Press release

Polyisoprene Production Plant Setup Cost, Profit Margins, & Capacity: The Investor's Guide

Introduction - Overview of a Polyisoprene Production Plant Setup:Establishing a polyisoprene production plant setup is a promising industrial venture due to rising demand for synthetic rubber across automotive, medical, footwear, and consumer goods industries. Polyisoprene, a synthetic equivalent of natural rubber, is produced through polymerization of isoprene monomers and is valued for its high elasticity, tensile strength, and durability.

This project-report-style guide outlines the production process, plant requirements, cost structure, and profitability insights essential for launching a polyisoprene manufacturing facility.

Market Overview & Trends - Growing Demand for Synthetic Rubber Materials:

The global market for polyisoprene is expanding due to increased tire manufacturing, demand for medical-grade latex alternatives, and rising use in industrial rubber goods. Synthetic polyisoprene provides improved quality consistency, controlled polymer structure, and better performance under varying industrial conditions.

Key trends include the rise of medical-grade polyisoprene for gloves and tubing, expansion of automotive rubber components, and advancements in polymerization catalysts. Challenges include raw material fluctuations and competition from natural rubber producers.

Peek Inside: Access the Sample Report Instantly: https://www.imarcgroup.com/polyisoprene-manufacturing-plant-project-report/requestsample

Report Coverage Highlights:

• Process Flow: Covers polymerization of isoprene monomers to produce high-purity polyisoprene.

• Land & Location: Requires industrial land with access to utilities and safe chemical-handling zones.

• Plant Layout: Allocates areas for reactors, purification units, QC labs, and packaging sections.

• Machinery: Includes polymerization reactors, purification systems, dryers, blenders, and packaging lines.

• Raw Materials: Isoprene monomers, catalysts, stabilizers, solvents, and processing additives.

• Packaging: Polyisoprene is packed in bales, bags, or drums for industrial distribution.

• Additional Needs: Requires utilities, safety systems, ventilation, and waste treatment units.

• Project Economics: Covers CapEx, OpEx, production cost, and revenue estimates.

• Financial Analysis: Includes ROI, break-even, and payback period evaluations.

• Market Insights: Highlights demand from automotive, medical, and industrial rubber sectors.

Technical Aspects / Manufacturing Process - How Polyisoprene Is Produced:

Polyisoprene is primarily produced using solution polymerization under controlled temperature and pressure. The steps include:

• Monomer Preparation: Isoprene monomer is purified and dried to remove impurities.

• Polymerization: Reactors initiate polymer growth using catalysts such as Ziegler-Natta or anionic systems.

• Quenching & Stabilization: Excess catalyst is neutralized and stabilizers are added to prevent degradation.

• Purification: Solvents are removed, and polymer is filtered for purity.

• Drying & Finishing: Polyisoprene is dried, cut, and formed into bales or granules.

Quality control involves molecular weight analysis, tensile strength testing, impurity profiling, and viscosity measurement.

Plant Setup Requirements - Machinery, Layout & Infrastructure:

A polyisoprene production plant setup must include designated sections for monomer storage, polymerization, solvent recovery, QC labs, and packaging.

Required machinery includes polymerization reactors, catalyst dosing systems, filtration units, distillation towers, dryers, blending machines, and automated packing equipment.

Infrastructure needs include cooling towers, boiler systems, chemical-resistant flooring, storage tanks, ventilation, fire safety, and an effluent treatment plant (ETP). A trained technical workforce and strict process controls are essential for safe operation.

Project Economics - Capital Cost, Operating Cost & Profitability:

The setup cost for a polyisoprene manufacturing plant includes land, construction, high-pressure reactors, purification systems, utilities, and working capital. Operating expenses involve monomer procurement, catalysts, solvents, energy, labor, maintenance, and quality testing.

Profitability depends on polymer grade, production efficiency, raw material cost, and industrial demand. Revenue comes from supplying automotive tire companies, medical device manufacturers, rubber product manufacturers, and industrial clients. ROI, break-even, and payback period analyses help evaluate financial feasibility.

Risk Factors & Success Strategies - Ensuring Efficiency & Market Competitiveness:

Key risks include raw material price variations, equipment failures, polymerization inconsistencies, and strict safety requirements. Ensuring stable monomer supply, adopting advanced catalysts, implementing efficient solvent recovery systems, and maintaining strong QC standards are crucial.

Success strategies include diversifying into medical-grade polyisoprene, partnering with automotive manufacturers, investing in R&D, and offering customized polymer grades tailored to client needs.

Talk to Our Analyst - Get a Tailored Investment Plan: https://www.imarcgroup.com/request?type=report&id=18137&flag=C

How IMARC Group Supports Plant Setup:

IMARC Group helps investors and entrepreneurs establish a manufacturing plant by providing detailed market research, technical guidance, and financial feasibility analysis. Their reports outline process flow, machinery requirements, raw materials, project cost, profitability, and regulatory needs, offering a complete roadmap for setup. With expert consulting and customized solutions, IMARC ensures smoother planning, reduced risks, and faster project execution.

Conclusion - Feasibility and Growth Potential of Polyisoprene Production:

A polyisoprene production plant setup offers strong long-term potential due to demand from automotive tires, industrial rubber goods, and medical products. With efficient process control, strict safety compliance, and strategic market positioning, investors can build a scalable and profitable polyisoprene production unit.

FAQs - Polyisoprene Production Plant Setup:

1. What raw materials are required to manufacture polyisoprene?

A. Isoprene monomers, catalysts, stabilizers, solvents, and additives.

2. What machinery is needed for polyisoprene production?

A. Reactors, distillation units, filtration systems, dryers, blending equipment, and packaging machines.

3. What factors influence production cost?

A. Monomer prices, catalyst efficiency, solvent consumption, energy use, and maintenance needs.

4. Which industries use polyisoprene?

A. Automotive tires, medical devices, footwear, rubber goods, adhesives, and consumer products.

About Us:

IMARC Group is a leading global market research and management consulting firm. We specialize in helping organizations identify opportunities, mitigate risks, and create impactful business strategies.

Contact Us:

IMARC Group

134 N 4th St., Brooklyn, NY 11249, USA

Email: sales[@]imarcgroup.com

Tel No:(D) +91 120 433 0800

United States: (+1-201971-6302)

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Polyisoprene Production Plant Setup Cost, Profit Margins, & Capacity: The Investor's Guide here

News-ID: 4306685 • Views: …

More Releases from IMARC Group

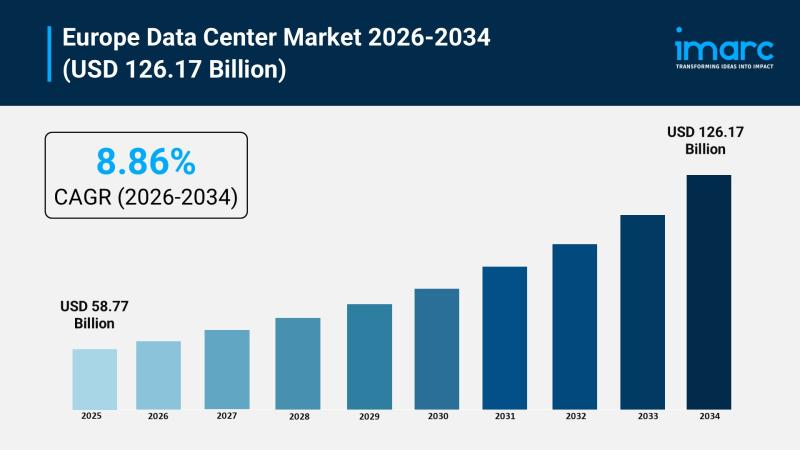

IMARC Group Forecasts 8.86% CAGR for Europe Data Center Market Amidst AI and Clo …

The Europe data center market is experiencing a critical phase of infrastructure evolution, having reached a valuation of USD 58.77 Billion in 2025. Propelled by the accelerating digitalization of the region's economy and sovereign cloud ambitions, the market is projected to reach USD 126.17 Billion by 2034. This growth trajectory represents a solid Compound Annual Growth Rate (CAGR) of 8.86% during the forecast period of 2026-2034.

Key Market Trends &…

Hot Sauce Manufacturing Plant DPR & Unit Setup - 2026: Demand Analysis and Proje …

Setting up a hot sauce manufacturing plant positions investors within one of the fastest-growing and flavor-driven segments of the global condiment industry, fueled by rising consumer appetite for spicy, bold, and ethnic flavors, increasing demand for clean-label and premium condiment products, and expanding utilization of hot sauce across food service, retail, and food processing applications. Made primarily from chili peppers, vinegar, salt, and complementary flavoring ingredients, hot sauce is recognized…

Glyoxylic Acid Prices Q4 2025: US Stable While Europe Remains High Price Trend

The Glyoxylic Acid Price Trend Analysis indicates dynamic shifts in global supply-demand balance, feedstock volatility, and regional trade flows. In 2026, Glyoxylic Acid Prices are reflecting fluctuations in raw material costs and downstream demand from pharmaceuticals, cosmetics, and agrochemicals. Market participants closely track the Glyoxylic Acid price index and forecast data to understand pricing momentum, risk exposure, and procurement strategies across key global regions.

Glyoxylic Acid Current Glyoxylic Acid Price Movements:

Recent…

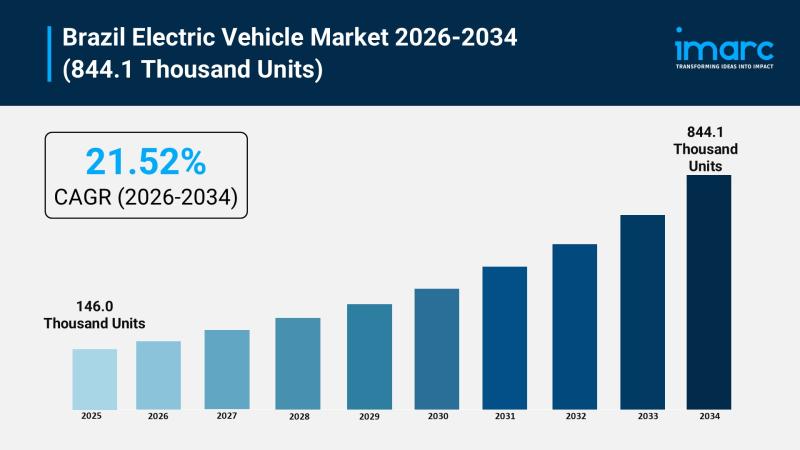

IMARC Group Forecasts 21.52% CAGR for Brazil EV Market as BYD and GWM Ramp Up Lo …

The Brazil electric vehicle (EV) market is currently witnessing an unprecedented surge, having reached a volume of 146.0 Thousand Units in 2025. Fueled by a combination of stringent environmental policies and a strategic shift toward domestic production by global automakers, the market is projected to reach 844.1 Thousand Units by 2034. This rapid expansion represents a robust Compound Annual Growth Rate (CAGR) of 21.52% during the forecast period of 2026-2034.

Key…

More Releases for Polyisoprene

Polyisoprene Surgical Gloves Research:he global Polyisoprene Surgical Gloves mar …

QY Research Inc. (Global Market Report Research Publisher) announces the release of 2025 latest report "Polyisoprene Surgical Glove- Global Market Share and Ranking, Overall Sales and Demand Forecast 2025-2031". Based on current situation and impact historical analysis (2020-2024) and forecast calculations (2025-2031), this report provides a comprehensive analysis of the global Wire Drawing Dies market, including market size, share, demand, industry development status, and forecasts for the next few years.

The…

Polyisoprene Market Is Booming So Rapidly | Kuraray, Zeon, Sibur

The global Polyisoprene Market is poised to register a 5.4% CAGR from $20.6 Billion in 2025 to $28.2 Billion in 2034.

The latest study released on the Global Polyisoprene Market by USD Analytics Market evaluates market size, trend, and forecast to 2034. The Polyisoprene market study covers significant research data and proofs to be a handy resource document for managers, analysts, industry experts and other key people to have ready-to-access and…

Polyisoprene Market Trend Forecast till 2032

According to Ameco Research 'Polyisoprene Market report, the analysts took this into account when estimating the Polyisoprene Market size and CAGR for the respective industry. The report's author has thoroughly examined the market and concluded that the Polyisoprene Market 's growth will level off in the coming years. In addition to that, the prominent qualitative information added in the report includes Polyisoprene Market trends, segmentation, key companies, SWOT, PORTER and…

Polyisoprene Market Size, CAGR | Growth - 2028

The Polyisoprene Market Research Report provides an in-depth analysis of the market dynamics, key players, and competitive landscape of the Polyisoprene industry. It aims to provide valuable insights into the market trends, growth opportunities, and challenges faced by the industry stakeholders. The report serves as a comprehensive guide for businesses and investors looking to make informed decisions in the Polyisoprene business.

The Polyisoprene Market share is influenced by several factors that…

Polyisoprene Latex Market Future Demand Analysis With Forecast

The global Polyisoprene Latex Market is expected to grow on an enormous note In Upcoming Years. The industry, in all, is slated to witness an insight-driven revolution, which would, in turn, open the doors for efficient and effective solutions. These insights would be backed by digital tech catalysis, right from making use of consumers’ data for understanding their preferences to getting those customized solutions at the right time. This trend…

Polyisoprene Latex Market Size, Share, Development by 2025

Market Research Report Store offers a latest published report on Polyisoprene Latex Market Analysis and Forecast 2019-2025 delivering key insights and providing a competitive advantage to clients through a detailed report.

This report focuses on the key global Polyisoprene Latex players, to define, describe and analyze the value, market share, market competition landscape, SWOT analysis and development plans in next few years.

To analyze the Polyisoprene Latex with respect to individual growth…