Press release

Drilling Operations Turn to Advanced Bit Design as Formation Complexity Increases

As drilling projects move into more complex geological formations, operators across mining, construction, and energy sectors are placing greater emphasis on bit performance and durability. Harder rock layers, mixed lithology, and longer drilling intervals are driving renewed interest in advanced drill bit design that balances penetration efficiency with operational stability.Rather than relying solely on traditional crushing mechanisms, many drilling teams are adopting cutting-based approaches that improve rate of penetration while reducing vibration and tool wear. This shift reflects a broader trend toward efficiency-driven drilling strategies, where minimizing downtime is as critical as advancing depth.

Changing Demands in Rock Drilling

Modern drilling environments often involve unpredictable conditions, including abrasive rock, fractured zones, and variable hardness within a single borehole. Under these circumstances, drill bits are required to perform consistently while maintaining structural integrity over extended runs.

Engineering teams increasingly evaluate bit geometry, cutter materials, and hydraulic design as part of a system-level approach to drilling. Performance is no longer measured only by speed, but also by stability, tool life, and the ability to maintain borehole quality.

"Operators are looking for tools that perform reliably across changing formations," said a spokesperson from Sinodrills. "Consistency and durability have become just as important as penetration rate."

The Role of Cutting-Based Drill Bit Technology

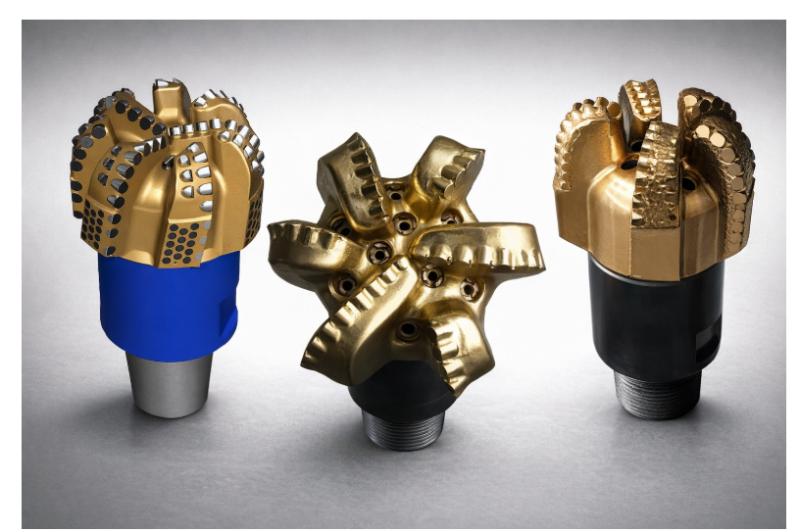

Cutting-based drill bits, particularly those using polycrystalline diamond compact cutters, have gained wider adoption due to their ability to shear rock efficiently rather than relying on impact alone. This approach can reduce energy loss and help maintain smoother drilling conditions in suitable formations.

Such designs are commonly applied in formations where abrasive wear and excessive vibration limit the effectiveness of conventional bits. By optimizing cutter placement and blade structure, drilling teams can achieve more predictable performance and fewer interruptions.

For example, detailed information on PDC drill bit design, including cutter layout and material selection, is available at https://www.sinodrills.com/pdc-drill-bit/, illustrating how these factors affect drilling performance in different formations.

Performance, Data, and Field Feedback

Advances in drill bit design are increasingly informed by operational data. Parameters such as torque variation, vibration levels, and cutter wear patterns provide valuable insight into how tools interact with specific formations.

By analyzing this data, drilling teams can refine tool selection and operating practices to better match geological conditions. Manufacturers also use field feedback to improve durability and optimize designs for real-world performance rather than laboratory conditions.

This data-driven feedback loop is becoming a key factor in improving drilling efficiency and reducing non-productive time.

Balancing Efficiency and Reliability

Improving drilling efficiency is not solely about speed. Longer bit life and fewer trips out of the hole contribute to lower operational costs and improved safety. Stable drilling conditions also reduce stress on the drill string and associated equipment.

As sustainability and resource efficiency gain importance, tools that help complete drilling operations with fewer interruptions and lower energy consumption are increasingly valued across the industry.

Industry Outlook

Despite ongoing innovation in drilling technologies, bit design remains a foundational element of successful operations. As projects extend into deeper and more challenging formations, the demand for reliable, cutting-based drill bits is expected to continue.

For operators, understanding how drill bit technology aligns with formation characteristics will remain essential to achieving consistent, efficient results.

About Sinodrills

Guizhou Sinodrills Equipment Co., LTD is an international supplier of rock drilling tools serving mining, construction, and energy projects worldwide. The company focuses on the development and manufacturing of drilling tools designed for diverse geological conditions, supporting global customers through integrated research, production, and quality management systems.

Media Contact

Email: sales@sinodrills.com

Website: https://www.sinodrills.com

sinodrills

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Drilling Operations Turn to Advanced Bit Design as Formation Complexity Increases here

News-ID: 4317828 • Views: …

More Releases from BusinesNewswire

CleanVsFactory Establishes Trusted Online Presence for Super Clone Watches

CleanVsFactory continues to build its presence as an online platform focused on providing clear and accessible information related to super clone luxury watches. The platform offers a structured environment for watch enthusiasts who want to explore luxury inspired timepieces with an emphasis on understanding quality, design, and overall standards.

For more details, visit the official website:

https://www.cleanvsfactory.com

As interest in super clone watches grows, buyers increasingly look for platforms that offer clarity…

How People Talk to Strangers Online in Everyday Moments

Online communication keeps changing as people move between text, calls, and voice tools during the day. Voice feels more natural than typing and less demanding than video. Many people now prefer to talk to strangers online when they want quick and real interaction without planning ahead.

Random strangers https://www.airtalk.live/ conversations make this possible in a simple way. Users can start talking instantly and leave when they choose. This freedom helps people…

I Didn't Mean to Stop Using Cable TV

I'm now not positive whilst it began..

I desire I could factor to an afternoon or a second, however I can't. It become greater like a slow irritation. The kind you ignore until you don't.

Cable TV was always on in my house. Always. Even when nobody was really watching it. Especially then. It filled silence. Or maybe it just made more noise. Hard to tell now.

At some factor, I observed I…

The Real Cost of Saying "I Do" in Modern Weddings

Singaporean couples face some of the highest wedding expenses in Southeast Asia-the median wedding cost in Singapore sits around S$37,000, with typical celebrations ranging from S$30,000 to S$50,000. Savings accounts rarely hold enough to cover everything upfront, which explains why wedding loans https://crawfort.com/sg/wedding-loan/ have become a practical financing tool for couples who want meaningful celebrations without draining every dollar they've saved.

The Banquet: Where Most of Your Money Disappears

Hotel ballrooms and…

More Releases for Drill

What Is Difference Between HSS Twist Drill Bits And Cobalt Drill Bits?

Welcome to our product introduction on twist drill bits and cobalt drill bits. In the world of drilling tools, these two types of drill bits have become quite popular among professionals and DIY enthusiasts alike. They are known for their durability, versatility, and efficiency when it comes to drilling through various materials, including metal, wood, and plastic.

The purpose of this introduction is to explain the key differences between twist drill…

Construction Industry Core Drill Market, By Type (Wet Drill Bits and Dry Drill B …

With thorough company profiles, recent developments, and other information, the Construction Industry Core Drill Market Report provides an in-depth analysis of major trends, motivating reasons, obstacles, segmentation, regulatory policies, and important players. The Construction Industry Core Drill Market Report offers a thorough synopsis of the product portfolio, including product development, planning, and positioning of products with emerging technologies, impending opportunities, and problems. The market's views and viewpoints assess the potential…

Drill Collars in Oilfield Market: Players Tapping Emerging Markets | Drill Pipe …

Market Description -

Los Angeles, (United States) - The information made available in the Drill Collars in Oilfield report will definitely facilitate to increase the knowledge and decision-making skills of the business, thus providing an immense opportunity for growth. This will at last increase the return rate and drive the competitive edge within. Being a custom market report, it provides services tailored to the exact challenge. Whether it is survey work,…

Boring Tools Market Report 2018: Segmentation by Type (Drill Bits, Drilling Tubu …

Global Boring Tools market research report provides company profile for NACHI-FUJIKOSHI, OSG, Sandvik, BIG KAISER, Kennametal and Others.

This market study includes data about consumer perspective, comprehensive analysis, statistics, market share, company performances (Stocks), historical analysis 2012 to 2017, market forecast 2018 to 2025 in terms of volume, revenue, YOY growth rate, and CAGR for the year 2018 to 2025, etc. The report also provides detailed segmentation on the basis…

Drill Pipe Market Countering growth 2025 | Tenaris S. A, Drill Pipe Internationa …

Global Drill Pipe Market: Snapshot

Drill pipes are hollow pipes, usually made of aluminum alloys or steel and are a core component in the drilling process. The hollow drill pipes enable for the transfer of drilling fluids downwards towards the drill point or back upwards through the annulus. Although a standard length for drill pipes is up to 32 feet, there are longer pipes that could stretch till 45 feet and…

Drill Bits Market Research Report- Forecast to 2027 | Global Drill Bits Industry

Global Drill Bits Market Information Report by Type (rolling cutter and fixed cutter bits), by End Market (land and offshore.) and by Region - Forecast to 2027

Increasing demand for energy has been a major factor in the significant growth of the drill bits market In recent times. Furthermore the recent expansion and exploratory activities undertaken across the globe are expecte4d to positively influence the Drill Bits market.

Get a sample copy…