Press release

Coil Coating Market Outlook 2035: Rising Demand for Pre-Painted Metals to Drive USD 14.5 Billion Global Industry by 2035

The global coil coating market is entering a phase of strong and sustained growth, driven by rapid expansion in construction and automotive applications, technological advancements in coating formulations, and an accelerating shift toward sustainable, low-VOC, and energy-efficient materials. Valued at US$ 7.8 billion in 2024, the coil coating market is forecast to reach US$ 14.5 billion by 2035, exhibiting a CAGR of 5.8% from 2025 to 2035. With automated, high-speed coating technologies enabling superior corrosion resistance, durability, and aesthetic performance, coil coated metals have become essential materials in modern infrastructure, electric mobility, appliances, and industrial components.Discover Market Opportunities - Request Your Sample Copy Now: https://www.transparencymarketresearch.com/sample/sample.php?flag=S&rep_id=3344

Market Size and Key Highlights

In 2024, the global coil coating market reached US$ 7.8 billion, and demand is growing as industries increasingly adopt pre-painted metal solutions to enhance product longevity and sustainability. By 2035, the market will almost double to US$ 14.5 billion, supported by rising consumption of coated steel and aluminum across construction, automotive, appliances, HVAC, and furniture sectors. Some of the leading companies shaping this evolving industry include Akzo Nobel N.V., PPG Industries, BASF SE, and Axalta Coating Systems.

The Asia Pacific region, home to rapid urbanization and large-scale infrastructure development, dominated the market in 2024 with approximately 35% revenue share, and is projected to remain the fastest-growing region through 2035.

Market Overview

Coil coating is an automated, continuous process in which metal strips-typically steel or aluminum-are cleaned, pretreated, and coated with specialized primer and topcoat layers. This pre-painted metal is later fabricated into end-products without compromising finish quality. The process provides multiple advantages, including enhanced corrosion resistance, UV stability, scratch resistance, and superior aesthetic appeal.

Pre-coated metals have become the material of choice in roofing, wall cladding, window frames, automotive body components, home appliances, HVAC units, and furniture. With megatrends such as smart cities, energy-efficient buildings, and lightweight automotive manufacturing gaining momentum, the demand for coil coating continues to accelerate.

Growing environmental concerns are reshaping the market as industries transition from solvent-based coatings (high VOC) to water-based, UV-curable, and low-VOC systems, aligning with global sustainability regulations.

Analyst's Viewpoint

The global coil coating market is evolving beyond traditional functionalities of protection and aesthetics to become a critical enabler of lightweighting, energy efficiency, extended durability, and design flexibility. Automotive OEMs increasingly rely on pre-coated materials that offer uniform finishes, reduced manufacturing costs, and improved vehicle performance. Meanwhile, architects and builders prefer coil coated metals for their extensive color palettes, weather resistance, and ability to meet green building certification requirements.

Polyester coatings currently dominate the market due to cost efficiency, availability, and versatile outdoor performance, while silicone-modified polyester (SMP) and PVDF coatings are gaining traction for high-end architectural use. As sustainability becomes a mandatory requirement, next-generation coil coatings are integrating bio-based materials, recyclable components, and energy-curable technologies that significantly reduce emissions.

Key Market Growth Drivers

Rising Demand for Pre-Painted Metals in Construction

Urbanization, industrialization, and rapid smart-city development across Asia-Pacific, the Middle East, and Africa continue to fuel consumption of coil coated metals. Applications such as roofing sheets, facades, wall cladding, shutters, panels, and window frames rely heavily on coil coated steel and aluminum for durability and visual appeal. Architects increasingly prefer materials that offer custom textures, anti-bacterial finishes, design flexibility, and long-term weatherability, making coil coating integral to modern building practices.

Lightweight and Aesthetic Materials in Automotive Manufacturing

Automotive manufacturers are under pressure to meet emission norms while improving performance and fuel efficiency. Coil coated metals offer:

Lightweight structural strength

Superior corrosion resistance

High-gloss and custom finish options

Long-term color retention

Uniform coating and reduced post-painting costs

The growth of electric vehicles (EVs) is an additional catalyst, as EV

manufacturers prioritize lightweight materials without compromising aesthetics or durability.

Sustainability and Low-VOC Coating Technologies

Stringent environmental regulations worldwide are accelerating adoption of:

Water-based coil coatings

UV and EB-curable systems

Low-odor, low-emission formulations

These innovations minimize VOC emissions, reduce energy consumption, and support green building ratings such as LEED.

Market Challenges and Opportunities

Challenges

Volatility in raw material prices, especially for steel and aluminum

Environmental restrictions on solvent-based coatings

High initial investment in coil coating production lines

Intense competition from substitute materials such as powder coating in specific applications

Opportunities

Rising adoption of energy-curable (UV/EB) coil coatings

Growing demand in emerging markets such as India, Indonesia, Brazil, and GCC countries

Increasing use of coated metals in EV battery housings, charging stations, and interior components

Expansion of color customization and matte-metallic architectural finishes

The transition toward eco-friendly formulations presents one of the largest long-term opportunities for manufacturers.

Explore Strategies & Trends - Request Full Report Access - https://www.transparencymarketresearch.com/sample/sample.php?flag=S&rep_id=3344

Analysis of Key Players and Strategic Initiatives

The global market is competitive, with major players leveraging strategies such as R&D investments, product innovation, expansion of production facilities, and acquisitions.

Leading companies include:

Akzo Nobel N.V. - Strong global distribution and broad product portfolio

PPG Industries, Inc. - Advancements in energy-curable coating technologies

BASF SE - Portfolio restructuring to sharpen focus on high-margin coating divisions

Axalta Coating Systems - Expansion in industrial coatings and high-performance solutions

Sherwin-Williams - Innovations in PVDF and architectural-grade systems

Nippon Paint Holdings, Beckers Group, Jotun Group, Kansai Nerolac Paints - Strong regional penetration and tailored solutions

These companies are investing in sustainable coatings, low-energy curing technologies, and enhanced durability products to maintain market leadership.

Recent Developments

February 2025 - BASF SE appointed Bank of America Corp. and JPMorgan Chase & Co. to advise regarding the proposed sale of its automotive paints and industrial coatings division, which generated US$ 4.4 Bn in 2024 sales. The deal may involve US$ 2.5 Bn in debt financing via high-yield Euro and Dollar bonds.

October 2024 - Sherwin-Williams Coil Coatings unveiled its latest innovation called Fluropon® Continuum during METALCON 2024. This high-performance two-coat 70% PVDF system provides robust weather and fade resistance while supporting stringent architectural standards.

September 2023 - PPG Industries introduced its DuraNEXTTM portfolio of energy-curable coil coatings, reducing VOC emissions and aligning with green building requirements.

Investment Landscape and ROI Outlook

The coil coating industry offers attractive ROI prospects due to:

Growing consumption of coated metals in high-volume sectors

Significant cost savings over post-paint processes

Rising number of infrastructure and housing projects globally

Expanding EV and appliance manufacturing

Investments in automated coating lines, energy-efficient formulations, and regional manufacturing hubs can generate strong margins. The shift from solvent-based to sustainable coatings creates additional investment potential for technology providers.

Market Segmentations

By Resin Type

The market is dominated by polyester coatings, followed by SMP, PVDF, FEVE, plastisol, and others. Polyester coatings remain the preferred choice due to low cost, outdoor durability, and widespread availability.

By Method

Roll coating is the most widely used method globally, while die coating caters to specialized applications.

By Metal Type

Steel continues to hold the highest share, while aluminum is growing rapidly due to its lightweight characteristics.

By Finish

Topcoat and primer finishes dominate usage, along with backing coats for structural reinforcement.

By End-Use

The building & construction sector was the largest end-user in 2024, followed by automotive, appliances, HVAC, furniture, and lighting fixtures.

Regional Outlook

Asia Pacific - Largest and fastest-growing market due to rapid construction and manufacturing expansion

North America - Strong demand in appliances and automotive production

Europe - Growth fueled by energy-efficient building initiatives

Latin America & Middle East/Africa - Emerging markets with increasing adoption of pre-painted metal solutions

Why Buy This Report?

Provides a comprehensive assessment of the global coil coating market from 2024-2035

Includes detailed analysis of drivers, opportunities, and competitive landscape

Offers market forecasts, value projections, and expert insights for strategic planning

Covers regulatory, technological, and sustainability trends shaping the industry

Helps investors, manufacturers, and end-users identify high-performance materials and growth areas

FAQs

How big was the coil coating market in 2024?

The market was valued at US$ 7.8 billion in 2024.

What is the expected market size by 2035?

The market is projected to reach US$ 14.5 billion by 2035, growing at a 5.8% CAGR.

What are the major growth drivers?

Key drivers include rising demand for pre-painted metals in construction and growing preference for lightweight, aesthetic materials in automotive manufacturing.

Which segment dominated the market in 2024?

The building & construction segment held the largest share in 2024.

Which region led the global market in 2024?

Asia Pacific was the most lucrative region, holding the largest revenue share.

Buy Full Report Now: https://www.transparencymarketresearch.com/checkout.php?rep_id=3344<ype=S

Explore Latest Research Reports by Transparency Market Research:

Lubrication Systems Market: https://www.transparencymarketresearch.com/lubrication-systems-market.html

Glycerol Market: https://www.transparencymarketresearch.com/glycerol-market.html

Bioactive Films Market: https://www.transparencymarketresearch.com/bioactive-films-market.html

Contact Us:

Transparency Market Research Inc.

CORPORATE HEADQUARTER DOWNTOWN,

1000 N. West Street,

Suite 1200, Wilmington, Delaware 19801 USA

Tel: +1-518-618-1030

USA - Canada Toll Free: 866-552-3453

About Transparency Market Research

Transparency Market Research, a global market research company registered at Wilmington, Delaware, United States, provides custom research and consulting services. Our exclusive blend of quantitative forecasting and trends analysis provides forward-looking insights for thousands of decision makers. Our experienced team of Analysts, Researchers, and Consultants use proprietary data sources and various tools & techniques to gather and analyses information.

Our data repository is continuously updated and revised by a team of research experts, so that it always reflects the latest trends and information. With a broad research and analysis capability, Transparency Market Research employs rigorous primary and secondary research techniques in developing distinctive data sets and research material for business reports.

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Coil Coating Market Outlook 2035: Rising Demand for Pre-Painted Metals to Drive USD 14.5 Billion Global Industry by 2035 here

News-ID: 4310144 • Views: …

More Releases from Transparency Market Research

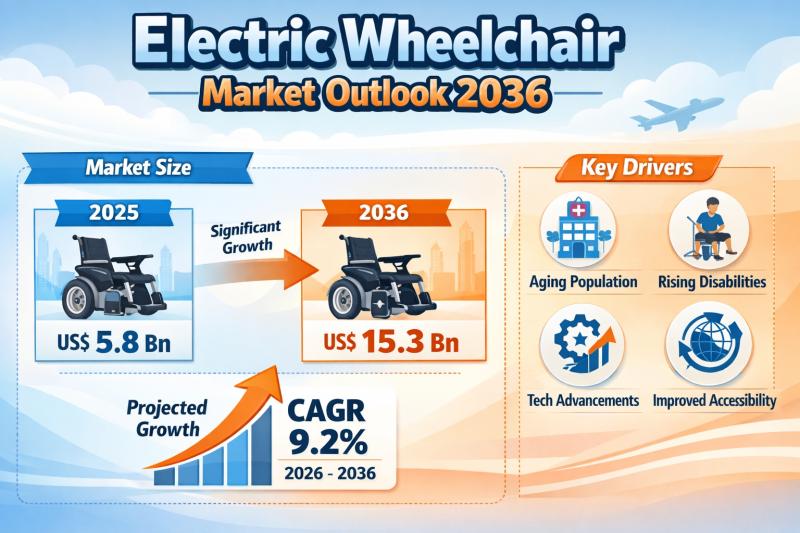

Electric Wheelchair Market Expanding at 9.2% CAGR Through 2036 - By Control Type …

The global electric wheelchair market continues to demonstrate strong and sustained growth, fueled by demographic transitions, technological innovation, and expanding healthcare access worldwide. Valued at US$ 5.8 billion in 2025, the market is projected to reach US$ 15.3 billion by 2036, expanding at a compound annual growth rate (CAGR) of 9.2% from 2026 to 2036.

Discover essential conclusions and data from our Report in this sample -

https://www.transparencymarketresearch.com/sample/sample.php?flag=S&rep_id=4198

This robust trajectory reflects rising…

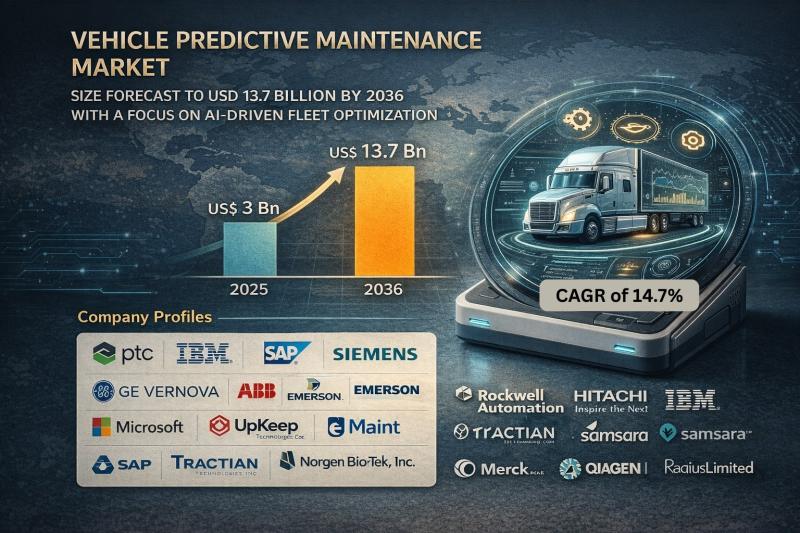

Vehicle Predictive Maintenance Market Size Forecast to USD 13.7 Billion by 2036 …

Vehicle Predictive Maintenance Market Outlook 2036

The global vehicle predictive maintenance market was valued at USD 3 Billion in 2025 and is projected to reach USD 13.7 Billion by 2036, expanding at a robust CAGR of 14.7% from 2026 to 2036. Market growth is driven by increasing adoption of connected vehicles, rising fleet digitalization, advancements in AI-driven analytics, and growing emphasis on minimizing vehicle downtime and maintenance costs.

👉 Get your sample…

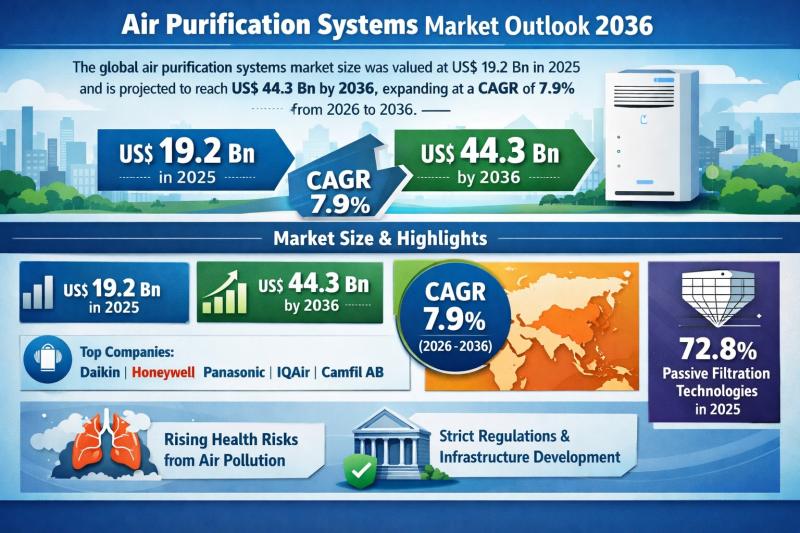

Global Air Purification Systems Market to Reach USD 44.3 Billion by 2036 at 7.9% …

The global Air Purification Systems Market was valued at US$ 19.2 Bn in 2025 and is projected to expand to US$ 44.3 Bn by 2036, registering a compound annual growth rate (CAGR) of 7.9% from 2026 to 2036. The market's upward trajectory reflects the structural shift in indoor air quality (IAQ) management, moving from discretionary consumer spending to mission-critical infrastructure investment.

With historical data available from 2021 to 2024, the industry…

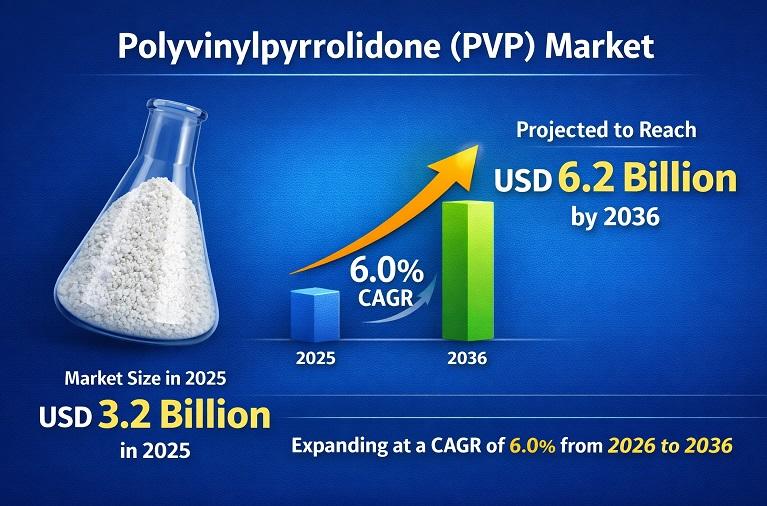

Polyvinylpyrrolidone (PVP) Market to Reach USD 6.2 Billion by 2036 Driven by Pha …

The Polyvinylpyrrolidone (PVP) Market was valued at around US$ 3.2 billion in 2025 and is projected to reach approximately US$ 6.2 billion by 2036, expanding at a steady CAGR of about 6.0% during the forecast period. This growth is primarily driven by rising demand from the pharmaceutical industry, where PVP is widely used as a tablet binder, solubilizer, and stabilizer, along with increasing consumption in cosmetics and personal care products…

More Releases for Coating

Medical Grade Coating Market: How Nanotechnology Is Advancing Coating Solutions

► Medical Grade Coating Market Poised for Significant Growth, Projected to Reach USD 22.01 Billion by 2032

The global medical grade coating market, valued at USD 13.40 billion in 2024, is anticipated to experience robust growth, reaching approximately USD 22.01 billion by 2032. This represents a compound annual growth rate (CAGR) of 6.4% during the forecast period.

Curious to peek inside? Grab your sample copy of this report now:https://www.maximizemarketresearch.com/request-sample/100541/

► Market…

Powder Coating Market - Advanced Coating Solutions for Industrial Applications | …

Powder Coating Market is expected to grow at a CAGR of 6.0% during the forecast period (2024 - 2031).

Powder Coating Market report, published by DataM Intelligence, provides in-depth insights and analysis on key market trends, growth opportunities, and emerging challenges. Committed to delivering actionable intelligence, DataM Intelligence empowers businesses to make informed decisions and stay ahead of the competition. Through a combination of qualitative and quantitative research methods, it offers…

Coating Equipment Market by Type (Powder coating equipment, Liquid coating equip …

The Coating Equipment Market research report incorporates the scope and objective of the study. Moreover, the report highlights key market segments and players covered. It also covers industry trends, focusing on market use cases and top market size by region, market trends, and global market size. Moreover, the Coating Equipment Market research report covers market growth rate and market share by region. Supply chain analysis, regional marketing analysis, opportunities, challenges,…

Powder Coating Market, Powder Coating Market share, global Powder Coating Market …

High application scope in consumer goods, industrial and automotive applications will drive the powder coating market. Stringent government regulation regarding VOC emissions along with product features including emit less, ecofriendly and solvent free will fuel the industry growth.

Expansion in the automotive & transportation industry particularly in the emerging nations will propel the powder coating market growth. Shifting trends towards reduction of heat requirement during the production process are the…

Powder Coating Market, Powder Coating Market share, global Powder Coating Market …

High application scope in consumer goods, industrial and automotive applications will drive the powder coating market. Stringent government regulation regarding VOC emissions along with product features including emit less, ecofriendly and solvent free will fuel the industry growth.

Expansion in the automotive & transportation industry particularly in the emerging nations will propel the powder coating market growth. Shifting trends towards reduction of heat requirement during the production process are the…

Powder Coating Market, Powder Coating Market share, global Powder Coating Market …

High application scope in consumer goods, industrial and automotive applications will drive the powder coating market. Stringent government regulation regarding VOC emissions along with product features including emit less, ecofriendly and solvent free will fuel the industry growth.

Expansion in the automotive & transportation industry particularly in the emerging nations will propel the powder coating market growth. Shifting trends towards reduction of heat requirement during the production process are the…