Press release

Is a Furfural Plant Profitable? Full CAPEX/OPEX Analysis & ROI Guide

Introduction - Overview of Furfural Production Plant Cost:Evaluating the furfural production plant cost is essential for investors planning to enter the bio-based chemicals and green solvents industry. Furfural is an organic aldehyde derived from agricultural residues such as corn cobs, sugarcane bagasse, rice husk, and oat hulls. It is widely used as a solvent, chemical intermediate, and precursor for furfuryl alcohol, resins, pharmaceuticals, and refinery chemicals.

This project-report-style guide explains the cost components, process requirements, plant setup, and financial feasibility of establishing a furfural manufacturing plant.

Market Overview & Trends - Rising Demand for Bio-Based Chemicals:

The global furfural market is expanding due to increasing preference for renewable and biomass-derived chemicals. Furfural is increasingly used in petrochemical refining, lubricant refining, resins, agrochemicals, and pharmaceuticals.

Market trends include rising demand for furfuryl alcohol, growth in green solvents, utilization of agro-waste for chemical production, and increasing adoption of sustainable chemical manufacturing practices. Export demand and tightening environmental regulations further support long-term market growth.

See the Data First: Download Your Sample Report: https://www.imarcgroup.com/furfural-manufacturing-plant-project-report/requestsample

Investor Insight: Furfural Price Fluctuations -

In Q3 2025, furfural prices showed a clear regional split, offering strategic signals for investors. Prices declined notably in the USA (USD 1,440/MT, -7.3%) and Japan (USD 1,136/MT, -8.5%), reflecting easing demand and improved supply conditions. Conversely, prices increased in Germany (USD 1,978/MT, +2.1%), Spain (USD 1,666/MT, +2.5%), and Brazil (USD 1,891/MT, +1.6%), indicating stronger regional demand and cost pressures, which may support investment opportunities in these markets.

Report Coverage Highlights:

• Process Flow: Covers hydrolysis of biomass, acid digestion, steam stripping, condensation, and purification.

• Land & Location: Requires industrial land near agricultural waste sources and utilities.

• Plant Layout: Includes biomass handling, reactor section, distillation units, storage, and QC labs.

• Machinery: Digesters, reactors, steam strippers, condensers, distillation columns, and storage tanks.

• Raw Materials: Corn cobs, bagasse, rice husk, sulfuric acid, water, and utilities.

• Packaging: Furfural stored in drums, barrels, or bulk storage tanks.

• Additional Needs: Boilers, steam supply, ETP, safety systems, and material handling equipment.

• Project Economics: Covers CapEx, OpEx, biomass cost, utilities, and production yield.

• Financial Analysis: Includes ROI, break-even point, payback period, and cost sensitivity.

• Market Insights: Highlights demand from resins, solvents, petrochemicals, and export markets.

Technical Aspects / Manufacturing Process - How Furfural Is Produced:

Furfural is produced by acid hydrolysis of pentosan-rich biomass. The process includes:

• Raw Material Preparation: Agricultural residues are cleaned, crushed, and prepared for processing.

• Acid Digestion: Biomass reacts with dilute acid under high temperature and pressure, converting pentosans into furfural vapors.

• Steam Stripping: Furfural vapors are separated using steam.

• Condensation: Vapors are condensed into crude furfural liquid.

• Distillation & Purification: Crude furfural is refined to achieve commercial purity.

Quality control includes purity testing, moisture content analysis, boiling point verification, and compliance with industrial solvent standards.

Plant Setup Requirements - Machinery, Infrastructure & Utilities:

A furfural manufacturing plant requires robust chemical-processing infrastructure.

Key machinery includes digesters, reactors, acid-resistant piping, steam boilers, condensers, distillation columns, storage tanks, pumps, and automated control systems.

Infrastructure needs include continuous water supply, high-pressure steam systems, biomass storage yards, waste-handling facilities, effluent treatment plants, ventilation, and fire safety systems. Proximity to biomass sources significantly reduces raw material cost.

Project Economics - Capital Cost, Operating Cost & Profitability:

The furfural production plant cost consists of land development, civil construction, reactors, distillation systems, boilers, utilities, storage tanks, and working capital.

Operating expenses include biomass procurement, acid consumption, steam and power usage, labor, maintenance, packaging, and environmental compliance.

Production cost is influenced by biomass availability, conversion efficiency, energy consumption, and plant scale. Revenue is generated from furfural sales to chemical manufacturers, resin producers, refineries, and exporters. Profitability improves with integrated furfuryl alcohol production and byproduct utilization.

Risk Factors & Success Strategies - Managing Cost & Operational Efficiency:

Key risks include inconsistent biomass supply, corrosion due to acidic processes, high energy consumption, and effluent management challenges.

Success strategies include locating plants near agro-waste sources, using corrosion-resistant equipment, optimizing steam recovery, recycling process water, and maintaining long-term supply contracts with chemical buyers. Process optimization and waste heat recovery significantly reduce operating costs.

How IMARC Group Supports Plant Setup:

IMARC Group helps investors and entrepreneurs establish a manufacturing plant by providing detailed market research, technical guidance, and financial feasibility analysis. Their reports outline process flow, machinery requirements, raw materials, project cost, profitability, and regulatory needs, offering a complete roadmap for setup. With expert consulting and customized solutions, IMARC ensures smoother planning, reduced risks, and faster project execution.

Top Furfural Manufacturers:

• Illovo Sugar Africa (Pty.) Ltd

• Linzi Organic Chemical Inc. Ltd.

• Trans Furans Chemicals bvba

• Central Romana Corporation

• DalinYebo

• Hebeichem

• KRBL Ltd.

• Silva team S.p.a.

• LENZING AG

Get a Personalized Setup Cost & ROI Analysis: https://www.imarcgroup.com/request?type=report&id=18217&flag=C

Conclusion - Feasibility and Investment Outlook of Furfural Production:

Analyzing the furfural plant cost highlights the strong commercial potential of this bio-based chemical project. With abundant agricultural residues, rising demand for renewable chemicals, and export opportunities, a well-designed furfural manufacturing plant can achieve attractive returns when supported by efficient process control, energy optimization, and strong market linkages.

About Us:

IMARC Group is a leading global market research and management consulting firm. We specialize in helping organizations identify opportunities, mitigate risks, and create impactful business strategies.

Contact Us:

IMARC Group

134 N 4th St., Brooklyn, NY 11249, USA

Email: sales[@]imarcgroup.com

Tel No:(D) +91 120 433 0800

United States: (+1-201971-6302)

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Is a Furfural Plant Profitable? Full CAPEX/OPEX Analysis & ROI Guide here

News-ID: 4316269 • Views: …

More Releases from IMARC Group

India Robotic Sensors Market Growing at 7.75% CAGR Through 2034, Driven by AI & …

Summary

The India robotic sensors market size reached USD 64.08 Million in 2025, according to the latest comprehensive industry analysis by IMARC Group. Fueled by robust government initiatives, escalating labor costs, and the rapid integration of artificial intelligence in industrial automation, the market is projected to reach USD 125.42 Million by 2034. This highlights a steady compound annual growth rate (CAGR) of 7.75% during the forecast period (2026-2034).

Request a Free Sample…

India Beer Market Size to Reach INR 832.93 Billion by 2034: Industry Trends, Gro …

Summary

The beer market size in india reached INR 477.05 Billion in 2025, according to the latest comprehensive industry analysis by IMARC Group. Driven by rapid urbanization, a burgeoning young demographic, and a massive cultural shift toward premium and craft beverages, the market is projected to reach INR 832.93 Billion by 2034. This represents a steady compound annual growth rate (CAGR) of 6.45% during the forecast period (2026-2034).

What are the Key…

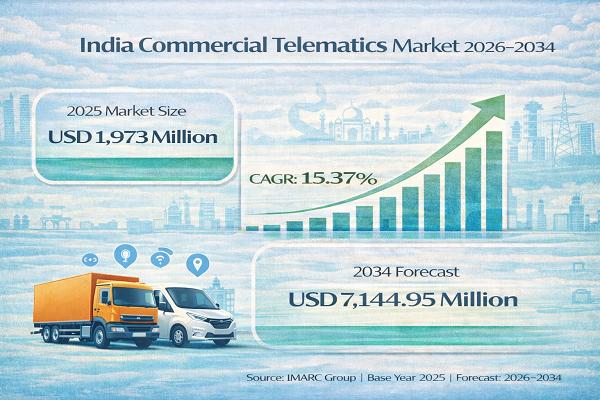

India Commercial Telematics Market Expected to Reach USD 7,144.95 Million by 203 …

India Commercial Telematics Market : Report Introduction

According to IMARC Group's report titled "India Commercial Telematics Market Size, Share, Trends and Forecast by Type, System Type, Provider Type, End Use Industry, and Region, 2026-2034" the report offers a comprehensive analysis of the industry, including market share, growth, trends, and regional insights.

Free Sample Download PDF (Exclusive Offer on Corporate Email): https://www.imarcgroup.com/india-commercial-telematics-market/requestsample

Commercial Telematics Market in India : Overview (2026-2034)

The India commercial telematics market…

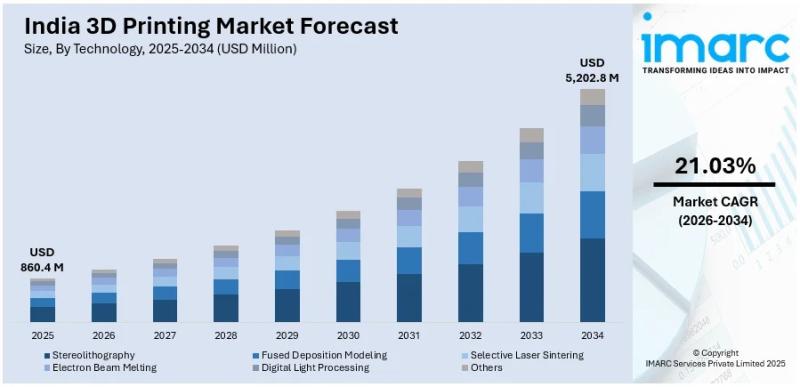

India 3D Printing Market Growing at 21.03% CAGR Through 2034, Led by Healthcare …

Summary

The 3d printing market size in india reached USD 860.4 Million in 2025, according to the latest comprehensive industry analysis by IMARC Group. Fueled by the rapid adoption of additive manufacturing across the aerospace, healthcare, and construction sectors, along with strong government backing for digital manufacturing, the market is projected to reach an impressive USD 5,202.8 Million by 2034. This represents a massive compound annual growth rate (CAGR) of 21.03%…

More Releases for Furfural

Furfural Solvent Market: A Comprehensive Overview

The global market for furfural solvent has been experiencing notable growth, driven by its diverse industrial applications and sustainability advantages. Furfural, an organic compound derived from agricultural byproducts, primarily plays a significant role in the chemical industry as a solvent and intermediate. As industries continue to seek environmentally friendly alternatives to conventional solvents, the demand for furfural is expected to rise. In this post, we will explore the furfural solvent…

Furfural Market Surges as Industries Embrace Sustainable Chemical Solutions | In …

The global furfural market was valued at $1.2 billion in 2019 and is projected to reach $2.0 billion by 2027, growing at a CAGR of 6.9% from 2020 to 2027, according to a new report published by Allied Market Research. The report provides a comprehensive analysis of market size & estimations, top winning strategies, value chain analysis, business performance, major segments, and competitive landscape.

𝗗𝗼𝘄𝗻𝗹𝗼𝗮𝗱 𝗣𝗗𝗙 𝗕𝗿𝗼𝗰𝗵𝘂𝗿𝗲: https://www.alliedmarketresearch.com/request-sample/1819

In 2019, the rice…

Furfural Solvent Market 2021 Status and Growth Outlook - Alchem Chemical Co., Fu …

The Furfural Solvent Market report is a compilation of first-hand information, qualitative and quantitative assessment by industry analysts, inputs from industry experts and industry participants across the value chain. The report provides in-depth analysis of parent market trends, macro-economic indicators and governing factors along with market attractiveness as per segments. The report also maps the qualitative impact of various market factors on market segments and geographies.

The furfural solvent market is…

Global Furfural Derivatives Market Snapshot Upto 2024

The global furfural derivatives market is characterized by the presence of several industry giants and is set to witness the rise in both large and small enterprises. Transparency Market Research (TMR) recently compiled a business intelligence report that distinguishes the market by names such as Hongye Chemical Co Ltd., Avantium, Ashland Inc., Mitsubushi Chemical and DynaChem Inc. The market is predicted to witness high level of competition, compelling the market…

Furfural Market Set to Boom 2018

Furfural Market Report, published by Allied Market Research, forecasts that the global market is expected to reach $1,434 million by 2022 from $663 million in 2015, with a CAGR of 11.6%. Furfural based on corn cob and sugarcane bagasse raw materials together accounted for half of the market share in 2015, in terms of revenue.

The economic development in emerging economies is expected to boost the demand for furfural during the…

Furfural Derivatives Market - Evolving Industry Trends 2024

The global furfural derivatives market has been prophesied by Transparency Market Research (TMR) to arrive at a situation where the degree of rivalry could stay high all through the course of the forecast period 2016–2024. The competition in the world market could intensify on account of a growing number of small and large players making their presence known in the furfural derivatives industry. Pricing has had its part played in…