Press release

Offshore Oil & Gas Welding Market Poised to Reach USD 6.1 Bn by 2034 as Robotic Welding and Infrastructure Investments Accelerate Adoption | TMR

The global offshore oil & gas welding market stood at US$ 3.3 Bn in 2023. Driven by intensifying offshore infrastructure development, rising adoption of robotic welding technologies, and sustained investments in offshore exploration, the market is projected to reach US$ 6.1 Bn by 2034, expanding at a robust CAGR of 5.9% from 2024 to 2034.With welding technologies playing a pivotal role in the construction, repair, and maintenance of offshore drilling platforms, subsea structures, and long-distance pipelines, the market continues to evolve through modernization, automation, and material advancements.

Access key findings and insights from our Report in this sample -

https://www.transparencymarketresearch.com/sample/sample.php?flag=S&rep_id=86056

Market Overview

The offshore oil & gas welding market forms a foundational pillar of the global energy extraction ecosystem, particularly in the context of offshore exploration and production. Welding operations underpin the development of high-strength, corrosion-resistant structures capable of withstanding harsh marine environments, deepwater pressures, and extended operational lifecycles.

Offshore welding activities typically span three critical forms:

On-board welding

Dry-dock welding

Underwater welding

Each of these welding environments requires tailored methodologies, specialized materials, and advanced technologies.

Modern welding techniques such as Arc Welding, Resistance Welding, Oxy-fuel Welding, Laser Welding, FCAW (Flux-Cored Arc Welding), and SAW (Submerged Arc Welding) are increasingly deployed to support critical works on offshore rigs, subsea pipelines, and FPSO units.

FCAW is gaining traction for its superior deposition rates and arc stability, while SAW's minimal fume generation and deep penetration capabilities make it suitable for large subsea and topside structures.

Furthermore, automatic welding systems and robot-guided welding solutions are redefining the operational efficiency of offshore fabrication. Robotic systems integrated with laser-vision sensing and AI-enhanced controls dramatically improve accuracy, reduce human risk, and enable welding in hazardous or hard-to-reach areas.

With offshore energy demand remaining high, technological adoption, enhanced repair cycles, and intensified exploration activities are collectively propelling market transformation.

Key Market Growth Drivers

1. Rise in Investment in Oil & Gas Infrastructure

Global demand for energy security is prompting nations to accelerate offshore exploration and production activities. This renewed commitment to energy independence and offshore development provides a significant boost to the market.

Offshore infrastructure-ranging from rigs to subsea production systems-requires extensive welding at every stage.

Upstream development projects, long-distance pipeline installations, and subsea platform expansions are major contributors to welding demand.

Numerous multinational companies are allocating substantial budgets to offshore development, further enhancing market prospects.

A notable example includes Vedanta's US$ 4 Bn investment (announced in February 2024) aimed at doubling oil & gas production. Such large-scale initiatives directly amplify the need for advanced welding processes, materials, and automation.

2. Increasing Adoption of Robotic Welding Solutions

The shift toward robotic and automated welding systems is one of the most transformative market forces today.

Drivers include:

Rising need for precision in deepwater and harsh-environment welding

Growing emphasis on speed, accuracy, and consistency

Increased repair and maintenance requirements to reduce downtime

Heightened focus on safety and access to difficult areas

Robotic welding systems-equipped with real-time vision sensing, AI-enabled analytics, and adaptive control-enhance operational throughput, reduce human risk, and offer superior weld quality.

One notable development was the launch of MR4WELD, a mobile robotic welding solution introduced by Comau and Fincantieri in 2023, designed for heavy-duty steel welding during vessel construction. Its potential application across offshore structures signals strong technological evolution in the sector.

Explore our report to uncover in-depth insights -

https://www.transparencymarketresearch.com/offshore-oil-and-gas-welding-market.html

Analysis of Key Players - Key Player Strategies

The competitive landscape of the offshore oil & gas welding market is shaped by companies that emphasize quality, performance, material innovation, and automation.

Key Leading Players

ESAB

Lincoln Electric

Miller Electric Mfg. LLC

Fronius International GmbH

Hypertherm Inc.

These companies focus on offering specialized welding consumables, high-strength filler materials, robust welding equipment, and automation-ready welding platforms tailored for the offshore sector.

Core Strategies Among Market Leaders

Material Innovation

Companies are developing low-hydrogen consumables suitable for high-strength steel welding in deepwater and corrosive conditions.

Automation and Robotics

Integration of AI-based system monitoring, adaptive welding controls, and advanced seam-tracking technologies.

Expansion of Product Portfolios

Development of versatile welding systems capable of performing in dry-dock, underwater, and topside environments.

Deepening Regional Reach

Strengthening sales networks in North America, the Middle East, and Asia Pacific due to increasing offshore investments.

Continuous R&D for Extreme Environments

Exploration of new alloy compositions and coatings that improve corrosion resistance and fatigue performance.

Market Challenges & Opportunities

Challenges

Harsh Offshore Environments

Extreme temperatures, deepwater pressures, and corrosive seawater pose challenges to weld durability.

High Operational Costs

Offshore welding requires specialized equipment, skilled welders, and rigorous quality control practices.

Safety Risks

Human welders face substantial risk during underwater and topside welding on unstable rigs.

Skills Shortage

A shortage of qualified welders experienced in underwater and robotic welding can limit growth.

Opportunities

Rapid Expansion of Deepwater Exploration

Growing investments in untapped deepwater reserves increase demand for advanced welding capabilities.

Adoption of Robotic and AI-Based Solutions

Automated systems reduce operational costs, safety risks, and repair downtime.

Advanced Materials Development

New high-strength, corrosion-resistant alloys create long-term value for offshore structures.

Rising Maintenance and Repair Cycles

Aging offshore rigs increase demand for welding repair and refurbishment services.

Technological Convergence

Integration of sensing technologies, simulation-based weld design, and real-time monitoring.

Key Player Strategies

To maintain competitiveness and market growth, leading companies are adopting forward-looking strategies:

1. Strategic Collaborations

Partnerships between automation companies, material providers, and offshore contractors help accelerate innovation and deployment.

2. Product Customization for Offshore Needs

Companies tailor their welding consumables and equipment for harsher marine operations and deeper subsea structures.

3. Focus on Efficiency & Sustainability

Energy-efficient welding technologies and low-fume processes such as SAW are being promoted.

4. Training & Skill Development

Improving workforce competency in robotic and advanced welding techniques.

5. Investment in High-Strength Alloys

The introduction of alloys such as SAF 3007 exemplifies next-generation materials engineered for deepwater umbilicals and subsea components.

Recent Developments

February 2024: Alleima introduced SAF 3007, a super-duplex stainless steel alloy engineered for subsea umbilicals, offering improved performance over SAF 2507 in extreme offshore conditions.

2023: Comau and Fincantieri showcased MR4WELD, a mobile robotic welding solution designed for large-scale steel welding and suitable for offshore applications.

2022: Express Engineering announced major investments in precision welding capabilities specifically targeted toward offshore and subsea equipment manufacturing.

These developments reflect the market's shift toward enhanced performance, automation, and material innovation.

Investment Landscape and ROI Outlook

The offshore oil & gas welding market presents a highly attractive investment opportunity driven by:

Consistent global demand for offshore crude and natural gas

Technological advancements that reduce welding errors and improve efficiency

High-value capital expenditure cycles in major oil-producing regions

Rising focus on deepwater and ultra-deepwater development

Investors are likely to benefit from:

Stable long-term revenue streams linked to multi-year exploration projects

Growing demand for advanced consumables and automation systems

Reduced risk exposure through diversification into repair and maintenance services

The ROI outlook remains strong, especially in regions actively expanding offshore production capabilities, such as North America, the Middle East, and Asia Pacific.

Market Segmentations (with Region)

By Welding Type

Arc Welding

Resistance Welding

Oxy-fuel Welding

Laser Welding

Others

By Application

Upstream

Midstream

Downstream

By Region

North America

U.S.

Canada

Europe

Germany

U.K.

France

Italy

Asia Pacific

China

Japan

India

Latin America

Brazil

Mexico

Middle East & Africa

GCC

South Africa

North America remains the dominant market due to high natural gas production, extensive offshore infrastructure, and increasing exploration activities.

Why Buy This Report?

Gain deep insights into market size, historical trends, and future forecasts.

Analyze key growth drivers, market challenges, and emerging opportunities.

Understand competitive strategies of leading welding equipment and consumable manufacturers.

Access regional market breakdowns for targeted investment decisions.

Evaluate the technological evolution in offshore welding, including automation and advanced materials.

Discover recent developments shaping the market landscape.

Obtain a clear perspective on the ROI potential and long-term market outlook.

Get comprehensive segmentation analysis for accurate market targeting.

Benefit from a strategic tool ideal for manufacturers, investors, offshore contractors, and industry consultants.

Buy this Premium Research Report for exclusive, in-depth insights -

https://www.transparencymarketresearch.com/checkout.php?rep_id=86056<ype=S

FAQs

1. What is the projected market size of the offshore oil & gas welding market by 2034?

The market is expected to reach US$ 6.1 Bn by 2034, growing at a CAGR of 5.9%.

2. What are the major welding types used in offshore oil & gas operations?

Key welding types include Arc Welding, Resistance Welding, Oxy-fuel Welding, Laser Welding, and additional advanced methods like FCAW and SAW.

3. Which regions show the highest market potential?

North America leads due to strong oil and natural gas production, followed by Europe, Asia Pacific, and the Middle East & Africa.

4. What factors are driving growth in the offshore oil & gas welding market?

Growth is driven by rising investments in offshore infrastructure, increasing adoption of automated and robotic welding technologies, and expanding deepwater exploration projects.

5. Who are the key players in this market?

Major companies include ESAB, Lincoln Electric, Miller Electric, Fronius International, and Hypertherm Inc.

Explore Latest Research Reports by Transparency Market Research:

Aviation Battery Market - https://www.transparencymarketresearch.com/aviation-battery-market.html

Micro‐ and Nano‐Silicon‐Based Battery Market - https://www.transparencymarketresearch.com/micro-and-nano-silicon-based-battery-market.html

Power Transmission and Distribution EPC Market - https://www.transparencymarketresearch.com/power-transmission-and-distribution-epc-market.html

Ammonia Energy Market - https://www.transparencymarketresearch.com/ammonia-energy-market.html

About Transparency Market Research

Transparency Market Research, a global market research company registered at Wilmington, Delaware, United States, provides custom research and consulting services. Our exclusive blend of quantitative forecasting and trends analysis provides forward-looking insights for thousands of decision makers. Our experienced team of Analysts, Researchers, and Consultants use proprietary data sources and various tools & techniques to gather and analyses information.

Our data repository is continuously updated and revised by a team of research experts, so that it always reflects the latest trends and information. With a broad research and analysis capability, Transparency Market Research employs rigorous primary and secondary research techniques in developing distinctive data sets and research material for business reports.

Contact:

Transparency Market Research Inc.

CORPORATE HEADQUARTER DOWNTOWN,

1000 N. West Street,

Suite 1200, Wilmington, Delaware 19801 USA

Tel: +1-518-618-1030

USA - Canada Toll Free: 866-552-3453

Website: https://www.transparencymarketresearch.com

Email: sales@transparencymarketresearch.com

Follow Us: LinkedIn| Twitter| Blog | YouTube

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Offshore Oil & Gas Welding Market Poised to Reach USD 6.1 Bn by 2034 as Robotic Welding and Infrastructure Investments Accelerate Adoption | TMR here

News-ID: 4311909 • Views: …

More Releases from Transparency Market Research

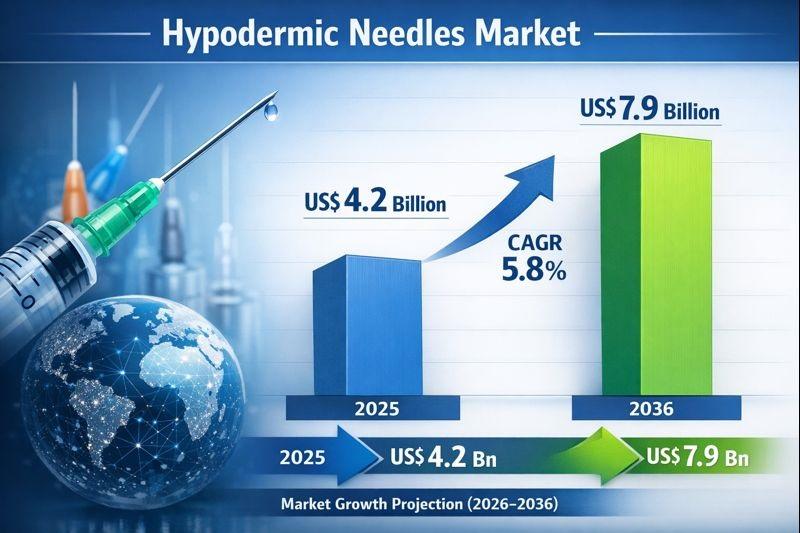

Hypodermic Needles Market to Reach US$ 7.9 Billion by 2036 on Rising Injectable …

The global hypodermic needles market was valued at approximately US$ 4.2 billion in 2025 and is projected to reach around US$ 7.9 billion by 2036, expanding at a CAGR of nearly 5.8% from 2026 to 2036, driven by the rising prevalence of diabetes, cancer, and chronic diseases, growing demand for injectable drugs and biologics, and the expansion of global vaccination and immunization programs; increasing adoption of safety-engineered and disposable needles,…

Connected Car Market to Reach US$ 467.2 Billion by 2036, Driven by Rising Adopti …

The global connected car market is entering a high-growth phase as vehicles increasingly evolve into software-defined, data-driven mobility platforms. Valued at US$ 100.8 billion in 2025, the market is projected to reach an impressive US$ 467.2 billion by 2036, expanding at a robust CAGR of 12.3% from 2026 to 2036. This growth is fueled by rapid advancements in automotive connectivity, rising consumer demand for intelligent features, and strong integration of…

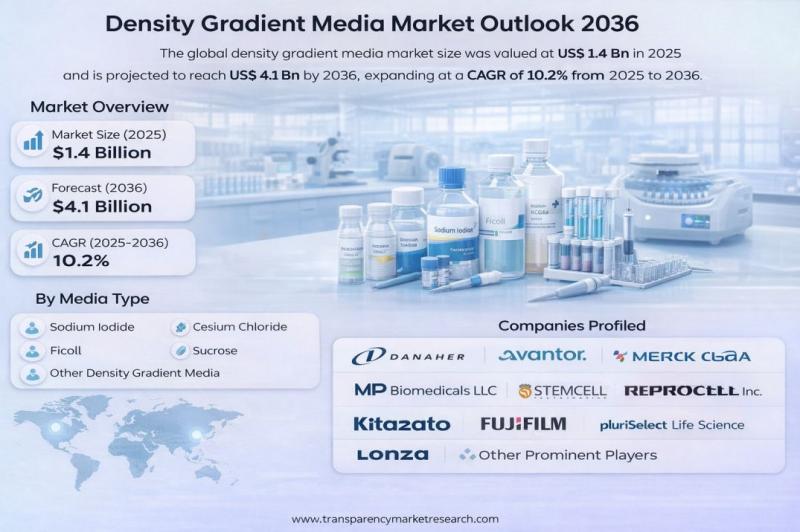

Density Gradient Media Market to Reach US$ 4.1 Billion by 2036, Driven by Rapid …

The global density gradient media market was valued at US$ 1.4 Billion in 2025 and is projected to reach US$ 4.1 Billion by 2036, expanding at a robust CAGR of 10.2% from 2025 to 2036. The market's rapid growth is primarily driven by increasing demand for rapid infectious disease screening, expanding cell therapy and immunology research, and continuous technological advancements improving sensitivity and multiplexing in laboratory workflows.

Access key findings and…

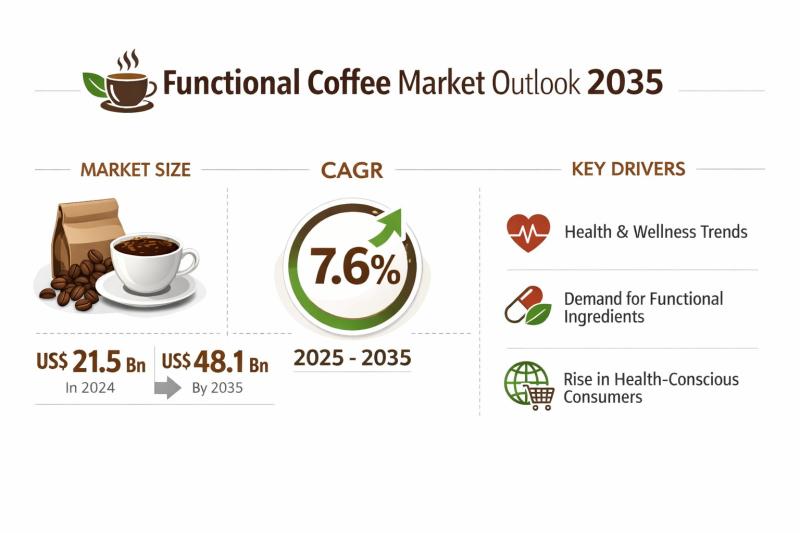

Functional Coffee Market Expanding at 7.6% CAGR Through 2035 - By Product Type / …

The global functional coffee market was valued at US$ 21.5 Bn in 2024 and is projected to reach US$ 48.1 Bn by 2035, expanding at a compound annual growth rate (CAGR) of 7.6% from 2025 to 2035. This steady growth trajectory reflects the strong convergence of coffee consumption habits with rising demand for functional and wellness-oriented beverages. Functional coffee has transitioned from a niche category to a mainstream product offering,…

More Releases for Welding

Welding Consumables Market to Witness Unbelievable Growth from 2024 to 2030: Ged …

The latest survey on Welding Consumables Market is conducted to provide hidden gems performance analysis of Welding Consumables to better demonstrate competitive environment. The study is a mix of quantitative market stats and qualitative analytical information to uncover market size revenue breakdown by key business segments and end-use applications. The report bridges the historical data from 2019 to 2023 and forecasted till 2030. The outbreak of the latest scenario in…

EMEA Welding Consumables Market | welding supplies, welding machine, welding equ …

Market Research Reports Search Engine (MRRSE) has been serving as an active source to cater intelligent research report to enlighten both readers and investors. This research study titled “Welding Equipment and Welding Services Market “

The welding industry comprises welding equipment, welding consumables and welding services. Welding consumables account for a significant share of the welding industry compared to welding equipment and welding services. The welding consumables industry has been experiencing…

EMEA Welding Consumables Market | welding supplies, welding machine, welding equ …

Market Research Reports Search Engine (MRRSE) has been serving as an active source to cater intelligent research report to enlighten both readers and investors. This research study titled “Welding Equipment and Welding Services Market “

The welding industry comprises welding equipment, welding consumables and welding services. Welding consumables account for a significant share of the welding industry compared to welding equipment and welding services. The welding consumables industry has been experiencing…

Electric Welding Clamp Market 2018 Shandong Solid Solider, Shandong Juli Welding …

Global Electric Welding Clamp market 2018 by ReportsQuest presents a professional and complete analysis of on the current Industry situation. The Global report includes Electric Welding Clamp Revenue, market Share, industry volume, Trends, Growth aspects. It analyses the important factors of the based on present industry situations, demands, business strategies utilized by Electric Welding Clamp market players and the future prospects from various angles in detail. Industry analysis is a…

Global Welding Equipment Market: Arc welding, Resistant welding, Oxy fuel weldin …

MarketResearchReports.Biz adds “Global Welding Equipment Market 2016 Share, Size, Trends and Forecast to 2021 Market Research Report” reports to its database. This report provides a strategic analysis of the Welding Equipment market and the growth estimates for the forecasted period.

A comprehensive research report created through extensive primary research (inputs from industry experts, companies, stakeholders) and secondary research, the report aims to present the analysis of global welding equipment market on…

Global Welding Consumables Market 2017 - Lincoln Electric, Hyundai Welding, Colf …

Global Welding Consumables Market 2017, presents a professional and in-depth study on the current state of the Welding Consumables market globally, providing basic overview of Welding Consumables market including definitions, classifications, applications and industry chain structure, Welding Consumables Market report provides development policies and plans are discussed as well as manufacturing processes and cost structures. Welding Consumables market size, share and end users are analyzed as well as segment markets…