacuum Pumps definitions, classifications and applications. It segments the market by applications, types, regions, competitive…

Metallurgical High Vacuum Announces High Vacuum Newsletter

Fennville, MI---Metallurgical High Vacuum has created a new “High Vacuum News” to provide heat treat industry professionals with tips and hints to keep their vacuum pumps running strong.

As Geoff Humberstone, MHV President, comments: “This year marks 30 years for us as Metallurgical High Vacuum. Back in 1981, I saw the need for vacuum design and consulting and started the company. Within four years we added pump remanufacturing because we…

Metallurgical High Vacuum Ships Vacuum Chambers (Corrected)

Special Designs are Built to Customer Specifications

Fennville, MI--- Metallurgical High Vacuum recently shipped two chambers for customer-specific applications. One vacuum chamber is over 72” high and will be used in P E. Chemical Vapor Deposition. The other chamber is a 12-inch square design that will be used to weld silicon sticks, complete with a two-stage booster vacuum pumping system. Both chambers are built of type 304 stainless steel for…