Press release

Rubber Conveyor Belts Manufacturing Plant: Cost Structure, Process & ROI

IMARC Group's report, "Rubber Conveyor Belts Manufacturing Plant Project Report 2025: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue," provides a comprehensive roadmap for establishing a rubber conveyor belts manufacturing plant. The report delivers detailed insights into production technologies, capital investments, operating costs, profitability forecasts, and financial analysis, enabling entrepreneurs, investors, and industry stakeholders to make informed decisions in the growing industrial and material handling sector.In 2025, global demand for rubber conveyor belts manufacturing plants is increasing steadily, driven by expanding applications across mining, cement, power generation, ports, steel, food processing, and logistics industries. This project report presents an in-depth overview of plant setup requirements, machinery selection, raw material sourcing, and cost structures for investors across India, the UAE, the US, Africa, and Europe.

Download the Sample Report: https://www.imarcgroup.com/rubber-conveyor-belts-manufacturing-plant-project-report/requestsample

What are Rubber Conveyor Belts?

Rubber conveyor belts are durable material-handling systems designed to transport bulk materials efficiently over short and long distances. Manufactured using layers of rubber compounds reinforced with fabric or steel cords, these belts offer high tensile strength, abrasion resistance, flexibility, and load-bearing capacity. Rubber conveyor belts are widely used in industries such as mining, cement, coal handling, steel plants, agriculture, warehousing, and manufacturing facilities. Their ability to operate under harsh conditions, including high temperatures, heavy loads, and continuous operation, makes them essential components in modern industrial automation and logistics systems.

Market Trends and Drivers of Rubber Conveyor Belts

The rubber conveyor belts market is witnessing steady growth due to:

• Rapid expansion of mining and mineral processing activities

• Rising demand from cement, steel, and power generation industries

• Growth in port operations, warehousing, and logistics infrastructure

• Increasing adoption of automation and bulk material handling systems

• Advancements in high-performance rubber compounds and belt durability

Types of Rubber Conveyor Belts and Their Industrial Applications

Rubber conveyor belts are engineered in various types to meet the specific needs of different industries. Each type is designed for unique load capacities, environmental conditions, and material-handling requirements. Selecting the right belt ensures efficiency, durability, and safety in operations across sectors such as mining, cement, ports, food processing, and logistics. Modern conveyor belts also incorporate specialized features like heat resistance, oil resistance, and high-tensile strength to enhance performance under challenging conditions.

Common Types and Applications:

Fabric-Reinforced Rubber Conveyor Belts: Suitable for general material handling, warehouses, and light to medium loads.

Steel Cord Conveyor Belts: Ideal for heavy-duty applications in mining, quarries, and bulk material transport.

Oil-Resistant Rubber Conveyor Belts: Used in petrochemical, oil refineries, and industries handling oily substances.

Heat-Resistant Rubber Conveyor Belts: Designed for cement plants, steel mills, and high-temperature operations.

Food-Grade Rubber Conveyor Belts: Suitable for food processing, packaging, and pharmaceutical industries.

Abrasion-Resistant Rubber Conveyor Belts: Used in mining, cement, and construction for transporting abrasive materials.

Buy Full Report: https://www.imarcgroup.com/checkout?id=8640&method=2142

Key Insights Covered in the Rubber Conveyor Belts Manufacturing Plant Report

Market Coverage:

• Market trends in material handling and industrial conveyor systems

• Market segmentation by belt type, application, and end-use industry

• Regional analysis of production capacity and consumption patterns

• Price analysis of rubber compounds, fabrics, steel cords, and additives

• Impact of global supply chain disruptions on raw materials

• Market forecast highlighting future growth opportunities

Key Aspects Required for Setting Up a Rubber Conveyor Belts Manufacturing Plant

Detailed Process Flow:

• Product Overview

• Unit Operations Involved

• Mass Balance and Raw Material Requirements

• Quality Assurance Criteria

• Technical and Performance Tests

Project Details, Requirements, and Costs Involved:

• Land, Location, and Site Development

• Plant Layout and Production Lines

• Machinery Requirements and Costs

• Raw Material Requirements and Costs

• Packaging and Storage Requirements and Costs

• Transportation and Logistics Requirements and Costs

• Utility Requirements and Costs

• Human Resource Requirements and Costs

Project Economics

• Capital Investments: Land, civil construction, machinery, utilities, and installation

• Operating Costs: Raw materials, power, labor, maintenance, and overheads

• Expenditure Projections: Short-term and long-term operational planning

• Revenue Projections: Based on industrial demand and contract manufacturing

• Taxation and Depreciation Analysis

• Profitability Metrics: ROI, NPV, break-even analysis

• Financial Feasibility and Risk Assessment

Request a Customized Project Report: https://www.imarcgroup.com/request?type=report&id=8640&flag=C

Customization Options Available:

• Plant Location: Selection of optimal location based on supply chain access and market proximity.

• Plant Capacity: Customization based on targeted production scale.

• Machinery: Options for fully automatic, semi-automatic, or manual production lines.

• List of Machinery Providers: Identification of domestic and international equipment suppliers

About Us:

IMARC is a global market research company offering comprehensive services to support businesses at every stage of growth, including market entry, competitive intelligence, procurement research, regulatory approvals, factory setup, company incorporation, and recruitment. Specializing in factory setup solutions, we provide detailed financial cost modelling to assess the feasibility and financial viability of establishing new manufacturing plants globally.

Our models cover capital expenditure (CAPEX) for land acquisition, infrastructure, and equipment installation while also evaluating factory layout and design's impact on operational efficiency, energy use, and productivity. Our holistic approach offers valuable insights into industry trends, competitor strategies, and emerging technologies, enabling businesses to optimize operations, control costs, and drive long-term growth.

Our expertise includes:

• Market Entry and Expansion Strategy

• Feasibility Studies and Business Planning

• Company Incorporation and Factory Setup Support

• Regulatory and Licensing Navigation

• Competitive Analysis and Benchmarking

• Procurement and Supply Chain Research

• Branding, Marketing, and Sales Strategy

Contact Us:

IMARC Group

134 N 4th St., Brooklyn, NY 11249, USA

Tel No:(D) +91 120 433 0800

United States: (+1-201971-6302)

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Rubber Conveyor Belts Manufacturing Plant: Cost Structure, Process & ROI here

News-ID: 4316272 • Views: …

More Releases from IMARC Group

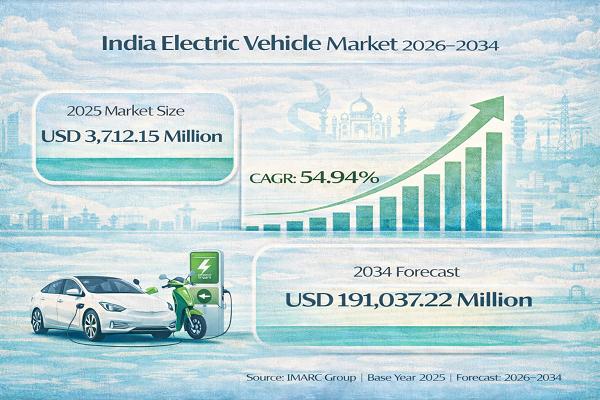

India Electric Vehicle Market Set to Reach USD 191,037.22 Million by 2034, Expan …

India Electric Vehicle Market : Report Introduction

According to IMARC Group's report titled "India Electric Vehicle Market Size, Share, Trends and Forecast by Vehicle Type, Price Category, Propulsion Type, and Region, 2026-2034" the report offers a comprehensive analysis of the industry, including market share, growth, trends, and regional insights.

Free Sample Download PDF (Exclusive Offer on Corporate Email) : https://www.imarcgroup.com/india-electric-vehicle-market/requestsample

India Electric Vehicle Market Overview

The India electric vehicle market size was valued at…

United States Revenue Cycle Management Market Size, Trends, Growth and Forecast …

IMARC Group has recently released a new research study titled "United States Revenue Cycle Management Market Size, Share, Trends and Forecast by Type, Component, Deployment, End User, and Region, 2026-2034", offers a detailed analysis of the market drivers, segmentation, growth opportunities, trends and competitive landscape to understand the current and future market scenarios.

Connect with a Research Analyst Now:

https://www.imarcgroup.com/united-states-revenue-cycle-management-market/requestsample

United States Revenue Cycle Management Market Summary:

The United States revenue cycle…

LED Chip Manufacturing Plant Cost Report 2026: Demand Analysis, CapEx/OpEx & ROI …

Setting up an LED chip manufacturing plant involves strategic planning, substantial capital investment, and comprehensive understanding of semiconductor fabrication technologies. These high-performance components power everything from general illumination and displays to automotive lighting and consumer electronics. Success requires careful site selection, advanced epitaxial growth processes, sophisticated cleanroom facilities, reliable raw material sourcing, and compliance with stringent quality and environmental regulations to ensure profitable and sustainable operations.

IMARC Group's report, "LED Chip…

Eyewear Manufacturing Plant DPR & Unit Setup - 2026: Machinery Cost, CapEx/OpEx, …

Setting up an eyewear manufacturing plant positions investors within a strategically important segment of the global optical and fashion accessories industry, driven by increasing demand for vision correction solutions, rising awareness of eye health, and growing fashion consciousness. As modern lifestyles advance, digital device usage expands, and the need for protective and corrective eyewear grows, eyewear continues to gain traction across prescription glasses, sunglasses, safety eyewear, and fashion accessories worldwide.…

More Releases for Rubber

Stationery Rubber Bands Market Size Set for Rapid Growth and Trend by 2030 | Dyk …

Global "Stationery Rubber Bands Market" Research report is an in-depth study of the market Analysis. Along with the most recent patterns and figures that uncovers a wide examination of the market offer. This report provides exhaustive coverage on geographical segmentation, latest demand scope, growth rate analysis with industry revenue and CAGR status. While emphasizing the key driving and restraining forces for this market, the report also offers a complete study…

Rubber Mulch Market Promising Regions for Companies in 2023 | Rubber Mulch Produ …

The global Rubber Mulch market is thoroughly researched in this report, noting important aspects like market competition, global and regional growth, market segmentation, and market structure. Our team of analysts has employed the latest research tools and techniques to estimate the size of the Rubber Mulch market in terms of both value and volume. Furthermore, this report includes detailed estimates for market share, revenue, production, consumption, gross profit margin, CAGR…

Reclaimed Rubber and Rubber Powder Market to Witness Huge Growth by Key Players: …

The Reclaimed Rubber and Rubber Powder report compiles the market information depending upon market development and growth factors, optimizing the growth path. In addition, it highlights the strategies and market share of the leading vendors in the particular market. The report follows a robust research methodology model that helps to make informed decisions. It obtains both qualitative and quantitative market information supported by primary research.

The Reclaimed Rubber and Rubber Powder…

Pakistan Rubber Tyre Market : Pneumatic Rubber Tyre, Retreaded Rubber Tyre, Cush …

According to a recent report published by Allied Market Research, titled, "Pakistan rubber tyre Market by Tyre, Component, Design, and Vehicle Type: Opportunity Analysis and Industry Forecast, 2018 - 2025," Pakistan rubber tyre market size was valued at $272.10 million in 2017, and is projected to reach $1,592.90 million by 2025, registering a CAGR of 24.8% from 2018 to 2025. The radial type design segment was the highest contributor to…

Pakistan Rubber Tyre Market : Pneumatic Rubber Tyre, Retreaded Rubber Tyre, Cush …

The global Pakistan rubber tyre market size was valued at $272.10 million in 2017, and is projected to reach $1,592.90 million by 2025, registering a CAGR of 24.8% from 2018 to 2025. The radial type by design segment was the highest revenue contributor in 2017, accounting for $207.7 million, and is estimated to reach $1,196.4 million by 2025, registering a CAGR of 24.6% during the forecast period.

Download Sample Report at…

Pakistan Rubber Tyre Market : Pneumatic Rubber Tyre, Retreaded Rubber Tyre, Cush …

According to a recent report published by Allied Market Research, titled, "Pakistan rubber tyre Market by Tyre, Component, Design, and Vehicle Type: Opportunity Analysis and Industry Forecast, 2018 - 2025," Pakistan rubber tyre market size was valued at $272.10 million in 2017, and is projected to reach $1,592.90 million by 2025, registering a CAGR of 24.8% from 2018 to 2025. The radial type design segment was the highest contributor to…