Press release

Comprehensive Analysis of the Multi-Layer Anti-Icing and De-Icing Coating Systems Market: Technology Evolution, Regional Demand & Forecast Scenarios to 2036

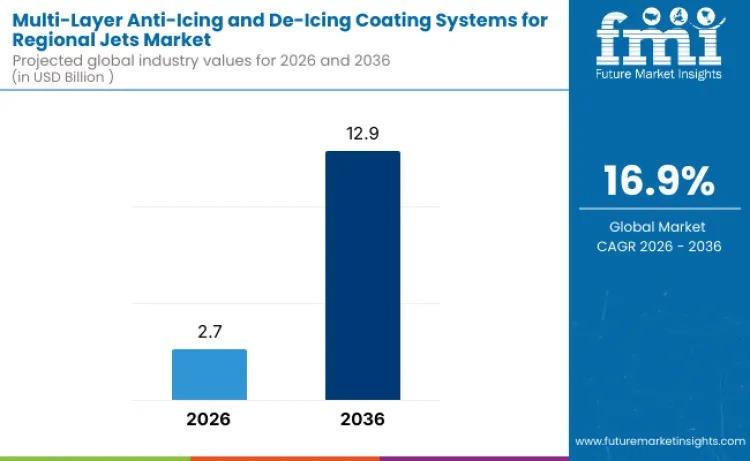

The multi-layer anti-icing and de-icing coating systems for regional jets market is valued at USD 2.7 billion in 2026 and is projected to reach USD 12.9 billion by 2036, expanding at a robust CAGR of 16.9%. Growth is driven by the operational realities of regional jet fleets flying across diverse climatic zones where icing risks directly affect aerodynamic efficiency, safety margins, and operating economics. As airlines seek alternatives to energy-intensive thermal de-icing systems, advanced surface-engineered coating architectures are gaining priority.Regional jets face frequent icing exposure during ascent, descent, and low-altitude cruise phases, particularly in winter-intensive networks. Multi-layer anti-icing and de-icing coating systems offer a compelling value proposition by reducing ice adhesion, delaying ice formation, and lowering dependence on traditional glycol-based ground de-icing. For operators, this translates into fewer weather-related delays, reduced fuel burn penalties, and improved aircraft availability during peak winter operations.

Explore trends before investing - request a sample report today! https://www.futuremarketinsights.com/reports/sample/rep-gb-29892

Adoption is accelerating as OEMs and airlines recognize the operational advantages of coatings that combine hydrophobic, ice-phobic, conductive, and abrasion-resistant layers within a single system. These coatings maintain aerodynamic smoothness while delivering consistent performance under cyclic freeze-thaw exposure. Compatibility with composite and metallic substrates used in modern regional jets further strengthens their appeal across new aircraft programs and retrofit applications.

Multi-Layer Hydrophobic + Ice-Phobic Stacks Dominate Coating Structure Demand

Multi-layer hydrophobic plus ice-phobic coating stacks account for 45.7% of global demand, making them the leading coating structure segment. These layered systems integrate surface-energy modification with mechanical durability, enabling reduced ice nucleation and lower ice adhesion on critical aerodynamic surfaces.

Nanostructured top layers minimize water retention and delay freezing onset, while underlying polymer-ceramic hybrid layers improve abrasion resistance, thermal stability, and adhesion strength. Rapid-cure and spray-friendly chemistries allow efficient application during scheduled MRO cycles, supporting scalability across regional fleets.

Key structural advantages include:

• Combined hydrophobicity and mechanical durability

• Enhanced resistance to erosion and particulate impact

• Improved performance stability under repeated icing cycles

• Compatibility with composite and metallic airframe materials

Passive Anti-Icing Leads Functional Mechanism Adoption

Passive anti-icing via surface-energy modification represents 43.9% of global demand, reflecting operator preference for energy-efficient, always-on ice-mitigation solutions. These coatings reduce initial ice formation without continuous power draw, supporting fuel-efficiency targets and lowering system complexity.

Active conductive de-icing coatings remain essential for severe icing encounters, enabling low-energy Joule heating when required. Phase-change-assisted systems and self-healing coatings add further resilience by reducing ice-bond strength and restoring surface properties after micro-damage.

Functional priorities shaping adoption include:

• Reduced reliance on energy-intensive thermal systems

• Consistent ice-shedding performance across flight cycles

• Lower maintenance burden over coating life

• Improved safety margins during winter operations

Wing Leading Edges Drive Application Demand

Wing leading edges account for 46.3% of global application demand, reflecting their high exposure to icing and aerodynamic sensitivity. Effective ice-mitigation in these areas directly influences lift, drag, and overall flight stability.

Nacelles and engine inlets require coatings that preserve airflow integrity and prevent ice ingestion, while tailplanes and control surfaces depend on consistent anti-icing to maintain handling authority. Fuselage and radome applications focus on reducing ice accumulation with lower aerodynamic penalties.

Asia and North America Anchor Global Growth Momentum

China, India, the USA, Japan, and the UK form the core demand hubs as regional jet deployments expand and winter-weather reliability becomes a strategic priority.

• China (CAGR 18.4%) benefits from rapid regional-aviation expansion, aircraft manufacturing growth, and national aerospace R&D programs advancing nanocomposite coatings.

• India (CAGR 17.8%) sees rising demand driven by regional connectivity initiatives, diverse climate exposure, and expanding MRO capabilities.

• USA (CAGR 16.6%) leverages advanced aerospace R&D, certification-focused development, and technology transfer from defense programs.

• Japan (CAGR 15.5%) emphasizes precision engineering and long-term durability under repeated freeze-thaw cycles.

• UK (CAGR 14.9%) supports adoption through aerospace-innovation programs and efficiency-driven winter-operations strategies.

Subscribe for Year-Round Insights → Stay ahead with quarterly and annual data updates! https://www.futuremarketinsights.com/reports/multi-layer-anti-icing-and-de-icing-coating-systems-for-regional-jets-market

Competitive Landscape Centers on Certified, Durable Coating Systems

Global demand is shaped by the need for certified, erosion-resistant, and maintenance-compatible coating systems. Buyers prioritize predictable recoat intervals, proven freeze-thaw durability, and seamless integration into existing MRO workflows.

• PPG Aerospace leads with an estimated 25% market share, supported by certified aerospace coatings with controlled surface-energy behavior.

• AkzoNobel advances aviation coating systems with strong exterior durability credentials.

• Mankiewicz maintains visibility through multi-layer coatings optimized for regional jet structures.

• 3M contributes engineered surface-modification materials that reduce ice adhesion.

• BASF supplies specialty polymers and functional components integrated into advanced coating stacks.

As regional jet operators balance safety, efficiency, and sustainability goals, multi-layer anti-icing and de-icing coating systems are transitioning from optional enhancements to core operational assets. Their ability to reduce energy consumption, improve winter reliability, and support next-generation aircraft materials positions this market for sustained, high-value growth through 2036.

Why FMI: https://www.futuremarketinsights.com/why-fmi

Browse Related Insights

Bio-Based and Low-VOC Aircraft Exterior Coating Systems Market: https://www.futuremarketinsights.com/reports/bio-based-and-low-voc-aircraft-exterior-coating-systems-market

Aircraft De-icing Market: https://www.futuremarketinsights.com/reports/aircraft-de-icing-market

Contact Us:

Future Market Insights Inc.

Christiana Corporate, 200 Continental Drive,

Suite 401, Newark, Delaware - 19713, USA

T: +1-347-918-3531

Website: https://www.futuremarketinsights.com

About Future Market Insights (FMI)

Future Market Insights, Inc. (FMI) is an ESOMAR-certified, ISO 9001:2015 market research and consulting organization, trusted by Fortune 500 clients and global enterprises. With operations in the U.S., UK, India, and Dubai, FMI provides data-backed insights and strategic intelligence across 30+ industries and 1200 markets worldwide.

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Comprehensive Analysis of the Multi-Layer Anti-Icing and De-Icing Coating Systems Market: Technology Evolution, Regional Demand & Forecast Scenarios to 2036 here

News-ID: 4317315 • Views: …

More Releases from Future Market Insights

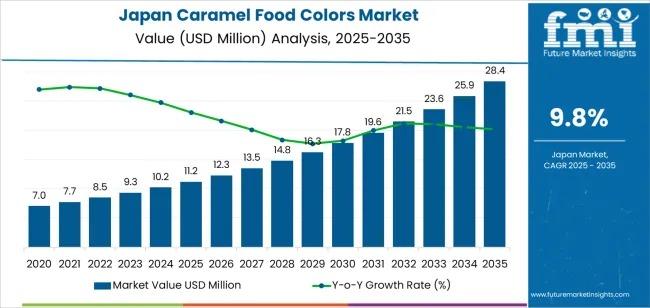

Japan Caramel Food Colors Industry Outlook to 2036: Strategic Insights for R&D, …

The Japanese caramel food colors market is on a steady growth trajectory, with demand projected to rise from USD 11.2 million in 2025 to USD 28.4 million by 2035, registering a CAGR of 9.8%. The initial phase of the forecast period (2025-2030) anticipates a steady increase in demand, reaching approximately USD 17.8 million by 2030, driven by the expanding use of caramel colors across confectionery, dairy, and baked goods.

The market's…

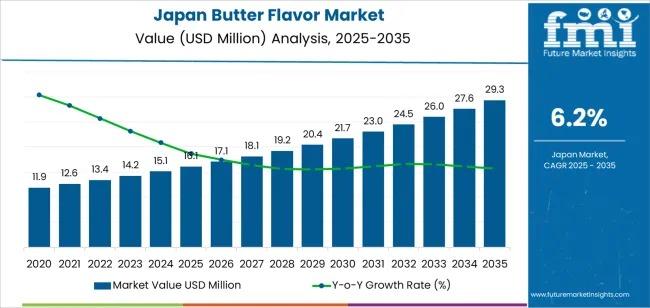

Comprehensive Analysis of the Japan Butter Flavor Market: Technology Evolution, …

The demand for butter flavor in Japan is projected to rise from USD 16.1 million in 2025 to USD 29.4 million by 2035, reflecting a steady compound annual growth rate (CAGR) of 6.2%. This growth is underpinned by increasing adoption across bakery products, confectionery items, and dairy-based preparations, as manufacturers seek to enhance taste experiences and deliver authentic dairy character in a wide range of food offerings.

The Japanese bakery and…

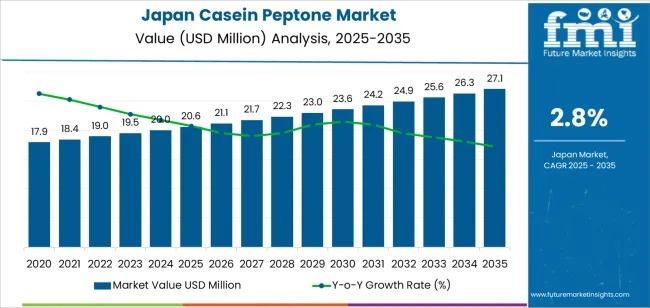

Japan Casein Peptone Market Deep-Dive 2026-2036: Strategic Forecasts, Market Ent …

The demand for casein peptone in Japan is projected to grow steadily, reaching USD 27.1 million by 2035, up from USD 20.6 million in 2025, reflecting a compound annual growth rate (CAGR) of 2.8%. During the early forecast period (2025-2030), demand is expected to rise from USD 20.6 million to approximately USD 23.6 million, supported by its widespread applications in biotechnology, pharmaceuticals, and food industries. Casein peptone continues to play…

Global Boride Powder Market Size, Share & Forecast: High-Growth Segments, Value …

The global boride powder market is valued at USD 19.7 billion in 2025 and is projected to reach USD 32.2 billion by 2035, advancing at a steady 5.0% CAGR over the forecast period. This upward trajectory reflects increasing adoption of boride-based compounds in aerospace technology, high-temperature processing environments, and advanced coating applications, where exceptional thermal stability, corrosion resistance, and mechanical strength are essential for operational performance and product reliability.

Key Market…

More Releases for Coating

Medical Grade Coating Market: How Nanotechnology Is Advancing Coating Solutions

► Medical Grade Coating Market Poised for Significant Growth, Projected to Reach USD 22.01 Billion by 2032

The global medical grade coating market, valued at USD 13.40 billion in 2024, is anticipated to experience robust growth, reaching approximately USD 22.01 billion by 2032. This represents a compound annual growth rate (CAGR) of 6.4% during the forecast period.

Curious to peek inside? Grab your sample copy of this report now:https://www.maximizemarketresearch.com/request-sample/100541/

► Market…

Powder Coating Market - Advanced Coating Solutions for Industrial Applications | …

Powder Coating Market is expected to grow at a CAGR of 6.0% during the forecast period (2024 - 2031).

Powder Coating Market report, published by DataM Intelligence, provides in-depth insights and analysis on key market trends, growth opportunities, and emerging challenges. Committed to delivering actionable intelligence, DataM Intelligence empowers businesses to make informed decisions and stay ahead of the competition. Through a combination of qualitative and quantitative research methods, it offers…

Coating Equipment Market by Type (Powder coating equipment, Liquid coating equip …

The Coating Equipment Market research report incorporates the scope and objective of the study. Moreover, the report highlights key market segments and players covered. It also covers industry trends, focusing on market use cases and top market size by region, market trends, and global market size. Moreover, the Coating Equipment Market research report covers market growth rate and market share by region. Supply chain analysis, regional marketing analysis, opportunities, challenges,…

Powder Coating Market, Powder Coating Market share, global Powder Coating Market …

High application scope in consumer goods, industrial and automotive applications will drive the powder coating market. Stringent government regulation regarding VOC emissions along with product features including emit less, ecofriendly and solvent free will fuel the industry growth.

Expansion in the automotive & transportation industry particularly in the emerging nations will propel the powder coating market growth. Shifting trends towards reduction of heat requirement during the production process are the…

Powder Coating Market, Powder Coating Market share, global Powder Coating Market …

High application scope in consumer goods, industrial and automotive applications will drive the powder coating market. Stringent government regulation regarding VOC emissions along with product features including emit less, ecofriendly and solvent free will fuel the industry growth.

Expansion in the automotive & transportation industry particularly in the emerging nations will propel the powder coating market growth. Shifting trends towards reduction of heat requirement during the production process are the…

Powder Coating Market, Powder Coating Market share, global Powder Coating Market …

High application scope in consumer goods, industrial and automotive applications will drive the powder coating market. Stringent government regulation regarding VOC emissions along with product features including emit less, ecofriendly and solvent free will fuel the industry growth.

Expansion in the automotive & transportation industry particularly in the emerging nations will propel the powder coating market growth. Shifting trends towards reduction of heat requirement during the production process are the…