Press release

Metal Sheet Bending Machine Market Projected to Reach US$1.14 Bn by 2031, Says Persistence Market Research

The global metal sheet bending machine market forms a vital segment of the metal fabrication and manufacturing ecosystem, supporting industries that rely on precision-formed sheet metal components. Metal sheet bending machines are used to shape flat metal sheets into complex angles and geometries through controlled bending processes, making them indispensable in sectors such as automotive, aerospace, construction, electronics, and industrial machinery manufacturing. These machines enable manufacturers to achieve consistent accuracy, repeatability, and efficiency, especially as production demands grow increasingly complex and quality-driven.Download Free Sample & Check the Latest Market Analysis: https://www.persistencemarketresearch.com/samples/34435

From a market valuation standpoint, the global market for metal sheet bending machines is projected to be worth US$0.94 billion in 2024 and is expected to surpass US$1.14 billion by 2031, expanding at a CAGR of 3.5% during the forecast period. Market growth is primarily driven by rising demand for fabricated metal components, expanding industrialization in emerging economies, and the gradual shift toward automated and CNC-enabled bending solutions. Among product segments, CNC press brake machines represent the leading category due to their high precision, programmability, and suitability for mass production. Geographically, Asia Pacific dominates the market, supported by strong manufacturing activity, rapid infrastructure development, and a robust automotive and electronics production base in countries such as China, India, and Japan.

Key Highlights from the Metal Sheet Bending Machine Market Report

• The global metal sheet bending machine market is expected to exceed US$1.14 billion by 2031.

• Market growth is supported by increasing demand for precision metal fabrication across industries.

• CNC and automated bending machines account for the largest share of total market revenue.

• Asia Pacific remains the leading regional market due to large-scale manufacturing expansion.

• Automotive and construction sectors are the primary end-users of metal sheet bending machines.

• Technological advancements are enhancing machine accuracy, speed, and energy efficiency.

Market Segmentation Analysis

The metal sheet bending machine market is segmented based on machine type, operation mode, material type, and end-user industry, each influencing purchasing decisions and adoption trends. By machine type, the market includes press brakes, folding machines, panel benders, and roll bending machines. Press brakes dominate the segment due to their versatility, ability to handle a wide range of materials and thicknesses, and suitability for both small-batch and large-scale production. Folding machines and panel benders are gaining traction in applications requiring high-speed production and minimal manual handling, particularly in HVAC and enclosure manufacturing.

Based on operation mode, the market is divided into manual, hydraulic, pneumatic, and CNC-controlled machines. CNC metal sheet bending machines hold the largest market share, driven by their precision, programmability, and ability to reduce human error. These machines are widely adopted in high-volume manufacturing environments where consistency and repeatability are critical. Hydraulic machines continue to be preferred for heavy-duty applications involving thicker metal sheets, while manual and pneumatic machines remain relevant in small workshops and low-volume production settings.

Get a Customized Market View in One Click : https://www.persistencemarketresearch.com/request-customization/34435

In terms of end-user industries, automotive manufacturing represents a major share of the market, as vehicle production relies heavily on precisely bent metal components for structural and aesthetic applications. The construction industry also contributes significantly, driven by demand for metal frames, panels, and architectural components. Aerospace, electronics, shipbuilding, and industrial equipment manufacturing further support market growth, as these sectors increasingly require customized and high-precision metal parts to meet stringent performance standards.

Regional Insights and Market Performance

Regionally, Asia Pacific leads the global metal sheet bending machine market, driven by rapid industrialization, expanding manufacturing hubs, and increasing investments in infrastructure and transportation projects. China remains the largest contributor in the region, supported by its strong metal fabrication industry and extensive use of automated machinery. India is emerging as a high-growth market, fueled by government initiatives promoting domestic manufacturing, infrastructure development, and industrial modernization. Japan and South Korea also contribute significantly due to their advanced manufacturing capabilities and focus on precision engineering.

North America represents a mature yet steadily growing market, supported by technological advancements and the modernization of existing fabrication facilities. The United States leads regional demand, driven by the automotive, aerospace, and industrial machinery sectors. Manufacturers in the region are increasingly adopting CNC-enabled and energy-efficient bending machines to improve productivity and reduce operating costs. Europe follows closely, with strong demand from automotive and industrial manufacturing hubs in Germany, Italy, and France. The region's emphasis on sustainable manufacturing and automation continues to influence equipment upgrades. Meanwhile, Latin America and the Middle East & Africa are witnessing gradual growth, supported by expanding construction activity, infrastructure projects, and increasing adoption of metal fabrication technologies.

Market Drivers Supporting Industry Growth

One of the primary drivers of the metal sheet bending machine market is the growing demand for fabricated metal components across a wide range of industries. As product designs become more complex and customized, manufacturers require advanced bending machines capable of delivering high precision and consistency. The expansion of automotive production, particularly electric vehicles, has further increased demand for lightweight and precisely formed metal components.

Another key driver is the increasing adoption of automation and CNC technologies in metal fabrication. CNC bending machines enhance productivity by reducing setup time, minimizing material waste, and improving overall operational efficiency. These systems also address labor shortages by reducing reliance on skilled manual operators. Additionally, rising investments in infrastructure development and industrial manufacturing in emerging economies are driving demand for metal sheet bending machines, as these projects require large volumes of fabricated metal parts.

Market Restraints Limiting Expansion

Despite steady growth prospects, the metal sheet bending machine market faces several restraints that may limit adoption in certain regions. One of the main challenges is the high initial cost of advanced CNC and automated machines, which can be prohibitive for small and medium-sized enterprises. The cost of installation, maintenance, and skilled operator training further adds to the total cost of ownership.

Another restraint is the relatively slow replacement cycle of metal fabrication equipment. Many manufacturers continue to operate older machines as long as they remain functional, delaying new purchases. Additionally, fluctuations in raw material prices and uncertainty in global manufacturing output can impact capital expenditure decisions, particularly during periods of economic slowdown. Limited awareness of advanced bending technologies in developing regions may also slow market penetration.

Click to Purchase the Full Report & Start Exploring : https://www.persistencemarketresearch.com/checkout/34435

Market Opportunities and Emerging Trends

The metal sheet bending machine market presents notable opportunities driven by the growing emphasis on smart manufacturing and Industry 4.0 integration. Manufacturers are increasingly adopting machines equipped with digital controls, real-time monitoring, and predictive maintenance capabilities to optimize production efficiency. These technologies enable better machine utilization, reduced downtime, and improved quality control.

Another significant opportunity lies in the rising demand for customized and low-volume production. As industries shift toward flexible manufacturing models, demand for versatile bending machines capable of handling diverse designs and materials is increasing. Additionally, growth in renewable energy, electric vehicles, and lightweight construction materials is expected to create new application areas for metal sheet bending machines. Emerging markets with expanding manufacturing bases also offer long-term growth potential, particularly as governments promote industrial automation and domestic production capabilities.

Company Insights and Competitive Landscape

The global metal sheet bending machine market is moderately competitive, with established manufacturers focusing on innovation, automation, and global expansion to strengthen their market position. Companies are investing in R&D to develop machines with enhanced precision, energy efficiency, and digital integration.

• TRUMPF Group

• Amada Co., Ltd.

• Bystronic Group

• LVD Group

• Salvagnini Italia S.p.A.

• Prima Industrie S.p.A.

• Durma Machinery

• Yawei Machine Tool Co., Ltd.

• ERMAKSAN

• Haco Group

Recent developments in the market include the launch of advanced CNC press brakes with improved control systems and automation features designed to support smart factory environments. Additionally, several manufacturers have expanded their production facilities and service networks in Asia Pacific to cater to rising demand from emerging manufacturing hubs.

Related Reports:

https://www.persistencemarketresearch.com/market-research/magnetic-separators-market.asp

https://www.persistencemarketresearch.com/market-research/land-survey-equipment-market.asp

https://www.persistencemarketresearch.com/market-research/carbon-brush-market.asp

https://www.persistencemarketresearch.com/market-research/construction-aggregates-market.asp

https://www.persistencemarketresearch.com/market-research/drilling-machines-market.asp

Persistence Market Research

Second Floor, 150 Fleet Street, London, EC4A 2DQ, United Kingdom

USA Phone: +1 646-878-6329

UK Phone: +44 203-837-5656

Email: sales@persistencemarketresearch.com

Web:

https://www.persistencemarketresearch.com

About Persistence Market Research:

At Persistence Market Research, we specialize in creating research studies that serve as strategic tools for driving business growth. Established as a proprietary firm in 2012, we have evolved into a registered company in England and Wales in 2023 under the name Persistence Research & Consultancy Services Ltd. With a solid foundation, we have completed over 3600 custom and syndicate market research projects, and delivered more than 2700 projects for other leading market research companies' clients.

Our approach combines traditional market research methods with modern tools to offer comprehensive research solutions. With a decade of experience, we pride ourselves on deriving actionable insights from data to help businesses stay ahead of the competition. Our client base spans multinational corporations, leading consulting firms, investment funds, and government departments. A significant portion of our sales comes from repeat clients, a testament to the value and trust we've built over the years.

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Metal Sheet Bending Machine Market Projected to Reach US$1.14 Bn by 2031, Says Persistence Market Research here

News-ID: 4316184 • Views: …

More Releases from Persistence Market Research

India Aluminum Beverage Can Market Size to Reach US$ 0.8 Bn by 2032 - Persistenc …

The India aluminum beverage can market is undergoing a significant transformation, driven by changing consumer lifestyles, rising urbanization, and a noticeable shift toward sustainable and convenient packaging formats. Aluminum beverage cans are increasingly preferred across carbonated soft drinks, energy drinks, sports beverages, alcoholic drinks, and ready-to-drink juices due to their lightweight structure, portability, fast chilling properties, and superior recyclability. In India, where on-the-go consumption is accelerating rapidly, aluminum cans are…

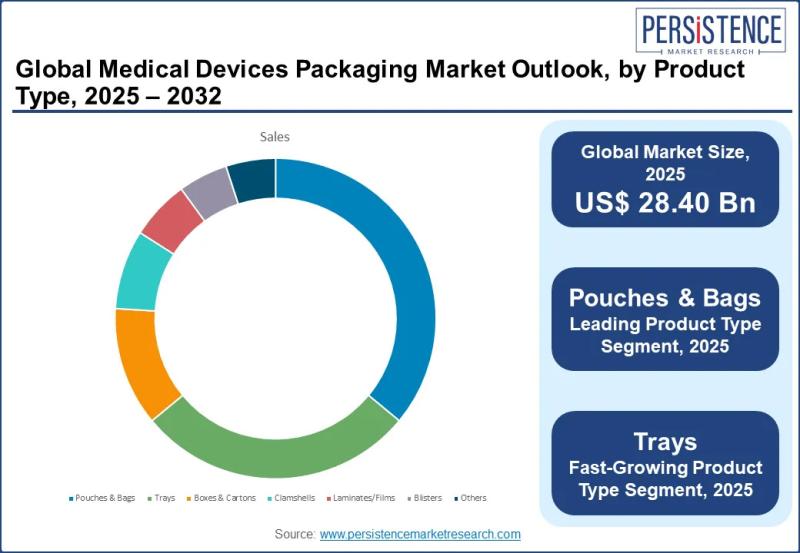

Medical Devices Packaging Market Size to Reach US$ 41.57 Billion by 2032 - Persi …

The medical devices packaging market plays a vital role within the global healthcare ecosystem, acting as a protective and regulatory bridge between manufacturers and end users. Medical device packaging refers to specialized materials and formats designed to safeguard medical instruments, implants, diagnostic tools, and consumables throughout storage, transportation, and clinical use. These packaging solutions are engineered to maintain sterility, prevent contamination, ensure ease of handling, and comply with strict regulatory…

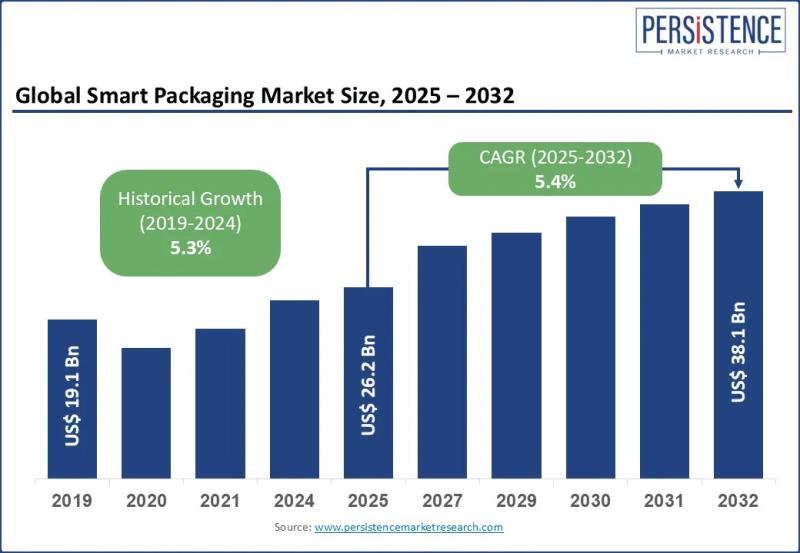

Smart Packaging Market Size Valued at US$ 26.2 Bn in 2025, Projected to Reach US …

The smart packaging market is rapidly transforming the global packaging landscape by integrating advanced technologies with traditional packaging materials to deliver enhanced functionality, traceability, and consumer engagement. Smart packaging refers to packaging systems embedded with features such as sensors indicators QR codes RFID tags and data tracking mechanisms that monitor product condition authenticity and movement across the supply chain. These solutions are increasingly adopted as businesses shift from passive containment…

Football Equipment Market Set for Strong Global Growth Through 2032

The global football equipment market continues to display resilient growth driven by rising participation in football across all age groups, expanding commercial opportunities, and technological advancements in sports gear. The industry is expected to grow from an estimated US$ 18.7 billion in 2025 to approximately US$ 24.1 billion by 2032, registering a compound annual growth rate (CAGR) of 3.7% over the forecast period.

➤ Download Your Free Sample & Explore Key…

More Releases for CNC

XTJ CNC Elevates Custom CNC Machining for Highly Precise Industrial Applications

Carmel, IN 46032, United States, 28th Jan 2026 - XTJ CNC, a prominent provider of custom CNC machining servicesa prominent provider of custom CNC machining services, has announced significant advancements in its capabilities to better serve industries requiring high-precision components. With a focus on custom CNC machining, the company is reinforcing its reputation as a trusted partner in the aerospace, automotive, and electronics sectors. These advancements reflect XTJ CNC's commitment…

Benefits of CNC Machining for Custom Robotic Projects - Tuofa CNC Machining

Robotics is evolving quickly, and higher-performance robots demand stronger mechanical consistency. As DOF increases, joint stacks and mounting interfaces must align accurately to preserve smooth, repeatable motion. CNC machining delivers custom parts with controlled dimensions and reliable quality, reducing fit issues during assembly. It also shortens prototype cycles and supports small-batch production, helping robotics teams convert designs into dependable hardware.

Robotics is getting smarter and smarter. Better perception, smarter control loops,…

CNC Controller Market Report 2024 - CNC Controller Market Trends, Opportunities …

"The Business Research Company recently released a comprehensive report on the Global CNC Controller Market Size and Trends Analysis with Forecast 2024-2033. This latest market research report offers a wealth of valuable insights and data, including global market size, regional shares, and competitor market share. Additionally, it covers current trends, future opportunities, and essential data for success in the industry.

Ready to Dive into Something Exciting? Get Your Free Exclusive Sample…

CNC Controller Global Market to Generate $3.84 Billion By 2028, Registering at a …

"The new report published by The Business Research Company, titled CNC Controller Global Market Report 2024 - Market Size, Trends, And Global Forecast 2024-2033, delivers an in-depth analysis of the leading size and forecasts, investment opportunities, winning strategies, market drivers and trends, competitive landscape, and evolving market trends.

As per the report, the cnc controller market size has grown strongly in recent years. It will grow from $2.82 billion…

Silver CNC Now Offers CNC Rotary Tables for CNC Machining Centers

Silver CNC is now offering a new line of CNC rotary tables that are perfect for use with CNC machining centers. The rotary tables are available in three different sizes, and each one is made from high-quality cast iron to ensure durability and precision. With a built-in indexing system, the rotary tables make it easy to position your workpiece exactly where you need it. Plus, they're backed by a full…

Trending 2020: CNC Machine (CNC Machine Tools) Market Booming Worldwide

Prophecy Market Insights recently presented CNC Machine (CNC Machine Tools) market report which provides reliable and sincere insights related to the various segments and sub-segments of the market. The market study throws light on the various factors that are projected to impact the overall dynamics of the CNC Machine (CNC Machine Tools) market over the forecast period (2019-2029).

The CNC Machine (CNC Machine Tools) research study contains 100+ market data Tables,…