Press release

3D Printing Materials Market Outlook 2035: Rising to USD 41.1 Billion on the Back of Additive Manufacturing Expansion, Lightweight Material Demand, and Rapid Industrial Adoption

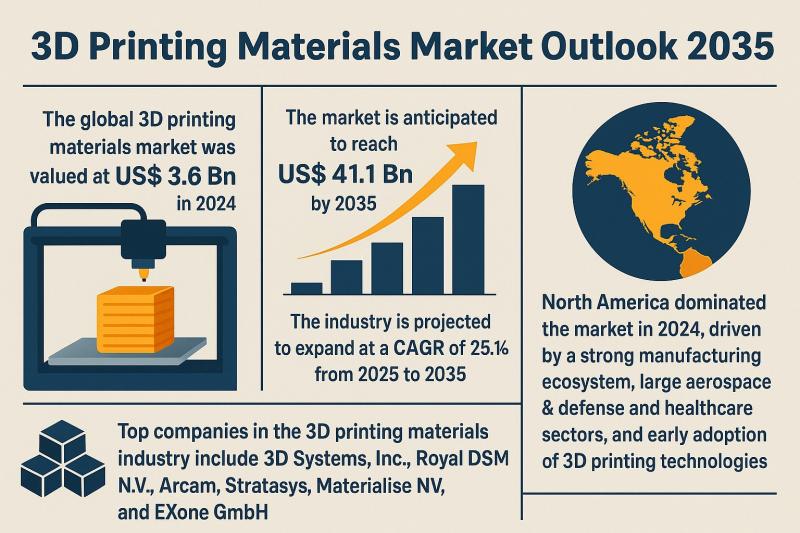

The global 3D printing materials market is entering a powerful growth phase, transforming from a niche supply segment into a central pillar of the global additive manufacturing ecosystem. Valued at US$ 3.6 Bn in 2024, the industry is projected to surge to US$ 41.1 Bn by 2035, expanding at a remarkable CAGR of 25.1% from 2025 to 2035. This strong upward trajectory is driven by increased applications across automotive, aerospace, healthcare, consumer goods, electronics, and industrial sectors. Advancements in polymers, metals, composites, bio-based materials, and engineering-grade thermoplastics are accelerating adoption and enabling 3D-printed parts to transition from prototyping to full-scale production.Discover Market Opportunities - Request Your Sample Copy Now: https://www.transparencymarketresearch.com/sample/sample.php?flag=S&rep_id=3605

Market Overview

The 3D printing materials market includes a wide spectrum of inputs used in additive manufacturing processes-polymers, metals, ceramics, composites, wood-based materials, and bio-derived resins. These materials enable prototyping, tooling, and end-use production across multiple industries.

The shift toward digital manufacturing and Industry 4.0 is pushing companies to adopt additive technologies for:

Rapid prototyping

Reduced waste and material optimization

Mass customization and personalization

Lightweighting and performance enhancement

On-demand manufacturing and decentralized production

Key 3D printing processes-FDM, SLA, SLS, PolyJet, DLP, MJF, and MSLA-use different classes of materials deposited or cured layer by layer, making it possible to achieve design accuracy that traditional manufacturing often cannot match.

Analysts' Viewpoint: Market Scenario Assessment

Market analysts observe that the 3D printing materials landscape is undergoing rapid material diversification and wider industrial acceptance. Additive manufacturing is progressively shifting from prototyping toward tooling and full-scale production, particularly in aerospace, automotive, and medical applications.

Growing demand for lightweight components, tighter regulatory requirements in aerospace, high customization in healthcare, and the push for automation in consumer goods are major catalysts. Analysts also highlight:

Strong manufacturer focus on high-performance polymers, composites, and recyclable materials.

Increasing collaboration between material science companies and printer OEMs to deliver integrated production solutions.

Robust R&D investments to improve heat resistance, strength, sustainability, and printability.

Key Market Growth Drivers

Growing Adoption in Automotive and Aerospace Industries

Automotive and aerospace remain the two most influential sectors driving material demand. Additive manufacturing enables:

Lightweight part development

Complex geometry design

Faster prototyping

Reduced tooling and manufacturing cost

Aerospace companies increasingly adopt metal powders, high-strength polymers, and composites to improve efficiency and minimize weight. Complex brackets, turbine components, and structural parts are now commonly produced using 3D-printed metals and engineering-grade thermoplastics.

In automotive, 3D printing supports:

On-demand replacement parts

Custom tooling

Performance-focused lightweight structures

Rapid design iterations for EVs and concept vehicles

Expansion in Consumer Goods and Electronics

Customization trends in consumer markets have accelerated additive

manufacturing adoption. Electronics manufacturers leverage 3D printing for:

Small-batch production

Connector housings

Sensor parts

Circuit board layout prototyping

Personalized consumer products-from footwear and eyewear to home décor-are increasingly created using specialized materials that enhance durability, surface finish, and aesthetic customization.

Material Science Advancements

Recent progress in high-temperature thermoplastics, biocompatible materials, recyclable resins, carbon-fiber composites, and metal powders is transforming the performance and applications of 3D printing.

Material development that enables precision, strength-to-weight optimization, chemical resistance, and sustainability is opening new industrial opportunities.

Market Challenges and Emerging Opportunities

Challenges

High cost of premium materials like carbon-fiber composites and metal powders

Quality variation, requiring rigorous process validation

Limited recycling infrastructure for polymers and composites

Regulatory complexities, particularly for medical and aerospace applications

Opportunities

Growing demand for sustainable and bio-based materials

Increased adoption of on-demand spare parts manufacturing

Rapid growth of 3D printing in construction and industrial tooling

Expanding opportunities in bioprinting and personalized medical care

Explore Strategies & Trends - Request Full Report Access - https://www.transparencymarketresearch.com/sample/sample.php?flag=S&rep_id=3605

Analysis of Key Players and Their Strategies

Prominent companies including Stratasys Ltd., 3D Systems Corporation, BASF SE, Arkema S.A., Hoganas AB, Materialise NV, and ExOne dominate the market with strong product portfolios and technological innovation.

Key Player Strategies

Innovation-led Material Development:

Stratasys and 3D Systems continually upgrade polymer and resin portfolios for prototyping and end-use manufacturing.

Partnerships and Collaborations:

Companies collaborate with aerospace, automotive, defense, and medical device manufacturers to deliver application-specific materials.

Sustainability Initiatives:

Arkema and BASF invest in bio-based resins, recyclable engineering plastics, and low-carbon materials.

Capacity Expansion and Regional Penetration:

Major players expand distribution networks and production capacity in Asia Pacific and Europe to meet rising demand.

Specialty Metal Powder Production:

Companies like Hoganas AB strengthen supply of highly specialized powders for aerospace and industrial manufacturing.

Recent Developments

In 2025, Stratasys released PolyJet ToughONETM White - a durable, impact-resistant material for functional prototyping and some end-use applications. It takes advantage of the benefits of classic PolyJet materials such as smooth surfaces, easy-to-use, multi-material capabilities and full color, and allows outputs to be drilled, milled, or self-tapping. With ToughONE, designers can achieve aesthetic realism and mechanical integrity, thereby allowing less design iterations on premium PolyJet platforms.

In 2023, Arkema established sustainability goals by beginning to manufacture bio-sourced high-performance materials and launching a recycling program (Virtucycle). During AMUG 2023, the company launched N3D-PR184-BIO, which is a UV resin containing 53% bio-renewable content.

During Formnext 2024 Arkema offered the bio-attributed resins at up to 84% USDA-certified bio-based resin content, and they achieved a meaningful carbon footprint reduction on their PA11, launched their recycling program, Virtucycle®, and another portfolio of UV-overcoatings for DLP and SLS applications, including flame-retardant and high-temperature suppliers.

Investment Landscape and ROI Outlook

The investment appeal of the 3D printing materials market is strengthening significantly as additive manufacturing becomes mainstream.

ROI is expected to rise due to:

Higher adoption of 3D printing in mass manufacturing

Strong revenue outlook through 2035

Increased government funding for industrial innovation

Expansion of healthcare 3D printing for implants, prosthetics, and surgical tools

Strong aerospace and automotive demand for advanced materials

Investors view the market as high-growth, innovation-driven, and resilient to traditional manufacturing cycles. Material companies with strong R&D pipelines and sustainable portfolios are particularly well positioned.

Market Segmentations

The 3D printing materials market is segmented by material type, form, technology, end-use industry, and region.

By Material Type

Includes plastics, resins, ceramics, metals, composites, wood, carbon fiber, graphene, concrete, and others.

By Form

Powders, filaments, and specialty forms.

By Technology

FDM, SLA, SLS, DLP, MSLA, MJF, PolyJet, and other additive processes.

By End-use

Automotive leads the market, followed by aerospace, healthcare, defense, consumer goods, industrial manufacturing, and construction.

Regional Segmentation

North America (Leading Region)

Driven by aerospace, healthcare, and defense sectors, along with robust R&D and favorable policies.

Europe

Strong adoption in automotive, industrial manufacturing, medical devices, and advanced research labs.

Asia Pacific

Fastest growth due to manufacturing expansion in China, Japan, India, and ASEAN countries.

Middle East & Africa

Emerging market with rising interest in construction 3D printing and industrial prototyping.

Latin America

Gradual adoption led by automotive manufacturing hubs and rising industrial digitization.

Why Buy This Report?

Gain comprehensive insights into a market projected to grow from US$ 3.6 Bn to US$ 41.1 Bn by 2035.

Understand competitive dynamics and strategies of leading manufacturers.

Identify high-growth opportunities across materials, technologies, and end-use industries.

Access detailed regional analysis covering North America, Europe, Asia Pacific, MEA, and Latin America.

Leverage expert analysis to support investment, expansion, and product development decisions.

Stay updated with latest market developments, sustainability trends, and material innovations.

FAQs: 3D Printing Materials Market

How big was the 3D printing materials market in 2024?

The market stood at US$ 3.6 Bn in 2024.

What is the forecasted growth rate of the market?

The market is projected to grow at a CAGR of 25.1% from 2025 to 2035.

What are the primary drivers behind market growth?

Adoption by automotive and aerospace industries, plus rising applications in consumer goods and electronics.

Which end-use segment dominated the market in 2024?

The automotive sector held the largest share.

Which region was the most lucrative in 2024?

North America was the leading revenue-generating region.

Buy Full Report Now: https://www.transparencymarketresearch.com/checkout.php?rep_id=3605<ype=S

Explore Latest Research Reports by Transparency Market Research:

Liquid Packaging Market: https://www.transparencymarketresearch.com/liquid-packaging-market.html

Insulation Materials Market: https://www.transparencymarketresearch.com/insulation-materials-market.html

Mobile Fuel Pumps Market: https://www.transparencymarketresearch.com/mobile-fuel-pumps-market.html

Contact Us:

Transparency Market Research Inc.

CORPORATE HEADQUARTER DOWNTOWN,

1000 N. West Street,

Suite 1200, Wilmington, Delaware 19801 USA

Tel: +1-518-618-1030

USA - Canada Toll Free: 866-552-3453

About Transparency Market Research

Transparency Market Research, a global market research company registered at Wilmington, Delaware, United States, provides custom research and consulting services. Our exclusive blend of quantitative forecasting and trends analysis provides forward-looking insights for thousands of decision makers. Our experienced team of Analysts, Researchers, and Consultants use proprietary data sources and various tools & techniques to gather and analyses information.

Our data repository is continuously updated and revised by a team of research experts, so that it always reflects the latest trends and information. With a broad research and analysis capability, Transparency Market Research employs rigorous primary and secondary research techniques in developing distinctive data sets and research material for business reports.

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release 3D Printing Materials Market Outlook 2035: Rising to USD 41.1 Billion on the Back of Additive Manufacturing Expansion, Lightweight Material Demand, and Rapid Industrial Adoption here

News-ID: 4310153 • Views: …

More Releases from Transparency Market Research

Wireless Earphone Market Size Forecast to USD 25.9 Billion by 2036 with Rising D …

Wireless Earphone Market Outlook 2036

The global wireless earphone market was valued at US$ 11.1 Billion in 2025 and is projected to reach US$ 25.9 Billion by 2036, expanding at a steady CAGR of 8.0% from 2026 to 2036. Market growth is driven by increasing smartphone penetration, rising demand for portable audio devices, advancements in Bluetooth technology, and growing consumer preference for hands-free communication and immersive entertainment experiences.

👉 Get your sample…

Middle East & Africa and Asia Pacific Baby Diaper Market Size Forecast to USD 46 …

Middle East & Africa and Asia Pacific Baby Diaper Market Outlook 2036

The Middle East & Africa and Asia Pacific baby diaper market was valued at US$ 25.4 Billion in 2025 and is projected to reach US$ 46.5 Billion by 2036, expanding at a steady CAGR of 5.6% from 2026 to 2036. Market growth is driven by rising infant hygiene awareness, increasing urbanization, changing lifestyles, and growing disposable incomes across emerging…

Automotive Display System Market Size Forecast to USD 29.7 Billion by 2031 with …

Automotive Display System Market Outlook 2031

The global automotive display system market was valued at US$ 15.3 Billion in 2022 and is projected to reach US$ 29.7 Billion by the end of 2031, expanding at a steady CAGR of 7.7% from 2023 to 2031. Market growth is driven by increasing demand for connected vehicles, rising adoption of advanced driver assistance systems (ADAS), and growing consumer preference for enhanced in-vehicle infotainment experiences.

👉…

Packaging Printing Market to be Worth USD 573.6 Bn by 2036 - By Type / By Packag …

The global packaging printing market continues to demonstrate stable and sustained growth, reflecting the increasing importance of printed packaging in global supply chains. The market was valued at US$ 351.8 Billion in 2025 and is projected to reach US$ 573.6 Billion by 2036, expanding at a CAGR of 4.5% from 2026 to 2036.

Explore the highlights and essential data from our Report in this sample -

https://www.transparencymarketresearch.com/sample/sample.php?flag=S&rep_id=9491

This growth trajectory highlights the expanding…

More Releases for Material

Firestop Material Market

LOS ANGELES, United States: The global Firestop Material market is carefully researched in the report while largely concentrating on top players and their business tactics, geographical expansion, market segments, competitive landscape, manufacturing, and pricing and cost structures. Each section of the research study is specially prepared to explore key aspects of the global Firestop Material market. For instance, the market dynamics section digs deep into the drivers, restraints, trends, and…

New Material Direction for Electric Toothbrushes - Si-TPV Soft Over Molded Mater …

When it comes to factors such as consumer experience or ergonomics, Si-TPV Soft Over Molded Material has had a huge impact on the improvement of various products such as electric toothbrushes, etc. Si-TPV is a Silicone Combine TPU developed and produced by SILIKE, a Thermoplastic Elastomer Manufacturer (Thermoplastic Elastomer Suppliers). Si-TPV material adopts Innovative Soft Slip Technology and Sustainable Overmolding Techniques, which can be used to make Stain Resistance Soft…

A new light on a misjudged material - Plastic waste: material for art

Used plastic bottles are not waste, but a valuable resource. They can be reprocessed in a variety of ways and transformed into new products or fresh energy. And into art. This is exactly what Ve-ronika Richterová does. The Czech artist creates fascinating sculp-tures made out of old PET bottles.

Plastic has inspired artists from the very beginning. The reason: plas-tic meets almost all technical and aesthetic requirements. It is a uni-versal…

Global Thermal Transfer Material Market, Global Thermal Transfer Material Indust …

Thermal conductivity refers as an important characteristic for several manufacturing operations. Thermal transfer properties of a variety of materials are effective in certain applications owing to natural molecular structure that allows for direct heat-transfer. Thermal transfer materials are extensively used to manufacture the heat conductive adhesive tapes, printable products and polymer sheets. These polymer sheets are utilized for barcodes, labeling, and QR code labels for retailing, logistics, and consumer goods.…

The Future of Smart Material Market Runs Through the Material Industry

Smart Materials Market is expected to garner $72.63 billion by 2022, registering a CAGR of 14.9% during the forecast period 2016-2022. Smart materials are adaptive or intelligent materials which pose intrinsic and extrinsic capabilities. These can be altered by external stimuli, such as moisture, temperature, electromagnetic field, and pressure to obtain the desired functional effects. In addition, these materials are dynamic in nature and respond to their immediate interaction environments…

Global Regenerative Artificial Skin Sales Market Research Report 2017 (Temporary …

The report "Global Regenerative Artificial Skin Sales Market Report 2017", has been prepared based on an in-depth market analysis with inputs from industry experts.

This report studies sales (consumption) of Regenerative Artificial Skin in Global market, especially in United States, China, Europe and Japan, focuses on top players in these regions/countries, with sales, price, revenue and market share for each player in these regions, covering

Integra Life Sciences Corporation

Mylan N.V

Johnson & Johnson…